Product Description

Helical Worm Gear Low Noise Cast Iron HT250 Ground Parallel Shaft Best Speed Reducer Gearbox Die Casting Lumen Good Price Nmrv High Efficiency Helical Worm Gear

F series gear reducer is 1 kind of parallel shaft helical gear reducer , which consist of 2 or 3 stages helical gears (relate to gear ratio) in the same case . The hard tooth surface gear use the high quality alloy steel ,the process of carburizing and quenching, grinding ,which give it follow characters :Stable transmission ,low noise and temperature ,high loading ,long working lift . Wide application ,specialize in Metallurgy ,Sewage treatment,

Chemical Industry , Pharmacy ,Agriculture equipment and Oil industry.

Specifications:

1) Output speed: 0.6~1,571r/min

2) Output torque: up to 21700N.m

3) Motor power: 0.12~200kW

4) Mounted form: foot-mounted and flange-mounted mounting

| Product Name | SLK Series Rigid Tooth helical bevel reducer |

| Gear Material | 20CrMnTi |

| Case Material | HT250 |

| Shaft Material | 20CrMnTi |

| Gear Processing | Grinding finish by HOFLER Grinding Machines |

| Color | Customized |

| Noise Test | 65~70dB |

| Efficiency | 94%~98% (depends on the transmission stage) |

| Lubricating oil | Shell Omala synthetic oil or mineral oil , or similar brand |

| Heat treatment | tempering, cementiting, quenching,etc. |

| Brand of bearings | C&U bearing, ZWZ,LYC, HRB, SKF,NSK and so on |

| Brand of oil seal | NAK or other brand |

| Temp. rise (MAX) | 40 ° |

| Temp. rise (Oil)(MAX) | 50 ° |

| Vibration | ≤20µm |

company information

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Layout: | Coaxial |

| Type: | Worm Reducer |

| Output Torque: | 3.5~21700n.M |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Precision and High-Accuracy Applications of Helical Gearboxes

Helical gearboxes are well-suited for precision and high-accuracy applications due to their unique design and performance characteristics:

- Helical Gearing: The helical gears in these gearboxes offer smooth and continuous meshing, resulting in reduced backlash and improved positioning accuracy.

- Efficiency: Helical gearboxes are known for their high efficiency, which minimizes energy losses and heat generation. This is crucial for maintaining precision in applications where even small deviations can have significant impacts.

- Noise and Vibration: The helical gear tooth engagement helps in reducing noise and vibration levels, making them suitable for environments where quiet operation is required.

- Load Distribution: Helical gears distribute load across multiple teeth, minimizing localized wear and extending the lifespan of the gearbox.

- Smooth Motion: Helical gearboxes provide smoother motion transitions, which is crucial in precision applications where jerky or sudden movements are undesirable.

- Positional Accuracy: The reduced backlash and improved meshing characteristics of helical gears contribute to higher positional accuracy, making these gearboxes ideal for applications such as CNC machines, robotics, and medical equipment.

- Compact Design: Helical gearboxes can achieve high gear ratios in a relatively compact form factor, making them suitable for applications where space is limited.

Examples of precision applications where helical gearboxes are commonly used include CNC machining, robotics, semiconductor manufacturing, medical equipment, and metrology devices. The combination of efficiency, smooth operation, and accuracy makes helical gearboxes a preferred choice for achieving consistent and reliable performance in such applications.

Handling Shock Loads and Sudden Changes in Torque in Helical Gearboxes

Helical gearboxes are designed to handle a range of operational conditions, including shock loads and sudden changes in torque. The helical design of the gears, which have slanted teeth that engage gradually, helps to distribute forces more evenly across the teeth compared to straight-cut gears. This design characteristic contributes to the gearbox’s ability to withstand sudden changes in torque and shock loads.

The gradual engagement of the helical teeth results in smoother and quieter operation, reducing the impact of abrupt torque changes. The slanted teeth also allow for more gradual transmission of force, which helps in dampening vibrations and minimizing stress concentrations that can occur in high-impact situations.

However, while helical gears are better suited for shock loads compared to straight-cut gears, it’s important to note that extreme shock loads or sudden torque changes can still impact the gearbox’s components over time. Manufacturers often take factors such as application requirements, load profiles, and anticipated shock loads into consideration when designing helical gearboxes to ensure reliable and durable performance.

Additionally, using appropriate lubrication and maintenance practices can further enhance the gearbox’s ability to handle shock loads and sudden torque changes. Regular inspection and timely maintenance help identify and address potential issues before they lead to component failure.

Industries Utilizing Helical Gearboxes

Helical gearboxes find widespread use in various industries due to their efficiency, smooth operation, and versatility. Some of the industries that commonly utilize helical gearboxes include:

- Manufacturing: Helical gearboxes are employed in manufacturing processes for conveyor systems, material handling, and machine tools. Their ability to provide high torque and smooth motion makes them suitable for precision manufacturing.

- Automotive: Automotive applications include power transmission in vehicles, especially in manual and automatic transmissions. Helical gearboxes contribute to improved fuel efficiency and smoother gear shifting.

- Energy Generation: Helical gearboxes are used in power generation systems, such as wind turbines and hydroelectric generators. Their efficiency and load-bearing capacity are crucial for converting rotational motion into electrical power.

- Construction: Construction equipment, such as cranes, excavators, and bulldozers, rely on helical gearboxes for efficient power transmission and control of heavy loads.

- Mining: Mining operations use helical gearboxes in conveyors, crushers, and other equipment for material handling and ore extraction. The durability and high torque capacity of helical gearboxes make them suitable for demanding mining environments.

- Marine: Marine vessels use helical gearboxes in propulsion systems to convert engine power into rotational motion for propellers. Their efficiency contributes to fuel savings and reliable marine operation.

- Food and Beverage: Helical gearboxes are employed in food processing and packaging machinery due to their sanitary design and precise motion control.

- Textile: Textile machinery relies on helical gearboxes for various processes, including spinning, weaving, and dyeing. Their ability to handle varying loads and provide smooth motion is beneficial in textile production.

The adaptability and efficiency of helical gearboxes make them a suitable choice for a wide range of industries, where reliable power transmission, smooth operation, and load-bearing capacity are essential.

editor by CX 2024-05-03

China Standard Low Price Bevel Helical Gear Box Speed Electric Gearmotor Reducer Machine Gearbox with OEM Custom best automatic gearbox

Product Description

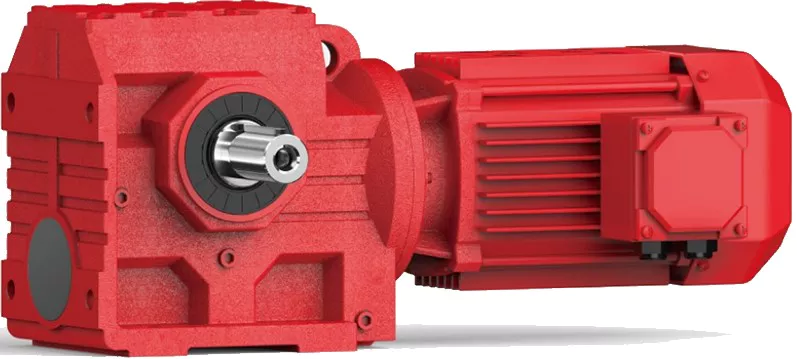

K187 gear reducer motor 45KW 55KW 90 degree high quality helical bevel gear

Product Description

Product Description

-K Series Helical Bevel Gearbox

K series gear reducer, manufactured according to international technical requirements, has a high scientific and technological content; Space saving, reliable and durable, high overload capacity, power up to 132KW; Low energy consumption, superior performance, reducer efficiency up to 95%

It is designed and manufactured on the basis of module combination system. There are a lot of motor combinations, installation forms and structural schemes. The transmission ratio is classified carefully to meet different operating conditions and realize electromechanical integration.

High transmission efficiency, low energy consumption and superior performance.

Reinforced high rigid cast iron box; The hardened gear is made of high-quality alloy steel. Its surface is carburized, quenched and hardened, and the gear is finely ground. It features stable transmission, low noise, large bearing capacity, low temperature rise, and long service life. Performance and characteristics:

1. The gear is carburized and quenched with high-quality alloy, the hardness of the tooth surface is up to 60 ± 2hrc, and the grinding accuracy of the tooth surface is up to 5-6

2. The computer modification technology is used to pre modify the gear, which greatly improves the bearing capacity of the reducer

3. Complete modular structure design is adopted from the box to the internal gear, which is suitable for large-scale production and flexible selection

4. The standard reducer models are divided according to the form of decreasing torque. Compared with the traditional equal proportion division, they are more in line with customer requirements and avoid power waste

5. It is designed and manufactured by cad/cam to ensure the stability of quality

6. Multiple sealing structures are adopted to prevent oil leakage

7. Multi directional noise reduction measures to ensure the excellent low noise performance of the reducer

8. The installation mode of Liyi products is flexible, which makes it easy for customers to choose K57 reducer, K67 reducer, K77 reducer, K87 reducer, K97 reducer, KA87 reducer, KA97 reducer, KA107 reducer, KA127 reducer

Product Features

1. Input mode: Coupled motor, belted motor, input shaft or connection flange.

2. Output: Right angle

3. Compact structure. Rigid tooth face. Carrying greater torque, high loading capacity.

4.High precision gear, ensuring the unit to operate stably, smooth transmission.

5. Low noise, long lifespan. Large overlap coefficient, abrasion resistant.

Product Parameters

|

Brand Name |

CZPT |

|

Product Name |

K Helical-bevel gear units |

|

Material |

Steel or cast iron |

|

Weight |

11Kg-1700Kg |

|

Color |

Customizable |

|

Heat treatment |

Carburising,Quenching,Gear Grinding |

|

Advantage |

1.K series spiral bevel gear reducer with small vibration, low noise, energy saving. 2.Selection of high quality steel material, steel cast iron box, gear surface after high frequency heat treatment. |

K series product performance

High transmission efficiency, low energy consumption and superior performance. High rigidity cast iron box with ribs; hard-toothed gears are made of high-quality alloy steel, the surface is carburized and quenched and hardened, and the teeth are finely machined, with stable transmission, low noise, large bearing capacity, low temperature rise and long service life.

Our process of production

Our product line

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | 90 Degree |

| Layout: | Expansion |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | |

|---|

Using Helical Gearboxes for Speed Reduction and Speed Increase

Yes, helical gearboxes can be used for both speed reduction and speed increase in various applications. The design of helical gears allows them to transmit motion and power between non-parallel shafts while changing the rotational speed.

Speed Reduction: When the driving gear (pinion) has fewer teeth than the driven gear, the gear ratio leads to speed reduction. This is commonly used in applications where the input speed needs to be decreased while increasing the output torque. For example, helical gearboxes are often employed in conveyor systems to reduce the speed of the motor while maintaining sufficient torque to move heavy loads.

Speed Increase: Helical gearboxes can also achieve speed increase by having the driving gear (pinion) with more teeth than the driven gear. This configuration is less common but can be used to increase the output speed while sacrificing some torque. Speed increase applications are typically seen in scenarios where higher speeds are required, such as in certain types of machinery or industrial processes.

It’s important to note that while helical gearboxes can perform both speed reduction and speed increase, the specific gear ratios and configurations need to be carefully chosen to ensure efficient and reliable operation for the intended application.

Impact of Thermal Expansion on Helical Gearbox Performance

Thermal expansion can significantly affect the performance of helical gearboxes due to changes in dimensions and clearances caused by temperature variations. Here’s how it impacts:

1. Misalignment: Temperature changes can lead to differential expansion of gearbox components. This can result in misalignment of gears, shafts, and bearings, leading to increased friction, noise, and reduced efficiency.

2. Lubrication: Thermal expansion can alter the clearances within the gearbox, affecting the distribution and viscosity of the lubricating oil. Inadequate lubrication due to temperature-induced changes can result in increased wear and premature failure.

3. Gear Tooth Engagement: Temperature fluctuations can cause gear teeth to expand or contract, affecting the meshing engagement and load distribution. Inconsistent gear tooth contact can lead to uneven wear and reduced gear life.

4. Bearing Performance: Bearings in helical gearboxes are sensitive to temperature changes. Excessive heat can lead to reduced bearing life, increased friction, and potential seizure, affecting overall gearbox performance.

5. Noise and Vibration: Thermal expansion can lead to changes in gear and component clearances, resulting in altered vibration patterns and increased noise levels. This can impact the comfort of the system and indicate potential issues.

6. Material Fatigue: Repeated cycles of thermal expansion and contraction can lead to material fatigue and stress accumulation, reducing the overall lifespan of gearbox components.

Managing Thermal Effects: Manufacturers design helical gearboxes with considerations for thermal expansion, using materials with low coefficients of thermal expansion and incorporating features like expansion joints or thermal isolators. Proper lubrication, monitoring temperature, and maintaining consistent operating conditions are also crucial in mitigating thermal expansion effects.

Understanding and managing the impact of thermal expansion is essential to maintain the performance, efficiency, and durability of helical gearboxes.

Limitations and Disadvantages of Helical Gear Systems

While helical gear systems offer numerous advantages, they also come with certain limitations and disadvantages:

- Axial Thrust: Helical gears generate axial thrust due to the helix angle of the teeth. This thrust can cause additional load on bearings and may require additional measures to counteract.

- Complex Manufacturing: The manufacturing process for helical gears is more complex than that of straight-toothed gears, which can lead to higher production costs.

- Axial Length: Helical gears require more axial space compared to spur gears with the same gear ratio. This can be a limitation in applications with space constraints.

- Sliding Contact: Helical gears have sliding contact between their teeth, which can result in higher friction and more heat generation compared to rolling contact gears.

- Efficiency: Although helical gears are generally efficient, their efficiency can be slightly lower than that of some other gear types, especially at high speeds.

- Complexity in Gearbox Design: The inclination of helical gear teeth introduces additional complexity in gearbox design and alignment.

- Reverse Thrust: In some cases, reverse thrust can occur when helical gears are subjected to high axial loads, leading to undesirable effects.

It’s important to consider these limitations and disadvantages when selecting gear systems for specific applications. Despite these challenges, helical gears remain a popular choice in various industries due to their benefits and overall performance characteristics.

editor by CX 2024-04-24

China factory Two Stage Helical Gearbox Motor Parallel Shaft Bevel Reducer Speed Spiral 90 Degree Right Angle Straight Supplier Competitive Price Stainless Steel Gearbox car gearbox

Product Description

Two Stage Helical Gearbox Motor Parallel Shaft Bevel Reducer Speed Spiral 90 Degree Right Angle Straight Supplier Competitive Price Stainless Steel Gearbox

Application of Helical Gearbox

Helical gearboxes are used in a wide variety of applications, including:

- Automotive: Helical gearboxes are used in a variety of automotive applications, including transmissions, differentials, and steering systems. They help to transmit power smoothly and efficiently, which improves the overall performance of the vehicle.

- Machinery: Helical gearboxes are used in a variety of machinery applications, including conveyor belts, elevators, and cranes. They help to transmit power smoothly and efficiently, which improves the overall performance of the equipment.

- Aerospace: Helical gearboxes are used in a variety of aerospace applications, including aircraft engines, landing gear, and control surfaces. They help to transmit power smoothly and efficiently, which improves the overall performance of the aircraft.

- Construction: Helical gearboxes are used in a variety of construction applications, including excavators, bulldozers, and cranes. They help to transmit power smoothly and efficiently, which improves the overall performance of the equipment.

- Other: Helical gearboxes are also used in a variety of other applications, such as wind turbines, robotics, and medical devices. They help to transmit power smoothly and efficiently, which improves the overall performance of the system.

Helical gears are a type of gear that has teeth that are cut at an angle. This angle allows the teeth to engage each other gradually and smoothly, which reduces noise and vibration. Helical gears are often used in high-speed applications, such as in automotive differentials.

Helical gears are made of a variety of materials, including steel, cast iron, and aluminum. The material of the gear will depend on the specific application and the environment in which it will be used.

Helical gears are available in a variety of sizes and styles to accommodate a wide range of applications. They are also available in a variety of ratios, which allows them to be used in a variety of applications.

Here are some of the advantages of using helical gears:

- Reduced noise and vibration: Helical gears help to reduce noise and vibration, which can improve the overall working environment.

- Increased efficiency: Helical gears are more efficient than straight gears, which can help to improve the overall performance of a system.

- Increased durability: Helical gears are made of durable materials that can withstand a lot of wear and tear.

- Cost-effectiveness: Helical gears are a cost-effective way to improve the performance and durability of a system.

Overall, helical gears are a versatile and reliable component that can be used in a wide variety of applications. They offer a number of advantages, including reduced noise and vibration, increased efficiency, increased durability, and cost-effectiveness.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Three-Ring |

| Hardness: | Hardened Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Stepless |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Key Factors for Selecting a Helical Gearbox

Choosing the right helical gearbox for an application involves considering several key factors:

- Load and Torque: Evaluate the maximum load and torque requirements to ensure the gearbox can handle the application’s demands.

- Speed Range: Determine the required speed range and ensure the gearbox’s gear ratios can accommodate it.

- Efficiency: Helical gearboxes are known for their high efficiency. Select a gearbox with efficiency ratings that meet your application’s needs.

- Space Constraints: Consider the available installation space and choose a compact gearbox that fits within the available dimensions.

- Mounting Position: The mounting position affects lubrication, cooling, and overall performance. Ensure the gearbox is suitable for the desired mounting orientation.

- Service Life: Choose a gearbox with a service life that matches your application’s expected lifespan.

- Backlash: Evaluate the allowable backlash, which affects precision and positioning accuracy.

- Noise and Vibration: Assess the acceptable noise and vibration levels and choose a gearbox with suitable characteristics.

- Environmental Conditions: Consider factors like temperature, humidity, and dust levels to ensure the gearbox can operate reliably in the application environment.

- Maintenance: Factor in maintenance requirements and choose a gearbox with manageable maintenance needs.

- Cost: Balance performance with budget constraints to find a gearbox that offers the best value for your application.

By carefully evaluating these factors, you can select a helical gearbox that optimally meets your application’s requirements and ensures efficient and reliable operation.

Relationship Between Helix Angle and Load Capacity in Helical Gears

The helix angle of helical gears plays a significant role in determining their load-carrying capacity and overall performance. Here’s the relationship between the helix angle and load capacity:

1. Load Distribution: The helix angle affects how the load is distributed along the gear teeth. A larger helix angle results in a more gradual tooth engagement, allowing for smoother load sharing across multiple teeth. This improves the gear’s ability to handle higher loads.

2. Contact Ratio: The contact ratio, which indicates the number of teeth in contact at any given time, increases with a larger helix angle. A higher contact ratio helps distribute the load over a larger area of the gear teeth, enhancing load-carrying capacity.

3. Tooth Meshing: The helix angle affects how the teeth mesh with each other. A higher helix angle promotes gradual and smoother meshing, reducing the concentration of stress on individual teeth. This results in improved resistance to wear and fatigue.

4. Axial Thrust: Helical gears produce axial thrust due to their helical nature. This thrust can affect the gear’s ability to handle radial loads. Proper consideration of the helix angle can help manage axial thrust and prevent overloading.

5. Lubrication: The helix angle affects the lubrication conditions between gear teeth. A larger helix angle may allow better oil flow and lubrication, reducing friction and wear, thereby enhancing load capacity.

6. Noise and Vibration: The helix angle also influences noise and vibration levels in helical gears. Optimal helix angle selection can minimize noise and vibration, contributing to smoother operation and prolonged gear life.

Optimal Helix Angle Selection: While a larger helix angle generally increases load capacity, it’s important to strike a balance. Extremely large helix angles can lead to reduced tooth strength and efficiency. Engineers consider factors like application requirements, tooth strength, and noise considerations when selecting the optimal helix angle for a specific gear design.

The relationship between the helix angle and load capacity underscores the importance of proper gear design to ensure optimal performance, durability, and reliability in various applications.

Limitations and Disadvantages of Helical Gear Systems

While helical gear systems offer numerous advantages, they also come with certain limitations and disadvantages:

- Axial Thrust: Helical gears generate axial thrust due to the helix angle of the teeth. This thrust can cause additional load on bearings and may require additional measures to counteract.

- Complex Manufacturing: The manufacturing process for helical gears is more complex than that of straight-toothed gears, which can lead to higher production costs.

- Axial Length: Helical gears require more axial space compared to spur gears with the same gear ratio. This can be a limitation in applications with space constraints.

- Sliding Contact: Helical gears have sliding contact between their teeth, which can result in higher friction and more heat generation compared to rolling contact gears.

- Efficiency: Although helical gears are generally efficient, their efficiency can be slightly lower than that of some other gear types, especially at high speeds.

- Complexity in Gearbox Design: The inclination of helical gear teeth introduces additional complexity in gearbox design and alignment.

- Reverse Thrust: In some cases, reverse thrust can occur when helical gears are subjected to high axial loads, leading to undesirable effects.

It’s important to consider these limitations and disadvantages when selecting gear systems for specific applications. Despite these challenges, helical gears remain a popular choice in various industries due to their benefits and overall performance characteristics.

editor by CX 2023-09-04

China Zlyj 173/180/200/225/250/280/375 Helical Gear Speed Reducer Soap Extruder Gearboxes for Plastic Extrusion Machine Factory Price bevel helical gearbox assembly

Solution Description

Item Description

ZLYJ gearbox series are transmission units, which are specifically designed for solitary-screw extruder with large precision, challenging gear surface area, accompany with thrust. Adopting the technical specifications stipulated in JB/T9050. 1-1999, all CZPT gearboxes are designed appropriately.

Solution Parameters

Thorough Pictures

Device Parts

Identify: Higher Quality CZPT Gearbox

First: China Gear material: high alloy metal low carbon (20CrMnTi)The interface is hardened, precision-floor and challenging-chrome-plated to 870HV hardness and Ra .8-1.6µm roughness, so the shaft-seal is super hard, resists put on and corrosion, and quite tough.

Principal Features

Manufactured of carburizing metal (Forging), go by way of normalization warmth remedy for solid carburizing steel and equipment faces are also nitride-handled to at the very least 60HRC hardness for best rigidity and carburizing depth .8-1.1MM and use resistance.

Solitary Screw Extruder Gearbox

Our CZPT gearbox for solitary screw extruder adopts large power alloy steel material and the gear is of high accuracy. It is much less

noisy, perform quietly and effortlessly. So it is a more time provider existence.

Gearbox casting physique

one. we get ready ample casting body in our workshop to ensure the supply time.

two. this is our new gearbox casting physique design.

3. rapidly shipping and delivery time and higher quality

Heat remedy furnace

We have own warmth therapy for the gears and gearshaft, so it’s effortless for us to manage the top quality and the quality is much more gurantee.

Packaging & Delivery

1)Packing: Wrapped up by movie in picket cases

2)Port Departure: HangZhou Port

three)Delivery time: 25 working times upon receipt of 30% deposit(days based on your quantity)

We use sturdy plywood or picket circumstance for all our goods.

FAQ

Q1. Are you a investing firm or a producer?

We are a BSCI&ISO-9001 certificated maker.

Q2. Can I area the tailored order for various sizes, colours, materials,packings….?

Yes, all the personalized orders are welcomed.

Q3. Could I get a QC report prior to shipping?

Indeed, the distinct QC reports will be despatched to you prior to delivery.

This fall. Can I get a lower price if I spot a more substantial get?

Of course, the value will be modified in accordance to your get portions.

| To Be Negotiated | 1 Piece (Min. Order) |

###

| After-sales Service: | Good After-Sales Service |

|---|---|

| Warranty: | One Year |

| Standard: | DIN, ASTM |

| Technics: | Casting |

| Feature: | Corrosion Resistance |

| Material: | Metal |

###

| Customization: |

Available

|

|---|

| To Be Negotiated | 1 Piece (Min. Order) |

###

| After-sales Service: | Good After-Sales Service |

|---|---|

| Warranty: | One Year |

| Standard: | DIN, ASTM |

| Technics: | Casting |

| Feature: | Corrosion Resistance |

| Material: | Metal |

###

| Customization: |

Available

|

|---|

Helical Gearbox

Depending on the helical gearbox, it can be either Crossed-axis or Inline. Basically, helical gearboxes are composed of a set of toothed gears that mesh with other toothed parts to transmit torque and speed to other parts of the machine.

Right angle helical gearboxes

Choosing the right angle gearbox can be difficult. This is because the design and specifications will depend on the type of application. The right gearbox can make or break the efficiency of the system. For example, a right angle gearbox will need to be corrosion resistant if it is used in a washdown application. It may also require special grease for use in cold temperatures.

There are many different types of right angle gearboxes. The types include worm, hypoid, and spiral bevel gearboxes. The most common are worm gearboxes. These are a great option for applications that need high torque and power. However, they are not as efficient as spur gears.

Helical gearboxes are ideal for heavy-duty industrial applications such as conveyors, blowers, and elevators. They are quiet and have better speed capabilities than spur gears. They can handle larger loads because of their gradual engagement. They are also capable of adjusting the rotation angle by 90 degrees. They are also more efficient at high speeds.

Spiral bevel gearboxes require more precision to manufacture. They are also more expensive to produce. This is because the teeth need to be drilled and shaped to fit the shafts. The gearbox needs to be designed with tight tolerances and requires basic lubrication. Its operating cycle is long.

Helical gearboxes can be used in conjunction with other gearboxes. For example, the output shaft may be a hollow shaft, or it may be designed with dual counter-rotating shafts. They can also be designed to operate in either a clockwise or counter-clockwise direction.

Right angle gearboxes are ideal for high-speed applications. They require less maintenance than other industrial components. They may require corrosion resistant plating or stainless steel shafts. If you are considering a right angle gearbox, check with a distributor to see what types of products are available. A representative will be able to help you with installation. They may also offer custom gearbox solutions to fit your needs.

A gearbox is made up of four main components. These components include the input shaft, the output shaft, the gear, and the backlash.

Crossed-axis helical gears

Normally, helical gearboxes are used to increase torque between two rotating shafts. Compared to other types of gearboxes, helical gearboxes offer greater speed and power carrying capacity. They are also quieter and smoother in operation. These gearboxes are used in many industries such as food processing, plastic, rubber, and oil industries. These gears also have the advantage of being cheaper than spur gears.

These gears are designed with special teeth that are positioned at an angle to the face of the gear. As they rotate, the teeth engage gradually. They have longer teeth, which allow them to carry heavy loads. The contact area also increases as the gears rotate.

A cross axis helical gearbox is one of the most common types of gearboxes. This gearbox has an advantage over spur gears, since it uses bearings to support the thrust load. It can also adjust the rotation angle by 90 degrees. These gearboxes are typically used to drive automobile oil pump/distribution shafts. They are also used to drive blowers. They have a large thrust force.

The cross axis helical gearbox has the advantage of using bearings to support the thrust load. However, it also has the disadvantage of using a large amount of bearings. In addition, these gears are not suitable for speed reduction beyond 1:2.

Thermoplastic crossed axis helical gears are a convenient solution for high volume applications. These gears are self-locking and offer high torque. These gears are also very durable. They are also available in a variety of configurations and sizes. They are used in a wide range of industries, including the textile industry. The output torque of these gears is also very high.

Crossed helical gears are also used to transmit motion and power between perpendicular but non-intersecting shafts. To achieve this, two mating helical gears must have the same helix angle, pressure angle, and normal pitch. They should also be mounted on perpendicular but non-intersecting, parallel shafts.

To calculate the real radial pitch of a gear, the angle of cut is measured. The gear teeth are then cut at an angle to the face of the gear. The helix angle is also measured.

Inline helical gears

Unlike spur gears, helical gears have a large surface contact and are characterized by low noise and large torque. Moreover, helical gears also have a high degree of meshing performance. They are also compact and durable.

As the name suggests, helical gears are produced using hard steel teeth. They are also hobbed to ensure smooth running and accurate surface finish. In addition, all gearing is ground for increased efficiency.

Inline helical gearboxes are used in a number of applications, including waste water systems and in solvent extraction. They are also used in industries like power plants and food & tobacco. They have good efficiency and are low in cost. They also have interchangeability and high durability. They can be installed in a single piece aluminum alloy housing. They can also be foot mounted or flange mounted. They are available in single stage and three stage constructions.

Helical gearboxes are typically used in high-load applications, such as in cement and waste water systems. They are also suitable for industrial applications, including in manufacturing. They are also used in applications where there is a large speed variation range. They are suitable for a wide temperature range, from -10 degC to 40 degC.

A helical gearbox has a high degree of interchangeability, and can be installed with a wide range of motors. They are also available in flame proof versions. They can also be supplied with an integrated output flange. They have standard IEC inputs, making them easy to install and operate. They also have a removable inspection cover, which allows periodic inspection of gearing. They can also be supplied with integral mounting bases.

The transmission ratio of helical gearboxes is finely graded to meet different working conditions. They also have an output torque that ranges from 1.4-250. They are also available in a modular model, which allows them to be produced in an economical manner. They can also be installed with a standard IEC input, which makes them easy to fit with any IEC motor. They also have a permanent nameplate, which indicates the ratio and the output torque.

Helix angle

Using a helical gearbox is a more economical and efficient way of creating a gearbox. It is also beneficial for production because it allows for more interchangeable components. It can also be used in the oil and plastic industries. It has advantages over conventional gears because it runs quieter.

The helical gearbox is a type of gearbox that uses a helical cut on the teeth of the gears. It carries more surface contact than conventional gears, which increases the power carrying capacity. It is also more durable and quieter than conventional gears.

The helical gearbox is generally used in enclosed gear systems because it allows for higher tooth overlap and smoother performance. It also eliminates thrust forces. The helical gearbox can be made of two helical sections that are close together. It is common to use double helical gearboxes in enclosed gear systems. The gears can be ground and hardened.

The radial pitch of helical gears is about eight millimeters. In the helical gearbox, the radial pitch of the gears is the same as the pitch of the spur gears. Using the same tooth cutting tools, it is possible to make helical gears more economically.

The pitch of the helical gearbox will vary with the helix angle. Typically, the helix angle is between 15 and 30 degrees. The pitch will also change with the number of teeth in the spur gear. The pitch will increase when the number of teeth increases.

The pitch is also affected by the pressure angle of the tooth. The pressure angle affects the normal force and curvature radii. The length of the helical gear contact line decreases as the pressure angle increases. This can also be seen when considering contact on the tooth surface. The helix angle is also important when calculating the forces between the helical gears.

It is important to understand that helical gears generate axial forces within the gear-mesh. These forces need to be supported by bearings. They also generate heat. This heat is also detrimental to the efficiency of the gear. It can also cause power loss.

editor by czh 2023-01-08

in Ranchi India sales price shop near me near me shop factory supplier Marine Gearbox Speed Reducer and Spare Parts with Low Price and Factory Directly manufacturer best Cost Custom Cheap wholesaler

In this way, our merchandise have continued to obtain market acceptance and customers satisfaction above the past few several years. Thanks to our sincerity in providing greatest services to our customers, comprehending of your requirements and overriding feeling of duty toward filling buying specifications, we have attained the have confidence in of purchasers throughout the world. ZheJiang monarch EPTT engineering limited can give you the Marine EPTT with distinct makes

Which can satisfy your distinct needs. We alwaEPTTchoose the very best a single to our customer!

EPT EPTT supplies the a single end marine solution, maritime motor, maritime EPTT, marine shaft, maritime propeller.

EPTT description:

HCT1100 EPT EPTT MAX. 1841HP at 1600RPM

Engine Velocity: seven-hundred~1600RPM

Ratio5.sixty five.986.396.857.357.9

Charge(HP/rpm)1.151.151.151.141.051

L*W*H: 1115*1350*1547mm Internet Weight: ~3000Kg

Choices/Responses: EPT(recommended) or EPT remote manage

Centre distance: 500mm

Engine: CW6200…

| commodity description: | ||||||

| HCT1100 EPT EPTT MAX.1841HP at 1600RPM | ||||||

| Motor Pace:seven-hundred~1600RPM | ||||||

| Ratio | five.6 | five.ninety eight | 6.39 | six.eighty five | seven.35 | seven.nine |

| Rate(hp/rpm) | 1.15 | 1.15 | 1.fifteen | one.14 | one.05 | 1 |

| L*W*H : 1115*1350*1547mm Web WeigEPTT : ~3000Kg | ||||||

| Alternatives/Remarks : EPT(recommended) or EPT remote control | ||||||

| Centre distance : 500mm | ||||||

| Engine : CW6200… | ||||||

| maritime EPTT product list | ||

| 06 maritime EPTT | ||

| 16A maritime EPTT | ||

| 26 marine EPTT | ||

| MA100 maritime EPTT | ||

| MA125 marine EPTT | ||

| MA142 marine EPTT | ||

| 40A marine EPTT | ||

| MB170 maritime EPTT | ||

| 120B marine EPTT | ||

| 120C marine EPTT | ||

| one hundred thirty five marine EPTT | ||

| MB242 maritime EPTT | ||

| HC138 marine EPTT | ||

| HCD138 marine EPTT | ||

| HCC200 maritime EPTT | ||

| MB270A maritime EPTT | ||

| 300 marine EPTT | ||

| J300 maritime EPTT | ||

| D300A maritime EPTT | ||

| T300 maritime EPTT | ||

| T300/1 marine EPTT | ||

| HC400 marine EPTT | ||

| HCD400A marine EPTT | ||

| HCT400A marine EPTT | ||

| HCT400A/one maritime EPTT | ||

| HC600A maritime EPTT | ||

| HCD600A maritime EPTT | ||

| HCT600A marine EPTT | ||

| HCT600A/one maritime EPTT | ||

| HCD800 maritime EPTT | ||

| HCT800 marine EPTT | ||

| HCT800/one maritime EPTT | ||

| HCT800/2 marine EPTT | ||

| HCT800/3 maritime EPTT | ||

| HC900 maritime EPTT | ||

| HC1000 marine EPTT | ||

| HCD1000 marine EPTT | ||

| HCT1100 maritime EPTT | ||

| HC1200 maritime EPTT | ||

| HC1200/1 marine EPTT | ||

| HCT1200 maritime EPTT | ||

| HC1250 maritime EPTT | ||

| HCT1400 maritime EPTT | ||

| HCK150 marine EPTT | ||

| hck1200 maritime EPTT | ||

| HCDS1200 marine EPTT | ||

| HC701 maritime EPTT | ||

| HC571 maritime EPTT | ||

| HC038A maritime EPTT | ||

| HC35 marine EPTT | ||

| HC65 marine EPTT | ||

| MV100A marine EPTT | ||

| HCV120 maritime EPTT | ||

| HCQ138 maritime EPTT | ||

| HC200 marine EPTT | ||

| HC201 marine EPTT | ||

| HCV230 marine EPTT | ||

| HCQ300 maritime EPTT | ||

| HCA300 maritime EPTT | ||

| HCA301 marine EPTT | ||

| HCV400 marine EPTT | ||

| HCQ401 maritime EPTT | ||

| HCQ501 marine EPTT | ||

| HCQ502 maritime EPTT | ||

| HCQ700 maritime EPTT | ||

| HCQ1000 maritime EPTT | ||

| HCQ1400 maritime EPTT | ||

| HCQH1600 maritime EPTT | ||

| HYEPTTLIC CLUTCH | ||

| Model | ||

| HCL30S | ||

| HCL30F | ||

| HCL100S | ||

| HCL100F | ||

| HCL250S | ||

| HCL320S | ||

| HCL320F | ||

| HCL600S | ||

| HCL600F | ||

| HCT800 | ||

| GCS320 | ||

| GCS350 | ||

| GCS390 | ||

| GCS410 | ||

| GCS450 | ||

| GCS490 | ||

| GCS540 | ||

| GCS590 | ||

| GCST33 | ||

| GCS660 | ||

| GCST44 | ||

| GCS700B | ||

| GCST66 | ||

| GCS760 | ||

| GCS880 | ||

| GWC28.thirty | ||

| CWL28.30 | ||

| GWC30.32 | ||

| GWL30.32 | ||

| GWC32.35 | ||

| GWL32.35 | ||

| GWC36.39 | ||

| GWL36.39 | ||

| GWC39.41 | ||

| GWL39.forty one | ||

| GWC42.45 | ||

| GWL42.forty five | ||

| GWC45.49 | ||

| GWL45.49 | ||

| GWC49.fifty four | ||

| GWL49.fifty four | ||

| GWC52.59 | ||

| GWL52.59 | ||

| GWC52.sixty two | ||

| GWL52.62 | ||

| GWC60.sixty six | ||

| GWL60.sixty six | ||

| GWC60.74 | ||

| GWL60.74 | ||

| GWC66.75 | ||

| GWL66.seventy five | ||

| GWC70.seventy six | ||

| GWL70.76 | ||

| GWC70.85 | ||

| GWL70.85 | ||

| GWC75.90 | ||

| GWL75.90 | ||

| GWC78.88 | ||

| GWL78.88 | ||

| GWC80.95 | ||

| GWL80.ninety five | ||

| GWC85.a hundred | ||

| GWL85.one hundred | ||

| GWS28.thirty | ||

| GWK28.thirty | ||

| GWH28.thirty | ||

| GWD28.30 | ||

| GWS30.32 | ||

| GWK30.32 | ||

| GWH30.32 | ||

| GWD30.32 | ||

| GWS32.35 | ||

| GWK32.35 | ||

| GWH32.35 | ||

| GWD32.35 | ||

| GWS36.39 | ||

| GWK36.39 | ||

| GWH36.39 | ||

| GWD36.39 | ||

| GWS39.forty one | ||

| GWK39.41 | ||

| GWH39.41 | ||

| GWD39.forty one | ||

| GWS42.forty five | ||

| GWK42.forty five | ||

| GWH42.forty five | ||

| GWD42.45 | ||

| GWS45.49 | ||

| GWK45.49 | ||

| GWH45.forty nine | ||

| GWD45.49 | ||

| GWS49.fifty four | ||

| GWK49.54 | ||

| GWH49.fifty four | ||

| GWD49.54 | ||

| GWS52.fifty nine | ||

| GWK52.fifty nine | ||

| GWH52.59 | ||

| GWD52.fifty nine | ||

| GWS60.sixty six | ||

| GWK60.66 |

in Warsaw Poland sales price shop near me near me shop factory supplier Manufacturer Direct Selling Udl Series Variable Speed Reducer manufacturer best Cost Custom Cheap wholesaler

Our products are applied in a lot of fields. Our item range also handles locking assemblies (clamping components/locking system), taper bushes, QD bushes, bolt-on hubs, torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod ends and yokes. We are seeking forward to establishing profitable organization relationships with new clientele around the entire world in the future. Item CEPTRACTERISTICS:

1.EPT velocity-regulating precision :.5-1 rotation

two.EPT velocity-modifying selection: ratio from one:1.4 to 1:7 freely

3.EPT toughness and EPTT service lifestyle

four.Hassle-free to regulate pace

five.Can operate repeatedly, entrance to again working direction, smooth managing,secure efficiency, and reduced noise.

six.Sealed completely and suitable for any surroundings

seven.Companct construction and small volume

eight.Manufactured of large good quality aluminium alloy diecast into foarming, nice appearance,ligEPTT weigEPTT and non-rusty.

9.Very good adaptation:UDL sequence speed variators can be mixed with all kinds of pace EPTTs to achive lower stepless pace regulating(this kind of as R-K-F-S Series and NMRV worm EPTTs).

Purposes:

UDL series stepless speed variators are extensively used for foodstaffs, EPTT, chemical compounds,pharmacy,plastics, paper-producing, EPTT resources,communications and all varieties of automatic lines,pipelines and assembly lines which require pace regulating. It is a very good companion for creation EPTTs.

| Functionality PARAMETER | ||||

| Performance table for UDL sequence velocity variators(n1=1400r/min) | ||||

| EPT EPTT | Model | i | n2(r/min) | M2(Nm) |

| .18KW | UDL002(UDL0.eighteen) | one.six #87658.2 | 880 #8765170 | one.5 #87653 |

| .37KW | UDL005(UDL0.37) | 1.four #87657 | 1000 #8765200 | three #87656 |

| .75KW | UDL571(UDL0.75) | 1.four #87657 | a thousand #8765200 | 6 #876512 |

| 1.5KW | UD571(UD1.5) | one.four #87657 | a thousand #8765200 | twelve #876524 |

| 2.2KW | UD030(UD2.2) | one.4 #87657 | 1000 #8765200 | 18 #876536 |

| 3.0KW | UD040(UD3.) | one.4 #87657 | one thousand #8765200 | 24 #876548 |

| 4.0KW | UD050(UD4.) | one.four #87657 | 1000 #8765200 | 32 #876564 |

Business Quick INTRODUCTION:

We are a skilled EPTT company situated in EPTTizhou, EPTT province.

Our major products is complete variety of RV571-one hundred fifty worm EPTTs , also equipped hypoid helical EPTT, Laptop models, UDL Variators and AC EPTs.

EPT are widely utilized for purposes these kinds of as: foodstuffs, EPT, EPTT, substances, pharmacy, plastics, paper-producing, building EPTTry, metallurgic EPT, environmental safety engineering, and all varieties of computerized strains, and assembly lines.

With fast shipping and delivery, exceptional right after-income provider, EPTd generating faXiHu (West EPT) Dis.Hu (West EPT) Dis.ty, our items offer effectively each at house and overseas. We have exported our EPTTs to SouthEPT Asia, EPTern Europe and the Center EPT and so on.Our purpose is to deveXiHu (West EPT) Dis.Hu (West EPT) Dis. and innovate on the basis of high high quality, and EPT a great status for EPTTs.

WORKSHOP:

EXHIBITIONS:

FAQ:

1.Q:Can you make as for every consumer drawing?

A: Sure, we offer you EPT support for customers accordingly. We can use customer’s nameplate for EPTTes.

2.Q:What is your conditions of payment ?

A: thirty% deposit prior to creation,equilibrium T/T prior to delivery.

3.Q:Are you a trading organization or manufacturer?

A:We are a manufacurer with EPTd equipment and experienced workers.

four.Q:What is your manufacturing capacity?

A:8000-9000 PCS/Month

four.Q:What is your MOQ?

A: one pcs

5.Q:Cost-free sample is offered or not?

A:Yes, we can provide totally free sample if buyer agree to shell out for the courier EPT

6.Q:Do you have any certificate?

A:Of course, we have CE certification and SGS certification report.

Make contact with data:

Ms Lingel Pan

For any inquiries just truly feel cost-free ton contact me. Several many thanks for your type focus to our business!

in Oujda Morocco sales price shop near me near me shop factory supplier Motorvario Equivalent Nmrv025 to Nmrv150 Worm Gear Speed Reducer manufacturer best Cost Custom Cheap wholesaler

we provide 1-end remedy for the acquire of mechanical electrical power transmission merchandise in China. It has recognized secure cooperation with several well acknowledged universities and institutes in china such as, Zhejiang College, Jilin University, Complex committee of countrywide chain push regular, Institute of nationwide chain travel, Zhejiang software engineering substance institute, Huhan material safety institute and it cooperated to located China Initial Vehicle chain institute with Countrywide chain generate institute. The group has taken part in the making and revising of ISO/TC100 worldwide chain standard numerous many years in achievement and hosted the sixteenth ISO/TC100 Worldwide once-a-year meeting in 2004. Product INTRODUCTION:

Principal Attributes:

one) Produced of higher top quality EPT alloy, ligEPTT weigEPTT and non-rusting

2) Big output torque and high radiating effectiveness 3) EPT operating and reduced sound, can operate EPTT time in dreadful problem

four) Great-searching physical appearance, tough support daily life and small quantity

five) Suited for omnibearing installation

Primary Supplies:

1)housing: aluminium alloy ADC12(dimensions 571-090) die cast iron EPTT200(size a hundred and ten-one hundred fifty)

2)Worm:20Cr, ZI Involute profile carbonize ampquencher warmth therapy make EPT surface hardness up to fifty six-62 EPTC Right after precision grinding, carburization layer’s thickness in between .three-.5mm.

three)Worm Wheel:wearable stannum alloy CuSn10-1

Product PARAMETERS:

| Measurement | Specification | EPTT ratio | |||||||||||||

| IEC | N | M | P | seven.five | 10 | fifteen | 20 | 25 | 30 | forty | fifty | sixty | eighty | one hundred | |

| D | |||||||||||||||

| 25 | 56B14 | fifty | 65 | 80 | nine | 9 | nine | 9 | nine | nine | nine | nine | 9 | ||

| 30 | 63B5 | ninety five | a hundred and fifteen | 140 | eleven | eleven | eleven | eleven | eleven | 11 | eleven | eleven | |||

| 63B14 | sixty | seventy five | 90 | ||||||||||||

| 56B5 | eighty | one hundred | 120 | 9 | nine | nine | 9 | nine | nine | nine | nine | 9 | nine | ||

| 56B14 | 50 | sixty five | eighty | nine | nine | 9 | 9 | 9 | 9 | 9 | nine | nine | 9 | ||

| 40 | 71B5 | one hundred ten | 130 | one hundred sixty | 14 | fourteen | fourteen | 14 | fourteen | 14 | 14 | fourteen | |||

| 71B14 | 70 | eighty five | a hundred and five | ||||||||||||

| 63B5 | ninety five | 115 | one hundred forty | 11 | eleven | 11 | 11 | 11 | 11 | 11 | 11 | eleven | 11 | eleven | |

| 63B14 | 60 | 75 | 90 | ||||||||||||

| 56B5 | 80 | one hundred | one hundred twenty | nine | nine | nine | 9 | ||||||||

| fifty | 80B5 | a hundred thirty | a hundred sixty five | two hundred | 19 | 19 | 19 | 19 | 19 | 19 | 19 | – | – | – | – |

| 80B14 | 80 | one hundred | 120 | ||||||||||||

| 71B5 | one hundred ten | a hundred thirty | one hundred sixty | fourteen | fourteen | 14 | fourteen | fourteen | fourteen | 14 | 14 | 14 | 14 | – | |

| 71B14 | 70 | eighty five | 105 | ||||||||||||

| 63B5 | ninety five | a hundred and fifteen | a hundred and forty | – | – | – | – | – | – | – | eleven | 11 | 11 | eleven | |

| sixty three | 90B5 | one hundred thirty | one hundred sixty five | two hundred | 24 | 24 | 24 | 24 | 24 | 24 | 24 | – | – | – | – |

| 90B14 | 95 | 115 | one hundred forty | ||||||||||||

| 80B5 | 130 | 165 | 200 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | – | |

| 80B14 | eighty | one hundred | one hundred twenty | ||||||||||||

| 71B5 | a hundred and ten | 130 | one hundred sixty | – | – | – | – | – | – | 14 | 14 | fourteen | 14 | fourteen | |

| 71B14 | 70 | 85 | 105 | ||||||||||||

| 75 | one hundred/112B5 | 180 | 215 | 250 | 28 | 28 | 28 | – | – | – | – | – | – | – | – |

| 100/112B14 | 110 | a hundred thirty | 160 | ||||||||||||

| 90B5 | a hundred thirty | 165 | 200 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | – | ||||

| 90B14 | 95 | one hundred fifteen | 140 | ||||||||||||

| 80B5 | 130 | 165 | 200 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | ||||

| 80B14 | eighty | one hundred | one hundred twenty | ||||||||||||

| 71B5 | a hundred and ten | 130 | 160 | 14 | 14 | fourteen | fourteen | ||||||||

| ninety | a hundred/112B5 | 180 | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | – | – | – | – | – |

| a hundred/112B14 | a hundred and ten | a hundred thirty | a hundred and sixty | ||||||||||||

| 90B5 | 130 | a hundred sixty five | two hundred | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | – | ||

| 90B14 | ninety five | a hundred and fifteen | 140 | ||||||||||||

| 80B5 | a hundred thirty | 165 | two hundred | 19 | 19 | 19 | 19 | 19 | |||||||

| 80B14 | eighty | one hundred | one hundred twenty | ||||||||||||

| 110 | 132B5 | 230 | 265 | 300 | 38 | 38 | 38 | 38 | – | – | – | ||||

| 100/112B5 | a hundred and eighty | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | |||

| one hundred/112B14 | a hundred and ten | a hundred thirty | 160 | ||||||||||||

| 90B5 | one hundred thirty | one hundred sixty five | two hundred | 24 | 24 | 24 | 24 | 24 | 24 | 24 | |||||

| 80B5 | a hundred thirty | one hundred sixty five | 200 | 19 | 19 | ||||||||||

| a hundred thirty | 132B5 | 230 | 265 | 300 | 38 | 38 | 38 | 38 | 38 | 38 | 38 | – | – | – | |

| one hundred/112B5 | one hundred eighty | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | |||||

| a hundred/112B14 | 110 | a hundred thirty | one hundred sixty | ||||||||||||

| 90B5 | a hundred thirty | 165 | 200 | 24 | 24 | ||||||||||

| a hundred and fifty | 160B5 | 250 | three hundred | 350 | forty two | 42 | forty two | forty two | forty two | – | – | – | – | – | – |

| 132B5 | 230 | 265 | 300 | 38 | 38 | 38 | 38 | 38 | 38 | ||||||

| a hundred/112B5 | a hundred and eighty | 215 | 250 | 28 | 28 | 28 | 28 | ||||||||

Product Outline Dimensions:

Firm Quick INTRODUCTION:

We are a expert EPTT manufacturer positioned in EPTTizhou, EPTT province.

Our leading goods is complete assortment of RV571-150 worm EPTTs , also provided hypoid helical EPTT, Personal computer units, UDL Variators and AC EPTs.

EPT are widely utilised for programs such as: foodstuffs, EPT, EPTT, chemicals, pharmacy, plastics, paper-making, construction EPTTry, metallurgic EPT, environmental safety engineering, and all varieties of computerized lines, and assembly strains.

With quickly delivery, exceptional soon after-revenue service, EPTd generating faXiHu (West EPT) Dis.Hu (West EPT) Dis.ty, our merchandise promote well each at home and abroad. We have exported our EPTTs to SouthEPT Asia, EPTern Europe and the Center EPT and so on.Our intention is to deveXiHu (West EPT) Dis.Hu (West EPT) Dis. and innovate on the basis of large quality, and EPT a great reputation for EPTTs.

WORKSHOP:

EXHIBITIONS:

FAQ:

one.Q:Can you make as per consumer drawing?

A: Indeed, we supply EPT service for buyers accordingly. We can use customer’s nameplate for EPTTes.

2.Q:What is your conditions of payment ?

A: 30% deposit just before manufacturing,balance T/T prior to shipping.

3.Q:Are you a trading firm or maker?

A:We are a manufacurer with EPTd gear and experienced employees.

4.Q:What is your production capability?

A:8000-9000 PCS/Month

4.Q:What is your MOQ?

A: 1 pcs

5.Q:Cost-free sample is obtainable or not?

A:Sure, we can source free of charge sample if client agree to spend for the courier EPT

6.Q:Do you have any certificate?

A:Of course, we have CE certification and SGS certification report.

Speak to information:

Ms Lingel Pan

For any queries just really feel free of charge ton get in touch with me. Several thanks for your type interest to our company!

in General Santos City Philippines sales price shop near me near me shop factory supplier Nmrv Right Angle 90 Degree Worm Gear Box Speed Reducer manufacturer best Cost Custom Cheap wholesaler

PersonnelOur product sales folks are well educated to accommodate your requests and communicate English for your comfort. Moreover, WE CAN Make Tailored VARIATORS, GEARED MOTORS, Electrical MOTORS AND OTHER HYDRAULIC Items In accordance TO CUSTOMERS’ DRAWINGS. we offer you 1-stop remedy for the obtain of mechanical electrical power transmission merchandise in China. NMRV rigEPTT angle ninety degree Worm EPT Box Speed EPTT

Features:

one. LigEPTT in weigEPTT and non-rusting

two. EPT in operating, can operate EPTT time in dreadful situations

3. EPT performance, minimal sound

four. Very good-hunting in appearance, durable in support daily life and little in quantity

Product picture:

Specification for worm EPTT:

| Design | 571 ~ a hundred and fifty |

| EPTT | .06kw ~ 15kw |

| Enter speed | 750rpm ~ 2000rpm |

| Reduction ratio | 1/five ~ one/100 |

| Enter motor | AC (1 section or three stage) / DC / BLDC / Stepper / Servo |

| Output shaft | Reliable shaft / Hollow shaft / Output flange #8230 |

| Dimension stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd | Metric dimension / Inch dimension |

| EPT of housing | die-forged EPT / Cast iron / Stainless metal |

| Components | Flange / Solid shaft / Torque arm / EPTT #8230 |

FAQ

Q: Can you make the EPTT with customization?

A: Sure, we can customise for every your request, like flange, shaft, configuration, materials, etc.

Q: Do you give samples?

A: Of course. Sample is available for testing.

Q: What is your MOQ?

A: It is 10pcs for the commencing of our business.

Q: What is your guide time?

A: StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd merchandise require 5-30days, a bit EPTTer for EPT items.

Q: Do you offer EPT assistance?

A: Of course. Our firm have design and style and deveXiHu (West EPT) Dis.Hu (West EPT) Dis.ment group, we can offer EPT help if you

want.

Q: How to ship to us?

A: It is available by air, or by sea, or by teach.

Q: How to spend the funds?

A: T/T and L/C is chosen, with diverse currency, incXiHu (West EPT) Dis.Hu (West EPT) Dis. USD, EUR, RMB, and so forth.

Q: How can I know the merchandise is suited for me?

A: gt1ST validate drawing and specification gt2nd test sample gt3rd begin mass generation.

Q: Can I occur to your company to go to?

A: Of course, you are welcome to check out us at any time.

Q: How shall we get in touch with you?

A: You can ship inquiry immediately, and we will answer within 24 several hours.

in Barquisimeto Venezuela (Bolivarian Republic of) sales price shop near me near me shop factory supplier Economic Shimpo Gearbox Vrsf-5c-400-Gv 5: 1 Speed Reducer manufacturer best Cost Custom Cheap wholesaler

we supply one particular-quit answer for the acquire of mechanical energy transmission goods in China. EPG was awarded with “famous solution of Zhejiang Province” and “well-known model of Zhejiang Province”. We also can style and make non-common items to meet up with customers’ specific requirements. EPTTnomic Shimpo EPTT VRSF-5C-400-GV five:1 Speed EPTT

Issue : EPTT and unique

Variety: VRSF sequence

Ratio: Various

Stock: Huge

-Merchandise photograph

-Large inventory

-Package deal photograph

-Payment amp Package deal amp Shipping and delivery

one,Payment

( T/T , Western union, Paypal , L/C and so on )

2,Pakcage

( Little EPTT use carton package deal, Huge EPTT use wooden box package deal )

3,Shipping and delivery

( By International Express, By Air , By Sea )

in Chandigarh India sales price shop near me near me shop factory supplier High Quality Cast Steel Cast Iron Metal Helical Gear for Speed Reducer manufacturer best Cost Custom Cheap wholesaler

At any time-Electrical power Team CO., LTD. IS Expert IN Making ALL Types OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Gear Pace REDUCERS, PARALLEL SHAFT HELICAL Gear REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Gear REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Car GEARBOXES, PTO Drive SHAFTS, Special REDUCER & Related Equipment Parts AND OTHER Relevant Products, SPROCKETS, HYDRAULIC Technique, VACCUM PUMPS, FLUID COUPLING, Gear RACKS, CHAINS, TIMING PULLEYS, UDL Velocity VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Equipment PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Low BACKLASH WORM REDUCERS AND SO ON. With several years’ encounter in these traces, we have been distinguished from other suppliers in China by our benefits in aggressive pricing, on-time shipping, prompt responses, on-hand engineering assistance and excellent after-sales services. We are aiming to meet the calls for of the consumers close to the entire world..

Item features

Helical EPTTs are spherical metallic disks with enamel reduce about the circumference. In orEPTTfor the EPTT to qualify as a EPTT, the tooth need to be minimize so that they run perpendicular to the EPTT’s experience. Helical EPTTs are the most basic design and style of EPTT made. They are usually utilized for the EPTT of rotary power. For example, if two shafts are pXiHu (West Lake) Dis.Hu (West Lake) Dis.lel to one one more, and one particular is spinning, a helical EPTT can help to transfer that pressure on to the other shaft. Helical EPTTs generally have an working efficiency of 98% to ninety nine%.

1.EPTT: C45 carbon steel,20CrMo,20CrMoTi,Stainless steel,brass,plastic,POM,and so on.

two.Moudle:M0.4-M10

three.Surface therapy: Galvanizing,zinc plating,Black oXiHu (West Lake) Dis.de,Spray EPTT, Mirror End, Burnishing, Sand-blasting and as your necessity.

4.Warmth treatment:Hardening and Tempering,Substantial Frequency Quenching, Carburizing Quenching..

5.We can make all kinds of Gears according to customers drawing and specifications ,EPTTizing in non-stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd objects.

6.We can manufacture with various percision,this kind of as DIN6,DIN7,DIN8,etc.

Technical specs

– OEM service presented

– Excellent high quality at aggressive value

-Customized

We can offer you OEM Services for Gear Metal Castings, and those steel castings can be produced in the following conditions:

- Heat treatment: Normalized, Normalized and Tempered, Quenched and Tempered

- Machining: Rough EPTTd, Semi-concluded EPTTd, Concluded EPTTd

- Non-Harmful Testing: EPTTic Particle Testing, EPTT Testing, Penetrant Screening

- EPTT: EPTT Metal, Alloy Metal, meet ASTM, BS, DIN, NF, JIS, ISO stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd

- Personal Fat: 500KG – 140MT

EPTT parameters:

The Process As Stick to: ingot #8594 warmth #8594 forging #8594 warmth remedy(normalizing tempering) #8594 inspection #8594 rough machining #8594 UT #8594 2nd heat treatment method #8594 finishing machining #8594 inspection .

EPTT Management: UT,MT,RT,PT,chemical composition take a look at,mechanical property check,etc.

Warmth Therapy: Normalize,Quenching,Tempering,Anealled.

Area Therapy: painting,plating,poEPTTng,black oXiHu (West Lake) Dis.de,transparent anti-rust oil.

Inspection: Besides our in-property inspecion, you could also pick a 3rd social gathering inspection.

StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd: EPTT,ASTM,AEPTE,API,JIS,DIN,BS,EN,KS,UNI,SABS,GOST.

Certificate: one, Uncooked material certificate(substance chemical compositon)

2, Heat treatment method sheet report

three, Dimension inspection report

four, UT examination report

EPTT: Seaworthy plywood packaged on stell pallets or as customer’s request

Shipping Day: Made the decision by the amount and dimensions of items. Typically we management the huge diameter rings’ supply time in 5 months soon after we EPTT your formal purchase.

Aggressive Gain: EPTT management and management to the EPTT create approach, incXiHu (West Lake) Dis.Hu (West Lake) Dis. ingot smelting,forging, heat remedy, machining and strictly closing inspection prior to shipping.

cnc lathe forging and teeth grinding

helical pinion EPTT

Equipment EPTT Capability:

| EPTT Sort | Attributes | |

| MAX. | MAX. | |

| Diameter | Peak | |

| (MM) | (KGS) | |

| Gear milling | 1500 | 15000 |

| Equipment hobbing | 5000 | 20000 |

| Gear grinding | 5000 | 20000 |

Superiority

one.Higher precision of dimensional tolerance

2.Outstanding mechanical property

three.Accessible in varities of dimensions and designs(acc to customer’s demands)

four.Superior manufacturing equipments and test devices

5.forty two superb technicist

6.strictly control the manufacturing procedures

seven.also pay out more consideration to the protection and EPTT

|

Merchandise Specifics |

|

|

Merchandise identify |

helical pinion EPTT |

|

Functions |

difficult tooth floor |

|

Software |

DIN 6 |

|

Tooth profile |

involute |

|

EPTT |

18CrNiMo6 |

|

Method |

forging carburizing internal grinding teeth grinding linear chopping |

|

Stress angle |

20 deg |

|

Design |

M=9,Z=32,a=twenty deg, beta=7.5 deg,x= .15 ,rigEPTT hand |

|

EPTT spot |

HangEPTT, EPTT |

EPTT handle

raquo Severe raw content inspection

raquo Rigorous manage more than the total producing procedure

raquo Sampling of all the goods after closing inspection before cargo

raquo EPTT trace soon after supply

| Title | Gears |

| EPTT | Stainless, metal,iron,brass, EPTT alloy,carbon steel, alloy steel,magnesium alloy, red brass,plastic or comply with your samples amp drawings on supplies. |

| Tolerance | plusmn .03% |

| Inspection | a hundred% inspection before shipment. |

| Method | PM/MIM/CNC/DIE-CASTING/STAMPING/HOBBING |

| Surface area remedy | E-coating,electroplating and black oxygen, anodizing,polish,sandblasting,heat therapy ,Nickel plating Zinc plating, Chrome plating, OXiHu (West Lake) Dis.dation. Anodization and so forth |

| Software | automobile,lock system,EPTT device,electric EPTT,communication EPTT,EPTT EPTT,healthcare gear,EPTTrtainment systems or other EPTT |

| weekly ability | 10000pcs |

| MOQ | 1000pcs |

| Samples | Samples are obtainable prior to bulk orders for good quality pleasure. |

| EPTT: | Carton, EPTTen Situation or in accordance to your prerequisite. |

| payment terms | T/T, PAYPAL,Income |

| EPTT time: | Samples are inside of 15 daEPTTafter the receipt of the deposit. Manufacturing will be concluded about 25~thirty daEPTTafter samples confirmation. |

| Cargo: | Specific, you can get the sample in 3~8days |

| roduct Name | Large EPTT EPTT EPTT Components Helical Equipment EPTT Manufacturing unit |

| EPTT | EPTT Stee:45#, SAE1571, SAE1045, Y15Pb, 1214L. |

| Alloy Metal:Cr12, 40Cr, 20CrMnTi, 16MnCr5, 20CrMnMo, 42CrMo, 17CrNiMo5… | |

| Brass/Bronze :HPb59-one, H70, CuZn39Pb2, CuZn40Pb2,C38000, CuZn40 | |

| Iron:Gray iron and ductile iron | |

| EPTT:6061, 6063,7075,5052 and so on. | |

| Forged Metal:Regular carbon metal, alloy metal, stainless metal, and so on | |

| Coloration | OEM |

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd | DIN GB ISO JIS BA EPTT |

| Grade | SUS201, SUS304, SUS316, A2-70, A2-eighty, A4-eighty, 4.8 six.eight eight.8 ten.9 twelve.9 |

| Area Therapy | Blacking, poEPTTng, anodization, anodized, passivation, portray, EPTT coating, black oXiHu (West Lake) Dis.de, silver/EPTT plating, electrolytic poEPTTng, nitrided, phosphating, sandblasting, nickel/zinc/chrome plating, and so forth.Rock |

| Treatment | Quenching amp Tempering, Carburizing amp Quenching, Large-frequency hardening, Carburization, and many others. |

| Utilised | Building equipment, outboard motors, EPTT resources, lawn and XiHu (West Lake) Dis.Hu (West Lake) Dis.den gear, maritime hoists, multi-spindle EPTTs, snow throwers, turbine EPTTs, pumps, centrifuges and other EPTT EPTT gear. |

| Product Name | Customized EPTTmotive EPTT AXiHu (West Lake) Dis.s FleXiHu (West Lake) Dis.ble Propeller Grinding Equipment Shaft |

| EPTT | C45,40Cr,20CrMnTi,42CrMo,Copper,Stainless metal and so on as for each your requests |

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd | DIN GB ISO JIS BA EPTT |

| Quality | SUS201, SUS304, SUS316, A2-70, A2-80, A4-eighty, four.eight 6.8 eight.8 10.nine 12.nine |

| Heat Treatment method | Carburizing,Induction,Flame,Nitriding |

| Certification | IATF 16949, ISO 9001 |

| Utilised | EPTT, EPTTry |

ear EPTT

Solution Name: Custom-made Spur EPTT shaft principal shaft EPTT EPTT input shaft

EPTT:20CrMnTi

Dimension:354*95*158mm

Approach:hobbing,carburizing,turning,drilling,EPTT shaping,CNC machining

Tolerance: /.01mm

Tooth profile: Spur

Tooth NO.:eighty

Method NO.four

Force angle:27 deg

Spline Data:

Enamel NO.:38

Manner NO.two.5

Force angle:20 deg

Roughness:Ra three.2

Warmth treatment: Carburizing

Surface area treatment method: None

Certifate: TS 16949

Main gear: EPTT hobbing EPTT, EPTT slotting EPTT, CNC lathe, and so forth

Supply materials certification,dimensional report,heat therapy report

| Gear OEM Support | |

| EPTT | EPTT metal,Alloy Metal,Substantial-energy metal , stainless steel,EPTT, Brass ,Copper,Forged Iron and so forth. |

| Heat remedy | Higher frequency quenching, hardened tooth, Normalizing, Carburizing , Nitriding , etc |

| Area therapy | Zinc/Nickel plating, black oXiHu (West Lake) Dis.de, electrophoresis ,Sandblasting, Anodizing Color, PoEPTTng or as for every the customer’s needs |

| Area Roughness | Ra0.2-six.4 |

| Bundle | Strategy one:Shrink film wooden box Method 2:cardboard box pallet Approach 3:Export picket case Method 4: personalized EPTT as customer’s need |

| EPTT | Equipment hobbing EPTT, EPTT slotting EPTT, CNC lathe, Cylindrical GrinEPTTEPTT,CNC Machining CEPTTr,CNC Lathe,Drilling EPTT, Laser Cutting EPTT,Bending EPTT,Stamping EPTT,Sand Blasting EPTT,Robert welding,and so forth |

| Supply time | 20-45DaEPTTDepends On EPTTtities and compleXiHu (West Lake) Dis.ty |

| Payment | T/T thirty% deposit and balanced 70% to pay out prior to cargo |

| Application | Practice, EPTT EPTT, healthcare unit, EPTT EPTT, vehicle, electrical EPTT, and other EPTT. |

| Min orEPTTand sample orEPTTis suitable. | |

| Machining support as for every your requests and specification drawings, both little or large amount is appropriate for us. We are sincerely anticipating to cooperate with you. |

|

machining vehicle components monitor moto tractor sprial spur helical bull wheel EPTT

We EPTTized in production vehicle EPTTs , bike EPTTs, EPTT, EPTT car (EPTT takeoff, snowmobiles, engineering vehicles) EPTTs, generator equipment, stainless metal ice crusher and so on.

| EPTT | 1571,1045,20CrMnTi, and so forth. |

| Machining Method | Gear Hobbing , Gear Shaping, Gear Shaving, Equipment Grinding |

| Modules | one., 1.25, one.5, one.75, 2., 2.twenty five, two.5….eight. and many others. |

| Heat Treatment | Carburizing amp Quenching, EPTTitriding |

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd | DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

Casting EPTT Steel Crusher Areas Mill Elements Massive Equipment

Item Description

EPTT description:

| Description | Casting EPTT Steel Crusher Components Mill Components Massive Equipment |

| Kind | Spur EPTTs, EPTT shafts, herringbone EPTTs, ring EPTTs, helical EPTTs, large-precision EPTTs, EPTTes, EPTT EPTTs, weighty-duty EPTTs, massive-module EPTTs, challenging-toothed EPTTs. |

| Application | Mines, metallurgy, oil, ports, ships, heavy EPTTry, and many others. |

| Processing | Casting Warmth Treatment method Machining |

| EPTT | Alloy metal ,carbon steel |

| Fat Ranges | 1T-10T |

| Tolernace | Controlled by ISO 8062 CT10-13 |

| Design and style Help | Pro-E, UG,SolidWorks,EPTTCad, PDF |

| EPTT Handle | EPTT, Dimension,Functionality,inside defects,Equilibrium examination |

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd | ASTM,DIN,JIS,ISO,GB stXiHu (West Lake) Dis.Hu (West Lake) Dis.rds |

Declaration:

EPTT shown herein are created to the requirements of distinct clients and are illustrative of the types of manufacturing capabilities offered inside of EPTT group of organizations.

Our plan is that none of these merchandise will be sold to third events without having created consent of the clients to whom the tooling, design and technical specs beEPTT.

roduct Description

| Solution title | Custom Scorching Market EPTT Sinter Stainless Metal Travel Equipment |

| EPTT | Stainless Steel or Customized |

| Finish | Thoroughly clean or Tailored |

| Approach | EPTT Sinter |

| Tolerance | plusmn0.1mm |

| Certification | ISO9001:2008,SGS, ROHS |

| Package deal | PP bag , Carton ,box or in accordance to customer’s demands |

| Usage | EPTT Components |

| MOQ | 5000 pcs |

| Sample | Obtainable |

| EPTT | Shipped by a hassle-free and EPTT-effective way. |

| EPTT Time | Sample: fifteen-20 workdaEPTTfor mold very first, Batch items: 12-fifteen workdaEPTTafter samples have been accepted. |

Our spur and helical EPTTs are welcomed by several customers for its stable substantial quality and competitive price tag.

The making character of JH EPTTs:

one. Equipment dimension: the greatest diameter is 1500mm

2. EPTT: Most typical steel is higher power metal 20CrMnTi. Others can be steel C45, stainless metal, higher power steel, copper, aluminium, plastic, POM and so on

3. Equipment module: .3-8 (pitch from .942-25.12mm, DP 3.175-eighty five)

4. Surface area: zinc (galvanized), black, chromium plating, nickel plating, quenching and tempering and so forth.

five. EPTT: secure and large, quality seven for with no tooth grinding, grade 6 after teeth grinding, grade 5 for exact grinding.

Rates for over top quality are really aggressive for us.

6. Heat therapy: teeth can be hardened to EPTC 55-63.

The top quality character of JH EPTTs:

one. Secure EPTT and low sounds

2. Properly stay away from normal tolerance primarily based on high precision

3. The teeth can be floor to grade six and grade 5 good quality

4. The bore will be poEPTTd to sleek and substantial precision

5. The price tag is aggressive even the quality is high.

| FaXiHu (West Lake) Dis.Hu (West Lake) Dis.ties | Machining cEPTTr CNC EPTT hobbing EPTT CNC EPTT shaper CNC EPTT grinding EPTT CNC turning EPTT CNC milling EPTT. Y58200 CNC large EPTT rack shaper, Y58125A EPTT rack shaper, England EPTT rack shaper and Russia EPTT rack shaper. Gleason EPTT |

| Gear types | Helical EPTTs (much more and much more extensively utilized for its stable transimission) Spur EPTTs Hub EPTTs EPTTl EPTTs EPTTl spiral EPTTs Gear ring and so forth. |

| EPTT | Metal: C45, Q235, 40Cr, 20CrMnTi, and many others. Stainless steel: 301, 201, 304, 316 etc. Brass: H59 H68 H80 H90 etc. Aluminium: 6082, 6061, A380 and many others. Aluminium alloy: 6061, 5083, 7050, and so on. More: PA6, PA66, POM, Abs and many others. |

| Surface area | PoEPTTng Plating Galvanized Blacken chromium plating, nickel plating portray etc. |

| aterial | C45 steel |

| Processing | Forging , Casting or Welding |

| Warmth Therapy | High Frenquency Quenching and Hard Enamel |

| Floor Treatment | Blacken or Galvanized as You Needed |

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd | GB1244-eighty five, DIN8187,8188, OEM, EPTT or DIN |

| Payment | T / T L/C |

| EPTT | Internal Plastic Bag and EPTTen Situation |

| ype | Single Roller Chain, EPTT Roller Chain, Quadruple Roller Chain…. |

| EPTT / ISO | 04C,06C,08A,10A-48A 2062 2082 C212A C216A |

| EPTT | 15,25,35,41,40,fifty~240 |

| Pitch | six.35 mm~76.two hundred mm–three hundred.00mm |

Requirements

We can make stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd EPTT and EPTT EPTT as per drawing or sample