Product Description

Km Series Aluminium Alloy 7.5~300 Ratio 90 Degree Hypoid Gear Motor Vertical Hypoid Reduction Gearbox with Electric Motor

Product Parameters

|

Applicable Industries |

Garment Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory |

|

Gearing Arrangement |

Hypoid |

|

Output Torque |

100~500NM |

|

Input Speed |

1400rpm |

|

Output Speed |

5~187 |

|

Place of CZPT |

China |

|

Brand Name |

CZPT |

|

Product name |

Hypoid gear reducer |

|

Color |

Blue |

|

Ratio |

5-400 |

|

Certificate |

ISO9001 CCC CE |

For more models, please contact us!

F helical gear reducer

Parallel output, compact structure, large transmission torque, stable operation, low noise and long life.

Installation method: base installation, flange installation, torque arm installation.

Reduction ratio: basic type 2 level 4.3-25.3, 3 level 28.2-273, combined to 18509.

The rotation direction of the input and output of the basic two-stage is the same, and the three-stage is opposite; please consult when combining.

Output mode: hollow shaft output or CZPT shaft output.

Average efficiency: Level 2 96%, Level 3 94%, F/CR average efficiency 85%.

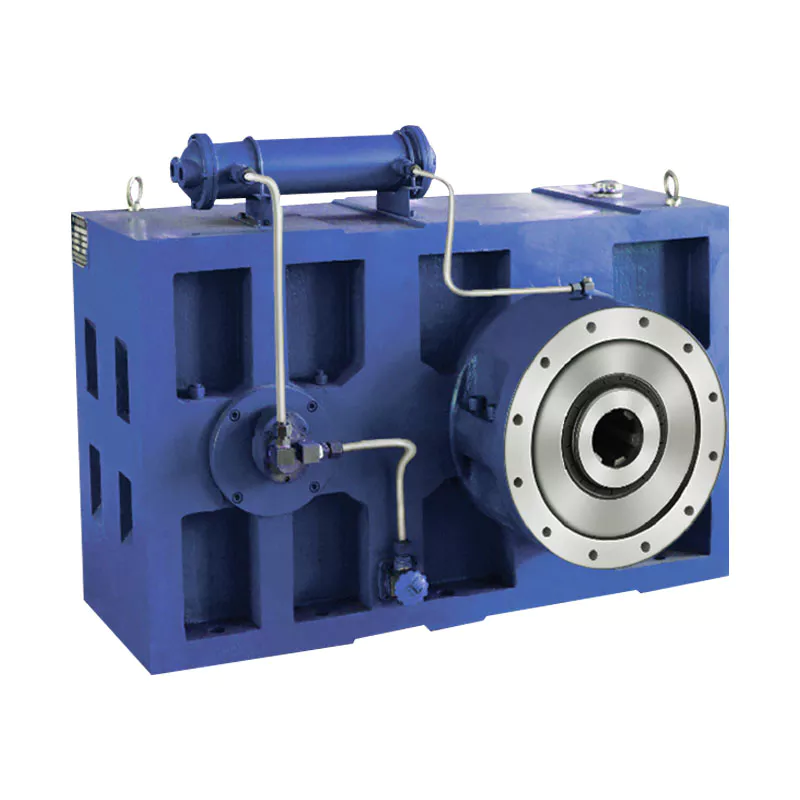

K helical bevel gear reducer

Vertical output, compact structure, hard tooth surface transmission torque, high-precision gears ensure stable work, low noise

and long life.

Installation method: base installation, flange installation, torque arm installation, small flange installation.

Input mode: motor direct connection, motor belt connection or input shaft, connection flange input.

Output mode: hollow shaft output or CZPT shaft output, the average efficiency is 94%.

Reduction ratio: basic type 8.1-191, combined to 13459.

R helical gear reducer

Small bias output, compact structure, maximum use of cabinet space, the second and third levels are in the same cabinet. Using an integral cast box, the box structure has good rigidity, which is easy to improve the strength of the shaft and the life of the

bearing.

Installation method: pedestal installation, flanges with large and small flanges are easy to choose.

CZPT shaft output, the average efficiency is 96% in the second stage, 94% in the third stage, and 85% in CR/CR. The CRM series specially designed for mixing can carry large axial and radial forces.

Company Profile

Certifications

Packaging & Shipping

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car, Transmission Parts |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Cycloidal |

| Hardness: | Hardened Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Single-Step |

| Samples: |

US$ 80/Piece

1 Piece(Min.Order) | |

|---|

Maintenance Tips to Prolong the Lifespan of Helical Gearboxes

Proper maintenance is essential to ensure the longevity and optimal performance of helical gearboxes. Here are some maintenance tips:

- Regular Inspections: Conduct routine visual inspections to check for any signs of wear, damage, or oil leakage. Detecting issues early can prevent further damage.

- Lubrication: Follow the manufacturer’s recommendations for lubrication intervals and use the correct type of lubricant. Proper lubrication reduces friction and wear between gear teeth.

- Cleanliness: Keep the gearbox environment clean and free from contaminants that could enter the gearbox and affect its performance.

- Tighten Fasteners: Check and tighten any loose fasteners or mounting bolts to ensure the gearbox remains securely in place.

- Alignment: Properly align the gearbox with connected equipment to prevent excessive loads and wear on the gear teeth.

- Temperature Monitoring: Monitor the operating temperature of the gearbox. Excessive heat can lead to premature wear and reduced efficiency.

- Vibration Analysis: Regularly analyze gearbox vibration levels to detect any unusual vibrations that might indicate issues with gear meshing or other components.

- Seal Integrity: Ensure that seals and gaskets are in good condition to prevent oil leakage and contamination.

- Load Considerations: Avoid overloading the gearbox beyond its specified capacity. High loads can accelerate wear and damage.

By following these maintenance practices, you can extend the lifespan of helical gearboxes and minimize the risk of unexpected failures. Regular maintenance not only reduces downtime and repair costs but also contributes to the efficient and reliable operation of equipment.

Troubleshooting Common Issues in Helical Gear Systems

Troubleshooting helical gear systems involves identifying and addressing common issues that can affect their performance. Here’s a step-by-step process:

- Visual Inspection: Begin by visually inspecting the gearbox for any signs of wear, damage, or misalignment. Look for worn or chipped gear teeth, oil leakage, and unusual noise.

- Noise Analysis: If noise is present, analyze its type and frequency. Whining or grinding noises could indicate misalignment or damaged gears, while clicking or knocking sounds might point to loose components.

- Lubrication Check: Ensure that the gearbox is properly lubricated with the recommended type and quantity of lubricant. Insufficient lubrication can lead to increased friction and wear.

- Alignment Check: Check the alignment of the gears and shafts. Misalignment can result in uneven wear, noise, and reduced efficiency. Realign components if necessary.

- Gear Inspection: Inspect gear teeth for signs of pitting, scoring, or wear. Replace any damaged gears to prevent further issues.

- Bearing Examination: Check the condition of bearings that support shafts and gears. Worn or damaged bearings can lead to increased vibration and noise.

- Tightening and Fastening: Ensure that all bolts, fasteners, and connections are properly tightened. Loose components can cause vibrations and noise.

- Load Analysis: Evaluate the load conditions and operating parameters of the gearbox. Ensure that the gearbox is not subjected to loads beyond its design capacity.

- Temperature Monitoring: Monitor the operating temperature of the gearbox. Excessive heat can indicate problems such as inadequate lubrication or overloading.

- Consulting Experts: If issues persist or if you’re unsure about the diagnosis and solution, consult gearbox experts or manufacturers for guidance.

By following this troubleshooting process, you can identify and resolve common issues in helical gear systems, ensuring optimal performance and longevity.

Helical Gearbox: Overview and Working Mechanism

A helical gearbox is a type of mechanical device used to transmit power and motion between rotating shafts. It employs helical gears, which are cylindrical gears with teeth that are cut at an angle to the gear axis. This design feature gives helical gearboxes their distinctive helical shape and provides several advantages in terms of efficiency, smoothness, and load-bearing capabilities.

The working mechanism of a helical gearbox involves the interaction of helical gears, which mesh together to transmit torque and motion. Here’s how it works:

- Gear Tooth Engagement: When power is applied to the input shaft of the gearbox, the helical gear on the input shaft meshes with the helical gear on the output shaft.

- Helical Angle: The helical angle of the gear teeth causes a gradual engagement between the teeth, resulting in a smooth and quiet meshing process compared to straight-cut gears.

- Torque Transfer: As the input gear rotates, it transfers rotational force (torque) to the output gear through the meshing of their helical teeth.

- Direction of Rotation: Depending on the arrangement of the helical gears, the output shaft’s direction of rotation can be the same as or opposite to that of the input shaft.

- Load Distribution: The helical design allows for multiple teeth to be engaged at any given moment, distributing the load more evenly across the gears. This results in higher load-carrying capacity and reduced wear on gear teeth.

- Efficiency: Helical gearboxes are known for their high efficiency due to the gradual tooth engagement and larger contact area, resulting in minimal energy loss as compared to other gear types.

Helical gearboxes find applications in various industries where smooth operation, high efficiency, and compact design are important. They are commonly used in machinery, conveyors, automotive transmissions, industrial equipment, and more.

editor by CX 2024-04-10

China best Right Angle Worm Helical Gear Speed Reducer S77 SA87 S97 SA Saf67 Motor Reducer 90 Degree Gearbox with Good quality

Product Description

Product Parameters

Features of S series reducer

The same model can be equipped with motors of various powers. It is easy to realize the combination and connection between various models.

The transmission efficiency is high, and the single reducer efficiency is up to 96%. three

The transmission ratio is subdivided and the range is wide. The combined model can form a large transmission ratio and low output speed.

The installation forms are various, and can be installed with any foot, B5 flange or B4 flange. The foot mounting reducer has 2 machined foot mounting planes.

Helical gear and worm gear combination, compact structure, large reduction ratio.

Installation mode: foot installation, hollow shaft installation, flange installation, torque arm installation, small flange installation.

Input mode: motor direct connection, motor belt connection or input shaft, connection flange input.

Average efficiency: reduction ratio 7.5-69.39 is 77%; 70.43-288 is 62%; The S/R combination is 57%.

Detailed Photos

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | 90 Degree |

| Layout: | Expansion |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 150/Piece

1 Piece(Min.Order) | |

|---|

Advancements in Helical Gearbox Technology

Advancements in helical gearbox technology have led to improved performance, efficiency, and versatility. Here are some notable advancements:

- Material Innovations: The use of advanced materials, such as high-strength alloys and composites, has enhanced the durability and load-carrying capacity of helical gears. These materials also contribute to reduced weight and improved efficiency.

- Precision Manufacturing: Modern manufacturing techniques, including CNC machining and gear grinding, have enabled the production of helical gears with higher accuracy and tighter tolerances. This results in smoother operation and reduced noise levels.

- Gear Tooth Profile Optimization: Advanced computer simulations and modeling techniques allow for the optimization of gear tooth profiles. This results in better load distribution, reduced stress concentration, and improved overall gearbox efficiency.

- Lubrication and Cooling: Improved lubrication systems and cooling mechanisms help maintain optimal operating temperatures and extend the lifespan of helical gearboxes. This is particularly important for high-demand applications.

- Noise and Vibration Reduction: Innovative designs and precision manufacturing techniques have led to helical gears with reduced noise and vibration levels. This advancement is crucial for industries where noise reduction is a priority.

- Compact Design: Advancements in gear design and manufacturing have allowed for more compact and lightweight helical gearbox configurations, making them suitable for space-constrained environments.

- Integration with Electronics: Some modern helical gearboxes are designed for seamless integration with electronic control systems. This enables better monitoring, control, and optimization of gearbox performance.

- Customization: Advancements in manufacturing and design tools allow for greater customization of helical gearboxes to meet specific application requirements. This includes adapting gear ratios, sizes, and configurations.

In summary, advancements in helical gearbox technology have led to enhanced performance, durability, efficiency, and customization options. These innovations continue to make helical gearboxes a versatile and reliable choice for a wide range of industrial applications.

Can Helical Gearboxes Be Retrofitted into Existing Machinery Designs?

Yes, helical gearboxes can often be retrofitted into existing machinery designs, providing an opportunity to upgrade the performance, efficiency, and reliability of older equipment. Here are the key points to consider when retrofitting helical gearboxes:

1. Compatibility: Before proceeding with a retrofit, it’s essential to ensure that the new helical gearbox is compatible with the existing machinery in terms of size, mounting, and shaft connections. Proper measurements and analysis are necessary to avoid any misalignment or fitment issues.

2. Space Considerations: Helical gearboxes may have a different physical profile compared to the original gearboxes. Engineers need to assess the available space in the machinery and confirm that the new gearbox will fit without major modifications.

3. Shaft Alignment: Proper shaft alignment is crucial to ensure smooth and efficient operation. During the retrofit, it’s important to align the new helical gearbox with other components in the system to prevent premature wear, noise, and vibration.

4. Power and Torque Ratings: The power and torque ratings of the helical gearbox should match or exceed the requirements of the machinery. This ensures that the new gearbox can handle the loads and stresses that the machinery may encounter.

5. Performance Improvements: Retrofitting with helical gearboxes can lead to improved efficiency, reduced noise, and smoother operation. These benefits can positively impact the overall performance and lifespan of the machinery.

6. Engineering Expertise: Retrofitting involves careful planning, engineering analysis, and implementation. Working with experienced engineers or gearbox specialists is advisable to ensure a successful retrofit without compromising the integrity of the machinery.

7. Cost-Benefit Analysis: Assessing the costs of the retrofit, including the cost of the new gearbox, installation, downtime, and potential modifications, is essential. Comparing these costs to the anticipated benefits of improved performance and efficiency will help make an informed decision.

8. Maintenance Considerations: Retrofitting may also impact maintenance practices. It’s important to understand any changes in lubrication requirements, inspection intervals, and servicing needs that come with the new gearbox.

Conclusion: Retrofitting helical gearboxes into existing machinery designs can be a cost-effective way to enhance the performance and extend the lifespan of equipment. However, careful planning, engineering analysis, and professional expertise are crucial to ensure a successful retrofit that delivers the desired improvements without causing unforeseen issues.

Differences Between Helical Gearboxes and Spur Gearboxes

Helical gearboxes and spur gearboxes are two common types of gearboxes used in various applications. Here are the key differences between them:

- Tooth Design: The main difference between helical and spur gearboxes lies in their tooth design. Helical gearboxes feature helical teeth that are cut at an angle to the gear axis, while spur gearboxes have straight-cut teeth that run parallel to the gear axis.

- Engagement: Helical gearboxes offer a gradual and smooth engagement of teeth due to their helical tooth design. This results in reduced noise and vibration compared to spur gearboxes, which can have more abrupt and noisy tooth engagement.

- Load Distribution: Helical gearboxes have a higher contact ratio between teeth at any given time, which leads to better load distribution across the gear teeth. Spur gearboxes, on the other hand, have fewer teeth in contact at a time, potentially leading to higher stress on individual teeth.

- Efficiency: Helical gearboxes tend to be more efficient than spur gearboxes due to the helical tooth design, which reduces friction and energy losses during gear meshing. The gradual engagement of helical teeth contributes to this higher efficiency.

- Noise and Vibration: Helical gearboxes generate less noise and vibration compared to spur gearboxes. The helical tooth design and smooth engagement help in reducing the impact of gear meshing on overall noise levels.

- Applications: Helical gearboxes are commonly used in applications that require higher torque and smoother operation, such as heavy machinery, automotive transmissions, and industrial equipment. Spur gearboxes are suitable for applications with moderate loads and where noise considerations are not critical.

Overall, helical gearboxes offer advantages in terms of efficiency, load distribution, and noise reduction compared to spur gearboxes. However, the choice between the two depends on specific application requirements and factors such as torque, speed, space constraints, and noise considerations.

editor by CX 2023-10-17

China wholesaler 90 Degree Hollow Output Shaft 25 28 30 35 38mm Helical Gear Motor Gearbox difference between helical and worm gearbox

Product Description

Product Description

KPM-KPB series helical-hypoid gearboxes are the new-generation product with a compromise of advanced technology both at home and abroad.This product is widely used in textile, foodstuff, beverage,tobacco, logistics industrial fields,etc.

Main Features:

(1) Driven by hypoid gears, which has big ratios.

(2) Large output torque, high efficiency(up to 92%), energy saving and environmental protection.

(3) High quality aluminum alloy housing, light in weight and non-rusting.

(4) Smooth in running and low in noise, and can work long time in dreadful conditions.

(5) Good-looking appearance, durable service life and small volume.

(6) Suitable for all round installation, wide application and easy use.

(7) KPM series can replace NMRV worm gearbox; KPB series can replace CZPT W series worm gearbox;

(8) Modular and multi-structure can meet the demands of various conditions.

Main Material:

(1) Housing: aluminum alloy

(2) Gear wheel: 20CrMnTiH1,carbonize & quencher heat treatment make the hardness of gears surface up to 56-62 HRC, retain carburization layers thickness between 0.3 and 0.5mm after precise grinding.

Detailed Photos

Product Parameters

Model Information:

| GEARBOX SELECTING TABLES | ||||||||||||

| KPM50.. | n1=1400r/min | 160Nm | ||||||||||

| Model | i | i | n2 | M2max | Fr2 | 63B5 | 71B5/B14 | 80B5/B14 | 90B5/B14 | |||

| nominal | actual | [r/min] | [Nm] | [N] | ||||||||

| 3 Stage | ||||||||||||

| KPM50C | 300 | 294.05 | 4.8 | 130 | 4100 | N/A | N/A | N/A | ||||

| KPM50C | 250 | 244.29 | 5.8 | 130 | 4100 | N/A | N/A | N/A | ||||

| KPM50C | 200 | 200.44 | 7.0 | 130 | 4100 | N/A | N/A | N/A | ||||

| KPM50C | 150 | 146.67 | 9.6 | 160 | 4000 | N/A | N/A | N/A | ||||

| KPM50C | 125 | 120.34 | 12 | 160 | 3770 | N/A | N/A | |||||

| KPM50C | 100 | 101.04 | 14 | 160 | 3560 | N/A | N/A | |||||

| KPM50C | 75 | 74.62 | 19 | 160 | 3220 | N/A | N/A | |||||

| KPM50C | 60 | 62.36 | 23 | 160 | 3030 | N/A | N/A | |||||

| KPM50C | 50 | 52.36 | 27 | 160 | 2860 | N/A | N/A | |||||

| 2 Stage | ||||||||||||

| KPM50B | 60 | 58.36 | 24 | 130 | 2960 | N/A | N/A | |||||

| KPM50B | 50 | 48.86 | 29 | 130 | 2790 | N/A | ||||||

| KPM50B | 40 | 40.09 | 35 | 130 | 2610 | N/A | ||||||

| KPM50B | 30 | 29.33 | 48 | 160 | 2350 | N/A | ||||||

| KPM50B | 25 | 24.07 | 59 | 160 | 2200 | |||||||

| KPM50B | 20 | 20.21 | 70 | 160 | 2080 | |||||||

| KPM50B | 15 | 14.92 | 94 | 160 | 1880 | |||||||

| KPM50B | 12.5 | 12.47 | 113 | 160 | 1770 | |||||||

| KPM50B | 10 | 10.47 | 134 | 160 | 1670 | |||||||

| KPM50B | 7.5 | 7.73 | 182 | 160 | 1510 | |||||||

| KPM63..,KPB63.. | n1=1400r/min | 180Nm | ||||||||||

| Model | i | i | n2 | M2max | Fr2 | 63B5 | 71B5/B14 | 80B5/B14 | 90B5/B14 | |||

| nominal | actual | [r/min] | [Nm] | [N] | ||||||||

| 3 Stage | ||||||||||||

| KPM63C | KPB63C | 300 | 302.50 | 4.7 | 160 | 4800 | N/A | N/A | N/A | |||

| KPM63C | KPB63C | 250 | 243.57 | 5.8 | 160 | 4800 | N/A | N/A | N/A | |||

| KPM63C | KPB63C | 200 | 196.43 | 7.2 | 160 | 4800 | N/A | N/A | ||||

| KPM63C | KPB63C | 150 | 151.56 | 9.3 | 180 | 4650 | N/A | N/A | ||||

| KPM63C | KPB63C | 125 | 122.22 | 12 | 180 | 4330 | N/A | N/A | ||||

| KPM63C | KPB63C | 100 | 94.50 | 14 | 180 | 4070 | N/A | N/A | ||||

| KPM63C | KPB63C | 75 | 73.33 | 20 | 180 | 3650 | N/A | |||||

| KPM63C | KPB63C | 60 | 63.33 | 23 | 180 | 3480 | N/A | |||||

| KPM63C | KPB63C | 50 | 52.48 | 27 | 180 | 3270 | N/A | |||||

| 2 Stage | ||||||||||||

| KPM63B | KPB63B | 60 | 60.50 | 24 | 160 | 3430 | N/A | |||||

| KPM63B | KPB63B | 50 | 48.71 | 29 | 160 | 3190 | ||||||

| KPM63B | KPB63B | 40 | 39.29 | 36 | 160 | 2970 | ||||||

| KPM63B | KPB63B | 30 | 30.31 | 47 | 180 | 2720 | ||||||

| KPM63B | KPB63B | 25 | 24.44 | 58 | 180 | 2530 | N/A | |||||

| KPM63B | KPB63B | 20 | 18.90 | 70 | 180 | 2380 | N/A | |||||

| KPM63B | KPB63B | 15 | 14.67 | 96 | 180 | 2130 | N/A | N/A | ||||

| KPM63B | KPB63B | 12.5 | 12.67 | 111 | 180 | 2030 | N/A | N/A | ||||

| KPM63B | KPB63B | 10 | 10.50 | 134 | 180 | 1910 | N/A | N/A | ||||

| KPM63B | KPB63B | 7.5 | 7.60 | 185 | 180 | 1710 | N/A | N/A | ||||

| KPM75..,KPB75.. | n1=1400r/min | 350Nm | ||||||||||

| Model | i | i | n2 | M2max | Fr2 | 63B5 | 71B5 | 80B5/B14 | 90B5/B14 | 100B5/B14 | 112B5/B14 | |

| nominal | actual | [r/min] | [Nm] | [N] | ||||||||

| 3 Stage | ||||||||||||

| KPM75C | KPB75C | 300 | 297.21 | 4.8 | 300 | 6500 | N/A | N/A | N/A | N/A | ||

| KPM75C | KPB75C | 250 | 240.89 | 5.9 | 300 | 6500 | N/A | N/A | N/A | N/A | ||

| KPM75C | KPB75C | 200 | 200.66 | 7.0 | 300 | 6500 | N/A | N/A | N/A | N/A | ||

| KPM75C | KPB75C | 150 | 149.30 | 9.3 | 350 | 6500 | N/A | N/A | N/A | |||

| KPM75C | KPB75C | 125 | 121.00 | 12 | 350 | 5980 | N/A | N/A | N/A | |||

| KPM75C | KPB75C | 100 | 100.80 | 15 | 350 | 5520 | N/A | N/A | N/A | |||

| KPM75C | KPB75C | 75 | 79.40 | 19 | 350 | 5040 | N/A | N/A | ||||

| KPM75C | KPB75C | 60 | 62.43 | 23 | 350 | 4730 | N/A | N/A | N/A | |||

| KPM75C | KPB75C | 50 | 49.18 | 29 | 350 | 4370 | N/A | N/A | N/A | |||

| 2 Stage | ||||||||||||

| KPM75B | KPB75B | 60 | 59.44 | 24 | 300 | 4660 | N/A | N/A | N/A | |||

| KPM75B | KPB75B | 50 | 48.18 | 30 | 300 | 4340 | N/A | N/A | N/A | |||

| KPM75B | KPB75B | 40 | 40.13 | 35 | 300 | 4080 | N/A | N/A | ||||

| KPM75B | KPB75B | 30 | 29.86 | 47 | 350 | 3720 | N/A | N/A | N/A | |||

| KPM75B | KPB75B | 25 | 24.20 | 56 | 350 | 3500 | N/A | N/A | ||||

| KPM75B | KPB75B | 20 | 20.16 | 71 | 350 | 3230 | N/A | N/A | ||||

| KPM75B | KPB75B | 15 | 15.88 | 93 | 350 | 2950 | N/A | N/A | ||||

| KPM75B | KPB75B | 12.5 | 12.49 | 113 | 350 | 2770 | N/A | N/A | N/A | |||

| KPM75B | KPB75B | 10 | 9.84 | 143 | 350 | 2550 | N/A | N/A | N/A | |||

| KPM75B | KPB75B | 7.5 | 7.48 | 188 | 350 | 2330 | N/A | N/A | N/A | |||

| KPM90..,KPB86.. | n1=1400r/min | 500Nm | ||||||||||

| Model | i | i | n2 | M2max | Fr2 | 63B5 | 71B5 | 80B5/B14 | 90B5/B14 | 100B5/B14 | 112B5/B14 | |

| nominal | actual | [r/min] | [Nm] | [N] | ||||||||

| 3 Stage | ||||||||||||

| KPM90C | KPB86C | 300 | 297.21 | 4.8 | 450 | 6500 | N/A | N/A | N/A | N/A | ||

| KPM90C | KPB86C | 250 | 240.89 | 5.9 | 450 | 6500 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | 200 | 200.66 | 7.0 | 450 | 6500 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | 150 | 151.20 | 9.3 | 500 | 6500 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | 125 | 125.95 | 12 | 500 | 5980 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | 100 | 99.22 | 15 | 500 | 5520 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | 75 | 75.45 | 19 | 500 | 5040 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | 60 | 62.43 | 23 | 500 | 4730 | N/A | N/A | N/A | |||

| KPM90C | KPB86C | 50 | 49.18 | 29 | 500 | 4370 | N/A | N/A | N/A | |||

| 2 Stage | ||||||||||||

| KPM90B | KPB86B | 60 | 59.44 | 24 | 450 | 5890 | N/A | N/A | ||||

| KPM90B | KPB86B | 50 | 48.18 | 30 | 450 | 5500 | N/A | N/A | ||||

| KPM90B | KPB86B | 40 | 40.13 | 35 | 450 | 5170 | N/A | N/A | ||||

| KPM90B | KPB86B | 30 | 30.24 | 47 | 500 | 4710 | N/A | N/A | ||||

| KPM90B | KPB86B | 25 | 25.19 | 56 | 500 | 4430 | N/A | N/A | ||||

| KPM90B | KPB86B | 20 | 19.84 | 71 | 500 | 4090 | N/A | N/A | N/A | |||

| KPM90B | KPB86B | 15 | 15.09 | 93 | 500 | 3730 | N/A | N/A | N/A | |||

| KPM90B | KPB86B | 12.5 | 12.49 | 113 | 500 | 3510 | N/A | N/A | N/A | |||

| KPM90B | KPB86B | 10 | 9.84 | 143 | 500 | 3240 | N/A | N/A | N/A | |||

| KPM90B | KPB86B | 7.5 | 7.48 | 188 | 500 | 2950 | N/A | N/A | N/A | |||

Outline Dimension:

Company Profile

About our company:

We are a professional reducer manufacturer located in HangZhou, ZHangZhoug province.Our leading products is full range of RV571-150 worm reducers , also supplied hypoid helical gearbox, PC units, UDL Variators and AC Motors.Products are widely used for applications such as: foodstuffs, ceramics, packing, chemicals, pharmacy, plastics, paper-making, construction machinery, metallurgic mine, environmental protection engineering, and all kinds of automatic lines, and assembly lines.With fast delivery, superior after-sales service, advanced producing facility, our products sell well both at home and abroad. We have exported our reducers to Southeast Asia, Eastern Europe and Middle East and so on.Our aim is to develop and innovate on basis of high quality, and create a good reputation for reducers.

Packing information:Plastic Bags+Cartons+Wooden Cases , or on request

We participate Germany Hannver Exhibition-ZheJiang PTC Fair-Turkey Win Eurasia

Logistics

After Sales Service

1.Maintenance Time and Warranty:Within 1 year after receiving goods.

2.Other Service: Including modeling selection guide, installation guide, and problem resolution guide, etc.

FAQ

1.Q:Can you make as per customer drawing?

A: Yes, we offer customized service for customers accordingly. We can use customer’s nameplate for gearboxes.

2.Q:What is your terms of payment ?

A: 30% deposit before production,balance T/T before delivery.

3.Q:Are you a trading company or manufacturer?

A:We are a manufacurer with advanced equipment and experienced workers.

4.Q:What’s your production capacity?

A:8000-9000 PCS/MONTH

5.Q:Free sample is available or not?

A:Yes, we can supply free sample if customer agree to pay for the courier cost

6.Q:Do you have any certificate?

A:Yes, we have CE certificate and SGS certificate report.

Contact information:

Ms Lingel Pan

For any questions just feel free ton contact me. Many thanks for your kind attention to our company!

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Layout: | Right Angle |

| Gear Shape: | Hypoid Helical Gear |

| Step: | 2-3 Stage |

| Samples: |

US$ 45/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What Is a Helical Gearbox?

Generally, the gear is a rotating circular machine part, and its purpose is to transmit speed and torque. It works by meshing with other toothed parts. This type of gear is made up of cut teeth, inserted teeth, and gear teeth.

Helix angle

Typical helical gearbox angle ranges from 15 to 30 degrees. It is commonly used in worm gears and screws. The angle is important in motion conversion and power transfer.

Helical gearboxes are suitable for high load applications. Because the teeth engage more gradually, helical gearboxes require bearings that can manage axial loading. In fact, the forces produced by helical gears are much less than those of spur gears. Moreover, helical gearboxes are often less efficient.

There are two basic gear systems: the spur gear system and the helical gear system. These systems are similar in their basic functions. However, they are distinguished by a number of important differences. The spur gear system produces thrust forces, while the helical gear system transmits energy through two axial configurations. Both systems operate at speeds of around 50m/s.

Spur gears have a common pitch, whereas helical gears have a different pitch. The pitch of helical gears changes as the helix angle changes. This leads to a difference in the diameter of the gear and the hobs. This changes the radial module system pitch and increases the manufacturing costs.

The normal pressure angle is the angle of the load line into the plane normal to the tooth axis. This angle is sometimes called the reference value.

Helical gears are available in both left-hand and right-hand configurations. Helical gears are typically characterized by quiet operation and higher power carrying capacity. They are also appreciated for their NVH characteristics. They are used in the oil, food, and plastic industries. They also have a higher efficiency than zero-helix angle gears.

Efficiency

Using helical gears in a gearbox provides several benefits. They are more efficient, quieter and better able to handle high load cases. However, they are also more expensive than classic gears.

The efficiency of a helical gearbox is calculated by measuring the efficiency of the entire working area. This is measured using a predefined measuring grid. The result is presented by an efficiency contour map. It shows that efficiency is not uniform in the working area.

This is because of the varying angles of the teeth of the gears. It is also important to consider the size of the pitch circle and the angle of the helix. The pitch circle is larger for helical gears than for spur gears. This means more surface contact and more potential for transmission of power between the parallel shafts.

Efficiency calculations for synchronizers are relatively new. Using data from power losses can help estimate the accuracy of these calculations.

The efficiency of a gearbox is mainly dependent on the power range and the torque. The higher the range, the better the efficiency. When the power range is reduced, the efficiency is reduced. The efficiency decreases sharply for high ratio gearboxes.

The efficiency of a gearbox also depends on the type of gearbox. Typically, spur gears are the most efficient, but helical gears are also quite efficient. In the same way that an electrical motor is more efficient than a standard cylinder engine, helical gears are more efficient than spur gears.

Applications

Various industries utilize helical gearboxes for different applications. These gears are primarily used in heavy industrial settings and are also used in the printing and plastic industries.

They are useful in transferring motion between parallel and right-angle shafts. Helical gears are more durable and offer smoother gear operation than other gear types. They are also less noisy and produce less friction.

Typical applications of helical gearboxes include conveyors, coolers, crushers, and other heavy industrial applications. They are also used in the food, chemical, and printing industries.

There are two main types of helical gearboxes: single helical gearboxes and double helical gearboxes. In the single gearbox, the teeth are at a certain angle to the axis. In the double gearbox, the teeth are at opposite angles.

Both gear types have their own advantages. The spur type is more suited for low-speed applications and is also less expensive to manufacture. However, helical gears are more efficient. They are also less noisy and have more teeth meshing capacity.

Helical gears also have a greater pitch circle diameter than spur gears. Because of this, they can tolerate a greater load and are more durable. The helical gearbox also uses thrust bearings to support the thrust force. In order to ensure smooth operation, the helical gears gradually engage.

Helical gears are also used in the automotive industry. They are the most common gear type used in the automotive transmission process.

Spiral teeth vs helical teeth

Depending on the application, there are two types of bevel gears: helical gears and spiral teeth bevel gears. They have a similar geometry, but they perform differently. While helical gears provide smoother operation and higher load carrying capacity, spiral teeth bevel gears are more flexible, reduce the risk of overheating, and have longer service life.

Helical gears are primarily used for helical or crossed shafts. They have teeth that are cut at a precise angle to the gear axis. They provide a smooth action during heavy loads and are used at high speeds. They can also be used for non-parallel shafts. However, they are less efficient than spur gears.

Spur gears are primarily used for parallel shafts. Their straight teeth are parallel to the gear axis. Their teeth come in sudden contact, which causes vibration and a noticeable noise. However, helical gears provide gradual engagement, minimizing vibration and backlash.

The root stress of helical gears is different from spur gears. It is dependent on the helix angle and the web thickness of the gear. The pressure angle of the teeth also affects the curvature radii. These factors affect the transverse contact ratio, which decreases the length of the contact line.

Helical gears are often used to change the angle of rotation by 90 degrees. They can also be used to eliminate shock loading. These gears can be used on parallel or crossed shafts.

PB and PLB Series

PB and PLB series helical gearboxes offer a bevy of benefits that include high power density and a compact modular design. Aside from offering a high output torque, they also offer low maintenance and a long life span. The manufacturers have also gone to great lengths to provide a robust case, a rigid worm and screw thread arrangement and a high reduction ratio. They also provide parallel shaft input options. This means you can use one gearbox to drive a whole train of synchronized gears.

Aside from the fact that it is one of the most durable gearboxes available, it is also one of the most versatile. In fact, the company manufactures a number of gearbox variants, ranging from a single gearbox to a fully modular multiple gearbox design. The high power density means it can operate in tight industrial spaces. PB and PLB series helical Gearboxes are available in a range of sizes, ensuring you find the perfect fit for your application. The PB and PLB Series helical gearboxes are also a cost-effective option for your next application. The company is also able to offer custom solutions to meet your specific needs.

The best part is that you can get your hands on these Gearboxes at a price that is well worth your hard earned dollars. The manufacturers also offer an industry leading warranty. PB and PLB series helical and worm gearboxes are available in a variety of sizes and configurations to suit your application.

Herringbone gears

Using Herringbone gears in helical gearboxes can give the advantages of quiet operation at high speed and minimal axial force. These gears can also be used in heavy machinery applications. However, manufacturing them is more difficult and expensive.

Herringbone gears are similar to double helical gears, except that they do not have a central gap. Originally, they were made by casting to an accurate pattern.

Today, they are characterized by two sets of gear teeth that are stuck together. They have a very high coincidence, which increases the bearing capacity of the gearbox. They also reduce wear and noise.

These gears are usually smaller than double helical gears. This makes them ideal for applications where vibration is high. The large contact area reduces stress. They also have a high carrying capacity. They are used in transmissions, heavy machinery, and differentials.

Herringbone gears are also used in torque gearboxes, especially those that do not have a significant thrust bearing. However, their use is less common because of manufacturing difficulties.

There are several solutions to the problem of making herringbone gears. One solution is to use a central groove to cut the gears. Another is to stack two helical gears together. Another solution is to use older machines that can be rebuilt to make herringbone gears.

Herringbone gears can be processed using milling methods. However, this method cannot be used to process all herringbone gears.

editor by CX 2023-06-09

China high quality gearbox ev reductor gear box 90 degree shaft gear reducer qm gearbox k helical bevel gear manufacturer

Guarantee: 12months

Applicable Industries: Constructing Substance Outlets, Producing Plant, Equipment Fix Retailers, Retail, Printing Shops, Other

Weight (KG): 2 KG

Custom-made support: OEM, ODM, High precision Manufacturing facility Powder metallurgy preserve 80% price sintered metallic personalize small pinion stainless steel spur gears OBM

Gearing Arrangement: Gear generate

Output Torque: 1.6NM~5235NM

Input Velocity: 1400RPM

Output Velocity: 7.25RPM~290RPM

Merchandise identify: Electric Motor Pace Reducer

Packaging Specifics: Carton or wooden box packagingAll products can be transported all more than the globe through DHL, UPS, FedEx, TNT, and so on.The packaging is secure and eco-friendly. If you have any unique demands, you should let me know.

Port: HangZhou

| item | value |

| Warranty | 12months |

| Applicable Industries | Manufacturing Plant, Equipment Repair Outlets, CDI Gs Gr Mt Buffer Elastic Rubber Aspect Spider Coupling merchandise by NOK-CN Spare Parts Producer auto Adaptable coupling Farms, Printing Shops, Energy & Mining, Other |

| Customized assist | OEM, ODM, OBM |

| Gearing Arrangement | Gear drive |

| Output Torque | 1.6NM~5235NM |

| Input Pace | 1400RPM |

| Output Pace | 7.25RPM~290RPM |

| Place of Origin | China |

| Brand Identify | SEIMEC |

| Product identify | Electric Motor Pace Reducer |

What Is a Gearbox?

A gearbox is the mechanical system of an automobile that allows a vehicle to change gear smoothly. This arrangement of gears is highly complex, which helps to provide a smooth gear change. In this article, we will explore some of the different types of gearboxes, including the Epicyclic gearbox, the Coaxial helical gearbox, and the Extruder helical gearing. These are three of the most common types of gearboxes used in automobiles.

Gearboxes

Gearboxes help drivers choose the appropriate gear for the conditions. A lower gear produces the least speed, while a higher gear gives the maximum torque. The number of gears used in a gearbox varies to meet different demands on the road and load. Short gearing provides maximum torque, while tall gearing offers higher top speeds. These features combine to improve the driveability of a vehicle. But what is a gearbox?

The gearbox has a slew of components, including the bearings and seals. Among these components is the gearbox, which is subjected to wear and tear due to metal-to-metal contact. As a result, gearboxes require close monitoring. Various tests are used to assess the condition of gears, such as corrosion and wear. Proactive tests emphasize wear, contamination, and oil condition. However, there are also proactive tests, such as the ferrous density test and the AN test, which monitor additive depletion and abnormal wear.

The separating force is a key factor for the design of a gearbox. The primary radial measurement point should be oriented to monitor normal forces. The secondary measurement point should be located in the opposite direction of rotation from the primary radial measurement point. The separating force generated by a helical gear set is called tangential force. The primary and secondary radial measurement points should be positioned so as to provide information about both normal and tangential forces.

Manual gearboxes are often manual. The driver can control the synchromesh by using a selector rod. This rod moves the synchromesh to engage the gear. Reverse gears are not synchromesh because they are used only when the vehicle is at a standstill. In older cars, the first gear often lacked synchromesh due to cost or lack of torque. Drivers could still use first gear with a double-declutch.

Coaxial helical gearbox

The R series rigid tooth flank helical gearbox features high versatility and good combination. They have a wide range of motor power and allow for fine classification of transmission ratios. The R series gearbox has several advantages, including high efficiency, long service life, and low vibration. This series of gearbox can be combined with a wide range of reducers and variators. Its size and high performance makes it an ideal choice for applications that require maximum torque and load transfer.

The main feature of a helical gearbox is that it presents a fixed velocity ratio, even if the center gaps are not perfectly set. This is sometimes referred to as the fundamental rule of gearing. A helical gearbox is similar to paper spur gears in terms of radial pitch, since the shafts in the helical gearbox cross at an angle. The center gap of a helical gearbox is the same for both the left and right-handed counterparts.

The EP Series is another popular model of a Coaxial helical gearbox. This series has high torque and a maximum reduction ratio of 25.6:1. It is an ideal choice for the plastic industry, and CZPT offers an extensive range of models. Their center distance ranges from 112 mm to 450 mm. The EP Series has several models with different center distances. In addition to high torque and efficiency, this gearbox has low noise and vibration, and it is easy to assemble and disassemble.

Another type of Coaxial helical gearboxes is the planetary gearbox. They have a high efficiency and power density. Unlike coaxial helical gearboxes, planetary gearboxes have an axis on the same direction as the output shaft. They are easy to integrate into existing drive trains. In addition, they are compact and easy to integrate with existing drive trains. For servo applications, they are another great choice.

Epicyclic gearbox

An epicyclic gearbox is a type of automatic gearbox used to drive cars. Its primary advantage is its compact design, and it is more reliable and efficient than manual gearboxes. It is comprised of a sun gear and two planetary gears, encased in a ring gear called the Annulus. This system is useful for drivers who need to shift gears frequently, as they will become tired if the gears are suddenly changed.

An epicyclic gearbox consists of three different types of gears: ring gear, sun gear, and annular ring gear. The ring gear is the outermost gear and has angular-cut teeth on its inner surface. It is used in conjunction with planetary gears to provide high-speed ratios to vehicles. The sun gear also reverses the direction of the output shaft. This helps reduce transmission error.

An epicyclic gearbox uses multiple planets to transfer power between the planets. This type of gearbox is lightweight and features a high power density. This gearbox has several benefits over a standard single-stage parallel axis gearbox, including multiple load paths, unequal load sharing, and phased meshing. Furthermore, epicyclic gearboxes require more complex transmission error optimisation than their counterparts, including more than one stage.

The objective of epicyclic gearbox research is to provide the lowest transmission error possible. The process includes an initial design and detailed specification. The system is defined by its load spectrum and required ratio. Deflections of the elastic mesh are calculated to understand their strength and how much energy the system can handle. Finally, micro-geometric corrections minimize transmission error. These improvements are crucial to the overall efficiency of an epicyclic gearbox.

Extruder helical gearing

The helix in an extruder helical gearing is fixed at an angle, enabling more interaction with the shaft in the same direction as it moves. As a result, the shaft and the bearing are in constant contact for a long period of time. Typically, extruder helical gearing is used in applications where there is low excitement, such as steel, rolling mills, conveyors, and the oil industry. The bevel gear train also plays a role in these applications.

The CZPT AEX extruder drive gear is specifically developed for this specific application. The gears are compact and lightweight and offer exceptional power density and a long service life. These extruder gears are highly reliable, and they can be used in a wide range of applications, including rubber processing, food production, and recycling plants. CZPT offers both standard and custom gearing for your extruder.

Another advantage of helical gearing is its versatility. Since the helical gearing teeth are inclined at a specific angle, they can be adjusted to meet the specific needs of a given application. These gears also have the advantage of eliminating noise and shock from straight teeth. Unlike other gearing types, they are able to achieve a wide range of loads, from small to large. These helical gears are very durable and are the best option for high-load applications.

In addition to this, asymmetric helical gears have increased flexibility, while asymmetrical helical gears have lower flexural stiffness. The ratio of teeth to the shaft has a positive effect on the strength of the gear. Furthermore, asymmetrical helical gears are easier to manufacture. But before you purchase your next extruder gear, make sure you know what you’re getting into.

1 speed gearbox

CZPT Group Components produces the one speed gearbox. It has the potential to make cars more efficient and environmentally friendly. The gear ratio of a car’s drivetrain is crucial for reaching maximum power and speed. Typically, a one-speed gearbox delivers a maximum of 200 hp. But the speed at which a car can reach this power must be high to get the full benefit from the electric motor. So, how can a one-speed gearbox improve the speed and torque of a car?

A one-speed gearbox is a mechanical device used to switch between second and third gears. It can include multiple gear sets, such as a shared middle gear for switching between second and third gears. It can also have an intermediate gear set that represents a switchable gear in both partial transmissions. The invention also includes a mechanism that makes it easier to change gears. The patent claims are detailed below. A typical one-speed gearbox may include two parts.

Generally, a one-speed gearbox will have up to seven forward gears, with each of these corresponding to a different speed. A one-speed gearbox can have five different gear sets and five different gear levels. It can have synchronized gear sets or last-shelf gear sets. In either case, the gears are arranged in a way that maximizes their efficiency. If the gears are placed on opposite sides of a car, the transmission may be a two-speed one.

CZPT Transmission specializes in the production of high-speed gearboxes. The company’s Milltronics HBM110XT gearbox machine is the perfect tool for this job. This machine has a large working table and a heavy-duty load capacity, making it a versatile option for many kinds of applications. There are also a wide variety of CZPT gearboxes for the automotive industry.

editor by czh2023-02-20

China AAW080AS-L1- 10 -RF-K small right angle gearbox spiral bevel gear tooth teeth gearhead 90 degree reducer steering gear marine gearbox assembly

Warranty: twelve months, twelve Months

Relevant Industries: Garment Outlets, Foodstuff & Beverage Factory, Development works , Advertising and marketing Organization, PV market, Laser reducing equipment, Semiconductor

Fat (KG): 4.5 KG

Personalized assist: OEM

Gearing Arrangement: Bevel / Miter

Output Torque: 70-85Nm

Input Pace: primarily based on motor

Output Velocity: primarily based on ratio

Ratio: 6-twenty

Shade: Black and Silver

Mounting Placement: Any Course

Certification: ISO9001 CE

Backlash: 1~8arcmin

Gear kind: Bevel Gear

Packing: Carton or wood box

Matching Motors: servo motor or stepper motor

Output Kind: Hollow shaft

Packaging Specifics: Carton and wooden box

Port: ZheJiang

AAW-AS-RF-K precision steering gearbox is also a hollow shaft steering gearbox with rotary output flange, extremely comparable to AAW-AS-RF steering gearbox, the variation is that AAW-AS-RF-K there is a keyway in the output flange hole. The optimized style helps prevent the transmission axis put in by way of the center gap of AAW-AS-RF-K output flange from slipping when perform in substantial torque or huge load. AAW-AS-RF-K steering gearbox is composed of compact housing, exact spiral bevel gears and motor adapter. The large effective mix functions the steering gearbox superb rigid construction for that changeable output loading specifically for large load occasions.The motor adapter on the enter side can make AAW-AS-RF-K right angle gearbox very easily and effectively related to motor. Aside from, the input flange measurement can also be customized according to diverse motor dimensions, so our steering gearbox are CZPT to substitute the item from competitors. If your venture needs to alter the transmission course and velocity at the exact same time, AAW-AS-RF-K steering gearbox is the proper selection(available ratio from 1:2 to 1:200).

| Backlash | B1 precision:L1≤3arcmin, L2≤5arcminB2 precision:L1≤5 arcmin, L2≤ CNC Machining Services Aluminum Alloy Road Bicycle Crankset Bicycle Areas Fastened Equipment Die Casting 8 arcminStandard precision:L1≤6 arcmin, L2≤9 arcmin |

| Dimension | AAW070AS-RF-K AAW080AS-RF-K AAW110AS-RF-K AAW135AS-RF-K AAW135BS-RF-K AAW165AS-RF-K AAWA65BS-RF-KAAW200AS-RF-K AAW200BS-RF-K |

| Ratio | 1:2/6:1/8:1/10:1…20:one |

| Match motor | servo motor, stepper motor |

| Lead time | Standard size for fifteen-20days |

| Guarantee | 12 months |

What Is a Gearbox?

A gearbox is the mechanical system of an automobile that allows a vehicle to change gear smoothly. This arrangement of gears is highly complex, which helps to provide a smooth gear change. In this article, we will explore some of the different types of gearboxes, including the Epicyclic gearbox, the Coaxial helical gearbox, and the Extruder helical gearing. These are three of the most common types of gearboxes used in automobiles.

Gearboxes

Gearboxes help drivers choose the appropriate gear for the conditions. A lower gear produces the least speed, while a higher gear gives the maximum torque. The number of gears used in a gearbox varies to meet different demands on the road and load. Short gearing provides maximum torque, while tall gearing offers higher top speeds. These features combine to improve the driveability of a vehicle. But what is a gearbox?

The gearbox has a slew of components, including the bearings and seals. Among these components is the gearbox, which is subjected to wear and tear due to metal-to-metal contact. As a result, gearboxes require close monitoring. Various tests are used to assess the condition of gears, such as corrosion and wear. Proactive tests emphasize wear, contamination, and oil condition. However, there are also proactive tests, such as the ferrous density test and the AN test, which monitor additive depletion and abnormal wear.

The separating force is a key factor for the design of a gearbox. The primary radial measurement point should be oriented to monitor normal forces. The secondary measurement point should be located in the opposite direction of rotation from the primary radial measurement point. The separating force generated by a helical gear set is called tangential force. The primary and secondary radial measurement points should be positioned so as to provide information about both normal and tangential forces.

Manual gearboxes are often manual. The driver can control the synchromesh by using a selector rod. This rod moves the synchromesh to engage the gear. Reverse gears are not synchromesh because they are used only when the vehicle is at a standstill. In older cars, the first gear often lacked synchromesh due to cost or lack of torque. Drivers could still use first gear with a double-declutch.

Coaxial helical gearbox

The R series rigid tooth flank helical gearbox features high versatility and good combination. They have a wide range of motor power and allow for fine classification of transmission ratios. The R series gearbox has several advantages, including high efficiency, long service life, and low vibration. This series of gearbox can be combined with a wide range of reducers and variators. Its size and high performance makes it an ideal choice for applications that require maximum torque and load transfer.

The main feature of a helical gearbox is that it presents a fixed velocity ratio, even if the center gaps are not perfectly set. This is sometimes referred to as the fundamental rule of gearing. A helical gearbox is similar to paper spur gears in terms of radial pitch, since the shafts in the helical gearbox cross at an angle. The center gap of a helical gearbox is the same for both the left and right-handed counterparts.

The EP Series is another popular model of a Coaxial helical gearbox. This series has high torque and a maximum reduction ratio of 25.6:1. It is an ideal choice for the plastic industry, and CZPT offers an extensive range of models. Their center distance ranges from 112 mm to 450 mm. The EP Series has several models with different center distances. In addition to high torque and efficiency, this gearbox has low noise and vibration, and it is easy to assemble and disassemble.

Another type of Coaxial helical gearboxes is the planetary gearbox. They have a high efficiency and power density. Unlike coaxial helical gearboxes, planetary gearboxes have an axis on the same direction as the output shaft. They are easy to integrate into existing drive trains. In addition, they are compact and easy to integrate with existing drive trains. For servo applications, they are another great choice.

Epicyclic gearbox

An epicyclic gearbox is a type of automatic gearbox used to drive cars. Its primary advantage is its compact design, and it is more reliable and efficient than manual gearboxes. It is comprised of a sun gear and two planetary gears, encased in a ring gear called the Annulus. This system is useful for drivers who need to shift gears frequently, as they will become tired if the gears are suddenly changed.

An epicyclic gearbox consists of three different types of gears: ring gear, sun gear, and annular ring gear. The ring gear is the outermost gear and has angular-cut teeth on its inner surface. It is used in conjunction with planetary gears to provide high-speed ratios to vehicles. The sun gear also reverses the direction of the output shaft. This helps reduce transmission error.

An epicyclic gearbox uses multiple planets to transfer power between the planets. This type of gearbox is lightweight and features a high power density. This gearbox has several benefits over a standard single-stage parallel axis gearbox, including multiple load paths, unequal load sharing, and phased meshing. Furthermore, epicyclic gearboxes require more complex transmission error optimisation than their counterparts, including more than one stage.

The objective of epicyclic gearbox research is to provide the lowest transmission error possible. The process includes an initial design and detailed specification. The system is defined by its load spectrum and required ratio. Deflections of the elastic mesh are calculated to understand their strength and how much energy the system can handle. Finally, micro-geometric corrections minimize transmission error. These improvements are crucial to the overall efficiency of an epicyclic gearbox.

Extruder helical gearing

The helix in an extruder helical gearing is fixed at an angle, enabling more interaction with the shaft in the same direction as it moves. As a result, the shaft and the bearing are in constant contact for a long period of time. Typically, extruder helical gearing is used in applications where there is low excitement, such as steel, rolling mills, conveyors, and the oil industry. The bevel gear train also plays a role in these applications.

The CZPT AEX extruder drive gear is specifically developed for this specific application. The gears are compact and lightweight and offer exceptional power density and a long service life. These extruder gears are highly reliable, and they can be used in a wide range of applications, including rubber processing, food production, and recycling plants. CZPT offers both standard and custom gearing for your extruder.

Another advantage of helical gearing is its versatility. Since the helical gearing teeth are inclined at a specific angle, they can be adjusted to meet the specific needs of a given application. These gears also have the advantage of eliminating noise and shock from straight teeth. Unlike other gearing types, they are able to achieve a wide range of loads, from small to large. These helical gears are very durable and are the best option for high-load applications.

In addition to this, asymmetric helical gears have increased flexibility, while asymmetrical helical gears have lower flexural stiffness. The ratio of teeth to the shaft has a positive effect on the strength of the gear. Furthermore, asymmetrical helical gears are easier to manufacture. But before you purchase your next extruder gear, make sure you know what you’re getting into.

1 speed gearbox

CZPT Group Components produces the one speed gearbox. It has the potential to make cars more efficient and environmentally friendly. The gear ratio of a car’s drivetrain is crucial for reaching maximum power and speed. Typically, a one-speed gearbox delivers a maximum of 200 hp. But the speed at which a car can reach this power must be high to get the full benefit from the electric motor. So, how can a one-speed gearbox improve the speed and torque of a car?

A one-speed gearbox is a mechanical device used to switch between second and third gears. It can include multiple gear sets, such as a shared middle gear for switching between second and third gears. It can also have an intermediate gear set that represents a switchable gear in both partial transmissions. The invention also includes a mechanism that makes it easier to change gears. The patent claims are detailed below. A typical one-speed gearbox may include two parts.

Generally, a one-speed gearbox will have up to seven forward gears, with each of these corresponding to a different speed. A one-speed gearbox can have five different gear sets and five different gear levels. It can have synchronized gear sets or last-shelf gear sets. In either case, the gears are arranged in a way that maximizes their efficiency. If the gears are placed on opposite sides of a car, the transmission may be a two-speed one.

CZPT Transmission specializes in the production of high-speed gearboxes. The company’s Milltronics HBM110XT gearbox machine is the perfect tool for this job. This machine has a large working table and a heavy-duty load capacity, making it a versatile option for many kinds of applications. There are also a wide variety of CZPT gearboxes for the automotive industry.

editor by czh2023-02-16

China K Series 90 Degree Helical Bevel Gear Reducer Gearbox with Good quality

Solution Description

Merchandise Description

Solution Description

-K Series Helical Bevel Gearbox

Item Attributes

1. Enter manner: Coupled motor, belted motor, input shaft or connection flange.

two. Output: Right angle

three. Compact structure. Rigid tooth face. Carrying higher torque, large loading potential.

4.Substantial precision gear, making certain the unit to function stably, smooth transmission.

5. Minimal sound, lengthy lifespan. Large overlap coefficient, abrasion resistant.

Merchandise Parameters

1. Technical data

| Size | 38 | 48 | 58 | 68 | 78 | 88 | 98 | 108 | 128 | 158 | 168 | 188 |

| Structure | K KA KF KAF KAZ KAT KAB | |||||||||||

| Enter energy rating(kw) | .18~3 | .18~three | .eighteen~5.five | .18~5.5 | .37~eleven | .75~22 | 1.3~thirty | 3~forty five | 7.5~ninety | eleven~a hundred and sixty | eleven~200 | eighteen.5~two hundred |

| Ratio | 5.36~ 106.38 |

five.81~ 131.87 |

6.fifty seven~ 145.fifteen |

7.fourteen~4 four.seventy nine |

7.22~ 192.eighteen |

seven.19~ 197.27 |

eight.ninety five~ 175.47 |

eight.seventy four~ 141.93 |

8.68~ 146.07 |

12.66~ a hundred and fifty.03 |

seventeen.35~ 164.forty four |

17.ninety seven~ 178.37 |

| Maximum Torque(N.m) | 200 | 400 | 600 | 820 | 1550 | 2770 | 4300 | 8000 | 13000 | 18000 | 32000 | 50000 |

| Weight | 11 | 20 | 27 | 33 | 57 | 85 | 130 | 250 | 380 | 610 | 1015 | 1700 |

2: Layout selection

| K series gear units are available in the following designs | |

| KAZ..Y.. | Limited-flange-mounted helical-bevel equipment models with hollow shaft |

| K…Y… | Foot-mounted helical-bevel gear models with sound shaft |

| KAT…Y… | Torque-arm-mounted helical-bevel equipment units with hollow shaft |

| KAB…Y… | Foot-mounted helical-bevel gear models with hollow shaft |

| K(KF,KA,KAF,KAB,KAZ)S… | Shaft enter helical-bevel gear units |

| KA…Y… | Helical-bevel gear models with hollow shaft |

| KA(K, KF ,KAF, KAB ,KAZ)R..Y… | Combinatorial helical-bevel equipment models |

| KF…Y… | Flange-mounted helical-bevel gear models with reliable shaft |

| KA(K, KF ,KAF ,KAZ)S…R… | Shaft input combinatorial helical-bevel equipment models |

| KAF…Y… | Flange-mounted helical-bevel equipment units with hollow shaft |

| KA(K, KF ,KAF, KAB ,KAZ)…Y… | When equipping the user’s motor or the particular 1 ,the flange is necessary to be related |

Materials Data Sheet

|

Housing content |

Grey Cast iron |

|

Housing hardness |

HBS163~255 |

|

Gear material |

20CrMnTi alloy metal |

|

Floor hardness of gears |

HRC58°~62 ° |

|

Gear main hardness |

HRC33~forty eight |

|

Input / Output shaft substance |

40Cr alloy metal |

|

Enter / Output shaft hardness |

HRC32~36 |

|

Machining precision of gears |

exact grinding, 6~5 Quality |

|

Lubricating oil |

GB L-CKC220-460, Shell Omala220-460 |

|

Heat therapy |

tempering, cementiting, quenching, normalizing, and many others. |

|

Efficiency |

ninety four%~96% (depends on the transmission stage) |

|

Sound (MAX) |

sixty~68dB |

|

Temp. increase (MAX) |

40°C |

|

Temp. rise (Oil)(MAX) |

50°C |

|

Vibration |

≤20µm |

|

Backlash |

≤20Arcmin |

|

Brand name of bearings |

China prime brand name bearing, HRB/LYC/ZWZ/C&U. Or other brand names asked for, SKF, FAG, INA, NSK. |

|

Brand name of oil seal |

NAK — ZheJiang or other brands asked for |

Thorough Images

Our approach of production

Our item line

Organization Profile

Organization Profile

Bode was established in 2007, which is located in HangZhou metropolis, ZHangZhoug province. As 1 professional manufacturer and exporter, we have more than 17 years’ experience in R & D of worm reducer, gear reducer, gearbox , AC motor and relative spare components. We have manufacturing facility with superior manufacturing and examination equipment, the powerful growth of staff and generating ability offer you our clients with large good quality goods. Our products broadly served to a variety of industries of Metallurgy, Chemical compounds, lifting, mining, Petroleum, textile, drugs, wooden and so on. Main markets: China, Africa, Australia, Vietnam, Turkey, Japan, Korea, Philippines… Welcome to question us any inquiries, excellent provide often for you for long term organization.

FAQ

Q1: Are you trading company or producer?

A: We are manufacturing unit.

Q2: What varieties of gearbox can you produce for us?

A: Primary goods of our business: R, S, K, F collection helical-tooth reducer, RV collection worm gear reducer,H Series Parallel Shaft Helical Reduction Equipment Box

Q3: Can you make as for each custom made drawing?

A: Yes, we offer you custom-made services for consumers.

Q4: Can we get 1 computer of every product for top quality tests?

A: Of course, we are glad to acknowledge trial purchase for quality screening.

Q5: What info shall we give ahead of placing a obtain get?

A: a) Kind of the gearbox, ratio, input and output type, input flange, mounting position, and motor informationetc.

b) Housing colour.

c) Acquire amount.

d) Other unique specifications.

Q6: How lengthy is your shipping time?

A: Generally it is 5-10 days if the merchandise are in stock. or it is fifteen-20 days if the goods are not in stock.

Q7: What is your conditions of payment ?

A: 30% Progress payment by T/T after signing the agreement.70% ahead of shipping

If you are interested in our merchandise, welcome to speak to with us.

Our staff will do our best to meet up with your need 🙂

|

US $90-5,500 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Three-Step |

###

| Samples: |

US$ 90/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Size | 38 | 48 | 58 | 68 | 78 | 88 | 98 | 108 | 128 | 158 | 168 | 188 |

| Structure | K KA KF KAF KAZ KAT KAB | |||||||||||

| Input power rating(kw) | 0.18~3 | 0.18~3 | 0.18~5.5 | 0.18~5.5 | 0.37~11 | 0.75~22 | 1.3~30 | 3~45 | 7.5~90 | 11~160 | 11~200 | 18.5~200 |

| Ratio | 5.36~ 106.38 |

5.81~ 131.87 |

6.57~ 145.15 |

7.14~4 4.79 |

7.22~ 192.18 |

7.19~ 197.27 |

8.95~ 175.47 |

8.74~ 141.93 |

8.68~ 146.07 |

12.66~ 150.03 |

17.35~ 164.44 |

17.97~ 178.37 |

| Maximum Torque(N.m) | 200 | 400 | 600 | 820 | 1550 | 2770 | 4300 | 8000 | 13000 | 18000 | 32000 | 50000 |

| Weight | 11 | 20 | 27 | 33 | 57 | 85 | 130 | 250 | 380 | 610 | 1015 | 1700 |

###

| K series gear units are available in the following designs | |

| KAZ..Y.. | Short-flange-mounted helical-bevel gear units with hollow shaft |

| K…Y… | Foot-mounted helical-bevel gear units with solid shaft |

| KAT…Y… | Torque-arm-mounted helical-bevel gear units with hollow shaft |

| KAB…Y… | Foot-mounted helical-bevel gear units with hollow shaft |

| K(KF,KA,KAF,KAB,KAZ)S… | Shaft input helical-bevel gear units |

| KA…Y… | Helical-bevel gear units with hollow shaft |

| KA(K, KF ,KAF, KAB ,KAZ)R..Y… | Combinatorial helical-bevel gear units |

| KF…Y… | Flange-mounted helical-bevel gear units with solid shaft |

| KA(K, KF ,KAF ,KAZ)S…R… | Shaft input combinatorial helical-bevel gear units |

| KAF…Y… | Flange-mounted helical-bevel gear units with hollow shaft |

| KA(K, KF ,KAF, KAB ,KAZ)…Y… | When equipping the user’s motor or the special one ,the flange is required to be connected |

###

|

Housing material

|

Grey Cast iron

|

|

Housing hardness

|

HBS163~255

|

|

Gear material

|

20CrMnTi alloy steel

|

|

Surface hardness of gears

|

HRC58°~62 °

|

|

Gear core hardness

|

HRC33~48

|

|

Input / Output shaft material

|

40Cr alloy steel

|

|

Input / Output shaft hardness

|

HRC32~36

|

|

Machining precision of gears

|

accurate grinding, 6~5 Grade

|

|

Lubricating oil

|

GB L-CKC220-460, Shell Omala220-460

|

|

Heat treatment

|

tempering, cementiting, quenching, normalizing, etc.

|

|

Efficiency

|

94%~96% (depends on the transmission stage)

|

|

Noise (MAX)

|

60~68dB

|

|

Temp. rise (MAX)

|

40°C

|

|

Temp. rise (Oil)(MAX)

|

50°C

|

|

Vibration

|

≤20µm

|

|

Backlash

|

≤20Arcmin

|

|

Brand of bearings

|

China top brand bearing, HRB/LYC/ZWZ/C&U. Or other brands requested, SKF, FAG, INA, NSK.

|

|

Brand of oil seal

|

NAK — Taiwan or other brands requested

|

|

US $90-5,500 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Three-Step |

###

| Samples: |

US$ 90/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Size | 38 | 48 | 58 | 68 | 78 | 88 | 98 | 108 | 128 | 158 | 168 | 188 |

| Structure | K KA KF KAF KAZ KAT KAB | |||||||||||

| Input power rating(kw) | 0.18~3 | 0.18~3 | 0.18~5.5 | 0.18~5.5 | 0.37~11 | 0.75~22 | 1.3~30 | 3~45 | 7.5~90 | 11~160 | 11~200 | 18.5~200 |

| Ratio | 5.36~ 106.38 |

5.81~ 131.87 |

6.57~ 145.15 |

7.14~4 4.79 |

7.22~ 192.18 |

7.19~ 197.27 |

8.95~ 175.47 |

8.74~ 141.93 |

8.68~ 146.07 |

12.66~ 150.03 |

17.35~ 164.44 |

17.97~ 178.37 |

| Maximum Torque(N.m) | 200 | 400 | 600 | 820 | 1550 | 2770 | 4300 | 8000 | 13000 | 18000 | 32000 | 50000 |

| Weight | 11 | 20 | 27 | 33 | 57 | 85 | 130 | 250 | 380 | 610 | 1015 | 1700 |

###

| K series gear units are available in the following designs | |

| KAZ..Y.. | Short-flange-mounted helical-bevel gear units with hollow shaft |

| K…Y… | Foot-mounted helical-bevel gear units with solid shaft |

| KAT…Y… | Torque-arm-mounted helical-bevel gear units with hollow shaft |

| KAB…Y… | Foot-mounted helical-bevel gear units with hollow shaft |

| K(KF,KA,KAF,KAB,KAZ)S… | Shaft input helical-bevel gear units |

| KA…Y… | Helical-bevel gear units with hollow shaft |

| KA(K, KF ,KAF, KAB ,KAZ)R..Y… | Combinatorial helical-bevel gear units |

| KF…Y… | Flange-mounted helical-bevel gear units with solid shaft |

| KA(K, KF ,KAF ,KAZ)S…R… | Shaft input combinatorial helical-bevel gear units |

| KAF…Y… | Flange-mounted helical-bevel gear units with hollow shaft |

| KA(K, KF ,KAF, KAB ,KAZ)…Y… | When equipping the user’s motor or the special one ,the flange is required to be connected |

###

|

Housing material

|

Grey Cast iron

|

|

Housing hardness

|

HBS163~255

|

|

Gear material

|

20CrMnTi alloy steel

|

|

Surface hardness of gears

|

HRC58°~62 °

|

|

Gear core hardness

|

HRC33~48

|

|

Input / Output shaft material

|

40Cr alloy steel

|

|

Input / Output shaft hardness

|

HRC32~36

|

|

Machining precision of gears

|

accurate grinding, 6~5 Grade

|

|

Lubricating oil

|

GB L-CKC220-460, Shell Omala220-460

|

|

Heat treatment

|

tempering, cementiting, quenching, normalizing, etc.

|

|

Efficiency

|

94%~96% (depends on the transmission stage)

|

|

Noise (MAX)

|

60~68dB

|

|

Temp. rise (MAX)

|

40°C

|

|

Temp. rise (Oil)(MAX)

|

50°C

|

|

Vibration

|

≤20µm

|

|

Backlash

|

≤20Arcmin

|

|

Brand of bearings

|

China top brand bearing, HRB/LYC/ZWZ/C&U. Or other brands requested, SKF, FAG, INA, NSK.

|

|

Brand of oil seal

|

NAK — Taiwan or other brands requested

|

NVH Characteristics of Helical Gearbox

Typically, a helical gearbox is used in the transmission of torque, speed, or both. Its primary function is to rotate a circular machine part while simultaneously meshing with other toothed parts. It operates on the same principle as a lever.

Typical applications

Typical applications of helical gearboxes include conveyors, blowers, and elevators. They are also used in the construction of plastics and rubber. Their basic benefits include reduced vibration, lower noise levels, and high load carrying capacity. They are also known to be more durable and quiet than spur gears.

There are several factors that should be taken into consideration when choosing the right gear set for a particular application. These include power requirements, torque requirements, and the environment in which it will operate. Also, bearings and lubricants will need to be considered.

Helical gears are used for heavy load applications, as they provide a high load-carrying capacity. They also are less expensive than spur gears. However, their efficiency is lower than spur gears. This is due to the fact that helical gears have larger teeth. They also have a lower dynamic load than spur gears. This reduces wear and tear on the gears.

Helical gears are also used in high-speed applications. They can also be used with non-parallel shafts. They are typically chosen over spur gears for non-parallel applications. However, helical gears are prone to misalignment due to axial thrust. This can be corrected by adjusting the bearing position.

Helical gears can also be used as power transmitting gears. They are commonly used in transmissions in the automotive industry. They are also used in a wide range of other industrial applications. These include blowers, feeders, coolers, and conveyors. They can also be used in the food and oil industries.

The most common types of helical gearboxes are single and double helical gearboxes. Single helical gears have one helical section that is parallel to the axis. Those with a circular arc curved tooth are also available.

NVH characteristics

NVH characteristics of helical gearbox are a major consideration in the development of new driveline products. NVH can be quantified using wavelet analysis, order analysis and statistical energy analysis. These techniques are typically used in the frequency domain, but can also be used in the real time domain.

The most basic NVH method uses a modal analysis to quantify the transmission noise. Simplified models use sinusoidal stiffness variations, but can also be used to study special effects.

One of the most important aspects of NVH is the integrity of the signal chain. The signal chain is affected by the gear meshing impact and the main transmission housing excitation. The first step in quantifying NVH is to establish a signal chain. This can be done by comparing the signals that are recorded on an analog to digital converter or hard disk. Then, using fast Fourier transforms, signals are converted from the time domain into the frequency domain.

For NVH analysis, it is important to obtain a representative prototype of the production vehicle. This is necessary early in the design phase, as changes to the final product often require substantial design modifications.

For helical gearboxes, the main benefit of reverse module configuration is that the radial type gearbox is more economical to produce. The radial type gearbox uses the same tooth-cutting tools as a spur gear, but can be produced more economically.

The basic characteristics of helical gears are that they have more surface contact and are more powerful in their carrying capacity. Because of this, the helical gearbox is typically used for high-load applications. However, helical gearboxes tend to produce lower efficiencies than spur types.

Thermal deformation of bearings can also change NVH characteristics of a helical gear transmission system. In this study, the effects of bearing temperature rise on the nonlinear dynamic characteristics of a helical gear system are investigated.

Helix

Compared to conventional gears, helical gears have more surface contact and produce less noise. These gears are a great choice for home and light industrial applications, especially where high-efficiency is required.