Product Description

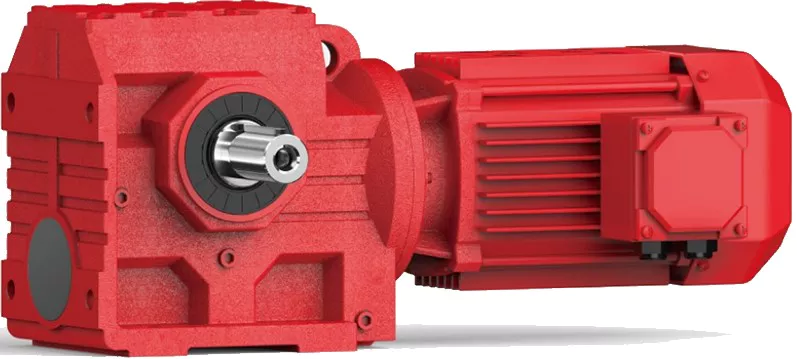

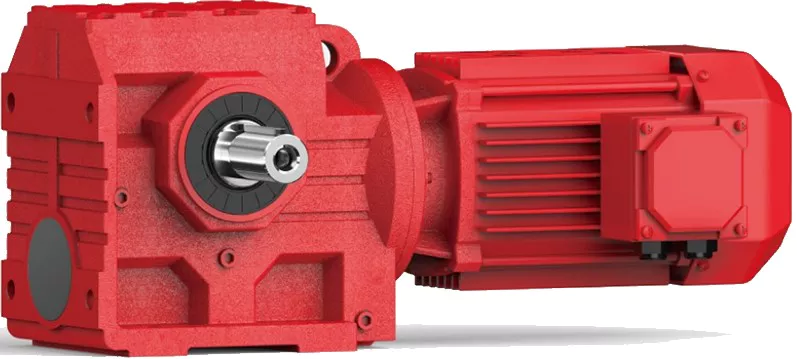

Bevel helical gearbox with permanent magnet synchronous motor integrate variable frequency driver for conveyor

SNKG Series prorduct adopt harden teeth surface bevel gear and helical gear to drive, following the design principle of modularization , FEA analyse technology, unique low-noise gear tooth profile, with the characteristics of compact volume, high load performance and stable running, reliability and long service life.

Key Benefits

-Simple wiring, low cost

-Large amount of data, fast speed, 100m, data transmission is 500K

-All control units have the same condition, it means each node has the same rights to occupy the bus (send and receive)

-Communication rate meets control requirements, communication data amount supports required data reading.

-Electric eye and proximity switch sensor supply signal to the driver directly, it is convenient and reliable.

About Us

ZheJiang CZPT Drive Co.,Ltd(Starshine) have a strong technical force with over 350 employees at present, including over 30 engineering technicians, 30 quality inspectors, covering an area of 80000 square CZPT and kinds of advanced processing machines and testing equipments. We have a good foundation for the industry application development and service of high-end speed reducers & variators owning to the provincial engineering technology research center,the lab of gear speed reducers, and the base of modern R&D.

Our Team

Quality Control

Quality:Insist on Improvement,Strive for CZPT With the development of equipment manufacturing indurstry,customer never satirsfy with the current quality of our products,on the contrary,wcreate the value of quality.

Quality policy:to enhance the overall level in the field of power transmission

Quality View:Continuous Improvement , pursuit of CZPT

Quality Philosophy:Quality creates value

3. Incoming Quality Control

To establish the AQL acceptable level of incoming material control, to provide the material for the whole inspection, sampling, immunity. On the acceptance of qualified products to warehousing, substandard goods to take return, check, rework, rework inspection; responsible for tracking bad, to monitor the supplier to take corrective measures to prevent recurrence.

4. Process Quality Control

The manufacturing site of the first examination, inspection and final inspection, sampling according to the requirements of some projects, judging the quality change trend; found abnormal phenomenon of manufacturing, and supervise the production department to improve, eliminate the abnormal phenomenon or state.

5. FQC(Final QC)

After the manufacturing department will complete the product, stand in the customer’s position on the finished product quality verification, in order to ensure the quality of customer expectations and needs.

6. OQC(Outgoing QC)

After the product sample inspection to determine the qualified, allowing storage, but when the finished product from the warehouse before the formal delivery of the goods, there is a check, this is called the shipment inspection.Check content:In the warehouse storage and transfer status to confirm, while confirming the delivery of the product is a product inspection to determine the qualified products.

Packing

Delivery

Factory: ZheJiang CZPT Drive Co., Ltd.

(Previous name: HangZhou XingGuang Transmission Machinery)

Add: No.10,Xihu (West Lake) Dis.n Industrial Park, Baini Town, Xihu (West Lake) Dis. District, HangZhou City, ZheJiang Province, China.

Web: gearbox1965 /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction |

| Layout: | Helical Bevel |

| Hardness: | Hardened Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Three-Step |

| Samples: |

US$ 569/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Role of Helical Gearboxes in Automotive Transmissions

Helical gearboxes play a crucial role in automotive transmissions, contributing to the efficient power transfer and smooth operation of vehicles:

- Power Transmission: Helical gearboxes are used to transmit power from the engine to the wheels through different gear ratios. They help in converting the high-speed, low-torque output of the engine into the appropriate speed and torque for the wheels.

- Smooth Shifting: In manual and automatic transmissions, helical gears are often used to provide smooth and quiet gear shifts. The gradual engagement of helical gear teeth helps in reducing the shock and noise associated with gear changes.

- Noise Reduction: Helical gears are known for their quieter operation compared to other gear types. This is especially important in automotive applications where minimizing noise and vibration is desired for a comfortable driving experience.

- Efficiency: The efficiency of helical gearboxes helps in optimizing fuel efficiency and reducing energy losses. This is crucial for improving the overall performance and economy of vehicles.

- Load Distribution: Helical gears distribute the load over multiple teeth, reducing wear and ensuring the gearbox’s longevity. This is important in vehicles that experience varying loads and driving conditions.

- Torque Handling: Helical gears can handle higher torque loads compared to some other gear types. This is essential for vehicles, especially those with powerful engines, towing capabilities, or off-road use.

In modern automotive transmissions, helical gearboxes can be found in various components, including the main transmission, differential, and gearbox synchronizers. They contribute to the smooth operation, improved fuel efficiency, and overall performance of vehicles. The design and arrangement of helical gears can be tailored to meet the specific requirements of different vehicle types, making them a versatile choice for automotive applications.

Considerations for Designing Helical Gearboxes for Heavy-Duty Applications

Designing helical gearboxes for heavy-duty applications requires careful consideration of various factors to ensure reliable and efficient operation under high loads and demanding conditions. Here are the key considerations:

- Load Capacity: Heavy-duty applications involve substantial loads. The gearbox must be designed to handle these loads while preventing premature wear and failure. Calculations of the load distribution, contact stresses, and material strength are crucial.

- Material Selection: High-strength and durable materials are essential for heavy-duty gearboxes. Alloy steels or special heat-treated materials are often chosen to provide the necessary strength and resistance to fatigue and wear.

- Gear Tooth Design: Optimal gear tooth profiles, such as optimized helix angles and tooth modifications, contribute to smoother engagement and reduced stress concentrations. This enhances the gearbox’s ability to handle heavy loads without excessive wear.

- Bearing Selection: Robust and high-capacity bearings are necessary to support the heavy loads and provide reliable shaft support. The bearings must be able to withstand both radial and axial forces generated during operation.

- Lubrication: Adequate lubrication is critical for heavy-duty gearboxes. Lubricants with high load-carrying capacity and extreme pressure properties are chosen to ensure proper lubrication under heavy loads and to reduce friction and wear.

- Heat Dissipation: Heavy-duty applications can generate significant heat due to friction and load. Efficient heat dissipation mechanisms, such as cooling fins or oil cooling, should be incorporated into the gearbox design to prevent overheating and thermal damage.

- Sealing: Effective sealing is necessary to prevent contaminants from entering the gearbox and to retain lubricants. Seals must be capable of withstanding the conditions of the application, including high loads, vibrations, and potential exposure to harsh environments.

- Efficiency: Although heavy-duty applications prioritize load capacity, achieving acceptable levels of efficiency is still important to minimize energy losses and heat generation. Proper gear tooth design and high-quality manufacturing contribute to better efficiency.

- Structural Integrity: The gearbox housing and components must be designed with structural integrity in mind. Rigidity and robustness are required to prevent distortion or failure of components under heavy loads.

- Reliability and Serviceability: Heavy-duty gearboxes should be designed with reliability and ease of maintenance in mind. Access to critical components, such as gears and bearings, for inspection and replacement is important to minimize downtime.

Conclusion: Designing helical gearboxes for heavy-duty applications involves a comprehensive approach that addresses load capacity, material selection, gear tooth design, lubrication, heat dissipation, sealing, efficiency, structural integrity, and serviceability. By carefully considering these factors, engineers can create gearboxes that deliver exceptional performance and longevity in demanding industrial settings.

Limitations and Disadvantages of Helical Gear Systems

While helical gear systems offer numerous advantages, they also come with certain limitations and disadvantages:

- Axial Thrust: Helical gears generate axial thrust due to the helix angle of the teeth. This thrust can cause additional load on bearings and may require additional measures to counteract.

- Complex Manufacturing: The manufacturing process for helical gears is more complex than that of straight-toothed gears, which can lead to higher production costs.

- Axial Length: Helical gears require more axial space compared to spur gears with the same gear ratio. This can be a limitation in applications with space constraints.

- Sliding Contact: Helical gears have sliding contact between their teeth, which can result in higher friction and more heat generation compared to rolling contact gears.

- Efficiency: Although helical gears are generally efficient, their efficiency can be slightly lower than that of some other gear types, especially at high speeds.

- Complexity in Gearbox Design: The inclination of helical gear teeth introduces additional complexity in gearbox design and alignment.

- Reverse Thrust: In some cases, reverse thrust can occur when helical gears are subjected to high axial loads, leading to undesirable effects.

It’s important to consider these limitations and disadvantages when selecting gear systems for specific applications. Despite these challenges, helical gears remain a popular choice in various industries due to their benefits and overall performance characteristics.

editor by CX 2024-04-29

China Standard Engine with Gearbox Speed Reducer Helical Bevel Gear Box/Elevator Gear Box manufacturer

Product Description

Engine with gearbox speed reducer helical bevel gear box/elevator gear box

< ABOUT TILI

Technical data

| Product Name | Engine with gearbox speed reducer helical bevel gear box/elevator gear box |

| Power | 0.12KW~160KW |

| Torque | 9.9N · m ~ 44822N · m |

| Output speed | 0.08 ~ 267r/min |

| Gear material | 20CrMnTi alloy steel |

| Gear Processing | Grinding finish by HOFLER Grinding Machines |

| Noise Test | Below 65dB |

| Brand of bearings | C&U bearing, ZWZ,LYC, HRB, CZPT ,etc |

| Brand of oil seal | NAK or other brand |

| Temp. rise (MAX) | 40ºC |

| Temp. rise (Oil)(MAX | 50ºC |

| Vibration | ≤20µm |

| Housing hardness | HBS190-240 |

| Surface hardness of gears | HRC58°~62 ° |

| Gear core hardness | HRC33~40 |

| Machining precision of gears | 5 Grade |

| Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

| Heat treatment | Carburizing, Quenching etc |

| Efficiency | 95%~96% (depends on the transmission stage) |

| Bearing output mode | Vertical output |

| Installation type and output mode | Bottom seated type flange type installation, solid,hollow shaft output. |

| Input mode | Direct motor, shaft input and connecting flange input |

| Input Method | Flange input(AM), shaft input(AD), inline AC motor input, or AQA servo motor |

Installation Instructions

Company Profile

< WORKSHOP

< QUALITY CONTROL

Certifications

Packaging & Shipping

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of reducer.

Q 2:Can you do OEM?

A:Yes, we can. We can do OEM for all the customers .if you want to order NON-STANDERD speed reducers,pls provide Drafts, Dimensions, Pictures and Samples if possible.

Q 3: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 4: Do you have inspection procedures for reducer?

A:100% self-inspection before packing.

Q 5: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 6:How to choose a gearbox? What if I don’t know which gear reducer I need?

A:You can refer to our catalogue to choose the gearbox or we can help to choose when you provide,the technical information of required output torque, output speed and motor parameter etc. Don’t worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q 7: What information shall we give before placing a purchase order?

A:a) Type of the gearbox, Size , Transmission Ratio, input and output type, input flange, mounting position, motor information and shaft deflection etc. b)Housing color.c) Purchase quantity. d) Other special requirements

Q 8:What is the payment term?

A:You can pay via T/T(30% in advance as deposit before production +70% before delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery, Industrial Automation Equipment, Chemical Industry |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Vertical Axis Output |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Comparison of Helical Gearboxes and Bevel Gearboxes

Helical gearboxes and bevel gearboxes are both widely used for power transmission in various industrial applications. Here’s a comparison of their performance:

- Gear Meshing: Helical gearboxes use helical gears with inclined teeth that gradually engage, resulting in smoother and quieter operation compared to the more abrupt engagement of straight-cut bevel gears.

- Efficiency: Helical gearboxes generally offer higher efficiency due to their helical gear design, which distributes loads evenly across the teeth. Bevel gearboxes can have slightly lower efficiency due to the sliding action of gear teeth during engagement.

- Load Capacity: Helical gearboxes can handle higher loads and torque due to the larger contact area of the gear teeth. Bevel gearboxes are suitable for moderate loads and applications where the direction of power transmission needs to be changed.

- Space Efficiency: Bevel gearboxes are often more compact and suitable for applications where space is limited and a change in direction is required. Helical gearboxes may require more space due to the parallel shaft arrangement.

- Noise and Vibration: Helical gearboxes generate less noise and vibration compared to straight-cut bevel gearboxes. Bevel gearboxes can be noisier, especially at higher speeds.

- Application: Helical gearboxes are commonly used in applications requiring smooth and efficient power transmission, such as conveyors, pumps, and mixers. Bevel gearboxes are preferred for applications where changes in direction are necessary, such as in automotive differentials and printing presses.

Ultimately, the choice between helical and bevel gearboxes depends on the specific requirements of the application, including load capacity, space constraints, efficiency goals, and the need for directional changes in power transmission.

Impact of Thermal Expansion on Helical Gearbox Performance

Thermal expansion can significantly affect the performance of helical gearboxes due to changes in dimensions and clearances caused by temperature variations. Here’s how it impacts:

1. Misalignment: Temperature changes can lead to differential expansion of gearbox components. This can result in misalignment of gears, shafts, and bearings, leading to increased friction, noise, and reduced efficiency.

2. Lubrication: Thermal expansion can alter the clearances within the gearbox, affecting the distribution and viscosity of the lubricating oil. Inadequate lubrication due to temperature-induced changes can result in increased wear and premature failure.

3. Gear Tooth Engagement: Temperature fluctuations can cause gear teeth to expand or contract, affecting the meshing engagement and load distribution. Inconsistent gear tooth contact can lead to uneven wear and reduced gear life.

4. Bearing Performance: Bearings in helical gearboxes are sensitive to temperature changes. Excessive heat can lead to reduced bearing life, increased friction, and potential seizure, affecting overall gearbox performance.

5. Noise and Vibration: Thermal expansion can lead to changes in gear and component clearances, resulting in altered vibration patterns and increased noise levels. This can impact the comfort of the system and indicate potential issues.

6. Material Fatigue: Repeated cycles of thermal expansion and contraction can lead to material fatigue and stress accumulation, reducing the overall lifespan of gearbox components.

Managing Thermal Effects: Manufacturers design helical gearboxes with considerations for thermal expansion, using materials with low coefficients of thermal expansion and incorporating features like expansion joints or thermal isolators. Proper lubrication, monitoring temperature, and maintaining consistent operating conditions are also crucial in mitigating thermal expansion effects.

Understanding and managing the impact of thermal expansion is essential to maintain the performance, efficiency, and durability of helical gearboxes.

Advantages of Helical Gearboxes in Industrial Applications

Helical gearboxes offer several advantages that make them well-suited for a wide range of industrial applications. Here are some of the key advantages:

- Smooth and Quiet Operation: The helical design of the gears results in gradual tooth engagement, reducing noise and vibration during operation. This makes helical gearboxes ideal for applications where noise reduction is important.

- High Efficiency: Helical gears provide a larger contact area compared to straight-cut gears, leading to improved power transmission efficiency. The gradual engagement of teeth also reduces energy losses due to friction.

- Higher Load Capacity: The helical angle allows for multiple teeth to be engaged simultaneously, distributing the load across a larger area. This results in higher load-carrying capacity and increased durability of the gearbox.

- Compact Design: Helical gearboxes can achieve high gear ratios with fewer gear stages, leading to a more compact overall design. This is advantageous in applications where space is limited.

- Wide Range of Ratios: Helical gearboxes can achieve a wide range of gear ratios, making them versatile for various speed and torque requirements.

- Less Backlash: The gradual tooth engagement of helical gears results in reduced backlash, which is the play between gear teeth. This leads to improved accuracy and positioning in applications that require precise motion control.

- Heat Dissipation: The helical design allows for better heat dissipation due to the continuous contact between gear teeth. This is beneficial in high-speed applications where heat generation can be a concern.

- Highly Customizable: Helical gearboxes can be customized to meet specific application requirements, including input and output configurations, gear ratios, and mounting options.

Overall, the advantages of helical gearboxes make them a popular choice in industries such as manufacturing, automation, robotics, material handling, and more.

editor by CX 2024-04-26

China Hot selling Kf Series Helical Bevel Industrial Gearbox with Good quality

Product Description

KF series Helical Bevel Industrial Gearbox

Product Description

K series gearbox is 1 kind of Helical Bevel type gearbox ,it is designed based on modularization , which bring many difference kinds of combinations ,mounting types ,and structure designs .The detail classification of ratio can meet various of working condition .High Transmission efficiency ,low energy consumption, superior performance . The hard tooth surface gear use the high quality alloy steel , the process of carburizing and quenching, grinding ,which give it follow characters : Stable transmission , low noise and temperature ,high loading ,long working life. Reinforced high rigid cast iron box; The hardened gear is made of high-quality alloy steel. Its surface is carburized, quenched and hardened, and the gear is finely ground. It features stable transmission, low noise, large bearing capacity, low temperature rise, and long service life. Performance and characteristics,which widely use for industry equipment of metallurgy ,Building Material , Chemical , Mining , Oil, Transportation , Papermaking , Sugar making , engineering Machines ,etc.

1.Technical data:

| Product Name | KF series Helical Bevel Industrial Gearbox |

| Power | 0.12KW~200KW |

| Torque | 10N · m ~ 50000N · m |

| Output speed | 0.06 ~ 1090r/min |

| Reduction ratio | 5.36~17396 |

| Output speed | 7 ~ 415r/min |

| Gear material | 20CrMnTi alloy steel |

| Gear Processing | Grinding finish by HOFLER Grinding Machines |

| Noise Test | Below 65dB |

| Brand of bearings | C&U bearing, ZWZ,LYC, HRB, CZPT ,etc |

| Brand of oil seal | NAK or other brand |

| Temp. rise (MAX) | 40ºC |

| Temp. rise (Oil)(MAX | 50ºC |

| Vibration | ≤20µm |

| Housing hardness | HBS190-240 |

| Surface hardness of gears | HRC58°~62 ° |

| Gear core hardness | HRC33~40 |

| Machining precision of gears | 5 Grade |

| Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

| Heat treatment | Carburizing, Quenching etc |

| Efficiency | 95%~96% (depends on the transmission stage) |

| Bearing output mode | parallel output |

| Installation type and output mode | Bottom seated type flange type installation, solid,hollow shaft output. |

| Input mode | Direct motor, shaft input and connecting flange input |

| Input Method | Flange input(AM), shaft input(AD), inline AC motor input, or AQA servo motor |

Detailed Photos

Company Profile

< ABOUT TILI

HangZhou Tili Reducer Co, Ltd has been committed to provide High-quality hardensurface extruder gearbox since established In 2003.

Since its establishment, we always been committed to creating High-quality products in the field of transmission in China and is determined to enter the global market the high-end market of the mechanical industry is based on technology, and industry serves the country. We have strong research and development capabilities and professional production team and elite salesteam have continuously innovated, we specialize in Planetary reducer, 4 series (R, K, F, S) reducers, CZPT series single screw extruder reducer, DJYG series high torque extruder reducer, cycloidal reducer, sell well in Europe, USA, Japan, India, Brazil, Southeast Asia etc.

Relying on the 20 years of industry accumulation, we hold our company’s vision of “sustainable operation”, based on quality and service, in the global competitive environment, we strive to meet customers’ quality requirements and strive for stable growth and strive for excellence.

Adhere to the principle of integrity, grow together with customers, and share with employees.

We’re pleased to get your inquiry and we will reply you as soon as possible. We stick to the principle of “Quality first, service first, continuous improvement and innovation to meet the customers” for the management and “Zero defect, zero complaints” as the quality objective.

< WORKSHOP

< QUALITY CONTROL

Certifications

Packaging & Shipping

Installation Instructions

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of reducer.

Q 2:Can you do OEM?

A:Yes, we can. We can do OEM for all the customers .if you want to order NON-STANDERD speed reducers,pls provide Drafts, Dimensions, Pictures and Samples if possible.

Q 3: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 4: Do you have inspection procedures for reducer?

A:100% self-inspection before packing.

Q 5: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 6:How to choose a gearbox? What if I don’t know which gear reducer I need?

A:You can refer to our catalogue to choose the gearbox or we can help to choose when you provide,the technical information of required output torque, output speed and motor parameter etc. Don’t worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q 7: What information shall we give before placing a purchase order?

A:a) Type of the gearbox, Size , Transmission Ratio, input and output type, input flange, mounting position, motor information and shaft deflection etc. b)Housing color.c) Purchase quantity. d) Other special requirements

Q 8:What is the payment term?

A:You can pay via T/T(30% in advance as deposit before production +70% before delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction |

| Layout: | Right Angle |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Comparison of Helical Gearboxes and Bevel Gearboxes

Helical gearboxes and bevel gearboxes are both widely used for power transmission in various industrial applications. Here’s a comparison of their performance:

- Gear Meshing: Helical gearboxes use helical gears with inclined teeth that gradually engage, resulting in smoother and quieter operation compared to the more abrupt engagement of straight-cut bevel gears.

- Efficiency: Helical gearboxes generally offer higher efficiency due to their helical gear design, which distributes loads evenly across the teeth. Bevel gearboxes can have slightly lower efficiency due to the sliding action of gear teeth during engagement.

- Load Capacity: Helical gearboxes can handle higher loads and torque due to the larger contact area of the gear teeth. Bevel gearboxes are suitable for moderate loads and applications where the direction of power transmission needs to be changed.

- Space Efficiency: Bevel gearboxes are often more compact and suitable for applications where space is limited and a change in direction is required. Helical gearboxes may require more space due to the parallel shaft arrangement.

- Noise and Vibration: Helical gearboxes generate less noise and vibration compared to straight-cut bevel gearboxes. Bevel gearboxes can be noisier, especially at higher speeds.

- Application: Helical gearboxes are commonly used in applications requiring smooth and efficient power transmission, such as conveyors, pumps, and mixers. Bevel gearboxes are preferred for applications where changes in direction are necessary, such as in automotive differentials and printing presses.

Ultimately, the choice between helical and bevel gearboxes depends on the specific requirements of the application, including load capacity, space constraints, efficiency goals, and the need for directional changes in power transmission.

Helical Gearboxes and Energy Efficiency

Helical gearboxes play a significant role in enhancing energy efficiency in various industrial processes. Their design and operating characteristics contribute to improved efficiency and reduced energy consumption. Here’s how helical gearboxes achieve energy efficiency:

- Helical Gear Meshing: Helical gears have inclined teeth that engage gradually, resulting in smoother and quieter meshing compared to other gear types. This smoother engagement reduces impact and friction losses, leading to higher efficiency and lower energy consumption.

- Load Distribution: Helical gears distribute the load across multiple teeth due to their helix angle. This even load distribution minimizes stress concentrations and prevents premature wear, ensuring efficient power transmission and reducing the need for frequent maintenance.

- Efficient Power Transmission: The inclined tooth profile of helical gears allows for more teeth to be in contact at any given time. This increased contact area improves power transmission efficiency by reducing sliding friction and minimizing energy losses.

- Reduced Vibration: The helical tooth engagement minimizes vibration and noise levels, which can be particularly advantageous in applications that require precise and stable operation. Reduced vibration translates to lower energy losses and increased overall efficiency.

- Optimized Gear Design: Engineers can fine-tune helical gear designs by adjusting parameters such as helix angle, number of teeth, and gear materials. This optimization process helps tailor the gearbox for specific applications, ensuring optimal efficiency and minimal energy wastage.

- Lubrication and Cooling: Proper lubrication and cooling strategies are crucial for maintaining efficiency. Helical gears benefit from efficient lubrication due to their continuous tooth engagement, which helps reduce friction and wear, further enhancing energy efficiency.

- Advanced Manufacturing: Modern manufacturing techniques enable precise production of helical gears, ensuring tight tolerances and accurate tooth profiles. This manufacturing precision contributes to minimal energy losses during gear operation.

Overall, helical gearboxes excel in energy efficiency by combining smoother tooth engagement, even load distribution, reduced vibration, and optimized designs. Their ability to transmit power efficiently and reliably makes them a preferred choice for industrial processes where energy conservation is a priority.

Advantages of Helical Gearboxes in Industrial Applications

Helical gearboxes offer several advantages that make them well-suited for a wide range of industrial applications. Here are some of the key advantages:

- Smooth and Quiet Operation: The helical design of the gears results in gradual tooth engagement, reducing noise and vibration during operation. This makes helical gearboxes ideal for applications where noise reduction is important.

- High Efficiency: Helical gears provide a larger contact area compared to straight-cut gears, leading to improved power transmission efficiency. The gradual engagement of teeth also reduces energy losses due to friction.

- Higher Load Capacity: The helical angle allows for multiple teeth to be engaged simultaneously, distributing the load across a larger area. This results in higher load-carrying capacity and increased durability of the gearbox.

- Compact Design: Helical gearboxes can achieve high gear ratios with fewer gear stages, leading to a more compact overall design. This is advantageous in applications where space is limited.

- Wide Range of Ratios: Helical gearboxes can achieve a wide range of gear ratios, making them versatile for various speed and torque requirements.

- Less Backlash: The gradual tooth engagement of helical gears results in reduced backlash, which is the play between gear teeth. This leads to improved accuracy and positioning in applications that require precise motion control.

- Heat Dissipation: The helical design allows for better heat dissipation due to the continuous contact between gear teeth. This is beneficial in high-speed applications where heat generation can be a concern.

- Highly Customizable: Helical gearboxes can be customized to meet specific application requirements, including input and output configurations, gear ratios, and mounting options.

Overall, the advantages of helical gearboxes make them a popular choice in industries such as manufacturing, automation, robotics, material handling, and more.

editor by CX 2024-04-26

China Good quality K Type Helical Bevel Gearbox gearbox design

Product Description

Technical Parameter

| Housing material | HT200 high-strength cast iron(EWK37, EWK47, EWK57, EWK67, EWK77, EWK87) |

| Housing material | HT250 High strength cast iron(EWK97, EWK107, EWK127, EWK157, EWK167, EWK187) |

| Gear material | 20CrMnTi |

| Gear Surface&hardness | HRC58°-62° |

| Gear core hardness | HRC33°-78° |

| Input/Output shaft material | 40Cr |

| Gear Machining precision | Accurate grinding 6-5 grade |

| Heat treatment | Carburizing, Quenching etc |

| Efficiency | Up to 92% |

| Noise(Max) | 60-67dB |

| Installation type | Foot mounted, flange mounted |

| Output type | Solid shaft, Hollow shaft, splined hollow shaft, shrink disk |

| Bearing brand | NSK, SKF, HRB, ZWZ etc |

| Oil seal brand | NAK, KSK etc |

| Lubricant | VG220 |

| Motor | IP55, F class |

| Motor shaft | 40Cr, Carburizing, Quenching etc |

| Warranty | 12months |

| Color | Blue, Grey |

Features

♦Specially designed for agitator.

♦Compact structure, Integrated casting housing, low noise and long service life.

♦High efficiency and low maintenance.

Technical Data

Ratio I=8.1~191, combination of EWK/EWR is up to13459

Efficiency: 94%, and combination of EWK/EWR85%.

Size EWK37~EWK187.

Industrial Application

Power Plant Equipment

Metallurgical Industry

Metal Forming Machinery

Petrochemical Industry

Mining Machine

Hoisting Machinery

Construction Industry

Environmental Protection Industry

Cable Industry

Food Machinery

Certificates

Passed ” ISO 9001 International Quality System Certificate”, “Europe CE Certificate”, ” Swiss SGS Certificate”, “High-tech enterprise certificate of ZheJiang city”, “Excellent performance management enterprise of ZheJiang city”, etc.

FAQ

1. Q: Can you make as per custom drawing?

A: Yes, we offer customized service for customers.

2. Q: Are you a factory or trading company?

A. We are manufacturer in ZheJiang China.

3. Q: What’s your MOQ?

A: One piece.

4. Q: What’s your production time?

A: 7-15 working days after receiving payment.

5. Q: What’s your payment terms?

A: T/T, 30% payment in advance, 70% balance payment should be paid before shipping.

6. Q: What’s your package?

A: In wooden box packaging.

ZheJiang CZPT Gear Reducer Co., Ltd., former a joint venture invested by is a ZheJiang CZPT GROUP and Well Company of America. We are professional manufacturer of the gear reducers and specialize in the gear reducers area in China for 20 years. CZPT has excellent R&D team, top-ranking production and test equipment. So we have the strong power in the developing and manufacturing the standards type as well as the customized type gear reducer for our customers. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | 90 Degree |

| Layout: | Right-Angle |

| Gear Shape: | Bevel Gear |

| Step: | Three-Step |

| Customization: |

Available

| Customized Request |

|---|

Installation and Alignment of Helical Gearboxes

Proper installation and alignment of a helical gearbox are essential to ensure its optimal performance and longevity. Here are the steps involved:

- Preparation: Gather all necessary tools, equipment, and safety gear. Ensure the work area is clean and well-lit.

- Mounting: Position the gearbox on the designated mounting surface and secure it using appropriate bolts. Follow the manufacturer’s guidelines for mounting torque and procedures.

- Shaft Alignment: Use precision tools such as dial indicators to align the input and output shafts. Achieving accurate shaft alignment minimizes stress on the gears and bearings.

- Bolt Tightening: Gradually and evenly tighten the mounting bolts, ensuring the gearbox remains properly aligned. Refer to torque specifications provided by the manufacturer.

- Lubrication: Fill the gearbox with the recommended lubricant according to the manufacturer’s specifications. Proper lubrication is crucial for reducing friction and wear.

- Alignment Check: After tightening the bolts, recheck the shaft alignment to ensure it hasn’t shifted during the tightening process.

- Run-In Period: Gradually introduce load to the gearbox to allow the gears to seat properly. Monitor the gearbox for any unusual noises, vibrations, or temperature changes during this period.

- Final Checks: Verify that the gearbox operates smoothly, without excessive noise or vibrations. Monitor the gearbox’s temperature during operation to ensure it remains within recommended limits.

- Regular Inspection: Schedule periodic inspections to check for any signs of wear, misalignment, or leakage. Address any issues promptly to prevent further damage.

It’s important to follow the manufacturer’s installation and alignment guidelines specific to the helical gearbox model you’re working with. Improper installation and alignment can lead to premature wear, reduced efficiency, and potential failure of the gearbox.

Relationship Between Helix Angle and Load Capacity in Helical Gears

The helix angle of helical gears plays a significant role in determining their load-carrying capacity and overall performance. Here’s the relationship between the helix angle and load capacity:

1. Load Distribution: The helix angle affects how the load is distributed along the gear teeth. A larger helix angle results in a more gradual tooth engagement, allowing for smoother load sharing across multiple teeth. This improves the gear’s ability to handle higher loads.

2. Contact Ratio: The contact ratio, which indicates the number of teeth in contact at any given time, increases with a larger helix angle. A higher contact ratio helps distribute the load over a larger area of the gear teeth, enhancing load-carrying capacity.

3. Tooth Meshing: The helix angle affects how the teeth mesh with each other. A higher helix angle promotes gradual and smoother meshing, reducing the concentration of stress on individual teeth. This results in improved resistance to wear and fatigue.

4. Axial Thrust: Helical gears produce axial thrust due to their helical nature. This thrust can affect the gear’s ability to handle radial loads. Proper consideration of the helix angle can help manage axial thrust and prevent overloading.

5. Lubrication: The helix angle affects the lubrication conditions between gear teeth. A larger helix angle may allow better oil flow and lubrication, reducing friction and wear, thereby enhancing load capacity.

6. Noise and Vibration: The helix angle also influences noise and vibration levels in helical gears. Optimal helix angle selection can minimize noise and vibration, contributing to smoother operation and prolonged gear life.

Optimal Helix Angle Selection: While a larger helix angle generally increases load capacity, it’s important to strike a balance. Extremely large helix angles can lead to reduced tooth strength and efficiency. Engineers consider factors like application requirements, tooth strength, and noise considerations when selecting the optimal helix angle for a specific gear design.

The relationship between the helix angle and load capacity underscores the importance of proper gear design to ensure optimal performance, durability, and reliability in various applications.

Helical Gear Meshing and Its Benefits

Helical gear meshing refers to the engagement of two helical gears with inclined teeth. The teeth are cut at an angle to the gear axis, creating a helix shape. When these gears mesh, the inclined teeth gradually come into contact, allowing for smoother and quieter operation compared to straight-toothed gears.

The benefits of helical gear meshing include:

- Reduced Noise: The gradual contact between helical gear teeth minimizes impact and noise during engagement, resulting in quieter operation. This is particularly advantageous in applications where noise reduction is essential, such as industrial machinery and automotive transmissions.

- Smooth Operation: Helical gears provide smoother and more continuous motion due to the gradual engagement of teeth. This feature makes them suitable for applications that require precise and controlled movement, such as CNC machines and conveyor systems.

- Higher Load Capacity: The helical tooth geometry allows for greater tooth contact area, distributing the load over a larger surface. This results in higher load-carrying capacity and improved durability, making helical gears suitable for heavy-duty applications.

- Efficient Power Transmission: Helical gears transmit power more efficiently due to their smooth engagement and increased contact area. This efficiency contributes to reduced energy consumption and heat generation in gearboxes.

- Less Vibrations: The gradual meshing of helical gears reduces vibrations, resulting in smoother operation and reduced wear and tear on gear teeth and bearings. This is especially important for extending the lifespan of the gearbox.

Overall, helical gear meshing offers numerous benefits, including reduced noise, smoother operation, higher load capacity, efficient power transmission, and reduced vibrations. These advantages make helical gears a popular choice in various industrial applications where performance, durability, and reliability are crucial.

editor by CX 2024-04-26

China Standard Low Price Bevel Helical Gear Box Speed Electric Gearmotor Reducer Machine Gearbox with OEM Custom best automatic gearbox

Product Description

K187 gear reducer motor 45KW 55KW 90 degree high quality helical bevel gear

Product Description

Product Description

-K Series Helical Bevel Gearbox

K series gear reducer, manufactured according to international technical requirements, has a high scientific and technological content; Space saving, reliable and durable, high overload capacity, power up to 132KW; Low energy consumption, superior performance, reducer efficiency up to 95%

It is designed and manufactured on the basis of module combination system. There are a lot of motor combinations, installation forms and structural schemes. The transmission ratio is classified carefully to meet different operating conditions and realize electromechanical integration.

High transmission efficiency, low energy consumption and superior performance.

Reinforced high rigid cast iron box; The hardened gear is made of high-quality alloy steel. Its surface is carburized, quenched and hardened, and the gear is finely ground. It features stable transmission, low noise, large bearing capacity, low temperature rise, and long service life. Performance and characteristics:

1. The gear is carburized and quenched with high-quality alloy, the hardness of the tooth surface is up to 60 ± 2hrc, and the grinding accuracy of the tooth surface is up to 5-6

2. The computer modification technology is used to pre modify the gear, which greatly improves the bearing capacity of the reducer

3. Complete modular structure design is adopted from the box to the internal gear, which is suitable for large-scale production and flexible selection

4. The standard reducer models are divided according to the form of decreasing torque. Compared with the traditional equal proportion division, they are more in line with customer requirements and avoid power waste

5. It is designed and manufactured by cad/cam to ensure the stability of quality

6. Multiple sealing structures are adopted to prevent oil leakage

7. Multi directional noise reduction measures to ensure the excellent low noise performance of the reducer

8. The installation mode of Liyi products is flexible, which makes it easy for customers to choose K57 reducer, K67 reducer, K77 reducer, K87 reducer, K97 reducer, KA87 reducer, KA97 reducer, KA107 reducer, KA127 reducer

Product Features

1. Input mode: Coupled motor, belted motor, input shaft or connection flange.

2. Output: Right angle

3. Compact structure. Rigid tooth face. Carrying greater torque, high loading capacity.

4.High precision gear, ensuring the unit to operate stably, smooth transmission.

5. Low noise, long lifespan. Large overlap coefficient, abrasion resistant.

Product Parameters

|

Brand Name |

CZPT |

|

Product Name |

K Helical-bevel gear units |

|

Material |

Steel or cast iron |

|

Weight |

11Kg-1700Kg |

|

Color |

Customizable |

|

Heat treatment |

Carburising,Quenching,Gear Grinding |

|

Advantage |

1.K series spiral bevel gear reducer with small vibration, low noise, energy saving. 2.Selection of high quality steel material, steel cast iron box, gear surface after high frequency heat treatment. |

K series product performance

High transmission efficiency, low energy consumption and superior performance. High rigidity cast iron box with ribs; hard-toothed gears are made of high-quality alloy steel, the surface is carburized and quenched and hardened, and the teeth are finely machined, with stable transmission, low noise, large bearing capacity, low temperature rise and long service life.

Our process of production

Our product line

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | 90 Degree |

| Layout: | Expansion |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | |

|---|

Using Helical Gearboxes for Speed Reduction and Speed Increase

Yes, helical gearboxes can be used for both speed reduction and speed increase in various applications. The design of helical gears allows them to transmit motion and power between non-parallel shafts while changing the rotational speed.

Speed Reduction: When the driving gear (pinion) has fewer teeth than the driven gear, the gear ratio leads to speed reduction. This is commonly used in applications where the input speed needs to be decreased while increasing the output torque. For example, helical gearboxes are often employed in conveyor systems to reduce the speed of the motor while maintaining sufficient torque to move heavy loads.

Speed Increase: Helical gearboxes can also achieve speed increase by having the driving gear (pinion) with more teeth than the driven gear. This configuration is less common but can be used to increase the output speed while sacrificing some torque. Speed increase applications are typically seen in scenarios where higher speeds are required, such as in certain types of machinery or industrial processes.

It’s important to note that while helical gearboxes can perform both speed reduction and speed increase, the specific gear ratios and configurations need to be carefully chosen to ensure efficient and reliable operation for the intended application.

Impact of Thermal Expansion on Helical Gearbox Performance

Thermal expansion can significantly affect the performance of helical gearboxes due to changes in dimensions and clearances caused by temperature variations. Here’s how it impacts:

1. Misalignment: Temperature changes can lead to differential expansion of gearbox components. This can result in misalignment of gears, shafts, and bearings, leading to increased friction, noise, and reduced efficiency.

2. Lubrication: Thermal expansion can alter the clearances within the gearbox, affecting the distribution and viscosity of the lubricating oil. Inadequate lubrication due to temperature-induced changes can result in increased wear and premature failure.

3. Gear Tooth Engagement: Temperature fluctuations can cause gear teeth to expand or contract, affecting the meshing engagement and load distribution. Inconsistent gear tooth contact can lead to uneven wear and reduced gear life.

4. Bearing Performance: Bearings in helical gearboxes are sensitive to temperature changes. Excessive heat can lead to reduced bearing life, increased friction, and potential seizure, affecting overall gearbox performance.

5. Noise and Vibration: Thermal expansion can lead to changes in gear and component clearances, resulting in altered vibration patterns and increased noise levels. This can impact the comfort of the system and indicate potential issues.

6. Material Fatigue: Repeated cycles of thermal expansion and contraction can lead to material fatigue and stress accumulation, reducing the overall lifespan of gearbox components.

Managing Thermal Effects: Manufacturers design helical gearboxes with considerations for thermal expansion, using materials with low coefficients of thermal expansion and incorporating features like expansion joints or thermal isolators. Proper lubrication, monitoring temperature, and maintaining consistent operating conditions are also crucial in mitigating thermal expansion effects.

Understanding and managing the impact of thermal expansion is essential to maintain the performance, efficiency, and durability of helical gearboxes.

Limitations and Disadvantages of Helical Gear Systems

While helical gear systems offer numerous advantages, they also come with certain limitations and disadvantages:

- Axial Thrust: Helical gears generate axial thrust due to the helix angle of the teeth. This thrust can cause additional load on bearings and may require additional measures to counteract.

- Complex Manufacturing: The manufacturing process for helical gears is more complex than that of straight-toothed gears, which can lead to higher production costs.

- Axial Length: Helical gears require more axial space compared to spur gears with the same gear ratio. This can be a limitation in applications with space constraints.

- Sliding Contact: Helical gears have sliding contact between their teeth, which can result in higher friction and more heat generation compared to rolling contact gears.

- Efficiency: Although helical gears are generally efficient, their efficiency can be slightly lower than that of some other gear types, especially at high speeds.

- Complexity in Gearbox Design: The inclination of helical gear teeth introduces additional complexity in gearbox design and alignment.

- Reverse Thrust: In some cases, reverse thrust can occur when helical gears are subjected to high axial loads, leading to undesirable effects.

It’s important to consider these limitations and disadvantages when selecting gear systems for specific applications. Despite these challenges, helical gears remain a popular choice in various industries due to their benefits and overall performance characteristics.

editor by CX 2024-04-24

China factory Right-Angle Gear Units S Seires Helical Bevel Gearbox for Conveyor automatic gearbox

Product Description

Right-Angle Gear Units S Seires Helical Bevel Gearbox for Conveyor

Technical data

| Product Name |

Right-Angle Gear Units S Seires Helical Bevel Gearbox for Conveyor |

| Power | 0.12KW~30KW |

| Nominal output torque | 9~ 8425N · m |

| Output speed | 0.1 ~ 374r/min |

| Gear material | 20CrMnTi alloy steel |

| Gear Processing | Grinding finish by HOFLER Grinding Machines |

| Noise Test | Below 65dB |

| Brand of bearings | C&U bearing, ZWZ, LYC, HRB, CZPT , etc |

| Brand of oil seal | NAK or other brand |

| Temp. rise (MAX) | 40ºC |

| Temp. rise (Oil)(MAX | 50ºC |

| Vibration | ≤20µm |

| Housing hardness | HBS190-240 |

| Surface hardness of gears | HRC58°~62 ° |

| Gear core hardness | HRC33~40 |

| Machining precision of gears | 5 Grade |

| Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

| Heat treatment | Carburizing, Quenching etc |

| Efficiency | 95%~96% (depends on the transmission stage) |

| Bearing output mode | Parallel output |

| Installation type and output mode | Bottom seated type flange type installation, solid,hollow shaft output. |

| Input mode | Direct motor, shaft input and connecting flange input |

| Input Method | Flange input(AM), shaft input(AD), inline AC motor input, or AQA servo motor |

Installation Instructions

Company Profile

< WORKSHOP

< QUALITY CONTROL

Certifications

Packaging & Shipping

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of reducer.

Q 2:Can you do OEM?

A:Yes, we can. We can do OEM for all the customers .if you want to order NON-STANDERD speed reducers,pls provide Drafts, Dimensions, Pictures and Samples if possible.

Q 3: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 4: Do you have inspection procedures for reducer?

A:100% self-inspection before packing.

Q 5: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 6:How to choose a gearbox? What if I don’t know which gear reducer I need?

A:You can refer to our catalogue to choose the gearbox or we can help to choose when you provide,the technical information of required output torque, output speed and motor parameter etc. Don’t worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q 7: What information shall we give before placing a purchase order?

A:a) Type of the gearbox, Size , Transmission Ratio, input and output type, input flange, mounting position, motor information and shaft deflection etc. b)Housing color.c) Purchase quantity. d) Other special requirements

Q 8:What is the payment term?

A:You can pay via T/T(30% in advance as deposit before production +70% before delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Vertical Output |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Role of Helical Gearboxes in Automotive Transmissions

Helical gearboxes play a crucial role in automotive transmissions, contributing to the efficient power transfer and smooth operation of vehicles:

- Power Transmission: Helical gearboxes are used to transmit power from the engine to the wheels through different gear ratios. They help in converting the high-speed, low-torque output of the engine into the appropriate speed and torque for the wheels.

- Smooth Shifting: In manual and automatic transmissions, helical gears are often used to provide smooth and quiet gear shifts. The gradual engagement of helical gear teeth helps in reducing the shock and noise associated with gear changes.

- Noise Reduction: Helical gears are known for their quieter operation compared to other gear types. This is especially important in automotive applications where minimizing noise and vibration is desired for a comfortable driving experience.

- Efficiency: The efficiency of helical gearboxes helps in optimizing fuel efficiency and reducing energy losses. This is crucial for improving the overall performance and economy of vehicles.

- Load Distribution: Helical gears distribute the load over multiple teeth, reducing wear and ensuring the gearbox’s longevity. This is important in vehicles that experience varying loads and driving conditions.

- Torque Handling: Helical gears can handle higher torque loads compared to some other gear types. This is essential for vehicles, especially those with powerful engines, towing capabilities, or off-road use.

In modern automotive transmissions, helical gearboxes can be found in various components, including the main transmission, differential, and gearbox synchronizers. They contribute to the smooth operation, improved fuel efficiency, and overall performance of vehicles. The design and arrangement of helical gears can be tailored to meet the specific requirements of different vehicle types, making them a versatile choice for automotive applications.

Handling Shock Loads and Sudden Changes in Torque in Helical Gearboxes

Helical gearboxes are designed to handle a range of operational conditions, including shock loads and sudden changes in torque. The helical design of the gears, which have slanted teeth that engage gradually, helps to distribute forces more evenly across the teeth compared to straight-cut gears. This design characteristic contributes to the gearbox’s ability to withstand sudden changes in torque and shock loads.

The gradual engagement of the helical teeth results in smoother and quieter operation, reducing the impact of abrupt torque changes. The slanted teeth also allow for more gradual transmission of force, which helps in dampening vibrations and minimizing stress concentrations that can occur in high-impact situations.

However, while helical gears are better suited for shock loads compared to straight-cut gears, it’s important to note that extreme shock loads or sudden torque changes can still impact the gearbox’s components over time. Manufacturers often take factors such as application requirements, load profiles, and anticipated shock loads into consideration when designing helical gearboxes to ensure reliable and durable performance.

Additionally, using appropriate lubrication and maintenance practices can further enhance the gearbox’s ability to handle shock loads and sudden torque changes. Regular inspection and timely maintenance help identify and address potential issues before they lead to component failure.

Helical Gear Meshing and Its Benefits

Helical gear meshing refers to the engagement of two helical gears with inclined teeth. The teeth are cut at an angle to the gear axis, creating a helix shape. When these gears mesh, the inclined teeth gradually come into contact, allowing for smoother and quieter operation compared to straight-toothed gears.

The benefits of helical gear meshing include:

- Reduced Noise: The gradual contact between helical gear teeth minimizes impact and noise during engagement, resulting in quieter operation. This is particularly advantageous in applications where noise reduction is essential, such as industrial machinery and automotive transmissions.

- Smooth Operation: Helical gears provide smoother and more continuous motion due to the gradual engagement of teeth. This feature makes them suitable for applications that require precise and controlled movement, such as CNC machines and conveyor systems.

- Higher Load Capacity: The helical tooth geometry allows for greater tooth contact area, distributing the load over a larger surface. This results in higher load-carrying capacity and improved durability, making helical gears suitable for heavy-duty applications.

- Efficient Power Transmission: Helical gears transmit power more efficiently due to their smooth engagement and increased contact area. This efficiency contributes to reduced energy consumption and heat generation in gearboxes.

- Less Vibrations: The gradual meshing of helical gears reduces vibrations, resulting in smoother operation and reduced wear and tear on gear teeth and bearings. This is especially important for extending the lifespan of the gearbox.

Overall, helical gear meshing offers numerous benefits, including reduced noise, smoother operation, higher load capacity, efficient power transmission, and reduced vibrations. These advantages make helical gears a popular choice in various industrial applications where performance, durability, and reliability are crucial.

editor by CX 2024-04-17

China Best Sales The Manufacturer Provides Four Major Series of K Series Spiral Bevel Gear Hard Tooth Reducer Gearboxes for Heavy Industry Use K Series Helical Bevel Gearbox gearbox drive shaft

Product Description

Product Description

-K Series Helical Bevel Gearbox

K series gear reducer, manufactured according to international technical requirements, has a high scientific and technological content; Space saving, reliable and durable, high overload capacity, power up to 132KW; Low energy consumption, superior performance, reducer efficiency up to 95%

It is designed and manufactured on the basis of module combination system. There are a lot of motor combinations, installation forms and structural schemes. The transmission ratio is classified carefully to meet different operating conditions and realize electromechanical integration.

High transmission efficiency, low energy consumption and superior performance.

Reinforced high rigid cast iron box; The hardened gear is made of high-quality alloy steel. Its surface is carburized, quenched and hardened, and the gear is finely ground. It features stable transmission, low noise, large bearing capacity, low temperature rise, and long service life. Performance and characteristics:

1. The gear is carburized and quenched with high-quality alloy, the hardness of the tooth surface is up to 60 ± 2hrc, and the grinding accuracy of the tooth surface is up to 5-6

2. The computer modification technology is used to pre modify the gear, which greatly improves the bearing capacity of the reducer

3. Complete modular structure design is adopted from the box to the internal gear, which is suitable for large-scale production and flexible selection

4. The standard reducer models are divided according to the form of decreasing torque. Compared with the traditional equal proportion division, they are more in line with customer requirements and avoid power waste

5. It is designed and manufactured by cad/cam to ensure the stability of quality

6. Multiple sealing structures are adopted to prevent oil leakage

7. Multi directional noise reduction measures to ensure the excellent low noise performance of the reducer

8. The installation mode of Liyi products is flexible, which makes it easy for customers to choose K57 reducer, K67 reducer, K77 reducer, K87 reducer, K97 reducer, KA87 reducer, KA97 reducer, KA107 reducer, KA127 reducer

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Marine, Agricultural Machinery, Car, Packing Machine, Food Process, Lift, Crane, Agita |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | 90 Degree |

| Layout: | Expansion |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Samples: |

US$ 800/Piece

1 Piece(Min.Order) | |

|---|

Role of Helical Gearboxes in Automotive Transmissions

Helical gearboxes play a crucial role in automotive transmissions, contributing to the efficient power transfer and smooth operation of vehicles:

- Power Transmission: Helical gearboxes are used to transmit power from the engine to the wheels through different gear ratios. They help in converting the high-speed, low-torque output of the engine into the appropriate speed and torque for the wheels.

- Smooth Shifting: In manual and automatic transmissions, helical gears are often used to provide smooth and quiet gear shifts. The gradual engagement of helical gear teeth helps in reducing the shock and noise associated with gear changes.

- Noise Reduction: Helical gears are known for their quieter operation compared to other gear types. This is especially important in automotive applications where minimizing noise and vibration is desired for a comfortable driving experience.

- Efficiency: The efficiency of helical gearboxes helps in optimizing fuel efficiency and reducing energy losses. This is crucial for improving the overall performance and economy of vehicles.

- Load Distribution: Helical gears distribute the load over multiple teeth, reducing wear and ensuring the gearbox’s longevity. This is important in vehicles that experience varying loads and driving conditions.

- Torque Handling: Helical gears can handle higher torque loads compared to some other gear types. This is essential for vehicles, especially those with powerful engines, towing capabilities, or off-road use.

In modern automotive transmissions, helical gearboxes can be found in various components, including the main transmission, differential, and gearbox synchronizers. They contribute to the smooth operation, improved fuel efficiency, and overall performance of vehicles. The design and arrangement of helical gears can be tailored to meet the specific requirements of different vehicle types, making them a versatile choice for automotive applications.

Handling Shock Loads and Sudden Changes in Torque in Helical Gearboxes

Helical gearboxes are designed to handle a range of operational conditions, including shock loads and sudden changes in torque. The helical design of the gears, which have slanted teeth that engage gradually, helps to distribute forces more evenly across the teeth compared to straight-cut gears. This design characteristic contributes to the gearbox’s ability to withstand sudden changes in torque and shock loads.

The gradual engagement of the helical teeth results in smoother and quieter operation, reducing the impact of abrupt torque changes. The slanted teeth also allow for more gradual transmission of force, which helps in dampening vibrations and minimizing stress concentrations that can occur in high-impact situations.

However, while helical gears are better suited for shock loads compared to straight-cut gears, it’s important to note that extreme shock loads or sudden torque changes can still impact the gearbox’s components over time. Manufacturers often take factors such as application requirements, load profiles, and anticipated shock loads into consideration when designing helical gearboxes to ensure reliable and durable performance.

Additionally, using appropriate lubrication and maintenance practices can further enhance the gearbox’s ability to handle shock loads and sudden torque changes. Regular inspection and timely maintenance help identify and address potential issues before they lead to component failure.

Handling High Torque and Heavy Loads in Helical Gearboxes

Helical gearboxes are well-suited for handling high torque and heavy loads due to their unique design and meshing characteristics:

- Helical Teeth: The helical shape of the gear teeth allows for gradual and continuous contact between the teeth during meshing. This results in smoother load distribution and reduced impact forces, making helical gears capable of handling heavy loads.

- Multiple Tooth Contact: Helical gears have multiple teeth in contact at any given time, spreading the load over a larger area of gear teeth. This helps to distribute the load evenly and prevent localized wear and stress concentrations.

- Increased Tooth Strength: The inclined orientation of helical gear teeth increases the tooth width, leading to greater tooth strength and improved load-carrying capacity.

- Bearings and Shaft Design: The gearbox housing is designed to support heavy loads and provide proper alignment for the shafts and bearings. High-quality bearings and shafts help distribute the load and reduce wear.

- Lubrication: Adequate lubrication is crucial to minimize friction and heat generation between gear teeth. Proper lubrication also helps to dissipate heat generated by the heavy loads.

- Material Selection: High-strength materials with good wear resistance properties are chosen for helical gears to ensure they can withstand the demands of heavy loads.

Overall, the gradual engagement of helical gear teeth and their ability to handle multiple tooth contact positions them as a reliable choice for applications that require high torque and can handle heavy loads. Engineers carefully design helical gearboxes to ensure they can withstand the stresses imposed by the application’s specific requirements.

editor by CX 2024-04-13

China factory High Torque K Series Helical Bevel Gear Motor Reduction Gearbox K Series Gearbox differential gearbox

Product Description

Product Description

-K Series Helical Bevel Gearbox

K series gear reducer, manufactured according to international technical requirements, has a high scientific and technological content; Space saving, reliable and durable, high overload capacity, power up to 132KW; Low energy consumption, superior performance, reducer efficiency up to 95%

It is designed and manufactured on the basis of module combination system. There are a lot of motor combinations, installation forms and structural schemes. The transmission ratio is classified carefully to meet different operating conditions and realize electromechanical integration.

High transmission efficiency, low energy consumption and superior performance.

Reinforced high rigid cast iron box; The hardened gear is made of high-quality alloy steel. Its surface is carburized, quenched and hardened, and the gear is finely ground. It features stable transmission, low noise, large bearing capacity, low temperature rise, and long service life. Performance and characteristics:

1. The gear is carburized and quenched with high-quality alloy, the hardness of the tooth surface is up to 60 ± 2hrc, and the grinding accuracy of the tooth surface is up to 5-6

2. The computer modification technology is used to pre modify the gear, which greatly improves the bearing capacity of the reducer

3. Complete modular structure design is adopted from the box to the internal gear, which is suitable for large-scale production and flexible selection

4. The standard reducer models are divided according to the form of decreasing torque. Compared with the traditional equal proportion division, they are more in line with customer requirements and avoid power waste

5. It is designed and manufactured by cad/cam to ensure the stability of quality

6. Multiple sealing structures are adopted to prevent oil leakage

7. Multi directional noise reduction measures to ensure the excellent low noise performance of the reducer

8. The installation mode of Liyi products is flexible, which makes it easy for customers to choose K57 reducer, K67 reducer, K77 reducer, K87 reducer, K97 reducer, KA87 reducer, KA97 reducer, KA107 reducer, KA127 reducer

Product Features

1. Input mode: Coupled motor, belted motor, input shaft or connection flange.

2. Output: Right angle

3. Compact structure. Rigid tooth face. Carrying greater torque, high loading capacity.

4.High precision gear, ensuring the unit to operate stably, smooth transmission.

5. Low noise, long lifespan. Large overlap coefficient, abrasion resistant.

Shaft gear box speed reducer high efficiency and stable operationGear box speed reducer gearbox with small vibration and low noise

Speed ratio is wide and the grading is fine

Gear reducer box Installation method variety

Detailed Photos

Our product line

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | 90 Degree |

| Layout: | Expansion |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | |

|---|

Installation and Alignment of Helical Gearboxes

Proper installation and alignment of a helical gearbox are essential to ensure its optimal performance and longevity. Here are the steps involved:

- Preparation: Gather all necessary tools, equipment, and safety gear. Ensure the work area is clean and well-lit.

- Mounting: Position the gearbox on the designated mounting surface and secure it using appropriate bolts. Follow the manufacturer’s guidelines for mounting torque and procedures.

- Shaft Alignment: Use precision tools such as dial indicators to align the input and output shafts. Achieving accurate shaft alignment minimizes stress on the gears and bearings.

- Bolt Tightening: Gradually and evenly tighten the mounting bolts, ensuring the gearbox remains properly aligned. Refer to torque specifications provided by the manufacturer.

- Lubrication: Fill the gearbox with the recommended lubricant according to the manufacturer’s specifications. Proper lubrication is crucial for reducing friction and wear.

- Alignment Check: After tightening the bolts, recheck the shaft alignment to ensure it hasn’t shifted during the tightening process.

- Run-In Period: Gradually introduce load to the gearbox to allow the gears to seat properly. Monitor the gearbox for any unusual noises, vibrations, or temperature changes during this period.

- Final Checks: Verify that the gearbox operates smoothly, without excessive noise or vibrations. Monitor the gearbox’s temperature during operation to ensure it remains within recommended limits.

- Regular Inspection: Schedule periodic inspections to check for any signs of wear, misalignment, or leakage. Address any issues promptly to prevent further damage.

It’s important to follow the manufacturer’s installation and alignment guidelines specific to the helical gearbox model you’re working with. Improper installation and alignment can lead to premature wear, reduced efficiency, and potential failure of the gearbox.

Helical Gearboxes and Energy Efficiency

Helical gearboxes play a significant role in enhancing energy efficiency in various industrial processes. Their design and operating characteristics contribute to improved efficiency and reduced energy consumption. Here’s how helical gearboxes achieve energy efficiency:

- Helical Gear Meshing: Helical gears have inclined teeth that engage gradually, resulting in smoother and quieter meshing compared to other gear types. This smoother engagement reduces impact and friction losses, leading to higher efficiency and lower energy consumption.

- Load Distribution: Helical gears distribute the load across multiple teeth due to their helix angle. This even load distribution minimizes stress concentrations and prevents premature wear, ensuring efficient power transmission and reducing the need for frequent maintenance.

- Efficient Power Transmission: The inclined tooth profile of helical gears allows for more teeth to be in contact at any given time. This increased contact area improves power transmission efficiency by reducing sliding friction and minimizing energy losses.

- Reduced Vibration: The helical tooth engagement minimizes vibration and noise levels, which can be particularly advantageous in applications that require precise and stable operation. Reduced vibration translates to lower energy losses and increased overall efficiency.