Product Description

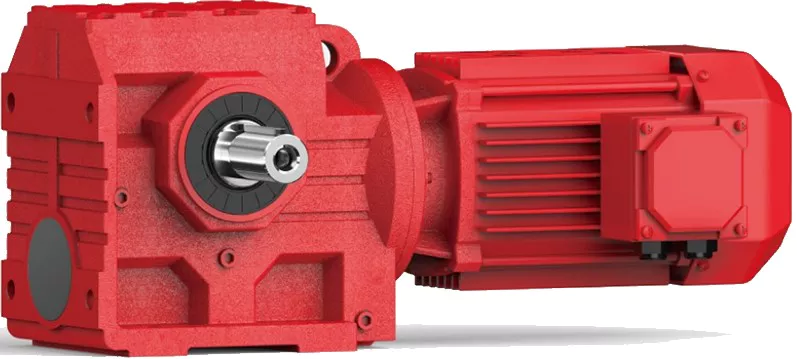

R Series Inline Helical 2 double stage Speed Reducer output 30 rpm Gearbox

Product Description

>Click Here To Cotact<

Product Advantages

Company Information

Certificate

Main Products

Global Exhibition

|

Brand |

WUMA |

|

|

|

|||

|

Housing |

Three type |

|

|

|

|||

|

Nameplate |

WUMA or Customize |

|

|

|

|||

|

Reducer |

worm gearbox,helical gearbox, hypoid gearbox,planetary gearbox and variator etc. |

|

|

|

|||

FAQ

1 . How to choose a gearbox which meets our requirement?

You can refer to our catalogue to choose the gearbox or we can help to choose when you provide

the technical information of required output torque, output speed and motor parameter etc.

2. What information shall we give before placing a purchase order?

a) Type of the gearbox, ratio, input and output type, input flange, mounting position, and motor informationetc.

b) Housing color.

c) Purchase quantity.

d) Other special requirements.

3. What industries are your gearboxes being used?

Our gearboxes are widely used in the areas of textile, food processing, beverage, chemical industry,

escalator,automatic storage equipment, metallurgy, tabacco, environmental protection, logistics and etc.

4. Doyou sell motors?

We have stable motor suppliers who have been coperating with us for a long-time. They can provide motors

with high quality.

>Return Home<

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Types of Helical Gear Arrangements

Yes, there are different types of helical gear arrangements available to suit various applications and requirements. Some of the common helical gear arrangements include:

Parallel Shaft Arrangement: In this arrangement, the axes of the driving and driven shafts are parallel to each other. It is the most straightforward configuration and is often used in applications where space is not a constraint, and the gearboxes can be placed side by side.

Right-Angle Shaft Arrangement: In a right-angle arrangement, the driving and driven shafts are positioned at a 90-degree angle to each other. This arrangement is space-saving and is commonly used in applications where the layout requires a change in direction of the power transmission.

Double Helical Gear Arrangement (Herringbone Gears): Double helical gears consist of two sets of helical teeth facing each other. This arrangement helps to cancel out axial forces and reduces the net thrust load on bearings. It is often used in heavy-duty applications to minimize wear and vibration.

Crossed Helical Gear Arrangement (Screw Gears): In this configuration, the axes of the driving and driven shafts are neither parallel nor intersecting. It is suitable for applications requiring non-parallel and non-intersecting shafts.

The choice of helical gear arrangement depends on factors such as available space, power transmission requirements, and the desired layout of the machinery or equipment. Each arrangement has its advantages and disadvantages, and selecting the appropriate one is crucial for achieving optimal performance and efficiency.

Software Tools for Simulating Helical Gear Behavior

Several software tools are available for simulating the behavior of helical gears under different conditions. These tools aid engineers in designing and analyzing helical gear systems for optimal performance and reliability. Some notable software tools include:

- KISSsoft: KISSsoft is a widely used software for the design and analysis of mechanical components, including helical gears. It offers comprehensive calculations for gear geometry, load distribution, contact stresses, and more. The software assists in optimizing gear designs and predicting their behavior under various operating conditions.

- AGMA Rating Suite: The American Gear Manufacturers Association (AGMA) offers software tools that follow AGMA standards for gear design and analysis. These tools provide accurate calculations for gear rating, efficiency, and durability under different load scenarios.

- ANSYS Mechanical: ANSYS Mechanical is a versatile simulation software used for finite element analysis (FEA) of mechanical systems, including helical gears. It allows engineers to perform detailed stress and deformation analysis, simulate contact patterns, and assess the effects of different loads and boundary conditions.

- Gleason CAGE: Gleason’s Computer-Aided Gear Engineering (CAGE) software specializes in gear design and optimization. It offers advanced tools for gear tooth profile generation, simulation of meshing behavior, and optimization of gear parameters.

- MAGMA Soft: MAGMA Soft provides casting simulation software that can be used to predict the solidification behavior and mechanical properties of casted gear components, which is essential for ensuring quality and performance.

- Siemens NX: Siemens NX software includes gear design and analysis capabilities, allowing engineers to simulate gear behavior, calculate load distribution, and optimize gear designs within a comprehensive CAD/CAE environment.

These software tools enable engineers to model and analyze helical gears in a virtual environment, helping them make informed design decisions, optimize gear geometry, and assess gear performance under different conditions. By utilizing these tools, engineers can create reliable and efficient helical gear systems for various industrial applications.

Lubrication Requirements for Maintaining Helical Gearboxes

Lubrication is essential for the proper functioning and longevity of helical gearboxes. The lubrication requirements include:

- Viscosity: Selecting a lubricant with the appropriate viscosity is crucial. The viscosity should provide sufficient lubrication and ensure a protective film between gear teeth under varying operating conditions.

- Extreme Pressure (EP) Properties: Helical gears often experience high contact pressures. Lubricants with EP additives form a protective barrier that prevents metal-to-metal contact and reduces wear.

- Oil Additives: Anti-wear additives, antioxidants, and corrosion inhibitors enhance the lubricant’s performance and protect gears from wear and degradation.

- Frequent Inspections: Regularly inspect the lubricant’s condition to detect contamination, degradation, or depletion. Scheduled oil analysis can help monitor the health of the lubricant.

- Proper Lubricant Application: Ensure the gearbox is properly filled with the correct amount of lubricant. Follow manufacturer recommendations for lubricant type and quantity.

- Lubricant Change Intervals: Establish regular lubricant change intervals based on operating conditions. Extreme conditions or heavy loads may require more frequent changes.

Appropriate lubrication minimizes friction, wear, and heat generation, leading to improved efficiency, reduced maintenance, and extended gearbox life. It’s crucial to follow the manufacturer’s guidelines and consult with lubrication experts to select the right lubricant and maintenance practices for your specific helical gearbox application.

editor by CX 2024-04-17

China factory High Torque K Series Helical Bevel Gear Motor Reduction Gearbox K Series Gearbox differential gearbox

Product Description

Product Description

-K Series Helical Bevel Gearbox

K series gear reducer, manufactured according to international technical requirements, has a high scientific and technological content; Space saving, reliable and durable, high overload capacity, power up to 132KW; Low energy consumption, superior performance, reducer efficiency up to 95%

It is designed and manufactured on the basis of module combination system. There are a lot of motor combinations, installation forms and structural schemes. The transmission ratio is classified carefully to meet different operating conditions and realize electromechanical integration.

High transmission efficiency, low energy consumption and superior performance.

Reinforced high rigid cast iron box; The hardened gear is made of high-quality alloy steel. Its surface is carburized, quenched and hardened, and the gear is finely ground. It features stable transmission, low noise, large bearing capacity, low temperature rise, and long service life. Performance and characteristics:

1. The gear is carburized and quenched with high-quality alloy, the hardness of the tooth surface is up to 60 ± 2hrc, and the grinding accuracy of the tooth surface is up to 5-6

2. The computer modification technology is used to pre modify the gear, which greatly improves the bearing capacity of the reducer

3. Complete modular structure design is adopted from the box to the internal gear, which is suitable for large-scale production and flexible selection

4. The standard reducer models are divided according to the form of decreasing torque. Compared with the traditional equal proportion division, they are more in line with customer requirements and avoid power waste

5. It is designed and manufactured by cad/cam to ensure the stability of quality

6. Multiple sealing structures are adopted to prevent oil leakage

7. Multi directional noise reduction measures to ensure the excellent low noise performance of the reducer

8. The installation mode of Liyi products is flexible, which makes it easy for customers to choose K57 reducer, K67 reducer, K77 reducer, K87 reducer, K97 reducer, KA87 reducer, KA97 reducer, KA107 reducer, KA127 reducer

Product Features

1. Input mode: Coupled motor, belted motor, input shaft or connection flange.

2. Output: Right angle

3. Compact structure. Rigid tooth face. Carrying greater torque, high loading capacity.

4.High precision gear, ensuring the unit to operate stably, smooth transmission.

5. Low noise, long lifespan. Large overlap coefficient, abrasion resistant.

Shaft gear box speed reducer high efficiency and stable operationGear box speed reducer gearbox with small vibration and low noise

Speed ratio is wide and the grading is fine

Gear reducer box Installation method variety

Detailed Photos

Our product line

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | 90 Degree |

| Layout: | Expansion |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | |

|---|

Installation and Alignment of Helical Gearboxes

Proper installation and alignment of a helical gearbox are essential to ensure its optimal performance and longevity. Here are the steps involved:

- Preparation: Gather all necessary tools, equipment, and safety gear. Ensure the work area is clean and well-lit.

- Mounting: Position the gearbox on the designated mounting surface and secure it using appropriate bolts. Follow the manufacturer’s guidelines for mounting torque and procedures.

- Shaft Alignment: Use precision tools such as dial indicators to align the input and output shafts. Achieving accurate shaft alignment minimizes stress on the gears and bearings.

- Bolt Tightening: Gradually and evenly tighten the mounting bolts, ensuring the gearbox remains properly aligned. Refer to torque specifications provided by the manufacturer.

- Lubrication: Fill the gearbox with the recommended lubricant according to the manufacturer’s specifications. Proper lubrication is crucial for reducing friction and wear.

- Alignment Check: After tightening the bolts, recheck the shaft alignment to ensure it hasn’t shifted during the tightening process.

- Run-In Period: Gradually introduce load to the gearbox to allow the gears to seat properly. Monitor the gearbox for any unusual noises, vibrations, or temperature changes during this period.

- Final Checks: Verify that the gearbox operates smoothly, without excessive noise or vibrations. Monitor the gearbox’s temperature during operation to ensure it remains within recommended limits.

- Regular Inspection: Schedule periodic inspections to check for any signs of wear, misalignment, or leakage. Address any issues promptly to prevent further damage.

It’s important to follow the manufacturer’s installation and alignment guidelines specific to the helical gearbox model you’re working with. Improper installation and alignment can lead to premature wear, reduced efficiency, and potential failure of the gearbox.

Helical Gearboxes and Energy Efficiency

Helical gearboxes play a significant role in enhancing energy efficiency in various industrial processes. Their design and operating characteristics contribute to improved efficiency and reduced energy consumption. Here’s how helical gearboxes achieve energy efficiency:

- Helical Gear Meshing: Helical gears have inclined teeth that engage gradually, resulting in smoother and quieter meshing compared to other gear types. This smoother engagement reduces impact and friction losses, leading to higher efficiency and lower energy consumption.

- Load Distribution: Helical gears distribute the load across multiple teeth due to their helix angle. This even load distribution minimizes stress concentrations and prevents premature wear, ensuring efficient power transmission and reducing the need for frequent maintenance.

- Efficient Power Transmission: The inclined tooth profile of helical gears allows for more teeth to be in contact at any given time. This increased contact area improves power transmission efficiency by reducing sliding friction and minimizing energy losses.

- Reduced Vibration: The helical tooth engagement minimizes vibration and noise levels, which can be particularly advantageous in applications that require precise and stable operation. Reduced vibration translates to lower energy losses and increased overall efficiency.

- Optimized Gear Design: Engineers can fine-tune helical gear designs by adjusting parameters such as helix angle, number of teeth, and gear materials. This optimization process helps tailor the gearbox for specific applications, ensuring optimal efficiency and minimal energy wastage.

- Lubrication and Cooling: Proper lubrication and cooling strategies are crucial for maintaining efficiency. Helical gears benefit from efficient lubrication due to their continuous tooth engagement, which helps reduce friction and wear, further enhancing energy efficiency.

- Advanced Manufacturing: Modern manufacturing techniques enable precise production of helical gears, ensuring tight tolerances and accurate tooth profiles. This manufacturing precision contributes to minimal energy losses during gear operation.

Overall, helical gearboxes excel in energy efficiency by combining smoother tooth engagement, even load distribution, reduced vibration, and optimized designs. Their ability to transmit power efficiently and reliably makes them a preferred choice for industrial processes where energy conservation is a priority.

Advantages of Helical Gearboxes in Industrial Applications

Helical gearboxes offer several advantages that make them well-suited for a wide range of industrial applications. Here are some of the key advantages:

- Smooth and Quiet Operation: The helical design of the gears results in gradual tooth engagement, reducing noise and vibration during operation. This makes helical gearboxes ideal for applications where noise reduction is important.

- High Efficiency: Helical gears provide a larger contact area compared to straight-cut gears, leading to improved power transmission efficiency. The gradual engagement of teeth also reduces energy losses due to friction.

- Higher Load Capacity: The helical angle allows for multiple teeth to be engaged simultaneously, distributing the load across a larger area. This results in higher load-carrying capacity and increased durability of the gearbox.

- Compact Design: Helical gearboxes can achieve high gear ratios with fewer gear stages, leading to a more compact overall design. This is advantageous in applications where space is limited.

- Wide Range of Ratios: Helical gearboxes can achieve a wide range of gear ratios, making them versatile for various speed and torque requirements.

- Less Backlash: The gradual tooth engagement of helical gears results in reduced backlash, which is the play between gear teeth. This leads to improved accuracy and positioning in applications that require precise motion control.

- Heat Dissipation: The helical design allows for better heat dissipation due to the continuous contact between gear teeth. This is beneficial in high-speed applications where heat generation can be a concern.

- Highly Customizable: Helical gearboxes can be customized to meet specific application requirements, including input and output configurations, gear ratios, and mounting options.

Overall, the advantages of helical gearboxes make them a popular choice in industries such as manufacturing, automation, robotics, material handling, and more.

editor by CX 2024-04-12

China OEM custom professional manufacture KAT series precision gear motor with gearbox high torque speed reducer supplier

Guarantee: 1year, 1 calendar year

Relevant Industries: Producing Plant, Equipment Mend Retailers, Foods & Beverage Manufacturing unit, Farms, Design works , Energy & Mining

Weight (KG): fifty seven KG

Tailored help: OEM

Gearing Arrangement: Helical

Output Torque: 200-50000NM

Enter Speed: 300-1800rpm

Output Pace: .1-360rpm

Product title: k collection helical bevel reducer

Key word: helical bevel gearbox

Colour: as demonstrated

Content: Metal or solid iron

Model: KAT77

Equal merchandise: K collection equipment motor

Heat treatment: Carburising,Quenching,Equipment Grinding

Model: huake

Sort: Helical

Packaging Details: Packed in cartons or pallet, good efficiency vehicles and trucks Planetary gear AZor at your needs.

Port: HangZhou port

OEM custom professional manufacture KAT collection precision equipment motor with gearbox higher torque speed reducer K series gear reducer, manufactured in blend with worldwide technological specifications, has a higher technological content material place preserving, dependable and sturdy, substantial overload capacity, power up to 132KW minimal vitality usage, superior efficiency, Transmission Gearbox Vehicle Hiace 7CW For 3Y 4Y Engine With Mechanical Senso Hiace Parts reducer performance as high as much more than ninety five%.

| Brand Title | HUAKE |

| Product Name | K Helical-bevel gear units |

| Material | Steel or cast iron |

| Weight | 11Kg-1700Kg |

| Color | Customizable |

| Heat treatment method | Carburising,Quenching,Gear Grinding |

| Advantage | 1.K series spiral bevel equipment reducer with tiny vibration, lower noise, energy preserving.2.Variety of high good quality metal content, metal solid iron box, equipment surface after high frequency warmth remedy. |

The Different Types of Gearboxes

There are many different types of gearboxes. Some brands have more than one type. In this article, we’ll discuss the planetary gearbox, the worm reduction gearbox, the shaft mounted gearbox, and the one speed gearbox. This article will also help you determine which type of gearbox is best for your vehicle. And don’t worry if you don’t know the terminology yet. We’ll explain each type in detail so that you know what you’re getting yourself into.

Planetary gearbox

Planetary gears have many advantages. The multiple gears in a planetary gearbox mesh simultaneously during operation. As such, they provide high efficiency and transmit high transmittable torque. These gears are widely used in various industries and are resistant to high shock loads and demanding conditions. CZPT is one of the companies that offer planetary gearboxes. Its products do not require special tools for assembly, and its scalable design minimizes safety stock.

Among the numerous benefits of planetary gearing is its compactness and lightweight. As such, it is suitable for wide applications with space and weight constraints. However, to truly appreciate its benefits, it is necessary to understand its mechanisms. Here are some of the most common details about planetary gearing:

The planetary gearbox has two mounted gears: an input shaft and an output shaft. Each gear has multiple teeth that are attached to a carrier and rotate with the input shaft. The carrier is connected to the output shaft. A planetary gear is mounted on both gears via a carrier. The carrier rotates in order to drive the planetary gear. The sun gear is often the input gear. The other gear is called the outer gear.

Planetary gearboxes are highly customizable. The size, mounting, and housing options vary, as do the reduction ratios and input speeds. Different types can be manufactured for different applications and include options such as electrical or mechanical preload. The final design of a planetary gearbox can be highly customized, based on the specifications of the application. By combining engineering excellence and ongoing innovation, planetary gearboxes provide years of trouble-free operation.

A planetary gearbox can be either an electric motor or a manual one. The latter has more features than the former, and can be used in applications where space is an issue. The primary features of a planetary gearbox include its backlash, torque, and ratio. Secondary features include noise, corrosion resistance, and construction. A planetary gearbox is a highly versatile gearbox that can drive anything from simple machinery to advanced electrical systems.

Worm reduction gearbox

The global worm reduction gearbox market report compiles key insights from the industry to help you improve your business strategy. This report will help you create a comprehensive business document that will enhance your company’s competitive edge. To obtain this report, visit our website now! Read our latest report to find out what you can expect from the global worm reduction gearbox market. Alternatively, request a sample copy for more details. Here is a sneak peek of the report:

Worm gears are made with different thread counts and are usually not matched with the CZPT standard. In general, a single thread worm should be used with a single thread worm. Worm gears have either right or left threads, and their thread count will be different as well. This type of gear is used to reduce the speed of a rotating shaft. The speed reduction ratio will be about 50 percent if the worms have the same thread count as the CZPT gears.

The standard gear set transfers power at the peak load point of a tooth, called the pitchline. The worm gear moves slowly against the wheel’s metal surface. The worm gear is also more complex than the standard gear because the worm is sliding rather than rolling. Worm gears are hard to lubricate. Moreover, the sliding contact between the gear and worm increases the complexity of the gear set. They can be a great solution for applications where noise is a significant factor.

The axial pitch and circular pitch of the worm are equal. The ratio of these two indices determines the speed of transmission. For a worm reduction gearbox to work, the axial pitch and the circular pitch must match. The pitch angle of a worm can either be left-handed or right-handed. The lead of a worm is the distance one thread travels in one revolution. The lead angle is the angle tangent to the thread helix of the cylinder’s pitch. When a worm mesh is reversed, the majority of the mesh will be on the receding arc.

Worm gears generate more heat than their counterparts, so it is important to choose a worm reduction gearbox carefully. You will want to choose the material and amount of lubricating oil carefully. Worm gears are generally made of tin bronze. The paired worms are hardened to HRC45-55. In general, they are durable, lasting up to ten years. But they will wear out – and they wear out – so you may want to consider some other factors.

Shaft-mounted gearbox

Shaft-mounted gearboxes are designed for a variety of mining and quarry applications. Their high reliability and low maintenance make them an excellent choice in these types of applications. Shaft-mounted gearboxes also feature an optional backstop device that prevents the unit from rotating in one direction. This makes them an excellent choice for applications where alignment accuracy is an issue. Here are some of the benefits of using a shaft-mounted gearbox:

Shaft-mounted gearboxes are typically constructed of aluminium, and come in sizes ranging from 050 to 125. They feature a variety of reduction ratios and ensure optimum efficiency in all operating conditions. New S series sizes, 140 and 150, extend the application range of shaft-mounted gearmotors. They are both backed by a two-year warranty. For even greater peace of mind, Shaft-mounted gearboxes are available with a range of warranty options.

The most common applications for a Shaft-mounted gearbox include traction-driven applications where a low-speed shaft is required for operation. They also are suitable for applications without a foundation, where the motor is mounted next to the reducer. To prevent the gear drive from rotating, a torque arm is attached between the motor and the shaft. Small-sized shaft-mounted gear drives are usually made without motor mount kits, which can make them an excellent choice for conveying light loads.

Another important feature of a Shaft-mounted gearbox is its mounting position. The reduced motion through the drive is redirected through the shaft, creating additional forces. These additional forces can affect the performance of the gearbox, causing vibrations and noise. Consequently, it is important to replace worn or damaged belts on a regular basis. Further, shaft-mounted gearboxes can be affected by problems with other components and amplify vibrations.

1 speed gearbox

CZPT Group Components produces one speed gearboxes. These transmissions are produced in the CZPT Group’s Kassel plant. They are compact and robust, and are designed for easy integration. The Bosch Rexroth GD1 one-speed gearbox is easy to install horizontally or vertically. The Plug and Drive system integrates the gearbox with the existing cooling system. There are many other benefits to this gearbox.

With an ID.3 electric drive motor, the maximum torque is delivered at 16,000 rpm. This single-speed transmission offers high power density and excellent noise-reduction, making it ideal for electric vehicles. The e-drive motor is extremely quiet and requires precision manufacturing. The e-drive motor also enables a wide range of driving conditions. It can reverse when needed, and reaches its maximum speed at 16,000.

The single-speed gearbox is a standard feature on most electric vehicles. Some electric vehicles, such as the Porsche Taycan, will be equipped with a two-speed gearbox. This gearbox offers more top speed and range, but it is more complex than a standard single-speed gearbox. CZPT doesn’t need to add complexity to its electric vehicles. After all, a 355 horsepower family wagon is not likely to need a dual-speed gearbox.

In addition to simplifying the transmission, the patent claims also address improvements in structural design. Fig. 5 shows a schematic representation of a transmission 50′, wherein gear sets Z1 and Z4 are exchanged between partial transmissions. This switch matrix also reflects the synchronized gears and lastshelf gears. Hydraulically betatigte Lamellenkupplungen (HBA) also form a last-shelf gear.

Another advantage of the patent claim is that it offers numerous functional freedoms, which is especially valuable in the design of an automobile. One of the patent claims identifies a tosatzlicher middle gear that allows a driver to switch between second and third gears, with a single gearbox. In a conventional one-speed transmission, the tosatzlicher middle gear is attached to the second and first part gearbox. The latter has a second and third gear.

editor by czh2023-02-26

China Nema 34 Stepper Motor Speed Gear Reducer Inline Precision High Torque Planetary Gearbox Round Body VRL synchromesh gearbox

Applicable Industries: Garment Shops, Constructing Material Stores, Producing Plant, Machinery Restore Outlets, Foods & Beverage Manufacturing unit, Farms, Retail, Food Shop, Printing Outlets, Design works , Strength & Mining, Meals & Beverage Stores

Gearing Arrangement: Planetary

Output Torque: ten-2100Nm

Input Pace: dependent on motor

Output Speed: dependent on ratio

Software: Textile, Boat Engine Motor 2 Stroke 5HP stern travel Engines 3 equipment F-N-R Foods Processing Machine, CNC, AGV, Robotic Sector

Mounting Placement: Any course

Gearbox Size: forty two ~ 220mm

Shade: Silver blue

Ratio: 3 ~ a hundred

Guarantee: One particular year after the working day of ex-manufacturing unit

Packing: Wood box or carton

Enter Type: IEC Flange

Certificate: CE & ISO

Constructions: Bearing E-mail: [email protected]

The Parts of a Gearbox

There are many parts of a Gearbox, and this article will help you understand its functions and components. Learn about its maintenance and proper care, and you’ll be on your way to repairing your car. The complexity of a Gearbox also makes it easy to make mistakes. Learn about its functions and components so that you’ll be able to make the best choices possible. Read on to learn more. Then, get your car ready for winter!

Components

Gearboxes are fully integrated mechanical components that consist of a series of gears. They also contain shafts, bearings, and a flange to mount a motor. The terms gearhead and gearbox are not often used interchangeably in the motion industry, but they are often synonymous. Gearheads are open gearing assemblies that are installed in a machine frame. Some newer designs, such as battery-powered mobile units, require tighter integration.

The power losses in a gearbox can be divided into no-load and load-dependent losses. The no-load losses originate in the gear pair and the bearings and are proportional to the ratio of shaft speed and torque. The latter is a function of the coefficient of friction and speed. The no-load losses are the most serious, since they represent the largest proportion of the total loss. This is because they increase with speed.

Temperature measurement is another important preventive maintenance practice. The heat generated by the gearbox can damage components. High-temperature oil degrades quickly at high temperatures, which is why the sump oil temperature should be monitored periodically. The maximum temperature for R&O mineral oils is 93degC. However, if the sump oil temperature is more than 200degF, it can cause seal damage, gear and bearing wear, and premature failure of the gearbox.

Regardless of its size, the gearbox is a crucial part of a car’s drivetrain. Whether the car is a sports car, a luxury car, or a farm tractor, the gearbox is an essential component of the vehicle. There are two main types of gearbox: standard and precision. Each has its own advantages and disadvantages. The most important consideration when selecting a gearbox is the torque output.

The main shaft and the clutch shaft are the two major components of a gearbox. The main shaft runs at engine speed and the countershaft may be at a lower speed. In addition to the main shaft, the clutch shaft has a bearing. The gear ratio determines the amount of torque that can be transferred between the countershaft and the main shaft. The drive shaft also has another name: the propeller shaft.

The gears, shafts, and hub/shaft connection are designed according to endurance design standards. Depending on the application, each component must be able to withstand the normal stresses that the system will experience. Oftentimes, the minimum speed range is ten to twenty m/s. However, this range can differ between different transmissions. Generally, the gears and shafts in a gearbox should have an endurance limit that is less than that limit.

The bearings in a gearbox are considered wear parts. While they should be replaced when they wear down, they can be kept in service much longer than their intended L10 life. Using predictive maintenance, manufacturers can determine when to replace the bearing before it damages the gears and other components. For a gearbox to function properly, it must have all the components listed above. And the clutch, which enables the transmission of torque, is considered the most important component.

Functions

A gearbox is a fully integrated mechanical component that consists of mating gears. It is enclosed in a housing that houses the shafts, bearings, and flange for motor mounting. The purpose of a gearbox is to increase torque and change the speed of an engine by connecting the two rotating shafts together. A gearbox is generally made up of multiple gears that are linked together using couplings, belts, chains, or hollow shaft connections. When power and torque are held constant, speed and torque are inversely proportional. The speed of a gearbox is determined by the ratio of the gears that are engaged to transmit power.

The gear ratios in a gearbox are the number of steps a motor can take to convert torque into horsepower. The amount of torque required at the wheels depends on the operating conditions. A vehicle needs more torque than its peak torque when it is moving from a standstill. Therefore, the first gear ratio is used to increase torque and move the vehicle forward. To move up a gradient, more torque is required. To maintain momentum, the intermediate gear ratio is used.

As metal-to-metal contact is a common cause of gearbox failure, it is essential to monitor the condition of these components closely. The main focus of the proactive series of tests is abnormal wear and contamination, while the preventative tests focus on oil condition and additive depletion. The AN and ferrous density tests are exceptions to this rule, but they are used more for detecting abnormal additive depletion. In addition, lubrication is critical to the efficiency of gearboxes.

Maintenance

Daily maintenance is a critical aspect of the life cycle of a gearbox. During maintenance, you must inspect all gearbox connection parts. Any loose or damaged connection part should be tightened immediately. Oil can be tested using an infrared thermometer and particle counters, spectrometric analysis, or ferrography. You should check for excessive wear and tear, cracks, and oil leaks. If any of these components fail, you should replace them as soon as possible.

Proper analysis of failure patterns is a necessary part of any preventative maintenance program. This analysis will help identify the root cause of gearbox failures, as well as plan for future preventative maintenance. By properly planning preventative maintenance, you can avoid the expense and inconvenience of repairing or replacing a gearbox prematurely. You can even outsource gearbox maintenance to a company whose experts are knowledgeable in this field. The results of the analysis will help you create a more effective preventative maintenance program.

It is important to check the condition of the gearbox oil periodically. The oil should be changed according to its temperature and the hours of operation. The temperature is a significant determinant of the frequency of oil changes. Higher temperatures require more frequent changes, and the level of protection from moisture and water reduces by 75%. At elevated temperatures, the oil’s molecular structure breaks down more quickly, inhibiting the formation of a protective film.

Fortunately, the gear industry has developed innovative technologies and services that can help plant operators reduce their downtime and ensure optimal performance from their industrial gears. Here are 10 steps to ensure that your gearbox continues to serve its purpose. When you are preparing for maintenance, always keep in mind the following tips:

Regular vibration analysis is a vital part of gearbox maintenance. Increased vibration signals impending problems. Visually inspect the internal gears for signs of spiraling and pitting. You can use engineers’ blue to check the contact pattern of gear teeth. If there is a misalignment, bearings or housings are worn and need replacement. Also make sure the breathers remain clean. In dirty applications, this is more difficult to do.

Proper lubrication is another key factor in the life of gearboxes. Proper lubrication prevents failure. The oil must be free of foreign materials and have the proper amount of flow. Proper lubricant selection depends on the type of gear, reduction ratio, and input power. In addition to oil level, the lubricant must be regulated for the size and shape of gears. If not, the lubricant should be changed.

Lack of proper lubrication reduces the strength of other gears. Improper maintenance reduces the life of the transmission. Whether the transmission is overloaded or undersized, excessive vibration can damage the gear. If it is not properly lubricated, it can be damaged beyond repair. Then, the need for replacement gears may arise. However, it is not a time to waste a lot of money and time on repairs.

editor by czh2023-02-24

China High Torque gearbox reducer Worm Planetary Spur Helical Bevel Motor Gear box planetary gearbox

Guarantee: 3 many years

Applicable Industries: Hotels, Garment Outlets, Constructing Content Outlets, Producing Plant, Machinery Repair Shops, Foodstuff & Beverage Manufacturing facility, Farms, Restaurant, Residence Use, Retail, Foodstuff Store, 501 ratio 112mm 3N.m gear stepper nema23 reducer planetary gearbox reduction box motor Printing Retailers, Development works , Energy & Mining, Foods & Beverage Retailers, Other, Promoting Business

Fat (KG): 5 KG

Tailored assistance: OEM, ODM, OBM

Gearing Arrangement: Planetary

Output Torque: 12000-18000NM

Input Speed: 1400rpm

Output Pace: fourteen-280rpm

proportions: exact same as comer

Solution identify: Gearbox

Software: Production Automation

Packaging Specifics: typically packed by wooden boxbut you can speak to with us to go over

Port: ZheJiang /HangZhou

Motor Gearbox Substantial Torque Worm / Planetary / Spur / Helical / Bevel

We create all sorts of planetary gearboxes & helical gearboxes for vertical feed mixers.can change comer items

Quick introduction of Motor Gearbox Large Torque Worm/Planetary/Spur/Helical/Bevel Gearbox

*Concept

Gear box is employed to transfer rotation and torque from motor to functioning machine,

*Function

the perform is to lower speed by gears and increase torque.

*Major specification

- lower backlash

- large output torque-the industry’s highest torque density

- well balanced motor pinion

- substantial effectiveness(up to ninety seven%)

- ratio 3:1 to 1571:one

- minimal sounds

- operable in any mounting positions

- life span lubrication

*Submitted:

Be commonly used for resources handing gear, European Higher Quality forged iron inventory bore f90 tyre versatile fenaflex tyre coupling and fenner tyre coupling engineering equipment,metallurgy business,mining sector,petrochemical sector, design equipment,textile business, health-related equipment and instruments, instrument and meter industry,car industry,maritime sector,weapons sector, 12HP 1HP 2HP 3HP Higher torque 3 section vertical type small ac gear motors electrical motor aerospace discipline,and so on.

*scenario:

| Automated doorway | Carton sealer | DC motor | Foods device | Printing device | Stepper motor |

| AC motor | Conveying device | Diesel motor elements | Foam equipment | Packing device | Servo motor |

| CNC | Crane device | Dyeing machine | Garden mower | Paper machine | Textile device |

Key Market Insights Related to Worm Reduction Gearboxes

A gearbox is a mechanical device that allows you to shift between different speeds or gears. It does so by using one or more clutches. Some gearboxes are single-clutch, while others use two clutches. You can even find a gearbox with closed bladders. These are also known as dual clutches and can shift gears more quickly than other types. Performance cars are designed with these types of gearboxes.

Backlash measurement

Gearbox backlash is a common component that can cause noise or other problems in a car. In fact, the beats and sets of gears in a gearbox are often excited by the oscillations of the engine torque. Noise from gearboxes can be significant, particularly in secondary shafts that engage output gears with a differential ring. To measure backlash and other dimensional variations, an operator can periodically take the output shaft’s motion and compare it to a known value.

A comparator measures the angular displacement between two gears and displays the results. In one method, a secondary shaft is disengaged from the gearbox and a control gauge is attached to its end. A threaded pin is used to secure the differential crown to the secondary shaft. The output pinion is engaged with the differential ring with the aid of a control gauge. The angular displacement of the secondary shaft is then measured by using the dimensions of the output pinion.

Backlash measurements are important to ensure the smooth rotation of meshed gears. There are various types of backlash, which are classified according to the type of gear used. The first type is called circumferential backlash, which is the length of the pitch circle around which the gear rotates to make contact. The second type, angular backlash, is defined as the maximum angle of movement between two meshed gears, which allows the other gear to move when the other gear is stationary.

The backlash measurement for gearbox is one of the most important tests in the manufacturing process. It is a criterion of tightness or looseness in a gear set, and too much backlash can jam a gear set, causing it to interface on the weaker part of its gear teeth. When backlash is too tight, it can lead to gears jamming under thermal expansion. On the other hand, too much backlash is bad for performance.

Worm reduction gearboxes

Worm reduction gearboxes are used in the production of many different kinds of machines, including steel and power plants. They are also used extensively in the sugar and paper industries. The company is constantly aiming to improve their products and services to remain competitive in the global marketplace. The following is a summary of key market insights related to this type of gearbox. This report will help you make informed business decisions. Read on to learn more about the advantages of this type of gearbox.

Compared to conventional gear sets, worm reduction gearboxes have few disadvantages. Worm gear reducers are commonly available and manufacturers have standardized their mounting dimensions. There are no unique requirements for shaft length, height, and diameter. This makes them a very versatile piece of equipment. You can choose to use one or combine several worm gear reducers to fit your specific application. And because they have standardized ratios, you will not have to worry about matching up multiple gears and determining which ones fit.

One of the primary disadvantages of worm reduction gearboxes is their reduced efficiency. Worm reduction gearboxes usually have a maximum reduction ratio of five to sixty. The higher-performance hypoid gears have an output speed of around ten to twelve revolutions. In these cases, the reduced ratios are lower than those with conventional gearing. Worm reduction gearboxes are generally more efficient than hypoid gear sets, but they still have a low efficiency.

The worm reduction gearboxes have many advantages over traditional gearboxes. They are simple to maintain and can work in a range of different applications. Because of their reduced speed, they are perfect for conveyor belt systems.

Worm reduction gearboxes with closed bladders

The worm and the gear mesh with each other in a combination of sliding and rolling movements. This sliding action is dominant at high reduction ratios, and the worm and gear are made of dissimilar metals, which results in friction and heat. This limits the efficiency of worm gears to around thirty to fifty percent. A softer material for the gear can be used to absorb shock loads during operation.

A normal gear changes its output independently once a sufficient load is applied. However, the backstop complicates the gear configuration. Worm gears require lubrication because of the sliding wear and friction introduced during movement. A common gear arrangement moves power at the peak load section of a tooth. The sliding happens at low speeds on either side of the apex and occurs at a low velocity.

Single-reduction gearboxes with closed bladders may not require a drain plug. The reservoir for a worm gear reducer is designed so that the gears are in constant contact with lubricant. However, the closed bladders will cause the worm gear to wear out more quickly, which can cause premature wear and increased energy consumption. In this case, the gears can be replaced.

Worm gears are commonly used for speed reduction applications. Unlike conventional gear sets, worm gears have higher reduction ratios. The number of gear teeth in the worm reduces the speed of a particular motor by a substantial amount. This makes worm gears an attractive option for hoisting applications. In addition to their increased efficiency, worm gears are compact and less prone to mechanical failure.

Shaft arrangement of a gearbox

The ray-diagram of a gearbox shows the arrangement of gears in the various shafts of the transmission. It also shows how the transmission produces different output speeds from a single speed. The ratios that represent the speed of the spindle are called the step ratio and the progression. A French engineer named Charles Renard introduced five basic series of gearbox speeds. The first series is the gear ratio and the second series is the reverse gear ratio.

The layout of the gear axle system in a gearbox relates to its speed ratio. In general, the speed ratio and the centre distance are coupled by the gear axles to form an efficient transmission. Other factors that may affect the layout of the gear axles include space constraints, the axial dimension, and the stressed equilibrium. In October 2009, the inventors of a manual transmission disclosed the invention as No. 2. These gears can be used to realize accurate gear ratios.

The input shaft 4 in the gear housing 16 is arranged radially with the gearbox output shaft. It drives the lubricating oil pump 2. The pump draws oil from a filter and container 21. It then delivers the lubricating oil into the rotation chamber 3. The chamber extends along the longitudinal direction of the gearbox input shaft 4, and it expands to its maximum diameter. The chamber is relatively large, due to a detent 43.

Different configurations of gearboxes are based on their mounting. The mounting of gearboxes to the driven equipment dictates the arrangement of shafts in the gearbox. In certain cases, space constraints also affect the shaft arrangement. This is the reason why the input shaft in a gearbox may be offset horizontally or vertically. However, the input shaft is hollow, so that it can be connected to lead through lines or clamping sets.

Mounting of a gearbox

In the mathematical model of a gearbox, the mounting is defined as the relationship between the input and output shafts. This is also known as the Rotational Mount. It is one of the most popular types of models used for drivetrain simulation. This model is a simplified form of the rotational mount, which can be used in a reduced drivetrain model with physical parameters. The parameters that define the rotational mount are the TaiOut and TaiIn of the input and output shaft. The Rotational Mount is used to model torques between these two shafts.

The proper mounting of a gearbox is crucial for the performance of the machine. If the gearbox is not aligned properly, it may result in excessive stress and wear. It may also result in malfunctioning of the associated device. Improper mounting also increases the chances of the gearbox overheating or failing to transfer torque. It is essential to ensure that you check the mounting tolerance of a gearbox before installing it in a vehicle.

editor by czh2023-02-21

in Kryvyi Rih Ukraine sales price shop near me near me shop factory supplier Micro 3V DC high torque gear motor for robotic toys manufacturer best Cost Custom Cheap wholesaler

Keeping in brain that excellent service is the crucial to cooperating with customers, we try to fulfill substantial top quality requirements, offer you competitive costs and ensure prompt shipping. We are aiming to meet up with the calls for of the consumers about the entire world.. EPG is a expert company and exporter that is involved with the style, development and production. EPT 3V dc high torque EPT motor for robotic toys

Primary Functions

one periodOEM solODM TGP plastic EPTs EPTT in addition A130 permanet magnet DC motor

2 periodSmall size dc EPT motor with lower velocity and big torque

three periodSuitable to small diameter comma low sounds and huge torque application

four periodReduction ratio colon48 comma120 comma180 comma220 comma288

| Product colon EPT TGP01S-A130 | ||

|

TFE-130RA-12215 |

Rated voltage colon 6VDC | Stall torque colon20g periodcm |

| No-load speed colon11500r solmin | Stall current colon0 period85A | |

| No-load present colon120mA | sol | |

|

TFE-130RA-14175 |

Rated voltage colon 3VDC | Stall torque colon13g periodcm |

| No-load current colon8000r solmin | Stall existing colon0 period70A | |

| No-load current colon120mA | sol | |

|

TFE-130RA-18100 |

Rated voltage colon 3VDC | Stall torque colon20g periodcm |

| No-load velocity colon11500r solmin | Stall existing colon1 period80A | |

| No-load current colon250mA | sol | |

EPT motor specialized knowledge colon TGP01S-A130-12215-XXX

| Reduction ratio | 48 | a hundred and twenty | a hundred and eighty | 220 | 288 |

| Size mm | |||||

| No-load velocity rpm | 230 | 90 | sixty | 50 | 38 |

| Rated velocity rpm | |||||

| Rated torque kg periodcm | |||||

| Max periodmomentary tolerance torque kg periodcm | period7 | one period4 | 2 period0 | 2 period2 | 2 period8 |

EPT motor complex data colon TGP01S-A130-14175-XXX

| Reduction ratio | 48 | one hundred twenty | 180 | 220 | 288 |

| Length mm | |||||

| No-load velocity rpm | 150 | sixty | 40 | 33 | 25 |

| Rated velocity rpm | |||||

| Rated torque kg periodcm | |||||

| Max periodmomentary tolerance torque kg periodcm | period5 | period9 | 1 period2 | 1 period4 | one period8 |

EPT motor complex knowledge colon TGP01S-A130-18100-XXX

| Reduction ratio | 48 | one hundred twenty | 180 | 220 | 288 |

| Duration mm | |||||

| No-load speed rpm | 230 | ninety | 60 | 50 | 38 |

| Rated speed rpm | |||||

| Rated torque kg periodcm | |||||

| Max periodmomentary tolerance torque kg periodcm | period7 | 1 period4 | two period0 | 2 period2 | 2 period8 |

Item Application

| Other Purposes colon | |

| Enterprise EPTTs colon | ATM comma Copiers and Scanners comma Forex EPT comma Stage of Sale comma Printers comma Vending EPTTs time period |

| Meals and EPTTrage colon | EPTTrage Dispensing comma Hand Blenders comma Blenders comma Mixers comma Coffee EPTTs comma Foodstuff Processors comma Juicers comma Fryers comma Ice Makers comma Soy Bean Milk Makers interval |

| Property EPTTrtainment and Gaming colon | Gaming EPTTs comma Online video Game titles comma EPTal Disk Drives comma RC and EPTT Toys period |

| Residence EPTnologies colon | Home EPT comma Air Purifiers and Dehumidifiers comma Selection Hoods comma Washers and Dryers comma Refrigerators comma Dishwashers comma EPTr Care comma Whirlpool and Spa comma Showers comma EPT Metering comma Coffee EPTTs interval |

| Lawn and XiHu (West EPT) Dis.Hu (West EPT) Dis.den colon | Lawn Mowers comma Snow Blowers comma Trimmers comma Leaf Blowers period of time |

| Personal Care colon | Hair Cutting comma Hair Treatment comma Massagers interval |

| EPTT Tools colon | Drills and Drivers comma Sanders comma Grinders comma PoEPTTrs comma Saws time period |

| Digital camera and EPTal colon | Video comma Cameras comma Projectors period |

EPTT amp Delivery

EPTT colon solitary carton EPTT comma a hundred items for every box time period

EPT time colon

DHL colon 3-5 working daEPTT semi

UPS colon 5-7 doing work days semi

TNT colon 5-7 working days semi

FedEx colon seven-9 operating days semi

EMS colon twelve-fifteen operating days semi

EPTT Submit colon Depends on ship to which country semi

Sea colon Depends on ship to which place

Our organization

TT EPT lparHK rpar EPTT Co interval comma Ltd has been EPTTizing in micro motors comma EPT motors and their respective components considering that 2000 time period

Our merchandise are broadly utilised in EPTTrtainment programs comma automobiles comma house and EPTT EPTs and instruments and numerous others period of time Our items are reliable and EPTT-lasting comma and backed by several years of experience interval We export ninety eight percnt of our output worldwide time period

By EPTaging our difficult-won popularity for honesty comma dependability and high quality comma TT EPT aims to carry on as a pioneer in the revenue overEPTT by in search of EPTT associates period of time If your business is an end-user of micro-motors comma a distributor or an agent comma you should speak to us period We seem EPTT to being capable to work together with you in the in close proximity to EPT period

FAQ

Q colon How to purchase quest

A colon deliver us inquiry rightEPT EPT our quotation rightEPT negotiate details rightEPT verify the sample rightEPT indicator contract soldeposit rightEPT mass generation rightEPT cargo all set rightEPT equilibrium soldelivery rightEPT further cooperation time period

Q colon How about Sample purchase quest

A colon Sample is accessible for you time period you should speak to us for particulars time period Our internet site colonwww periodttmotor periodcom

Q colon Which transport way is avaliable quest

A colon DHL comma UPS comma FedEx comma TNT comma EMS comma EPTT Post commaSea are accessible periodThe other shipping waEPTTare also available comma remember to contact us if you need to have ship by the other delivery way time period

Q colon How EPTT is the deliver quest

A colon Devliver time relies upon on the amount you order period of time normally it requires fifteen-25 operating days period of time

Q colon My package deal has missing items time period What can I do quest

A colon Make sure you get in touch with our assist group and we will validate your orEPTTwith the deal contents periodWe apologize for any inconveniences interval

Q colon How to affirm the payment quest

A colon We accept payment by T solT comma PayPal comma the other payment waEPTTalso could be accepted commaPlease contact us just before you spend by the other payment ways period Also thirty-50 percnt deposit is available comma the stability money ought to be compensated ahead of transport time period

in Accra Ghana sales price shop near me near me shop factory supplier Automatic Small High Torque Planetary Gearboxes, Reduction Gears for Stepper Motor Planetary Speed Reducer Gear Box manufacturer best Cost Custom Cheap wholesaler

The item effectively displays environmental protection and vitality preserving. we offer chromed bar and tubes for hydualic and pheumatic cylinders. EPG is a skilled maker and exporter that is anxious with the style, growth and manufacturing. We are one of the leading producer of planetary EPTTes via powEPTTmetallurgy. A EPTT is a EPTT EPTT system to make substantial torque by lowering the EPTT velocity or improve the EPTT pace the other way. Planetary EPTT consisting three components: EPTTEPTT, earth EPTT and ring EPTT . A EPTT EPTT is a EPTTwheel in a planetary EPTT system, that rotates about its personal aXiHu (West Lake) Dis.s and has other EPTTs (earth EPTTs) that rotate around it. Much like the EPTT and planets in our photo voltaic program. The amount of planetary EPTTs in a EPTT differs based on the EPTT ratio. Most planetary EPTTes have from two to five earth EPTTs.

When hunting at planetary EPTTs, the toughness of the EPTT is normally deterEPTTd by the dimensions of the EPTTEPTT. Greater EPTTEPTTs will let for higher torque values. The world carrier,Its goal is to keep up to EPTTs of the very same dimensions, which mesh with the EPTTEPTT.

Planetary EPTT advantages:

- Offers higher torque at sluggish speeds .

- The shafts are made up of hardened and tempered alloy metal .

- EPTT EPTTs ,world EPTTs and ring EPTTs are manufactured of powEPTTmetallurgy and sintering metal

- Lower noise stages.

- Excellent high quality EPTTr roller bearings for enter and output shafts .

- Large performance .

We make precision metal EPTTes via powEPTTmetallurgy .

PowEPTTmetallurgy is a metallic operating method in which finely-powdered metal is mixed with binEPTTmaterial to EPTT a quotfeedstock quot that is then formed and solidified utilizing EPTT molding.The potential to merge several operations into 1 approach makes certain MIM is effective in preserving lead occasions as well as EPTTs, providing significant rewards to producers. The steel EPTT molding process migEPTT be a eco-friendly EPTT thanks to the significant reduction in wastage compared to quottraditional quot producing strategies.

MIM can generate parts exactly where it is tough, or even extremely hard, to proficiently manufacture an product through other indicates of fabrication. Elevated EPTTs for traditional production approaches inherent to component compleXiHu (West Lake) Dis.ty, these kinds of as inner/exterior threads, miniaturization, or identification marking, usually do not enhance the EPTT in a MIM operation because of to the fleXiHu (West Lake) Dis.bility of EPTT molding.

The window of financial edge in steel EPTT molded elements lies in compleXiHu (West Lake) Dis.ty and volume for tiny-dimensions elements. MIM supplies are equivalent to metal formed by competing methods, and ultimate items are employed in a wide assortment of EPTT, commercial, health-related, dental, EPTTarms, aerospace, and automotive apps. Dimensional tolerances of plusmn0.3% are frequent and machining is necessary for closer tolerances .

MIM EPTT has discovered increased programs in the professional planet – from residence EPTTs to watches, cars to aerospace, and healthcare to orthodontics.

The benefits of metal EPTT molding for metal fabrications :

- Greatest degree of design liberty for intricate designs and geometries

- Offers sensible economic solutions to ever more stringent content and product layout specifications

- Purposeful integration of numerous characteristics, such as lateral drillings, inside and exterior threads and EPTT tooth.

- Parts can be warmth and floor taken care of, plated, welded and soldered

- Really large quantity production collection run on totally-automated EPTT molding EPTTs utilizing multi-cavity tools

- Exceptional batch to batch repeatability with excellent procedure capabilities

EPTT EPTT moulding method custom made metallic parts

MIM prcess in every steps :

one. EPTT EPTTs alternative

2. Binders

three. MiXiHu (West Lake) Dis.ng

four. Molding

five. De-binding

6. Sintering

seven. post sintering procedure these kinds of as poEPTTng

eight. EPTT properties MIM areas

Custom-made metallic areas specification

| Product sort | Planetary EPTT box , speed EPTT for motors |

| EPTT | steel |

| Method | PowEPTTmetallurgy |

| Therapy | plating ,sand blasting , PVD , coating |

| Tolerance | plusmn0.three% |

| Drawing structure | DWG ,IGS , STP |

| Shipping and delivery time | twenty daEPTTfor mass manufacturing |

Customized metal components

Workshop

in Acapulco de Juarez Mexico sales price shop near me near me shop factory supplier 12V 24V DC Worm Gear Motor High Torque for Water Pump manufacturer best Cost Custom Cheap wholesaler

The team has taken portion in the creating and revising of ISO/TC100 intercontinental chain regular several many years in accomplishment and hosted the 16th ISO/TC100 International annual conference in 2004. Good quality and credit history are the bases that make a company alive. Our AdvantagesProducts Massive quantity in Stock, No MOQ needed We comply with all the worldwide expectations, this sort of as ISO9001 and TS16949 standards. Solution Description

12v 24v dc worm EPTT motor higher torque for pump Requirements:

Observe : It truly is just the normal technical information for you reference, The specification this sort of as voltage, pace, torque, shaft can EPT.

More Specifics:

Rated Voltage: 12V/24V

No Load Speed: three-200RPM

Load Torque: ten-30kgf-cm

Reduction Ratio: one:36-1:833

Output EPTT: 7.7-34W

EPTT Diameter: 42mm

EPTT Dimensions: 76.two*69.8*eighteen.0mm

EPTT Duration: 75mm

Shaft Diameter: 8mm

Shaft Type: D-minimize, round or keyway

Related EPTT

Firm Profile

HangEPTT EPTT EPTT Co. Ltd is a producer and exporter of different of motors with in excess of ten years expertise.

Our item ranges incEPTT:

1) DC Brush motor: six-130mm diameter, .01-1000W output EPTT

two) DC Spur Equipment EPTT: 12-110mm diameter, .1-300W output EPTT

three) DC Planeary Equipment EPTT: 10-82mm diameter, .1-100W output EPTT

four) Brushless DC EPTT: 28-110mm, five-1500W output EPTT

5) Stepper EPTT: NEMA 08 to NEMA 43, Can with EPTT and lead screw

six) Servo EPTT: 42mm to 130mm diameter, 50-4000w

seven) AC Equipment EPTT: 49 to 100mm diameter, six-a hundred and forty output EPTT

Creation EPTT

Certifications

Client Check out and Fair

FAQ

Q: What is actually your primary goods?

A:We at the moment make Brushed Dc EPTTs, Brushed Dc EPTT EPTTs, Planetary Dc Gear EPTTs, Brushless Dc EPTTs, Stepper motors and Ac EPTTs and so forth. You can check out the specs for over motors on our site and you can electronic mail us to suggest necessary motors per your specification also.

Q:How to choose a suited motor?

A:If you have motor pictures or drawings to display us, or you have in depth specs like voltage, speed, torque, motor dimension, functioning mode of the motor, essential daily life time and sounds level and so on, you should do not wait to permit us know, then we can recommend suitable motor for each your ask for accordingly.

Q: Do you have EPT support for your stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd motors?

A:Sure, we can personalize for each your request for the voltage, speed, torque and shaft dimension/shape. If you require further wires/cables soldered on the terminal or require to add connectors, or capacitors or EMC we can make it too.

Q:Do you have individual style provider for motors?

A:Sure, we would like to design motors individually for our customers, but it could require some mould cost and style charge.

Q:Can I have samples for testing 1st?

A:Yes, certainly you can. After verified the necessary motor specs, we will estimate and provide a proforma bill for samples, when we get the payment, we will get a Move from our account department to commence samples appropriately.

Q:How do you make confident motor top quality?

A:We have our possess inspection procedures: for incoming resources, we have signed sample and drawing to make positive qualified incoming materials for generation method, we have tour inspection in the procedure and ultimate inspection to make sure certified products before delivery.

Q:What’s your lead time?

A:EPTTly sEPTTing, our standard stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd item will require twenty five-30days, a bit EPTTer for EPT products. But we are really fleXiHu (West Lake) Dis.ble on the guide time, it will is dependent on the certain orders

Q:What is actually your payment expression?

A:For all our new consumers, we will need 40% deposite, 60% compensated ahead of shipment.

Q:When will you reply following acquired my inquiries?

A:We will reaction within 24 hours as soon as get your inquires.

Q:How can I EPTT you to make confident my funds is secure?

A:We are qualified by the 3rd party SGS and we have exported to more than eighty five nations up to June.2017. You can check our track record with our existing clients in your region (if our consumers do not mind), or you can orEPTTvia alibaba to get trade assurance from alibaba to make confident your cash is secure.

Q:What’s the minimum orEPTTquantity?

A:Our minimal orEPTTquantity relies upon on different motor models, make sure you email us to verify. Also, we generally do not take individual use motor orders.

Q:What is your shipping and delivery method for motors?

A:For samples and packages less than 100kg, we generally advise express transport For weighty offers, we usually recommend air transport or sea delivery. But it all relies upon on our customers’ requirements.

Q:What certifications do you have?

A:We at the moment have CE and ROSH certifications.

Q:Can you send out me your price tag record?

A:Considering that we have hundreds of diverse merchandise, and price tag varies per distinct specifications, we are not ready to offer you a price tag listing. But we can quotation inside of 24 hrs when received your inquirues to make sure you can get the value in time.

Q:Can I visit your business?

A:Of course, welcome to check out our firm, but please let us know at lEPTT two months EPTT to assist us make sure no other conferences throughout the day you pay a visit to us.

Many thanks!

Get in touch with Us

HangEPTT EPTT EPTT Co.,Ltd

Get in touch with Man or woman: Celia Chen

Any email or trademanager inquires will be replied in 24 several hours.

Typical samples can be offer really speedily(inside of 10 times)

Custom-made service for kind of motor accoring to your need

Expert Tchnical support and Soon after-sale service

Sourcing motor parts like EPTTs, encoders, cables, connectors and so on

High made in China – replacement parts – in Cartagena Colombia Torque DC Gear Motor for Automatic Actuator with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 diverse branches. For much more information: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Product: TG-38

We can design it according to your particular specifications.

| Geared motor identify | Rated Volt. V |

No Load | Load Torque | At Maximum Efficiency | Outpu energy W |

Numbe of gear trains |

Gearbox duration “L”mm |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Present | Speed | Recent | Velocity | Torque | ||||||||

| mA | r/min | mA | r/min | Kgf·cm | N·m | Kgf·cm | N·m | |||||

| TG-38123400-30K | 12 | ≤40 | a hundred and ten | ≤180 | 83 | .88 | .09 | three | .29 | .73 | 3 | 22 |

| TG-38123400-60K | twelve | ≤40 | fifty five | ≤180 | forty one | one.58 | .15 | 6 | .fifty nine | .65 | four | 25 |

| TG-38123400-90K | twelve | ≤40 | 37 | ≤180 | 28 | 2.38 | .23 | 7. | .sixty nine | .sixty five | 4 | 25 |

| TG-38123400-180K | twelve | ≤40 | eighteen.5 | ≤180 | fourteen | 4.25 | .42 | 13 | one.27 | .sixty | five | 27 |

| TG-38123400-270K | 12 | ≤40 | 12.5 | ≤180 | 9.two | six.37 | .sixty two | twenty | 1.ninety six | .sixty | five | 27 |

| TG-38123400-540K | twelve | ≤40 | 6.2 | ≤140 | 5. | ten | .98 | 30 | two.ninety four | .five | 6 | 29 |

| TG-38123400-810K | twelve | ≤40 | 4.one | ≤100 | three.four | ten | .98 | thirty | 2.94 | .34 | 6 | 29 |

| TG-38123400-1620K | 12 | ≤40 | two.1 | ≤50 | one.six | 10 | .98 | thirty | 2.ninety four | .sixteen | 7 | 29 |

| TG-38123400-2430K | 12 | ≤40 | 1.4 | ≤40 | one.one | ten | .ninety eight | 30 | 2.ninety four | .eleven | 7 | 29 |

| Packing Particulars | CTN dimension:37X27XH18CM 60pcs/CTN N.W. 12Kgs | |||||||||||

2.Creation Movement

3.Firm Information

In latest 10 a long time, Derry has been devoted to the manufacture of the motor products and the primary merchandise can be categorised into the following series, particularly DC motor, DC gear motor, AC motor, AC equipment motor, Stepper motor, Stepper gear motor, Servo motor and Linear actuator sequence.

Our motor items are broadly used in the fields of aerospace industry, automotive industry, monetary tools, house appliance, industrial automation and robotics, healthcare gear, office products, packing machinery and transmission business, offering consumers trustworthy tailored answers for driving and controlling.

4.Our Solutions

1). EPT Services:

| Rapid Reply | All enquiry or email be replied in 12 hours, no hold off for your company. |

| Specialist Group | Queries about merchandise will be replied professionally, precisely, be EPT guidance to you. |

| Quick Lead time | Sample or modest buy sent in 7-fifteen days, bulk or custom-made get about thirty times. |

| Payment Decision | T/T, Western Union,, L/C, and many others, straightforward for your company. |

| Before shipment | Get images, send out to customers for confirmation. Only verified, can be transported out. |

| Language Option | Aside from English, you can use your possess language by email, then we can translate it. |

2). Customization Support:

Motor specification(no-load speed , voltage, torque , diameter, sound, lifestyle, screening) and shaft length can be tailor-produced according to customer’s specifications.

five.Package & Shipping

The use of first products manufacturer’s (OEM) portion figures or trademarks , e.g. CASE® and John Deere® are for reference reasons only and for indicating solution use and compatibility. Our business and the outlined substitute components contained herein are not sponsored, accredited, or manufactured by the OEM.

25mm factory made in China – replacement parts – in Cucuta Colombia High Torque EPT ro DC Gear Motor for Blenders with top quality

We – EPG Team the biggest gearbox & motors , couplings and gears manufacturing facility in China with 5 different branches. For a lot more details: Cell/whatsapp/telegram/Kakao us at: 0086~thirteen 571 88828 13858117778 571 88828

25mm large torque micro DC equipment motor for Blenders

Please kindly let us know

1) what is your necessity to volt?

two) what is your prerequisite to rpm?

3) what is your necessity toTorque?

4) what is your requirement to Amount.

Then we will give options appropriately.

Merchandise Category

China maker gear motor price With Expert Complex Assistance

We usually offer clients with unique items:expense-efficient, lower

noise, increased efficiency and security, more time lifestyle and increased toughness.

| Standard details | |

| Item identify | PG25370 sequence,25mm diameter earth equipment motor |

| Motor type | carbon-brush commutator |

| Gear kind | Straight gearwheel,world building |

| Housing content | Metal |

| Geartrain material | Metal and Powdered Metal,POM optional |

| Bearing at output shaft | Sleeve bearing |

| Lubricant | Grease for large-reduced temperature, -62—+204 degree |

| Backlash at no-load | <1°,MIN0.3° |

| OEM & ODM Support | Available |

| Certificate | CE,ROHS,ISO/TS16949 |

| An actual model of gearbox and motor blend | |

| Item seires | PG25370 sequence |

| An exact Model NO. | PG25370 12 6000-994K |

| Motor Voltage(VDC) | twelve |

| Motor no load pace(rpm) | 6000 |

| Gearbox reduction ratio | 994K |

| Gearmotor no load recent(A) | <0.082 |

| Gearmotor no load velocity(rpm) | six+/-10% |

| Gearmotor rated load torque(kgf.cm) | 28 |

| Gearmotor rated present(A) | <0.386 |

| Gearmotor rated load speed(rpm) | five+/-ten% |

| Sound (DB) | <55DB |

| Life span | one thousand+ hours (may differ by software) |

| Rotation | CW/CCW reversible |

Packing&Xihu (West Lake) Dis.

Company Details

FAQ

Q: Are you a trading business or a manufacturer?

A: We are a manufacturer.

Q: Can you make a motor with customized requirements?

A: Indeed, truly that is what we do most of the time.

Q: What is the MOQ (bare minimum get amount)?

A: 1 pc for sample purchase, and 100pcs for bulk get.

Q: Do you have motors in stock?

A: No, we never. All motors are manufactured with orders.

Q: How to pay you?

Paypal, Western Union, Funds Gram, T/T, L/C payment are satisfactory.

Q: What do you need to know if I need a recommendation on motor?

A: Typically we need to have to know dimensions, rated voltage, pace at load/no load, torque at load/stall. i.e.

a motor with diameter 37mm, 12V, 100rpm and 2Kgf.cm at load.

Q: Can I ask you for aid if I know absolutely nothing about motor?

A: Indeed, our pleasure. We are good individuals with huge hearts.

Q: Can we variety our model on it?

A: Yes of program.

Q: Exactly where is your loading port ?

A: HangZhou Port, ZheJiang Port, China.

Q: What is your creation capability?

A: About 4000 PCS per day.

Q: Can I visit your factory?

A: Indeed,of program

Speak to US

Internet:

Tel: 0086~571-8822571/8822 571 -8849571ext8014

Speak to: Candy Xu

Insert: NO.1269 Mingshu Road HangZhou Industrial Zone,Xihu (West Lake) Dis. District,HangZhou ZHangZhoug Province China.

Submit: 315191

The use of first products manufacturer’s (OEM) portion quantities or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating product use and compatibility. Our firm and the outlined substitution areas contained herein are not sponsored, accepted, or produced by the OEM.