Product Description

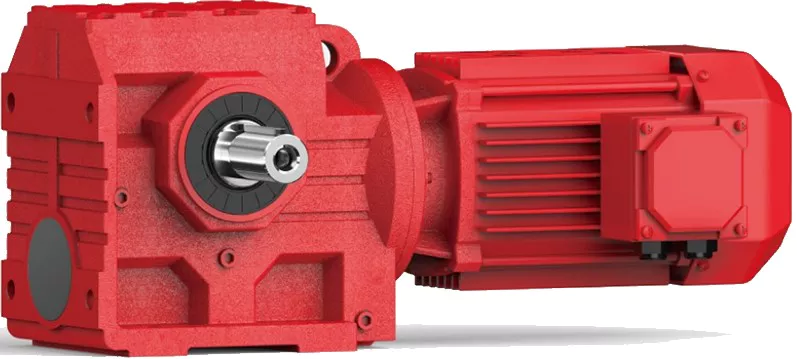

R Series Inline Helical 2 double stage Speed Reducer output 30 rpm Gearbox

Product Description

>Click Here To Cotact<

Product Advantages

Company Information

Certificate

Main Products

Global Exhibition

|

Brand |

WUMA |

|

|

|

|||

|

Housing |

Three type |

|

|

|

|||

|

Nameplate |

WUMA or Customize |

|

|

|

|||

|

Reducer |

worm gearbox,helical gearbox, hypoid gearbox,planetary gearbox and variator etc. |

|

|

|

|||

FAQ

1 . How to choose a gearbox which meets our requirement?

You can refer to our catalogue to choose the gearbox or we can help to choose when you provide

the technical information of required output torque, output speed and motor parameter etc.

2. What information shall we give before placing a purchase order?

a) Type of the gearbox, ratio, input and output type, input flange, mounting position, and motor informationetc.

b) Housing color.

c) Purchase quantity.

d) Other special requirements.

3. What industries are your gearboxes being used?

Our gearboxes are widely used in the areas of textile, food processing, beverage, chemical industry,

escalator,automatic storage equipment, metallurgy, tabacco, environmental protection, logistics and etc.

4. Doyou sell motors?

We have stable motor suppliers who have been coperating with us for a long-time. They can provide motors

with high quality.

>Return Home<

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Types of Helical Gear Arrangements

Yes, there are different types of helical gear arrangements available to suit various applications and requirements. Some of the common helical gear arrangements include:

Parallel Shaft Arrangement: In this arrangement, the axes of the driving and driven shafts are parallel to each other. It is the most straightforward configuration and is often used in applications where space is not a constraint, and the gearboxes can be placed side by side.

Right-Angle Shaft Arrangement: In a right-angle arrangement, the driving and driven shafts are positioned at a 90-degree angle to each other. This arrangement is space-saving and is commonly used in applications where the layout requires a change in direction of the power transmission.

Double Helical Gear Arrangement (Herringbone Gears): Double helical gears consist of two sets of helical teeth facing each other. This arrangement helps to cancel out axial forces and reduces the net thrust load on bearings. It is often used in heavy-duty applications to minimize wear and vibration.

Crossed Helical Gear Arrangement (Screw Gears): In this configuration, the axes of the driving and driven shafts are neither parallel nor intersecting. It is suitable for applications requiring non-parallel and non-intersecting shafts.

The choice of helical gear arrangement depends on factors such as available space, power transmission requirements, and the desired layout of the machinery or equipment. Each arrangement has its advantages and disadvantages, and selecting the appropriate one is crucial for achieving optimal performance and efficiency.

Software Tools for Simulating Helical Gear Behavior

Several software tools are available for simulating the behavior of helical gears under different conditions. These tools aid engineers in designing and analyzing helical gear systems for optimal performance and reliability. Some notable software tools include:

- KISSsoft: KISSsoft is a widely used software for the design and analysis of mechanical components, including helical gears. It offers comprehensive calculations for gear geometry, load distribution, contact stresses, and more. The software assists in optimizing gear designs and predicting their behavior under various operating conditions.

- AGMA Rating Suite: The American Gear Manufacturers Association (AGMA) offers software tools that follow AGMA standards for gear design and analysis. These tools provide accurate calculations for gear rating, efficiency, and durability under different load scenarios.

- ANSYS Mechanical: ANSYS Mechanical is a versatile simulation software used for finite element analysis (FEA) of mechanical systems, including helical gears. It allows engineers to perform detailed stress and deformation analysis, simulate contact patterns, and assess the effects of different loads and boundary conditions.

- Gleason CAGE: Gleason’s Computer-Aided Gear Engineering (CAGE) software specializes in gear design and optimization. It offers advanced tools for gear tooth profile generation, simulation of meshing behavior, and optimization of gear parameters.

- MAGMA Soft: MAGMA Soft provides casting simulation software that can be used to predict the solidification behavior and mechanical properties of casted gear components, which is essential for ensuring quality and performance.

- Siemens NX: Siemens NX software includes gear design and analysis capabilities, allowing engineers to simulate gear behavior, calculate load distribution, and optimize gear designs within a comprehensive CAD/CAE environment.

These software tools enable engineers to model and analyze helical gears in a virtual environment, helping them make informed design decisions, optimize gear geometry, and assess gear performance under different conditions. By utilizing these tools, engineers can create reliable and efficient helical gear systems for various industrial applications.

Lubrication Requirements for Maintaining Helical Gearboxes

Lubrication is essential for the proper functioning and longevity of helical gearboxes. The lubrication requirements include:

- Viscosity: Selecting a lubricant with the appropriate viscosity is crucial. The viscosity should provide sufficient lubrication and ensure a protective film between gear teeth under varying operating conditions.

- Extreme Pressure (EP) Properties: Helical gears often experience high contact pressures. Lubricants with EP additives form a protective barrier that prevents metal-to-metal contact and reduces wear.

- Oil Additives: Anti-wear additives, antioxidants, and corrosion inhibitors enhance the lubricant’s performance and protect gears from wear and degradation.

- Frequent Inspections: Regularly inspect the lubricant’s condition to detect contamination, degradation, or depletion. Scheduled oil analysis can help monitor the health of the lubricant.

- Proper Lubricant Application: Ensure the gearbox is properly filled with the correct amount of lubricant. Follow manufacturer recommendations for lubricant type and quantity.

- Lubricant Change Intervals: Establish regular lubricant change intervals based on operating conditions. Extreme conditions or heavy loads may require more frequent changes.

Appropriate lubrication minimizes friction, wear, and heat generation, leading to improved efficiency, reduced maintenance, and extended gearbox life. It’s crucial to follow the manufacturer’s guidelines and consult with lubrication experts to select the right lubricant and maintenance practices for your specific helical gearbox application.

editor by CX 2024-04-17

in Nottingham United Kingdom sales price shop near me near me shop factory supplier AC Motor Speed Reduction RV Series Worm Transmission Gearbox with High Quality manufacturer best Cost Custom Cheap wholesaler

More importantly, we make specific elements in accordance to equipped drawings/samples and warmly welcome OEM inquiries. Our merchandise are used in numerous fields. Hangzhou EPG Co.,Ltd. , was launched in November, 1997. With its 5 wholly owned subsidiaries.

Solution Identify: EPTT

Apps:

The merchandise are extensively utilized in electrical energy, coal, cement, metallurgy, harbor, EPT, delivery, lifting, atmosphere protection, phase, logistic, weaving, paper generating, ligEPTT sector, plastics and other areas.

EPTT Description:

1. EPT:

Die-forged Aluminium Alloy EPTT (RV571~RV090)Cast Iron EPTT (RV110~RV150)

two. Worm Wheel: Wearable Tin Bronze Alloy, EPTT Bronze Alloy

3. Worm Shaft: 20Cr Steel, carburizing, quenching, grinding, floor hardness 56-62EPTC, .three-.5mm remaining carburized layer soon after specific grinding

4. Input Configurations:

Outfitted with Electric powered EPTs (AC EPT, Brake EPT, DC EPT, Servo EPT)

IEC-normalized EPT Flange

Sound Shaft Input

Worm Shaft EPTTil Extension Enter

5. Output Configurations:

Keyed Hollow Shaft Output

Hollow Shaft with Output Flange

Plug-in Solid Shaft Output

six. EPT Elements: Worm Shaft EPTTil Extension, Single Output Shaft, EPTT Output Shaft, Output Flange, Torque Arm, Dust EPTT

7. EPTT Painting:

Aluminium Alloy EPTT:

After Shot Blasting, Anticorrosion Treatment method and Phosphating, Paint with the EPTT of RAL 5571 Gentian EPTT or RAL 7035 LigEPTT Grey

Forged Iron EPTT:

Right after Portray with Crimson Antirust Paint, Paint with the EPTT of RAL 5571 Gentian EPTT

Models:

Hollow Shaft Input with IEC-normalized EPT Flange

RV571~RV150

Reliable Shaft Enter

RV571~RV150

Functions:

1. EPTT EPT alloy EPT box, ligEPTT weigEPTT and not rust

2. 2 optional worm wheel supplies: Tin bronze or EPT bronze alloy

3. StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd areas and extremely fleXiHu (West EPT) Dis.ble for shaft configurations and motor flange interface

4. Many optional mounting possibilities

five. Minimal noise, EPT efficiency in heat dissipation

EPTT EPTnical Info:

| Types | Rated EPTT | Rated Ratio | Enter Hole Dia. | Input Shaft Dia. | Output Hole Dia. | Output Shaft Dia. | CEPTTr Length |

| RV571 | .06KW~.12KW | 5~sixty | Phi9 | Phi9 | Phi11 | Phi11 | 25mm |

| RV030 | .06KW~.25KW | 5~80 | Phi9( Phi11) | Phi9 | Phi14 | Phi14 | 30mm |

| RV040 | .09KW~.55KW | five~100 | Phi9( Phi11, Phi14) | Phi11 | Phi18( Phi19) | Phi18 | 40mm |

| RV050 | .12KW~1.5KW | five~a hundred | Phi11( Phi14, Phi19) | Phi14 | Phi25( Phi24) | Phi25 | 50mm |

| RV063 | .18KW~2.2KW | seven.five~a hundred | Phi14( Phi19, Phi24) | Phi19 | Phi25( Phi28) | Phi25 | 63mm |

| RV075 | .25KW~four.0KW | 7.five~one hundred | Phi14( Phi19, Phi24, Phi28) | Phi24 | Phi28( Phi35) | Phi28 | 75mm |

| RV090 | .37KW~four.0KW | seven.5~a hundred | Phi19( Phi24, Phi28) | Phi24 | Phi35( Phi38) | Phi35 | 90mm |

| RV110 | .55KW~7.5KW | seven.5~100 | Phi19( Phi24, Phi28, Phi38) | Phi28 | Phi42 | Phi42 | 110mm |

| RV130 | .75KW~seven.5KW | seven.5~100 | Phi24( Phi28, Phi38) | Phi30 | Phi45 | Phi45 | 130mm |

| RV150 | 2.2KW~15KW | seven.five~100 | Phi28( Phi38, Phi42) | Phi35 | Phi50 | Phi50 | 150mm |

Ratio: five, seven.five, 10, fifteen, twenty, twenty five, thirty, 40, fifty, sixty, eighty, a hundred

Set up:

Flange Mounted

Foot Mounted

Torque Arm Mounted

Lubrication:

Grease Lubrication

Oil-bathtub and Splash Lubrication

Cooling:

Organic Cooling

Our Production and EPTT:

FAQ:

Q: Do you offer OEM support?

A: Of course.

Q: What is your payment terms?

A: 30% T/T as deposit in EPT, 70% harmony right after receipt of the duplicate of B/L or ahead of shipment.

Also we do L/C at sight, D/P, West EPT, Cash Gram and so on.

Q: What is your lead time?

A: About 5-ten functioning daEPTTfor LCL shipment orEPTTand about 20daEPTTfor container orEPTTafter receipt the deposit or unique irrevocable L/C.

Q: What certifiicate do you have?

A: We have CE, ISO, SASO. And we can apply for distinct certificates for various nations around the world demand.

Q:How EPTT is your goods warranty?

A: 12months quality guarantee.

If the motor is damaged or can not function generally due to the production problems, our business will mend and replace the spare elements or full motors by cost-free of demand.

Why Us?

a. Manufacturing unit Costs — with EPTd lamination,casting,rotor pouring, winding, portray, tests and EPTT EPTTs, all of significant supplies are produced by ourselves which saved the production EPT a lot which provides clientele more income to resell or distribute.

b.Guaranteed EPTT — Excellent visual appeal, reduced sounds, no heating also sligEPTT vibration tends to make high quality merchandise. Also we do one hundred% new substance,100% cooper wire,100% EPTT, 100% analyzed certified ahead of shipment.

c.Specialist Support — Within 12hours to reply you all inquiries and concerns, also much skilled income can offer you great remedies and cooperate with you really well on each ahead of and right after sale.

Welcome to get in touch with with us !