Product Description

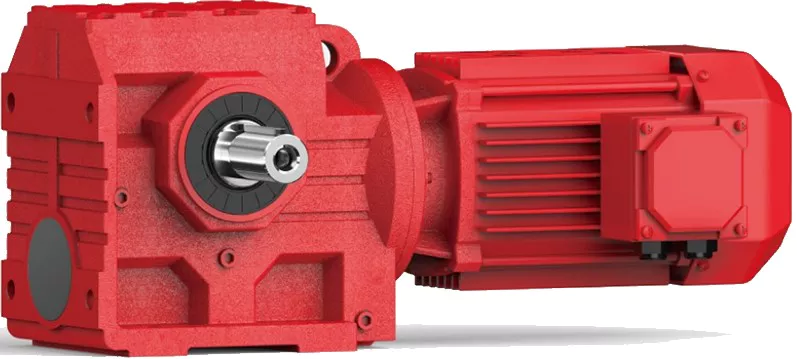

Helical Worm Gear Motor S Series hollow shaft Gear Reducer Reduction Gearbox

< ABOUT TILI

Technical data

| Product Name | Helical Worm Gear Motor S Series hollow shaft Gear Reducer Reduction Gearbox |

| Power | 0.12KW~30KW |

| Nominal output torque | 9~ 8425N · m |

| Output speed | 0.1 ~ 374r/min |

| Gear material | 20CrMnTi alloy steel |

| Gear Processing | Grinding finish by HOFLER Grinding Machines |

| Noise Test | Below 65dB |

| Brand of bearings | C&U bearing, ZWZ, LYC, HRB, CZPT , etc |

| Brand of oil seal | NAK or other brand |

| Temp. rise (MAX) | 40ºC |

| Temp. rise (Oil)(MAX | 50ºC |

| Vibration | ≤20µm |

| Housing hardness | HBS190-240 |

| Surface hardness of gears | HRC58°~62 ° |

| Gear core hardness | HRC33~40 |

| Machining precision of gears | 5 Grade |

| Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

| Heat treatment | Carburizing, Quenching etc |

| Efficiency | 95%~96% (depends on the transmission stage) |

| Bearing output mode | Parallel output |

| Installation type and output mode | Bottom seated type flange type installation, solid,hollow shaft output. |

| Input mode | Direct motor, shaft input and connecting flange input |

| Input Method | Flange input(AM), shaft input(AD), inline AC motor input, or AQA servo motor |

Installation Instructions

Company Profile

< WORKSHOP

< QUALITY CONTROL

Certifications

Packaging & Shipping

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of reducer.

Q 2:Can you do OEM?

A:Yes, we can. We can do OEM for all the customers .if you want to order NON-STANDERD speed reducers,pls provide Drafts, Dimensions, Pictures and Samples if possible.

Q 3: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 4: Do you have inspection procedures for reducer?

A:100% self-inspection before packing.

Q 5: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 6:How to choose a gearbox? What if I don’t know which gear reducer I need?

A:You can refer to our catalogue to choose the gearbox or we can help to choose when you provide,the technical information of required output torque, output speed and motor parameter etc. Don’t worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q 7: What information shall we give before placing a purchase order?

A:a) Type of the gearbox, Size , Transmission Ratio, input and output type, input flange, mounting position, motor information and shaft deflection etc. b)Housing color.c) Purchase quantity. d) Other special requirements

Q 8:What is the payment term?

A:You can pay via T/T(30% in advance as deposit before production +70% before delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Vertical Output |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Precision and High-Accuracy Applications of Helical Gearboxes

Helical gearboxes are well-suited for precision and high-accuracy applications due to their unique design and performance characteristics:

- Helical Gearing: The helical gears in these gearboxes offer smooth and continuous meshing, resulting in reduced backlash and improved positioning accuracy.

- Efficiency: Helical gearboxes are known for their high efficiency, which minimizes energy losses and heat generation. This is crucial for maintaining precision in applications where even small deviations can have significant impacts.

- Noise and Vibration: The helical gear tooth engagement helps in reducing noise and vibration levels, making them suitable for environments where quiet operation is required.

- Load Distribution: Helical gears distribute load across multiple teeth, minimizing localized wear and extending the lifespan of the gearbox.

- Smooth Motion: Helical gearboxes provide smoother motion transitions, which is crucial in precision applications where jerky or sudden movements are undesirable.

- Positional Accuracy: The reduced backlash and improved meshing characteristics of helical gears contribute to higher positional accuracy, making these gearboxes ideal for applications such as CNC machines, robotics, and medical equipment.

- Compact Design: Helical gearboxes can achieve high gear ratios in a relatively compact form factor, making them suitable for applications where space is limited.

Examples of precision applications where helical gearboxes are commonly used include CNC machining, robotics, semiconductor manufacturing, medical equipment, and metrology devices. The combination of efficiency, smooth operation, and accuracy makes helical gearboxes a preferred choice for achieving consistent and reliable performance in such applications.

Can Helical Gearboxes Be Retrofitted into Existing Machinery Designs?

Yes, helical gearboxes can often be retrofitted into existing machinery designs, providing an opportunity to upgrade the performance, efficiency, and reliability of older equipment. Here are the key points to consider when retrofitting helical gearboxes:

1. Compatibility: Before proceeding with a retrofit, it’s essential to ensure that the new helical gearbox is compatible with the existing machinery in terms of size, mounting, and shaft connections. Proper measurements and analysis are necessary to avoid any misalignment or fitment issues.

2. Space Considerations: Helical gearboxes may have a different physical profile compared to the original gearboxes. Engineers need to assess the available space in the machinery and confirm that the new gearbox will fit without major modifications.

3. Shaft Alignment: Proper shaft alignment is crucial to ensure smooth and efficient operation. During the retrofit, it’s important to align the new helical gearbox with other components in the system to prevent premature wear, noise, and vibration.

4. Power and Torque Ratings: The power and torque ratings of the helical gearbox should match or exceed the requirements of the machinery. This ensures that the new gearbox can handle the loads and stresses that the machinery may encounter.

5. Performance Improvements: Retrofitting with helical gearboxes can lead to improved efficiency, reduced noise, and smoother operation. These benefits can positively impact the overall performance and lifespan of the machinery.

6. Engineering Expertise: Retrofitting involves careful planning, engineering analysis, and implementation. Working with experienced engineers or gearbox specialists is advisable to ensure a successful retrofit without compromising the integrity of the machinery.

7. Cost-Benefit Analysis: Assessing the costs of the retrofit, including the cost of the new gearbox, installation, downtime, and potential modifications, is essential. Comparing these costs to the anticipated benefits of improved performance and efficiency will help make an informed decision.

8. Maintenance Considerations: Retrofitting may also impact maintenance practices. It’s important to understand any changes in lubrication requirements, inspection intervals, and servicing needs that come with the new gearbox.

Conclusion: Retrofitting helical gearboxes into existing machinery designs can be a cost-effective way to enhance the performance and extend the lifespan of equipment. However, careful planning, engineering analysis, and professional expertise are crucial to ensure a successful retrofit that delivers the desired improvements without causing unforeseen issues.

Lubrication Requirements for Maintaining Helical Gearboxes

Lubrication is essential for the proper functioning and longevity of helical gearboxes. The lubrication requirements include:

- Viscosity: Selecting a lubricant with the appropriate viscosity is crucial. The viscosity should provide sufficient lubrication and ensure a protective film between gear teeth under varying operating conditions.

- Extreme Pressure (EP) Properties: Helical gears often experience high contact pressures. Lubricants with EP additives form a protective barrier that prevents metal-to-metal contact and reduces wear.

- Oil Additives: Anti-wear additives, antioxidants, and corrosion inhibitors enhance the lubricant’s performance and protect gears from wear and degradation.

- Frequent Inspections: Regularly inspect the lubricant’s condition to detect contamination, degradation, or depletion. Scheduled oil analysis can help monitor the health of the lubricant.

- Proper Lubricant Application: Ensure the gearbox is properly filled with the correct amount of lubricant. Follow manufacturer recommendations for lubricant type and quantity.

- Lubricant Change Intervals: Establish regular lubricant change intervals based on operating conditions. Extreme conditions or heavy loads may require more frequent changes.

Appropriate lubrication minimizes friction, wear, and heat generation, leading to improved efficiency, reduced maintenance, and extended gearbox life. It’s crucial to follow the manufacturer’s guidelines and consult with lubrication experts to select the right lubricant and maintenance practices for your specific helical gearbox application.

editor by CX 2024-05-09

China supplier R37 R47 R57 R67 R77 R87 R97 R107 R137 R147 Series in-Line Helical Gear Motor Reduction Gearbox for Food Machinery gearbox and motor

Product Description

R37 R47 R57 R67 R77 R87 R97 R107 R137 R147 Series In-line Helical Gear Motor Reduction Gearbox For Food Machinery

< ABOUT TILI

Technical data

| Product Name | R37 R47 R57 R67 R77 R87 R97 R107 R137 R147 Series In-line Helical Gear Motor Reduction Gearbox For Food Machinery |

| Power | 0.12KW~160KW |

| Torque | 1.4N · m ~ 36600N · m |

| Output speed | 0.06 ~ 1090r/min |

| Gear material | 20CrMnTi alloy steel |

| Gear Processing | Grinding finish by HOFLER Grinding Machines |

| Noise Test | Below 65dB |

| Brand of bearings | C&U bearing, ZWZ,LYC, HRB, CZPT ,etc |

| Brand of oil seal | NAK or other brand |

| Temp. rise (MAX) | 40ºC |

| Temp. rise (Oil)(MAX | 50ºC |

| Vibration | ≤20µm |

| Housing hardness | HBS190-240 |

| Surface hardness of gears | HRC58°~62 ° |

| Gear core hardness | HRC33~40 |

| Machining precision of gears | 5 Grade |

| Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

| Heat treatment | Carburizing, Quenching etc |

| Efficiency | 95%~96% (depends on the transmission stage) |

| Bearing output mode | parallel output |

| Installation type and output mode | Bottom seated type flange type installation, solid,hollow shaft output. |

| Input mode | Direct motor, shaft input and connecting flange input |

| Input Method | Flange input(AM), shaft input(AD), inline AC motor input, or AQA servo motor |

Installation Instructions

Company Profile

< WORKSHOP

< QUALITY CONTROL

Certifications

Packaging & Shipping

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of reducer.

Q 2:Can you do OEM?

A:Yes, we can. We can do OEM for all the customers .if you want to order NON-STANDERD speed reducers,pls provide Drafts, Dimensions, Pictures and Samples if possible.

Q 3: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 4: Do you have inspection procedures for reducer?

A:100% self-inspection before packing.

Q 5: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 6:How to choose a gearbox? What if I don’t know which gear reducer I need?

A:You can refer to our catalogue to choose the gearbox or we can help to choose when you provide,the technical information of required output torque, output speed and motor parameter etc. Don’t worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q 7: What information shall we give before placing a purchase order?

A:a) Type of the gearbox, Size , Transmission Ratio, input and output type, input flange, mounting position, motor information and shaft deflection etc. b)Housing color.c) Purchase quantity. d) Other special requirements

Q 8:What is the payment term?

A:You can pay via T/T(30% in advance as deposit before production +70% before delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery, Industrial Automation Equipment, Chemical Industry |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Coaxial |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Types of Helical Gear Arrangements

Yes, there are different types of helical gear arrangements available to suit various applications and requirements. Some of the common helical gear arrangements include:

Parallel Shaft Arrangement: In this arrangement, the axes of the driving and driven shafts are parallel to each other. It is the most straightforward configuration and is often used in applications where space is not a constraint, and the gearboxes can be placed side by side.

Right-Angle Shaft Arrangement: In a right-angle arrangement, the driving and driven shafts are positioned at a 90-degree angle to each other. This arrangement is space-saving and is commonly used in applications where the layout requires a change in direction of the power transmission.

Double Helical Gear Arrangement (Herringbone Gears): Double helical gears consist of two sets of helical teeth facing each other. This arrangement helps to cancel out axial forces and reduces the net thrust load on bearings. It is often used in heavy-duty applications to minimize wear and vibration.

Crossed Helical Gear Arrangement (Screw Gears): In this configuration, the axes of the driving and driven shafts are neither parallel nor intersecting. It is suitable for applications requiring non-parallel and non-intersecting shafts.

The choice of helical gear arrangement depends on factors such as available space, power transmission requirements, and the desired layout of the machinery or equipment. Each arrangement has its advantages and disadvantages, and selecting the appropriate one is crucial for achieving optimal performance and efficiency.

Helical Gearboxes and Energy Efficiency

Helical gearboxes play a significant role in enhancing energy efficiency in various industrial processes. Their design and operating characteristics contribute to improved efficiency and reduced energy consumption. Here’s how helical gearboxes achieve energy efficiency:

- Helical Gear Meshing: Helical gears have inclined teeth that engage gradually, resulting in smoother and quieter meshing compared to other gear types. This smoother engagement reduces impact and friction losses, leading to higher efficiency and lower energy consumption.

- Load Distribution: Helical gears distribute the load across multiple teeth due to their helix angle. This even load distribution minimizes stress concentrations and prevents premature wear, ensuring efficient power transmission and reducing the need for frequent maintenance.

- Efficient Power Transmission: The inclined tooth profile of helical gears allows for more teeth to be in contact at any given time. This increased contact area improves power transmission efficiency by reducing sliding friction and minimizing energy losses.

- Reduced Vibration: The helical tooth engagement minimizes vibration and noise levels, which can be particularly advantageous in applications that require precise and stable operation. Reduced vibration translates to lower energy losses and increased overall efficiency.

- Optimized Gear Design: Engineers can fine-tune helical gear designs by adjusting parameters such as helix angle, number of teeth, and gear materials. This optimization process helps tailor the gearbox for specific applications, ensuring optimal efficiency and minimal energy wastage.

- Lubrication and Cooling: Proper lubrication and cooling strategies are crucial for maintaining efficiency. Helical gears benefit from efficient lubrication due to their continuous tooth engagement, which helps reduce friction and wear, further enhancing energy efficiency.

- Advanced Manufacturing: Modern manufacturing techniques enable precise production of helical gears, ensuring tight tolerances and accurate tooth profiles. This manufacturing precision contributes to minimal energy losses during gear operation.

Overall, helical gearboxes excel in energy efficiency by combining smoother tooth engagement, even load distribution, reduced vibration, and optimized designs. Their ability to transmit power efficiently and reliably makes them a preferred choice for industrial processes where energy conservation is a priority.

Efficiency of Helical Gearboxes Compared to Other Gearbox Types

Helical gearboxes are known for their relatively high efficiency compared to some other gearbox types. Here’s a comparison of their efficiency with other common gearbox configurations:

- Straight-Cut (Spur) Gearboxes: Helical gearboxes are generally more efficient than straight-cut gearboxes. The helical tooth design allows for smoother engagement and better load distribution, reducing friction and energy losses. This results in higher overall efficiency for helical gearboxes.

- Bevel Gearboxes: Bevel gearboxes, which are commonly used for right-angle applications, typically have lower efficiency compared to helical gearboxes. The bevel gear design involves sliding contact between gear teeth, leading to higher friction and energy losses.

- Worm Gearboxes: Helical gearboxes are generally more efficient than worm gearboxes. Worm gearboxes have a relatively lower efficiency due to the sliding action between the worm and the gear, resulting in higher friction and heat generation.

- Planetary Gearboxes: Planetary gearboxes can offer comparable efficiency to helical gearboxes, especially when well-designed. However, planetary gearboxes can have variations in efficiency depending on factors such as the number of planet gears and gear arrangements.

While helical gearboxes tend to offer good efficiency, it’s important to note that efficiency can also be influenced by factors such as gear quality, lubrication, operating conditions, and maintenance practices. Consulting with gearbox manufacturers and considering specific application requirements is crucial when determining the most efficient gearbox solution.

editor by CX 2024-05-07

China factory High Torque K Series Helical Bevel Gear Motor Reduction Gearbox K Series Gearbox differential gearbox

Product Description

Product Description

-K Series Helical Bevel Gearbox

K series gear reducer, manufactured according to international technical requirements, has a high scientific and technological content; Space saving, reliable and durable, high overload capacity, power up to 132KW; Low energy consumption, superior performance, reducer efficiency up to 95%

It is designed and manufactured on the basis of module combination system. There are a lot of motor combinations, installation forms and structural schemes. The transmission ratio is classified carefully to meet different operating conditions and realize electromechanical integration.

High transmission efficiency, low energy consumption and superior performance.

Reinforced high rigid cast iron box; The hardened gear is made of high-quality alloy steel. Its surface is carburized, quenched and hardened, and the gear is finely ground. It features stable transmission, low noise, large bearing capacity, low temperature rise, and long service life. Performance and characteristics:

1. The gear is carburized and quenched with high-quality alloy, the hardness of the tooth surface is up to 60 ± 2hrc, and the grinding accuracy of the tooth surface is up to 5-6

2. The computer modification technology is used to pre modify the gear, which greatly improves the bearing capacity of the reducer

3. Complete modular structure design is adopted from the box to the internal gear, which is suitable for large-scale production and flexible selection

4. The standard reducer models are divided according to the form of decreasing torque. Compared with the traditional equal proportion division, they are more in line with customer requirements and avoid power waste

5. It is designed and manufactured by cad/cam to ensure the stability of quality

6. Multiple sealing structures are adopted to prevent oil leakage

7. Multi directional noise reduction measures to ensure the excellent low noise performance of the reducer

8. The installation mode of Liyi products is flexible, which makes it easy for customers to choose K57 reducer, K67 reducer, K77 reducer, K87 reducer, K97 reducer, KA87 reducer, KA97 reducer, KA107 reducer, KA127 reducer

Product Features

1. Input mode: Coupled motor, belted motor, input shaft or connection flange.

2. Output: Right angle

3. Compact structure. Rigid tooth face. Carrying greater torque, high loading capacity.

4.High precision gear, ensuring the unit to operate stably, smooth transmission.

5. Low noise, long lifespan. Large overlap coefficient, abrasion resistant.

Shaft gear box speed reducer high efficiency and stable operationGear box speed reducer gearbox with small vibration and low noise

Speed ratio is wide and the grading is fine

Gear reducer box Installation method variety

Detailed Photos

Our product line

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | 90 Degree |

| Layout: | Expansion |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | |

|---|

Installation and Alignment of Helical Gearboxes

Proper installation and alignment of a helical gearbox are essential to ensure its optimal performance and longevity. Here are the steps involved:

- Preparation: Gather all necessary tools, equipment, and safety gear. Ensure the work area is clean and well-lit.

- Mounting: Position the gearbox on the designated mounting surface and secure it using appropriate bolts. Follow the manufacturer’s guidelines for mounting torque and procedures.

- Shaft Alignment: Use precision tools such as dial indicators to align the input and output shafts. Achieving accurate shaft alignment minimizes stress on the gears and bearings.

- Bolt Tightening: Gradually and evenly tighten the mounting bolts, ensuring the gearbox remains properly aligned. Refer to torque specifications provided by the manufacturer.

- Lubrication: Fill the gearbox with the recommended lubricant according to the manufacturer’s specifications. Proper lubrication is crucial for reducing friction and wear.

- Alignment Check: After tightening the bolts, recheck the shaft alignment to ensure it hasn’t shifted during the tightening process.

- Run-In Period: Gradually introduce load to the gearbox to allow the gears to seat properly. Monitor the gearbox for any unusual noises, vibrations, or temperature changes during this period.

- Final Checks: Verify that the gearbox operates smoothly, without excessive noise or vibrations. Monitor the gearbox’s temperature during operation to ensure it remains within recommended limits.

- Regular Inspection: Schedule periodic inspections to check for any signs of wear, misalignment, or leakage. Address any issues promptly to prevent further damage.

It’s important to follow the manufacturer’s installation and alignment guidelines specific to the helical gearbox model you’re working with. Improper installation and alignment can lead to premature wear, reduced efficiency, and potential failure of the gearbox.

Helical Gearboxes and Energy Efficiency

Helical gearboxes play a significant role in enhancing energy efficiency in various industrial processes. Their design and operating characteristics contribute to improved efficiency and reduced energy consumption. Here’s how helical gearboxes achieve energy efficiency:

- Helical Gear Meshing: Helical gears have inclined teeth that engage gradually, resulting in smoother and quieter meshing compared to other gear types. This smoother engagement reduces impact and friction losses, leading to higher efficiency and lower energy consumption.

- Load Distribution: Helical gears distribute the load across multiple teeth due to their helix angle. This even load distribution minimizes stress concentrations and prevents premature wear, ensuring efficient power transmission and reducing the need for frequent maintenance.

- Efficient Power Transmission: The inclined tooth profile of helical gears allows for more teeth to be in contact at any given time. This increased contact area improves power transmission efficiency by reducing sliding friction and minimizing energy losses.

- Reduced Vibration: The helical tooth engagement minimizes vibration and noise levels, which can be particularly advantageous in applications that require precise and stable operation. Reduced vibration translates to lower energy losses and increased overall efficiency.

- Optimized Gear Design: Engineers can fine-tune helical gear designs by adjusting parameters such as helix angle, number of teeth, and gear materials. This optimization process helps tailor the gearbox for specific applications, ensuring optimal efficiency and minimal energy wastage.

- Lubrication and Cooling: Proper lubrication and cooling strategies are crucial for maintaining efficiency. Helical gears benefit from efficient lubrication due to their continuous tooth engagement, which helps reduce friction and wear, further enhancing energy efficiency.

- Advanced Manufacturing: Modern manufacturing techniques enable precise production of helical gears, ensuring tight tolerances and accurate tooth profiles. This manufacturing precision contributes to minimal energy losses during gear operation.

Overall, helical gearboxes excel in energy efficiency by combining smoother tooth engagement, even load distribution, reduced vibration, and optimized designs. Their ability to transmit power efficiently and reliably makes them a preferred choice for industrial processes where energy conservation is a priority.

Advantages of Helical Gearboxes in Industrial Applications

Helical gearboxes offer several advantages that make them well-suited for a wide range of industrial applications. Here are some of the key advantages:

- Smooth and Quiet Operation: The helical design of the gears results in gradual tooth engagement, reducing noise and vibration during operation. This makes helical gearboxes ideal for applications where noise reduction is important.

- High Efficiency: Helical gears provide a larger contact area compared to straight-cut gears, leading to improved power transmission efficiency. The gradual engagement of teeth also reduces energy losses due to friction.

- Higher Load Capacity: The helical angle allows for multiple teeth to be engaged simultaneously, distributing the load across a larger area. This results in higher load-carrying capacity and increased durability of the gearbox.

- Compact Design: Helical gearboxes can achieve high gear ratios with fewer gear stages, leading to a more compact overall design. This is advantageous in applications where space is limited.

- Wide Range of Ratios: Helical gearboxes can achieve a wide range of gear ratios, making them versatile for various speed and torque requirements.

- Less Backlash: The gradual tooth engagement of helical gears results in reduced backlash, which is the play between gear teeth. This leads to improved accuracy and positioning in applications that require precise motion control.

- Heat Dissipation: The helical design allows for better heat dissipation due to the continuous contact between gear teeth. This is beneficial in high-speed applications where heat generation can be a concern.

- Highly Customizable: Helical gearboxes can be customized to meet specific application requirements, including input and output configurations, gear ratios, and mounting options.

Overall, the advantages of helical gearboxes make them a popular choice in industries such as manufacturing, automation, robotics, material handling, and more.

editor by CX 2024-04-12

China manufacturer Helical Worm Gear Motor S Series Gear Reducer Reduction Gearbox gearbox design

Product Description

Helical Worm Gear Motor S Series Gear Reducer Reduction Gearbox

< ABOUT TILI

Technical data

| Product Name | Helical Worm Gear Motor S Series Gear Reducer Reduction Gearbox |

| Power | 0.12KW~30KW |

| Nominal output torque | 9~ 8425N · m |

| Output speed | 0.1 ~ 374r/min |

| Gear material | 20CrMnTi alloy steel |

| Gear Processing | Grinding finish by HOFLER Grinding Machines |

| Noise Test | Below 65dB |

| Brand of bearings | C&U bearing, ZWZ, LYC, HRB, CZPT , etc |

| Brand of oil seal | NAK or other brand |

| Temp. rise (MAX) | 40ºC |

| Temp. rise (Oil)(MAX | 50ºC |

| Vibration | ≤20µm |

| Housing hardness | HBS190-240 |

| Surface hardness of gears | HRC58°~62 ° |

| Gear core hardness | HRC33~40 |

| Machining precision of gears | 5 Grade |

| Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

| Heat treatment | Carburizing, Quenching etc |

| Efficiency | 95%~96% (depends on the transmission stage) |

| Bearing output mode | Parallel output |

| Installation type and output mode | Bottom seated type flange type installation, solid,hollow shaft output. |

| Input mode | Direct motor, shaft input and connecting flange input |

| Input Method | Flange input(AM), shaft input(AD), inline AC motor input, or AQA servo motor |

Installation Instructions

Company Profile

< WORKSHOP

< QUALITY CONTROL

Certifications

Packaging & Shipping

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of reducer.

Q 2:Can you do OEM?

A:Yes, we can. We can do OEM for all the customers .if you want to order NON-STANDERD speed reducers,pls provide Drafts, Dimensions, Pictures and Samples if possible.

Q 3: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 4: Do you have inspection procedures for reducer?

A:100% self-inspection before packing.

Q 5: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 6:How to choose a gearbox? What if I don’t know which gear reducer I need?

A:You can refer to our catalogue to choose the gearbox or we can help to choose when you provide,the technical information of required output torque, output speed and motor parameter etc. Don’t worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q 7: What information shall we give before placing a purchase order?

A:a) Type of the gearbox, Size , Transmission Ratio, input and output type, input flange, mounting position, motor information and shaft deflection etc. b)Housing color.c) Purchase quantity. d) Other special requirements

Q 8:What is the payment term?

A:You can pay via T/T(30% in advance as deposit before production +70% before delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Vertical Output |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Role of Helical Gearboxes in Automotive Transmissions

Helical gearboxes play a crucial role in automotive transmissions, contributing to the efficient power transfer and smooth operation of vehicles:

- Power Transmission: Helical gearboxes are used to transmit power from the engine to the wheels through different gear ratios. They help in converting the high-speed, low-torque output of the engine into the appropriate speed and torque for the wheels.

- Smooth Shifting: In manual and automatic transmissions, helical gears are often used to provide smooth and quiet gear shifts. The gradual engagement of helical gear teeth helps in reducing the shock and noise associated with gear changes.

- Noise Reduction: Helical gears are known for their quieter operation compared to other gear types. This is especially important in automotive applications where minimizing noise and vibration is desired for a comfortable driving experience.

- Efficiency: The efficiency of helical gearboxes helps in optimizing fuel efficiency and reducing energy losses. This is crucial for improving the overall performance and economy of vehicles.

- Load Distribution: Helical gears distribute the load over multiple teeth, reducing wear and ensuring the gearbox’s longevity. This is important in vehicles that experience varying loads and driving conditions.

- Torque Handling: Helical gears can handle higher torque loads compared to some other gear types. This is essential for vehicles, especially those with powerful engines, towing capabilities, or off-road use.

In modern automotive transmissions, helical gearboxes can be found in various components, including the main transmission, differential, and gearbox synchronizers. They contribute to the smooth operation, improved fuel efficiency, and overall performance of vehicles. The design and arrangement of helical gears can be tailored to meet the specific requirements of different vehicle types, making them a versatile choice for automotive applications.

Helical Gearboxes and Energy Efficiency

Helical gearboxes play a significant role in enhancing energy efficiency in various industrial processes. Their design and operating characteristics contribute to improved efficiency and reduced energy consumption. Here’s how helical gearboxes achieve energy efficiency:

- Helical Gear Meshing: Helical gears have inclined teeth that engage gradually, resulting in smoother and quieter meshing compared to other gear types. This smoother engagement reduces impact and friction losses, leading to higher efficiency and lower energy consumption.

- Load Distribution: Helical gears distribute the load across multiple teeth due to their helix angle. This even load distribution minimizes stress concentrations and prevents premature wear, ensuring efficient power transmission and reducing the need for frequent maintenance.

- Efficient Power Transmission: The inclined tooth profile of helical gears allows for more teeth to be in contact at any given time. This increased contact area improves power transmission efficiency by reducing sliding friction and minimizing energy losses.

- Reduced Vibration: The helical tooth engagement minimizes vibration and noise levels, which can be particularly advantageous in applications that require precise and stable operation. Reduced vibration translates to lower energy losses and increased overall efficiency.

- Optimized Gear Design: Engineers can fine-tune helical gear designs by adjusting parameters such as helix angle, number of teeth, and gear materials. This optimization process helps tailor the gearbox for specific applications, ensuring optimal efficiency and minimal energy wastage.

- Lubrication and Cooling: Proper lubrication and cooling strategies are crucial for maintaining efficiency. Helical gears benefit from efficient lubrication due to their continuous tooth engagement, which helps reduce friction and wear, further enhancing energy efficiency.

- Advanced Manufacturing: Modern manufacturing techniques enable precise production of helical gears, ensuring tight tolerances and accurate tooth profiles. This manufacturing precision contributes to minimal energy losses during gear operation.

Overall, helical gearboxes excel in energy efficiency by combining smoother tooth engagement, even load distribution, reduced vibration, and optimized designs. Their ability to transmit power efficiently and reliably makes them a preferred choice for industrial processes where energy conservation is a priority.

Limitations and Disadvantages of Helical Gear Systems

While helical gear systems offer numerous advantages, they also come with certain limitations and disadvantages:

- Axial Thrust: Helical gears generate axial thrust due to the helix angle of the teeth. This thrust can cause additional load on bearings and may require additional measures to counteract.

- Complex Manufacturing: The manufacturing process for helical gears is more complex than that of straight-toothed gears, which can lead to higher production costs.

- Axial Length: Helical gears require more axial space compared to spur gears with the same gear ratio. This can be a limitation in applications with space constraints.

- Sliding Contact: Helical gears have sliding contact between their teeth, which can result in higher friction and more heat generation compared to rolling contact gears.

- Efficiency: Although helical gears are generally efficient, their efficiency can be slightly lower than that of some other gear types, especially at high speeds.

- Complexity in Gearbox Design: The inclination of helical gear teeth introduces additional complexity in gearbox design and alignment.

- Reverse Thrust: In some cases, reverse thrust can occur when helical gears are subjected to high axial loads, leading to undesirable effects.

It’s important to consider these limitations and disadvantages when selecting gear systems for specific applications. Despite these challenges, helical gears remain a popular choice in various industries due to their benefits and overall performance characteristics.

editor by CX 2024-04-11

China best 220V 380V Speed Reduction AC Induction Electric Motor 100W 200W 400W 750W 1.5kw Helical Reducer Gear Box manufacturer

Product Description

3 Phase AC Reducer Motor 1/2hp 220V 380V 400W Gear Precision Foot Mounted Reducer Motor

CV and CH series motor can be designed as Single phase and 3 phases type. And power range is from 0.1KW to 3.7KW. The motor can be mounted with brake, and brake type is No excitation type. Material of gears is advanced special alloy steel and all gears are carburizing hardening. This gear motor has been added with senior lubricants, and no needs to added lubricants again.

Helical gear reducer has the characteristics of strong versatility, good combination, and strong bearing capacity, and has the advantages of easy access to various transmission ratios, high efficiency, small vibration, and high allowable axial and radial loads.

This series of products can not only be used in combination with various reducers and vibrators to meet the requirements, but also has the advantage of localization of related transmission equipment.

Mostly used in metallurgy, sewage treatment,chemical, pharmaceutical and other industries.

| Type | CH series three phase or single phase ac motors for industrial use | |

| Voltage | 220VAC, 380VAC, 415VAC | |

| Power range | Power range is 0.1KW to 3.7KW | |

| Output Speed | Speed range is from 7rpm to 500rpm | |

| Phase | Single phase and 3phases for choice | |

| Gears | Special alloy steel and high precise gears | |

| Grease | Good grease and no need add grease during using | |

| Cooling | Full closed fan | |

| USE | This motor is widely used in packing machine, textil machine |

motor is widely used in mix machine,elevator, conveyor,etc. |

| OEM Service | We offer OEM service. | |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Bevel Gear |

| Step: | Three-Step |

| Samples: |

US$ 70/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Role of Helical Gearboxes in Automotive Transmissions

Helical gearboxes play a crucial role in automotive transmissions, contributing to the efficient power transfer and smooth operation of vehicles:

- Power Transmission: Helical gearboxes are used to transmit power from the engine to the wheels through different gear ratios. They help in converting the high-speed, low-torque output of the engine into the appropriate speed and torque for the wheels.

- Smooth Shifting: In manual and automatic transmissions, helical gears are often used to provide smooth and quiet gear shifts. The gradual engagement of helical gear teeth helps in reducing the shock and noise associated with gear changes.

- Noise Reduction: Helical gears are known for their quieter operation compared to other gear types. This is especially important in automotive applications where minimizing noise and vibration is desired for a comfortable driving experience.

- Efficiency: The efficiency of helical gearboxes helps in optimizing fuel efficiency and reducing energy losses. This is crucial for improving the overall performance and economy of vehicles.

- Load Distribution: Helical gears distribute the load over multiple teeth, reducing wear and ensuring the gearbox’s longevity. This is important in vehicles that experience varying loads and driving conditions.

- Torque Handling: Helical gears can handle higher torque loads compared to some other gear types. This is essential for vehicles, especially those with powerful engines, towing capabilities, or off-road use.

In modern automotive transmissions, helical gearboxes can be found in various components, including the main transmission, differential, and gearbox synchronizers. They contribute to the smooth operation, improved fuel efficiency, and overall performance of vehicles. The design and arrangement of helical gears can be tailored to meet the specific requirements of different vehicle types, making them a versatile choice for automotive applications.

Helical Gearboxes and Energy Efficiency

Helical gearboxes play a significant role in enhancing energy efficiency in various industrial processes. Their design and operating characteristics contribute to improved efficiency and reduced energy consumption. Here’s how helical gearboxes achieve energy efficiency:

- Helical Gear Meshing: Helical gears have inclined teeth that engage gradually, resulting in smoother and quieter meshing compared to other gear types. This smoother engagement reduces impact and friction losses, leading to higher efficiency and lower energy consumption.

- Load Distribution: Helical gears distribute the load across multiple teeth due to their helix angle. This even load distribution minimizes stress concentrations and prevents premature wear, ensuring efficient power transmission and reducing the need for frequent maintenance.

- Efficient Power Transmission: The inclined tooth profile of helical gears allows for more teeth to be in contact at any given time. This increased contact area improves power transmission efficiency by reducing sliding friction and minimizing energy losses.

- Reduced Vibration: The helical tooth engagement minimizes vibration and noise levels, which can be particularly advantageous in applications that require precise and stable operation. Reduced vibration translates to lower energy losses and increased overall efficiency.

- Optimized Gear Design: Engineers can fine-tune helical gear designs by adjusting parameters such as helix angle, number of teeth, and gear materials. This optimization process helps tailor the gearbox for specific applications, ensuring optimal efficiency and minimal energy wastage.

- Lubrication and Cooling: Proper lubrication and cooling strategies are crucial for maintaining efficiency. Helical gears benefit from efficient lubrication due to their continuous tooth engagement, which helps reduce friction and wear, further enhancing energy efficiency.

- Advanced Manufacturing: Modern manufacturing techniques enable precise production of helical gears, ensuring tight tolerances and accurate tooth profiles. This manufacturing precision contributes to minimal energy losses during gear operation.

Overall, helical gearboxes excel in energy efficiency by combining smoother tooth engagement, even load distribution, reduced vibration, and optimized designs. Their ability to transmit power efficiently and reliably makes them a preferred choice for industrial processes where energy conservation is a priority.

Limitations and Disadvantages of Helical Gear Systems

While helical gear systems offer numerous advantages, they also come with certain limitations and disadvantages:

- Axial Thrust: Helical gears generate axial thrust due to the helix angle of the teeth. This thrust can cause additional load on bearings and may require additional measures to counteract.

- Complex Manufacturing: The manufacturing process for helical gears is more complex than that of straight-toothed gears, which can lead to higher production costs.

- Axial Length: Helical gears require more axial space compared to spur gears with the same gear ratio. This can be a limitation in applications with space constraints.

- Sliding Contact: Helical gears have sliding contact between their teeth, which can result in higher friction and more heat generation compared to rolling contact gears.

- Efficiency: Although helical gears are generally efficient, their efficiency can be slightly lower than that of some other gear types, especially at high speeds.

- Complexity in Gearbox Design: The inclination of helical gear teeth introduces additional complexity in gearbox design and alignment.

- Reverse Thrust: In some cases, reverse thrust can occur when helical gears are subjected to high axial loads, leading to undesirable effects.

It’s important to consider these limitations and disadvantages when selecting gear systems for specific applications. Despite these challenges, helical gears remain a popular choice in various industries due to their benefits and overall performance characteristics.

editor by CX 2024-04-09

China Custom High Efficiency Good Quality R Series RF57 Helical Gearbox Transmission Reduction Gear Box with Shaft Gear Motor with Good quality

Product Description

R Series reducers are designed and manufactured on the basis of modular combination system.

There are a lot of motor combinations, installation forms and structural schemes. The transmission

ratio is classified and fine to meet different operating conditions, and the performance is superior.

Reinforced high rigid cast iron box; The hardened gear is made of high-quality alloy steel. Its surface

is carburized, quenched and hardened, and the gear is finely ground. It has stable transmission, low

noise, and large bearing capacity. Low temperature rise, long service life. It is widely used in metallurgy,1. Features: small offset output, compact structure, maximum use of box space, use of integral casting box, good stiffness, can improve the strength of the shaft and bearing life.

2. Installation type and output mode: bottom seated type and large and small flange type installation, CZPT shaft output.

3. Input mode: direct motor, shaft input and connecting flange input.

4. Reduction ratio: secondary 5~24.8, tertiary 27.2~264, R/R combination up to 18125.

5. Average efficiency: Class II 96%, Class III 94%, R/R combination 85%.

6. The R series specially designed for mixing can bear large axial and radial forces.

Technical parameters:

Coaxial coaxial output

R reducer

Power: 0.12KW~160KW

Torque: 1.4N · m ~ 23200N · m

Output speed: 0.06 ~ 1090r/min

Model example:

R17-Y4-4P-32.40-M1-0°

R: Series code

F: Shaft extension flange installation

17: Machine model

Y: Three phase AC asynchronous motor

4: Motor power

4P: motor stage

32.40: Transmission ratio

M1: Installation type

0 °: junction box position (0 ° – 270 °)

R series helical gear hardened gear reducer

Basic model of R series reducer:

R17R27R37R47R57R67R77R87R97R107R137R147R167

RF17RF27RF37RF47RF57RF67RF77RF87RF97RF107RF137RF147RF167

RX37RX57RX67RX77RX87RX97RX107RX127RX157

RXF37RXF57RXF67RXF77RXF87RXF97RXF107RXF127RXF157

R series helical gear reducer with hard tooth surface features small size, light weight, high bearing capacity, high efficiency, long service life, convenient installation, wide motor power range, fine transmission ratio classification, etc. It can be widely used in equipment that needs to be decelerated in various industries.

sewage treatment, chemical industry, pharmacy and other industries.

Company Profile

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Horizontal Type |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 430/Piece

1 Piece(Min.Order) | |

|---|

Precision and High-Accuracy Applications of Helical Gearboxes

Helical gearboxes are well-suited for precision and high-accuracy applications due to their unique design and performance characteristics:

- Helical Gearing: The helical gears in these gearboxes offer smooth and continuous meshing, resulting in reduced backlash and improved positioning accuracy.

- Efficiency: Helical gearboxes are known for their high efficiency, which minimizes energy losses and heat generation. This is crucial for maintaining precision in applications where even small deviations can have significant impacts.

- Noise and Vibration: The helical gear tooth engagement helps in reducing noise and vibration levels, making them suitable for environments where quiet operation is required.

- Load Distribution: Helical gears distribute load across multiple teeth, minimizing localized wear and extending the lifespan of the gearbox.

- Smooth Motion: Helical gearboxes provide smoother motion transitions, which is crucial in precision applications where jerky or sudden movements are undesirable.

- Positional Accuracy: The reduced backlash and improved meshing characteristics of helical gears contribute to higher positional accuracy, making these gearboxes ideal for applications such as CNC machines, robotics, and medical equipment.

- Compact Design: Helical gearboxes can achieve high gear ratios in a relatively compact form factor, making them suitable for applications where space is limited.

Examples of precision applications where helical gearboxes are commonly used include CNC machining, robotics, semiconductor manufacturing, medical equipment, and metrology devices. The combination of efficiency, smooth operation, and accuracy makes helical gearboxes a preferred choice for achieving consistent and reliable performance in such applications.

Considerations for Designing Helical Gearboxes for Heavy-Duty Applications

Designing helical gearboxes for heavy-duty applications requires careful consideration of various factors to ensure reliable and efficient operation under high loads and demanding conditions. Here are the key considerations:

- Load Capacity: Heavy-duty applications involve substantial loads. The gearbox must be designed to handle these loads while preventing premature wear and failure. Calculations of the load distribution, contact stresses, and material strength are crucial.

- Material Selection: High-strength and durable materials are essential for heavy-duty gearboxes. Alloy steels or special heat-treated materials are often chosen to provide the necessary strength and resistance to fatigue and wear.

- Gear Tooth Design: Optimal gear tooth profiles, such as optimized helix angles and tooth modifications, contribute to smoother engagement and reduced stress concentrations. This enhances the gearbox’s ability to handle heavy loads without excessive wear.

- Bearing Selection: Robust and high-capacity bearings are necessary to support the heavy loads and provide reliable shaft support. The bearings must be able to withstand both radial and axial forces generated during operation.

- Lubrication: Adequate lubrication is critical for heavy-duty gearboxes. Lubricants with high load-carrying capacity and extreme pressure properties are chosen to ensure proper lubrication under heavy loads and to reduce friction and wear.

- Heat Dissipation: Heavy-duty applications can generate significant heat due to friction and load. Efficient heat dissipation mechanisms, such as cooling fins or oil cooling, should be incorporated into the gearbox design to prevent overheating and thermal damage.

- Sealing: Effective sealing is necessary to prevent contaminants from entering the gearbox and to retain lubricants. Seals must be capable of withstanding the conditions of the application, including high loads, vibrations, and potential exposure to harsh environments.

- Efficiency: Although heavy-duty applications prioritize load capacity, achieving acceptable levels of efficiency is still important to minimize energy losses and heat generation. Proper gear tooth design and high-quality manufacturing contribute to better efficiency.

- Structural Integrity: The gearbox housing and components must be designed with structural integrity in mind. Rigidity and robustness are required to prevent distortion or failure of components under heavy loads.

- Reliability and Serviceability: Heavy-duty gearboxes should be designed with reliability and ease of maintenance in mind. Access to critical components, such as gears and bearings, for inspection and replacement is important to minimize downtime.

Conclusion: Designing helical gearboxes for heavy-duty applications involves a comprehensive approach that addresses load capacity, material selection, gear tooth design, lubrication, heat dissipation, sealing, efficiency, structural integrity, and serviceability. By carefully considering these factors, engineers can create gearboxes that deliver exceptional performance and longevity in demanding industrial settings.

Industries Utilizing Helical Gearboxes

Helical gearboxes find widespread use in various industries due to their efficiency, smooth operation, and versatility. Some of the industries that commonly utilize helical gearboxes include:

- Manufacturing: Helical gearboxes are employed in manufacturing processes for conveyor systems, material handling, and machine tools. Their ability to provide high torque and smooth motion makes them suitable for precision manufacturing.

- Automotive: Automotive applications include power transmission in vehicles, especially in manual and automatic transmissions. Helical gearboxes contribute to improved fuel efficiency and smoother gear shifting.

- Energy Generation: Helical gearboxes are used in power generation systems, such as wind turbines and hydroelectric generators. Their efficiency and load-bearing capacity are crucial for converting rotational motion into electrical power.

- Construction: Construction equipment, such as cranes, excavators, and bulldozers, rely on helical gearboxes for efficient power transmission and control of heavy loads.

- Mining: Mining operations use helical gearboxes in conveyors, crushers, and other equipment for material handling and ore extraction. The durability and high torque capacity of helical gearboxes make them suitable for demanding mining environments.

- Marine: Marine vessels use helical gearboxes in propulsion systems to convert engine power into rotational motion for propellers. Their efficiency contributes to fuel savings and reliable marine operation.

- Food and Beverage: Helical gearboxes are employed in food processing and packaging machinery due to their sanitary design and precise motion control.

- Textile: Textile machinery relies on helical gearboxes for various processes, including spinning, weaving, and dyeing. Their ability to handle varying loads and provide smooth motion is beneficial in textile production.

The adaptability and efficiency of helical gearboxes make them a suitable choice for a wide range of industries, where reliable power transmission, smooth operation, and load-bearing capacity are essential.

editor by CX 2023-10-10

China TRC series helical gearbox speed reducer electric motor helical gearbox reduction gear motor transmission gear box components of gearbox

Guarantee: 3 a long time

Applicable Industries: Accommodations, Garment Shops, Building Substance Shops, Production Plant, Equipment Repair Stores, Meals & Beverage Factory, Farms, Restaurant, Home Use, Retail, Meals Shop, Printing Outlets, Development works , Energy & Mining, M1.5 15151005mm straight tooth CNC gear rack Meals & Beverage Retailers, Other, Advertising Organization

Fat (KG): 3 KG

Personalized assist: OEM, ODM, OBM

Gearing Arrangement: Helical

Output Torque: 99999N.m

Enter Velocity: 1450rpm

Output Speed: 1-one thousand

Ratio: 3.seventy seven~50.4

Certification: ISO9001-2008

Mount Placement: Foot Mounted

Bearing: LYC, HRB,ZWZ,NSK

Packaging Information: Wooden boxes , Cantons packed in 1 pallet

TRC collection helical gearbox speed reducer electric motor helical gearbox reduction gear motor transmisson equipment box

Technological features:The extremely modular is a style functions of SRC helical gearboxes variety. It can be related respectively with motors such as normal motor,brake motor,explosion-evidence motor,frequency conversion motor,servo motor,IEC motor and so on. This variety of solution is extensively utilized in push fields these kinds of as textile, BN excavator hydraulic gear motor shaft coupling foodstuff,ceramics packing,logistics,plastics and so on. It is feasible to set up the version essential utilizing flanges or feet

Solution attributes:SLRC collection helical gear units has more than 4 varieties,power .12kw-4kw,ratio3.66-54max torque120-500NM,It can be related(foot or flange)discretionary and use multi-mounting positions in accordance customers’ requirements1 Floor-hardened helical gears2. Modularity,can be mixed in many forms3. Aluminum casing,light weight4. Gears in carbonize tough,durable5. Universal mouting6. Refined style, compact in structure and lower sound

| Certification | ISO9001-2008 |

| Bearing | C&U |

| Coloration | Blue/black |

| Ratio | three.seventy seven~fifty.4 |

| Mount Placement | Foot Mounted |

| Bearing | LYC, SF08 Aluminum Push Coating Adapter Steering Axle Coupling Ball Spline Shaft HRB,ZWZ,SKF,NSK |

Business Info

Certifications

Our Services

Packaging & Shipping and delivery

Expo& Consumers

Related Products

FAQ: Are you trading firm or manufacturer ?A: We are factory.

Q: How prolonged is your supply time?A: Usually it is 5-10 days if the merchandise are in stock. or it is 15-20 days if the products are not in stock, it is according to amount.

Q: Do you offer samples ? is it cost-free or extra ?A: Sure, we could supply the sample for free of charge cost but do not pay the expense of freight.

Q: What is your terms of payment ?A: Payment=1000USD, 30% T/T in progress ,stability prior to shippment.If you have an additional issue, pls come to feel free to get in touch with us as under:

Types of Vehicle Gearboxes

In a vehicle, there are many types of gearboxes available. There are planetary gearboxes, Coaxial helical gearboxes, and skew bevel helical gearboxes, among others. In this article, we’ll cover all of them and help you determine which type of gearbox would be right for your vehicle. Also, we’ll discuss how each differs from the others.

planetary gearbox

A planetary gearbox is composed of three main components: a sun gear, an input bevel gear, and an output shaft. A planetary gearbox can have different output torques and ratios. The basic model of a planetary gearbox is highly efficient and transmits 97% of the power input. There are several kinds of planetary gearboxes, depending on the type of operation. In general, there are three types: the simple, the intermediate, and the complex.

The price of a planetary gearbox can vary a lot, and it’s important to know what you’ll need. Different manufacturers produce different planetary gearboxes, so check with a manufacturer to see what they have available. Make sure to check the quality of the planetary gearbox before making a final purchase. In addition, be sure to compare the prices and the availability of a particular product. A quality planetary gearbox will provide years of trouble-free operation and will not break your bank.

Planetary gears feature an integer number of teeth. Each planet has teeth that must mesh with its ring or sun. The number of planets, ring, and tooth count of each gear determine whether the teeth mesh. Some planets have fewer teeth than others, so they mesh better than others. However, compound planets can be more flexible and achieve higher reduction ratios. If you’re looking for a planetary gearbox for your next project, consider getting in touch with a manufacturer who specializes in this technology.

When it comes to construction, a planetary gearbox is no exception. It’s extremely important to choose the right planetary gear for your application, because an imbalance in the planet gear can cause increased wear and failure. Moreover, the compact size of a planetary gear ensures maximum heat dissipation. However, a planetary gear box may require cooling in some applications. A planetary gearbox will make your life easier, and it will give you years of trouble-free operation.

Straight bevel helical gearbox

The Straight bevel helical gearbox has a number of advantages, but it has a relatively short manufacturing process. Its most popular application is in the automotive industry, where it is used in many types of vehicles. Other applications include heavy and light equipment and the aviation and marine industries. Below is a brief introduction to this gearbox type. Read on to learn about its benefits. This type of gearbox is one of the easiest to manufacture.

The spiral bevel gear has larger teeth than straight bevel gears, resulting in a smoother, quieter rotation. It can handle high-speed heavy loads with less vibration. Spiral bevel gears are classified by their tooth form and cutting method. Straight bevel gears are easier to design and manufacture, but spiral bevel gears are more expensive. Both designs are suitable for high-speed, heavy-load operations, and general manufacturing applications.

In addition to being easy to install, the modular bevel gears have many advantages. They have an exceptionally high degree of interchangeability and feature the highest standards of component integrity. They can also be tailored to meet your specific requirements. The advantages of this gearbox type include high precision, optimum performance, and low noise. And because they are modular, they can be produced in a variety of finishes. These include stainless steel, titanium, and bronze.

Straight bevel helical gearbox manufacturers are committed to a high degree of precision in their designs. The radii, torques, and tooth profiles of straight bevel gears are more precisely measured than those of cylindrical bevel gears. The same calculations are used for all traditional bevel gear generators. This ensures that your 5-axis milled bevel gear sets have the same calculations and layout.

Coaxial helical gearbox

The Coaxial helical gearbox is a highly efficient transmission system that is well suited for light-duty applications. Compared to spur-type gearboxes, the real pitch of a Coaxial helical gearbox is low at all helix angles. This is because the coaxial type has the same number of teeth and center gap as the spur gearbox. Coaxial helical gearboxes also have a smaller footprint and are compact.

Several nations have implemented lockdown regulations for Industrial Gearbox trade, threatening the global economy. Several factors have been implicated in COVID-19, including supply chain, market, and financial markets. Experts are monitoring the situation globally and project remunerative prospects for gearbox manufacturers after the crisis. This report depicts the latest scenario and offers a comprehensive analysis of COVID-19’s impact on the entire industry.

This Coaxial helical gearbox features a compact structure and high precision gear. Its three-stage design combines two-stage gears with a single-stage gear, forging high-quality alloy steel for high precision and durability. The gears are serially-designed for easy interchangeability. They are also available in high-frequency heat-treated steel. A Coaxial helical gearbox is the perfect solution for many applications.

Coaxial helical gearboxes have the added benefit of using cylindrical gears instead of shafts. They operate quietly, and have more surface area to interact with. Their fixed angles make them suitable for heavy-duty applications, like in conveyors, coolers, and grinders. Compared to other gearbox types, Helical gearboxes have higher power-carrying capacity. Listed below are the benefits of a Coaxial Helical Gearbox

Skew bevel helical gearbox

A Skew bevel helical gear box is a common type of industrial gearbox. These gearboxes are rigid and compact and can be used in a variety of applications. They are commonly used in heavy-duty applications such as grinding mills, conveyors, and coolers. They are used in many applications to provide rotary motions between non-parallel shafts. They also have the added benefit of high-efficiency in a variety of industries.

Skew bevel helical gear boxes are suitable for heavy loads and are monolithic in construction. This type of gearbox combines the benefits of bevel and helical gears for right-angle torque, which makes it a popular choice for heavy-duty applications. In addition to being a robust and reliable gearbox, these gearboxes are highly customizable and can meet almost any industrial need.

To maximize the efficiency of bevel gears, FE-based tooth contact analysis is used to develop a sophisticated geometry optimization algorithm. The software also allows users to define optimal flank topography by introducing application-specific weightings for specific load levels. With this data, a manufacturing simulation is conducted to determine the best variant. A robust variant combines the benefits of efficiency, load-carrying capacity, and low excitation behavior.

The helical gear can be angled at 90 degrees. This is similar to a spur gear but produces less noise. It can achieve a nine-to-one speed reduction with one stage. However, a helical gear requires a larger driver gear for higher reductions. This gearbox is suitable for speeds from 1:1 to three times. They are often used in the manufacture of motors and generators.

Extruder helical gearbox

An extruder helical gearbox is one of the most common industrial gears. It is compact in size and low-power consuming, making it ideal for heavy-duty applications. Extruder helical gearboxes are suitable for a variety of industrial applications, including cement, plastics, rubber, conveyors, and coolers. In addition to its use in plastics and rubber manufacturing, this gearbox is also useful in other low-power applications such as crushers, coolers, and conveyors.

CZPT SG series Extruder Helical Gearboxes are available in Single Screw and Twin Screw Variations. These gears feature a compact design, high power density, and long service life. Axial bearing housing and thrust bearings are mounted on the input shafts. Extruder helical gearboxes can be installed in various positions, including horizontal, vertical, and inclined.

Helicoidal gears are often produced in a modular manner. This design provides multiple benefits, including engineering and performance advantages, modular production, and the highest level of component integrity. A single helical gearbox can be assembled into a larger gearbox if needed, but modular production ensures consistent performance and economy. This modular design is also cost-effective. It is a versatile and reliable solution for a wide range of applications.

In addition to its efficiencies, Extruder helical gearboxes also have a low noise profile. They have no squeal sounds, and they are silent when running. They can transfer more power than conventional gearboxes. This type of gear has been used in the manufacturing of high-quality plastic products for years. They are often used for applications in automotive transmissions. Aside from being quiet, helical gears have higher contact levels and lower vibration.

editor by czh2023-03-17

China r series variateur de vitesse coaxial helical gear motor gearbox speed reducer speed reduction gearbox for marine gearbox gear gearbox drive shaft

Warranty: 3 years, 18 Months

Applicable Industries: Hotels, Garment Outlets, Constructing Substance Retailers, Manufacturing Plant, Machinery Repair Shops, Foodstuff & Beverage Factory, Farms, Restaurant, House Use, Retail, Foodstuff Shop, Printing Stores, Design works , High quality Gearbox Transmission A168370 0571 Drum K1 Automatic Transmission 722.7 For Mercedess Benzs Power & Mining, Food & Beverage Outlets, Promoting Business

Fat (KG): sixty five

Customized assistance: OEM, ODM, OBM

Gearing Arrangement: Helical

Output Torque: 3.5~5 Flange Packing 30% T/T in advance ,equilibrium just before shippment.If you have another question, pls feel free of charge to speak to us as below: Make contact with Us

Types of Vehicle Gearboxes

In a vehicle, there are many types of gearboxes available. There are planetary gearboxes, Coaxial helical gearboxes, and skew bevel helical gearboxes, among others. In this article, we’ll cover all of them and help you determine which type of gearbox would be right for your vehicle. Also, we’ll discuss how each differs from the others.

planetary gearbox

A planetary gearbox is composed of three main components: a sun gear, an input bevel gear, and an output shaft. A planetary gearbox can have different output torques and ratios. The basic model of a planetary gearbox is highly efficient and transmits 97% of the power input. There are several kinds of planetary gearboxes, depending on the type of operation. In general, there are three types: the simple, the intermediate, and the complex.

The price of a planetary gearbox can vary a lot, and it’s important to know what you’ll need. Different manufacturers produce different planetary gearboxes, so check with a manufacturer to see what they have available. Make sure to check the quality of the planetary gearbox before making a final purchase. In addition, be sure to compare the prices and the availability of a particular product. A quality planetary gearbox will provide years of trouble-free operation and will not break your bank.

Planetary gears feature an integer number of teeth. Each planet has teeth that must mesh with its ring or sun. The number of planets, ring, and tooth count of each gear determine whether the teeth mesh. Some planets have fewer teeth than others, so they mesh better than others. However, compound planets can be more flexible and achieve higher reduction ratios. If you’re looking for a planetary gearbox for your next project, consider getting in touch with a manufacturer who specializes in this technology.

When it comes to construction, a planetary gearbox is no exception. It’s extremely important to choose the right planetary gear for your application, because an imbalance in the planet gear can cause increased wear and failure. Moreover, the compact size of a planetary gear ensures maximum heat dissipation. However, a planetary gear box may require cooling in some applications. A planetary gearbox will make your life easier, and it will give you years of trouble-free operation.

Straight bevel helical gearbox

The Straight bevel helical gearbox has a number of advantages, but it has a relatively short manufacturing process. Its most popular application is in the automotive industry, where it is used in many types of vehicles. Other applications include heavy and light equipment and the aviation and marine industries. Below is a brief introduction to this gearbox type. Read on to learn about its benefits. This type of gearbox is one of the easiest to manufacture.

The spiral bevel gear has larger teeth than straight bevel gears, resulting in a smoother, quieter rotation. It can handle high-speed heavy loads with less vibration. Spiral bevel gears are classified by their tooth form and cutting method. Straight bevel gears are easier to design and manufacture, but spiral bevel gears are more expensive. Both designs are suitable for high-speed, heavy-load operations, and general manufacturing applications.

In addition to being easy to install, the modular bevel gears have many advantages. They have an exceptionally high degree of interchangeability and feature the highest standards of component integrity. They can also be tailored to meet your specific requirements. The advantages of this gearbox type include high precision, optimum performance, and low noise. And because they are modular, they can be produced in a variety of finishes. These include stainless steel, titanium, and bronze.

Straight bevel helical gearbox manufacturers are committed to a high degree of precision in their designs. The radii, torques, and tooth profiles of straight bevel gears are more precisely measured than those of cylindrical bevel gears. The same calculations are used for all traditional bevel gear generators. This ensures that your 5-axis milled bevel gear sets have the same calculations and layout.

Coaxial helical gearbox

The Coaxial helical gearbox is a highly efficient transmission system that is well suited for light-duty applications. Compared to spur-type gearboxes, the real pitch of a Coaxial helical gearbox is low at all helix angles. This is because the coaxial type has the same number of teeth and center gap as the spur gearbox. Coaxial helical gearboxes also have a smaller footprint and are compact.

Several nations have implemented lockdown regulations for Industrial Gearbox trade, threatening the global economy. Several factors have been implicated in COVID-19, including supply chain, market, and financial markets. Experts are monitoring the situation globally and project remunerative prospects for gearbox manufacturers after the crisis. This report depicts the latest scenario and offers a comprehensive analysis of COVID-19’s impact on the entire industry.

This Coaxial helical gearbox features a compact structure and high precision gear. Its three-stage design combines two-stage gears with a single-stage gear, forging high-quality alloy steel for high precision and durability. The gears are serially-designed for easy interchangeability. They are also available in high-frequency heat-treated steel. A Coaxial helical gearbox is the perfect solution for many applications.

Coaxial helical gearboxes have the added benefit of using cylindrical gears instead of shafts. They operate quietly, and have more surface area to interact with. Their fixed angles make them suitable for heavy-duty applications, like in conveyors, coolers, and grinders. Compared to other gearbox types, Helical gearboxes have higher power-carrying capacity. Listed below are the benefits of a Coaxial Helical Gearbox

Skew bevel helical gearbox