Product Description

Professional Manufacturer in China of R/S/K/F Helical Gear Reducers Gear Motor /Speed Reducer /Transmission Gearbox

< ABOUT TILI

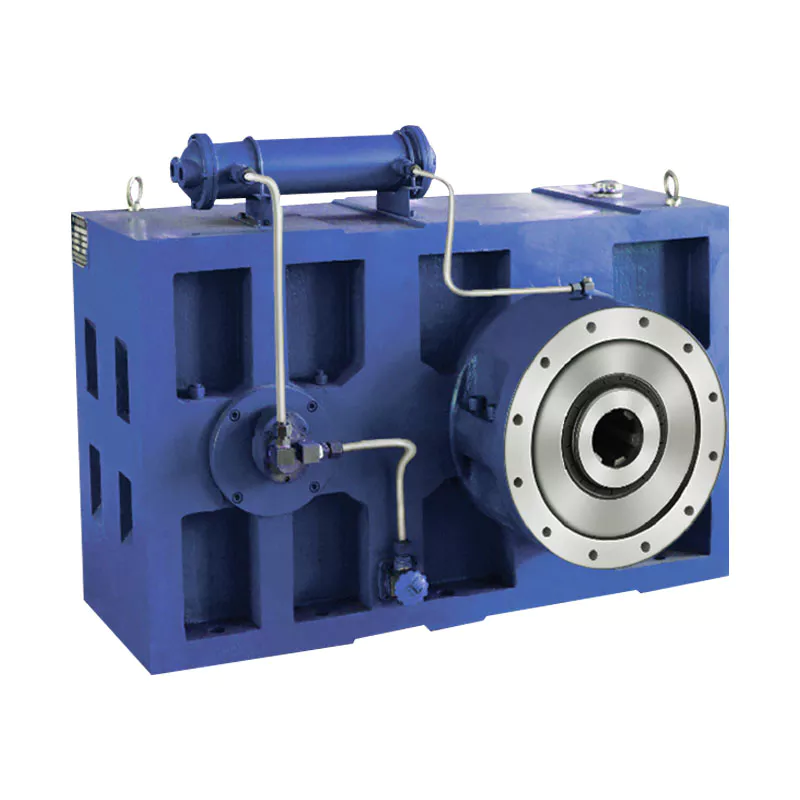

HangZhou Tili Reducer Co., Ltd. is located in CZPT Industrial Concentration Zone, Zou District, Xihu (West Lake) Dis. District, HangZhou, China. It is a professional company that produces reducers. The company specializes in the production of various reducer products, including DJYG series high torque series extruder gearboxes, CZPT series single screw extruder gearboxes, SZ, SZL series conical twin-screw extruder gearboxes, and more. In addition, the company also produces R, K, F, S series helical gear reducers, B/X series cycloidal pinwheel reducers, planetary reducers, etc. The company not only has professional capabilities in the design and manufacturing of hard tooth surface gearboxes and cycloidal pinwheel gearboxes, but also its products have entered various provinces, cities, and autonomous regions across the country. Some of its products are exported to foreign countries, mainly supporting the fields of plastics, rubber, metallurgy and mining, petrochemicals, lifting and transportation, light industry and food.

HangZhou Taili Reducer Co., Ltd. has been committed to providing customers with high-quality hard tooth extrusion reducers for more than 20 years since its establishment. The product quality has been unanimously recognized by domestic and foreign customers through market validation. The company has strong technological and business management capabilities, and has introduced top processing equipment from Germany and Switzerland. The product quality is reliable, and the after-sales service is complete. It can provide users with special designs to meet their requirements.

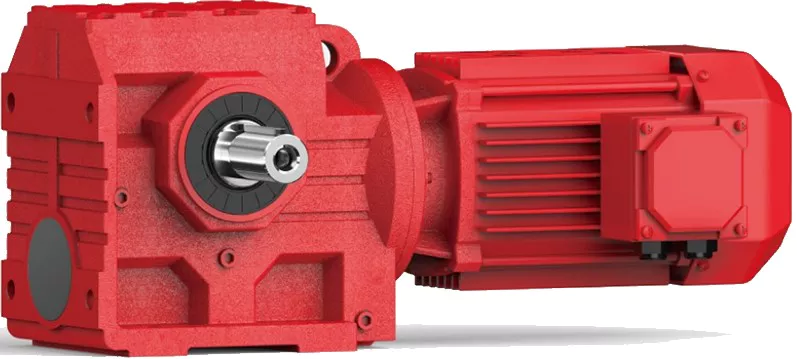

R series helical gear units

product/xteUysJGvQVq/China-R-Series-Foot-Mounted-Coaxial-Gearbox-with-Inline-Standard-Motor.html

R series:Small size, light weight, large transmission torque, superior performance, stable operation, low noise, durable, can be installed in a variety of ways, can be matched with different types of motors, a wide range of applications. sewage treatment, chemical industry, pharmacy and other industries.

K series helical-bevel gear units

product/CAepOqywMEhH/China-K-Series-Hardened-Tooth-Surface-Helical-Bevel-Foot-Mounted-Gearbox-with-Inline-Standard-Motor.html

K series gearbox is 1 kind of Helical Bevel type gearbox ,it is designed based on modularization , which bring many difference kinds of combinations ,mounting types ,and structure designs .The detail classification of ratio can meet various of working condition .High Transmission efficiency ,low energy consumption, superior performance .

S series helical-worm gear units

product/laXYVUyhOxWn/China-S-Series-Foot-Mounted-Helical-Worm-Gearbox-with-Solid-Shaft-with-Inline-Standard-Motor.html

S series: right-angle speed reduction gearing composed by helical gears, worms, and gears, optimized and designed according to international standard.High precision, high efficiency, fine classification in transmission ratio, wide range, large transmission torque, reliable performance, low noise, flexible installation, and convenient use and maintenance.

F series parallel-shaft helical gear units

product/wTPpMGtcvQVl/China-F-Series-Foot-Mounted-Parallel-Shaft-Gearbox-with-Inline-Standard-Motor.html

F series speed gear reducer is 1 kind of parallel shaft helical gear reducer , which consist of 2 or 3 stages helical gears (relate to gear ratio) in the same case . The hard tooth surface gear use the high quality alloy steel ,the process of carburizing and quenching, grinding .

| Product Name | Professional Manufacturer in China of R/S/K/F Helical Gear Reducers Gear Motor /Speed Reducer /Transmission Gearbox |

| Power | 0.12KW~160KW |

| Torque | 1.4N · m ~ 36600N · m |

| Output speed | 0.06 ~ 1090r/min |

| Gear material | 20CrMnTi alloy steel |

| Gear Processing | Grinding finish by HOFLER Grinding Machines |

| Noise Test | Below 65dB |

| Brand of bearings | C&U bearing, ZWZ,LYC, HRB, CZPT ,etc |

| Brand of oil seal | NAK or other brand |

| Temp. rise (MAX) | 40ºC |

| Temp. rise (Oil)(MAX | 50ºC |

| Vibration | ≤20µm |

| Housing hardness | HBS190-240 |

| Surface hardness of gears | HRC58°~62 ° |

| Gear core hardness | HRC33~40 |

| Machining precision of gears | 5 Grade |

| Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

| Heat treatment | Carburizing, Quenching etc |

| Efficiency | 95%~96% (depends on the transmission stage) |

| Bearing output mode | parallel output |

| Installation type and output mode | Bottom seated type flange type installation, solid,hollow shaft output. |

| Input mode | Direct motor, shaft input and connecting flange input |

| Input Method | Flange input(AM), shaft input(AD), inline AC motor input, or AQA servo motor |

Detailed Photos

R SERIES

K SERIES

S SERIES

F SERIES

Company Profile

< WORKSHOP

< QUALITY CONTROL

Certifications

Packaging & Shipping

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of reducer.

Q 2:Can you do OEM?

A:Yes, we can. We can do OEM for all the customers .if you want to order NON-STANDERD speed reducers,pls provide Drafts, Dimensions, Pictures and Samples if possible.

Q 3: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 4: Do you have inspection procedures for reducer?

A:100% self-inspection before packing.

Q 5: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 6:How to choose a gearbox? What if I don’t know which gear reducer I need?

A:You can refer to our catalogue to choose the gearbox or we can help to choose when you provide,the technical information of required output torque, output speed and motor parameter etc. Don’t worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q 7: What information shall we give before placing a purchase order?

A:a) Type of the gearbox, Size , Transmission Ratio, input and output type, input flange, mounting position, motor information and shaft deflection etc. b)Housing color.c) Purchase quantity. d) Other special requirements

Q 8:What is the payment term?

A:You can pay via T/T(30% in advance as deposit before production +70% before delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery, Agricultural Machinery, Industrial Automation Equipment, Chemical Industry |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Coaxial |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Advancements in Helical Gearbox Technology

Advancements in helical gearbox technology have led to improved performance, efficiency, and versatility. Here are some notable advancements:

- Material Innovations: The use of advanced materials, such as high-strength alloys and composites, has enhanced the durability and load-carrying capacity of helical gears. These materials also contribute to reduced weight and improved efficiency.

- Precision Manufacturing: Modern manufacturing techniques, including CNC machining and gear grinding, have enabled the production of helical gears with higher accuracy and tighter tolerances. This results in smoother operation and reduced noise levels.

- Gear Tooth Profile Optimization: Advanced computer simulations and modeling techniques allow for the optimization of gear tooth profiles. This results in better load distribution, reduced stress concentration, and improved overall gearbox efficiency.

- Lubrication and Cooling: Improved lubrication systems and cooling mechanisms help maintain optimal operating temperatures and extend the lifespan of helical gearboxes. This is particularly important for high-demand applications.

- Noise and Vibration Reduction: Innovative designs and precision manufacturing techniques have led to helical gears with reduced noise and vibration levels. This advancement is crucial for industries where noise reduction is a priority.

- Compact Design: Advancements in gear design and manufacturing have allowed for more compact and lightweight helical gearbox configurations, making them suitable for space-constrained environments.

- Integration with Electronics: Some modern helical gearboxes are designed for seamless integration with electronic control systems. This enables better monitoring, control, and optimization of gearbox performance.

- Customization: Advancements in manufacturing and design tools allow for greater customization of helical gearboxes to meet specific application requirements. This includes adapting gear ratios, sizes, and configurations.

In summary, advancements in helical gearbox technology have led to enhanced performance, durability, efficiency, and customization options. These innovations continue to make helical gearboxes a versatile and reliable choice for a wide range of industrial applications.

Troubleshooting Common Issues in Helical Gear Systems

Troubleshooting helical gear systems involves identifying and addressing common issues that can affect their performance. Here’s a step-by-step process:

- Visual Inspection: Begin by visually inspecting the gearbox for any signs of wear, damage, or misalignment. Look for worn or chipped gear teeth, oil leakage, and unusual noise.

- Noise Analysis: If noise is present, analyze its type and frequency. Whining or grinding noises could indicate misalignment or damaged gears, while clicking or knocking sounds might point to loose components.

- Lubrication Check: Ensure that the gearbox is properly lubricated with the recommended type and quantity of lubricant. Insufficient lubrication can lead to increased friction and wear.

- Alignment Check: Check the alignment of the gears and shafts. Misalignment can result in uneven wear, noise, and reduced efficiency. Realign components if necessary.

- Gear Inspection: Inspect gear teeth for signs of pitting, scoring, or wear. Replace any damaged gears to prevent further issues.

- Bearing Examination: Check the condition of bearings that support shafts and gears. Worn or damaged bearings can lead to increased vibration and noise.

- Tightening and Fastening: Ensure that all bolts, fasteners, and connections are properly tightened. Loose components can cause vibrations and noise.

- Load Analysis: Evaluate the load conditions and operating parameters of the gearbox. Ensure that the gearbox is not subjected to loads beyond its design capacity.

- Temperature Monitoring: Monitor the operating temperature of the gearbox. Excessive heat can indicate problems such as inadequate lubrication or overloading.

- Consulting Experts: If issues persist or if you’re unsure about the diagnosis and solution, consult gearbox experts or manufacturers for guidance.

By following this troubleshooting process, you can identify and resolve common issues in helical gear systems, ensuring optimal performance and longevity.

Lubrication Requirements for Maintaining Helical Gearboxes

Lubrication is essential for the proper functioning and longevity of helical gearboxes. The lubrication requirements include:

- Viscosity: Selecting a lubricant with the appropriate viscosity is crucial. The viscosity should provide sufficient lubrication and ensure a protective film between gear teeth under varying operating conditions.

- Extreme Pressure (EP) Properties: Helical gears often experience high contact pressures. Lubricants with EP additives form a protective barrier that prevents metal-to-metal contact and reduces wear.

- Oil Additives: Anti-wear additives, antioxidants, and corrosion inhibitors enhance the lubricant’s performance and protect gears from wear and degradation.

- Frequent Inspections: Regularly inspect the lubricant’s condition to detect contamination, degradation, or depletion. Scheduled oil analysis can help monitor the health of the lubricant.

- Proper Lubricant Application: Ensure the gearbox is properly filled with the correct amount of lubricant. Follow manufacturer recommendations for lubricant type and quantity.

- Lubricant Change Intervals: Establish regular lubricant change intervals based on operating conditions. Extreme conditions or heavy loads may require more frequent changes.

Appropriate lubrication minimizes friction, wear, and heat generation, leading to improved efficiency, reduced maintenance, and extended gearbox life. It’s crucial to follow the manufacturer’s guidelines and consult with lubrication experts to select the right lubricant and maintenance practices for your specific helical gearbox application.

editor by CX 2024-04-30

China Professional Gear Units Km Series Hypoid Helical Gearbox Electric Motor Speed Reducer components of gearbox

Product Description

|

item |

value |

|

Warranty |

1 year |

|

Applicable Industries |

Manufacturing Plant, Construction works , Energy & Mining, Other |

|

Customized support |

OEM |

|

Place of Origin |

ZheJiang , China |

|

Input speed |

750-1500rpm |

|

Ratio |

7.5 10 12.5 |

|

Material |

Aluminum |

|

Product name |

KM Series Hypoid Gear Reducer |

|

MOQ |

10pcs |

|

Color |

Customization |

PRODUCTS CHARACTERISTICS

1. Mad of high-quality aluminum alloy,light weight and non-rusting

2. Large output torque

3. Smooth in running and low in noise,can work long time in dreadful conditions.

4. High in radiating efficiency.

5. Good-looking in appearance,durable in service life and small in volume.

6. Suitable for omnibearing installation.

FAQ

Q1:Are you a manufacturer or trading company?

Yes, We are a leading manufacturer specialized in production of various kinds of small and medium-sized

motor.

Q2:How to choose a gearbox which meets our requirement?

You can refer to our catalogue to choose the gearbox or we can help to choose when you provide

the technical information of required output torque, output speed and motor parameter etc.

Q3:What information shall we give before placing a purchase order?

a) Type of the gearbox, ratio, input and output type, input flange, mounting position, and motor information etc.

b) Housing color.

c) Purchase quantity.

d) Other special requirements.

Q4:What industries are your gearboxes being used?

Our gearboxes are widely used in the areas of textile, food processing, beverage, chemical industry, escalator,automatic storage equipment, metallurgy, tabacco, environmental protection, logistics and etc.

Q5:How about your delivery time?

For micro brush dc gear motor, the sample delivery time is 2-5 days, bulk delivery time is about 15-20 days, depends on the order qty. For brushless dc motor, the sample deliver time is about 10-15 days; bulk time is 15-20 days.Please take the sales confirmation for final reference.

Q6:What’s your warranty terms?

One year

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | as for Request |

| Hardness: | Hardened Tooth Surface |

| Installation: | as for Request |

| Step: | as for Request |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Types of Helical Gear Arrangements

Yes, there are different types of helical gear arrangements available to suit various applications and requirements. Some of the common helical gear arrangements include:

Parallel Shaft Arrangement: In this arrangement, the axes of the driving and driven shafts are parallel to each other. It is the most straightforward configuration and is often used in applications where space is not a constraint, and the gearboxes can be placed side by side.

Right-Angle Shaft Arrangement: In a right-angle arrangement, the driving and driven shafts are positioned at a 90-degree angle to each other. This arrangement is space-saving and is commonly used in applications where the layout requires a change in direction of the power transmission.

Double Helical Gear Arrangement (Herringbone Gears): Double helical gears consist of two sets of helical teeth facing each other. This arrangement helps to cancel out axial forces and reduces the net thrust load on bearings. It is often used in heavy-duty applications to minimize wear and vibration.

Crossed Helical Gear Arrangement (Screw Gears): In this configuration, the axes of the driving and driven shafts are neither parallel nor intersecting. It is suitable for applications requiring non-parallel and non-intersecting shafts.

The choice of helical gear arrangement depends on factors such as available space, power transmission requirements, and the desired layout of the machinery or equipment. Each arrangement has its advantages and disadvantages, and selecting the appropriate one is crucial for achieving optimal performance and efficiency.

Handling Shock Loads and Sudden Changes in Torque in Helical Gearboxes

Helical gearboxes are designed to handle a range of operational conditions, including shock loads and sudden changes in torque. The helical design of the gears, which have slanted teeth that engage gradually, helps to distribute forces more evenly across the teeth compared to straight-cut gears. This design characteristic contributes to the gearbox’s ability to withstand sudden changes in torque and shock loads.

The gradual engagement of the helical teeth results in smoother and quieter operation, reducing the impact of abrupt torque changes. The slanted teeth also allow for more gradual transmission of force, which helps in dampening vibrations and minimizing stress concentrations that can occur in high-impact situations.

However, while helical gears are better suited for shock loads compared to straight-cut gears, it’s important to note that extreme shock loads or sudden torque changes can still impact the gearbox’s components over time. Manufacturers often take factors such as application requirements, load profiles, and anticipated shock loads into consideration when designing helical gearboxes to ensure reliable and durable performance.

Additionally, using appropriate lubrication and maintenance practices can further enhance the gearbox’s ability to handle shock loads and sudden torque changes. Regular inspection and timely maintenance help identify and address potential issues before they lead to component failure.

Efficiency of Helical Gearboxes Compared to Other Gearbox Types

Helical gearboxes are known for their relatively high efficiency compared to some other gearbox types. Here’s a comparison of their efficiency with other common gearbox configurations:

- Straight-Cut (Spur) Gearboxes: Helical gearboxes are generally more efficient than straight-cut gearboxes. The helical tooth design allows for smoother engagement and better load distribution, reducing friction and energy losses. This results in higher overall efficiency for helical gearboxes.

- Bevel Gearboxes: Bevel gearboxes, which are commonly used for right-angle applications, typically have lower efficiency compared to helical gearboxes. The bevel gear design involves sliding contact between gear teeth, leading to higher friction and energy losses.

- Worm Gearboxes: Helical gearboxes are generally more efficient than worm gearboxes. Worm gearboxes have a relatively lower efficiency due to the sliding action between the worm and the gear, resulting in higher friction and heat generation.

- Planetary Gearboxes: Planetary gearboxes can offer comparable efficiency to helical gearboxes, especially when well-designed. However, planetary gearboxes can have variations in efficiency depending on factors such as the number of planet gears and gear arrangements.

While helical gearboxes tend to offer good efficiency, it’s important to note that efficiency can also be influenced by factors such as gear quality, lubrication, operating conditions, and maintenance practices. Consulting with gearbox manufacturers and considering specific application requirements is crucial when determining the most efficient gearbox solution.

editor by CX 2023-10-31

China 1.1kw 1.5kw 2.2kw 3kw Cast Iron R37 R47 Gearmotors, R Series Helical Gear Speed Reducer with AC Electric Motor components of gearbox

Warranty: 1 year

Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Retail, Printing Shops, Construction works , Energy & Mining

Weight (KG): 45 KG

Customized support: OEM, ODM, OBM

Gearing Arrangement: Helical

Output Torque: 50~28000Nm

Input Speed: 750-3000 rpm

Output Speed: 0.04-1200 rpm

Product name: R Series Helical Gearmotor

Type: Reduction Motor

Application: Food Processing Machine

Keyword: Gearmotor

Color: Blue/Silver or customized

Structures: helical Gearbox + Motor

Mounting Position: Foot Mounted

Packing: Wooden Box

Output Form: CZPT Shaft Output

Motor type: Asynchronous Reducer Motor

Packaging Details: Cartons or wooden cases

Port: HangZhou YanTian GuangZhou

R series helical geared motor Product Paramenters

| Product Name | R series helical geared motor | ||||||

| Gear Material | 20CrMnTi | ||||||

| Color | Customized | ||||||

| Efficiency | 94%~98% | ||||||

| Surface hardness of gear | HRC58-HRC62 | ||||||

| Ratio | 34.82-21342 | ||||||

| Model | R27/37/47/57/67/77/87/97/107/137/147/167/177/187 | ||||||

| Usages | Industrial Machine:Food Stuff,Ceramics,CHEMICAL,Packing,Dyeing, New fashion personalized magnetic snap snake pattern leather striped couple bracelet Woodworking,Glass. | ||||||

| Noise(Max) | 60-70dB | ||||||

| Brand | beiji or customized | ||||||

What Is a Gearbox?

A gearbox is the mechanical system of an automobile that allows a vehicle to change gear smoothly. This arrangement of gears is highly complex, which helps to provide a smooth gear change. In this article, we will explore some of the different types of gearboxes, including the Epicyclic gearbox, the Coaxial helical gearbox, and the Extruder helical gearing. These are three of the most common types of gearboxes used in automobiles.

Gearboxes

Gearboxes help drivers choose the appropriate gear for the conditions. A lower gear produces the least speed, while a higher gear gives the maximum torque. The number of gears used in a gearbox varies to meet different demands on the road and load. Short gearing provides maximum torque, while tall gearing offers higher top speeds. These features combine to improve the driveability of a vehicle. But what is a gearbox?

The gearbox has a slew of components, including the bearings and seals. Among these components is the gearbox, which is subjected to wear and tear due to metal-to-metal contact. As a result, gearboxes require close monitoring. Various tests are used to assess the condition of gears, such as corrosion and wear. Proactive tests emphasize wear, contamination, and oil condition. However, there are also proactive tests, such as the ferrous density test and the AN test, which monitor additive depletion and abnormal wear.

The separating force is a key factor for the design of a gearbox. The primary radial measurement point should be oriented to monitor normal forces. The secondary measurement point should be located in the opposite direction of rotation from the primary radial measurement point. The separating force generated by a helical gear set is called tangential force. The primary and secondary radial measurement points should be positioned so as to provide information about both normal and tangential forces.

Manual gearboxes are often manual. The driver can control the synchromesh by using a selector rod. This rod moves the synchromesh to engage the gear. Reverse gears are not synchromesh because they are used only when the vehicle is at a standstill. In older cars, the first gear often lacked synchromesh due to cost or lack of torque. Drivers could still use first gear with a double-declutch.

Coaxial helical gearbox

The R series rigid tooth flank helical gearbox features high versatility and good combination. They have a wide range of motor power and allow for fine classification of transmission ratios. The R series gearbox has several advantages, including high efficiency, long service life, and low vibration. This series of gearbox can be combined with a wide range of reducers and variators. Its size and high performance makes it an ideal choice for applications that require maximum torque and load transfer.

The main feature of a helical gearbox is that it presents a fixed velocity ratio, even if the center gaps are not perfectly set. This is sometimes referred to as the fundamental rule of gearing. A helical gearbox is similar to paper spur gears in terms of radial pitch, since the shafts in the helical gearbox cross at an angle. The center gap of a helical gearbox is the same for both the left and right-handed counterparts.

The EP Series is another popular model of a Coaxial helical gearbox. This series has high torque and a maximum reduction ratio of 25.6:1. It is an ideal choice for the plastic industry, and CZPT offers an extensive range of models. Their center distance ranges from 112 mm to 450 mm. The EP Series has several models with different center distances. In addition to high torque and efficiency, this gearbox has low noise and vibration, and it is easy to assemble and disassemble.

Another type of Coaxial helical gearboxes is the planetary gearbox. They have a high efficiency and power density. Unlike coaxial helical gearboxes, planetary gearboxes have an axis on the same direction as the output shaft. They are easy to integrate into existing drive trains. In addition, they are compact and easy to integrate with existing drive trains. For servo applications, they are another great choice.

Epicyclic gearbox

An epicyclic gearbox is a type of automatic gearbox used to drive cars. Its primary advantage is its compact design, and it is more reliable and efficient than manual gearboxes. It is comprised of a sun gear and two planetary gears, encased in a ring gear called the Annulus. This system is useful for drivers who need to shift gears frequently, as they will become tired if the gears are suddenly changed.

An epicyclic gearbox consists of three different types of gears: ring gear, sun gear, and annular ring gear. The ring gear is the outermost gear and has angular-cut teeth on its inner surface. It is used in conjunction with planetary gears to provide high-speed ratios to vehicles. The sun gear also reverses the direction of the output shaft. This helps reduce transmission error.

An epicyclic gearbox uses multiple planets to transfer power between the planets. This type of gearbox is lightweight and features a high power density. This gearbox has several benefits over a standard single-stage parallel axis gearbox, including multiple load paths, unequal load sharing, and phased meshing. Furthermore, epicyclic gearboxes require more complex transmission error optimisation than their counterparts, including more than one stage.

The objective of epicyclic gearbox research is to provide the lowest transmission error possible. The process includes an initial design and detailed specification. The system is defined by its load spectrum and required ratio. Deflections of the elastic mesh are calculated to understand their strength and how much energy the system can handle. Finally, micro-geometric corrections minimize transmission error. These improvements are crucial to the overall efficiency of an epicyclic gearbox.

Extruder helical gearing

The helix in an extruder helical gearing is fixed at an angle, enabling more interaction with the shaft in the same direction as it moves. As a result, the shaft and the bearing are in constant contact for a long period of time. Typically, extruder helical gearing is used in applications where there is low excitement, such as steel, rolling mills, conveyors, and the oil industry. The bevel gear train also plays a role in these applications.

The CZPT AEX extruder drive gear is specifically developed for this specific application. The gears are compact and lightweight and offer exceptional power density and a long service life. These extruder gears are highly reliable, and they can be used in a wide range of applications, including rubber processing, food production, and recycling plants. CZPT offers both standard and custom gearing for your extruder.

Another advantage of helical gearing is its versatility. Since the helical gearing teeth are inclined at a specific angle, they can be adjusted to meet the specific needs of a given application. These gears also have the advantage of eliminating noise and shock from straight teeth. Unlike other gearing types, they are able to achieve a wide range of loads, from small to large. These helical gears are very durable and are the best option for high-load applications.

In addition to this, asymmetric helical gears have increased flexibility, while asymmetrical helical gears have lower flexural stiffness. The ratio of teeth to the shaft has a positive effect on the strength of the gear. Furthermore, asymmetrical helical gears are easier to manufacture. But before you purchase your next extruder gear, make sure you know what you’re getting into.

1 speed gearbox

CZPT Group Components produces the one speed gearbox. It has the potential to make cars more efficient and environmentally friendly. The gear ratio of a car’s drivetrain is crucial for reaching maximum power and speed. Typically, a one-speed gearbox delivers a maximum of 200 hp. But the speed at which a car can reach this power must be high to get the full benefit from the electric motor. So, how can a one-speed gearbox improve the speed and torque of a car?

A one-speed gearbox is a mechanical device used to switch between second and third gears. It can include multiple gear sets, such as a shared middle gear for switching between second and third gears. It can also have an intermediate gear set that represents a switchable gear in both partial transmissions. The invention also includes a mechanism that makes it easier to change gears. The patent claims are detailed below. A typical one-speed gearbox may include two parts.

Generally, a one-speed gearbox will have up to seven forward gears, with each of these corresponding to a different speed. A one-speed gearbox can have five different gear sets and five different gear levels. It can have synchronized gear sets or last-shelf gear sets. In either case, the gears are arranged in a way that maximizes their efficiency. If the gears are placed on opposite sides of a car, the transmission may be a two-speed one.

CZPT Transmission specializes in the production of high-speed gearboxes. The company’s Milltronics HBM110XT gearbox machine is the perfect tool for this job. This machine has a large working table and a heavy-duty load capacity, making it a versatile option for many kinds of applications. There are also a wide variety of CZPT gearboxes for the automotive industry.

editor by Cx 2023-07-11

China TRC series helical gearbox speed reducer electric motor helical gearbox reduction gear motor transmission gear box components of gearbox

Guarantee: 3 a long time

Applicable Industries: Accommodations, Garment Shops, Building Substance Shops, Production Plant, Equipment Repair Stores, Meals & Beverage Factory, Farms, Restaurant, Home Use, Retail, Meals Shop, Printing Outlets, Development works , Energy & Mining, M1.5 15151005mm straight tooth CNC gear rack Meals & Beverage Retailers, Other, Advertising Organization

Fat (KG): 3 KG

Personalized assist: OEM, ODM, OBM

Gearing Arrangement: Helical

Output Torque: 99999N.m

Enter Velocity: 1450rpm

Output Speed: 1-one thousand

Ratio: 3.seventy seven~50.4

Certification: ISO9001-2008

Mount Placement: Foot Mounted

Bearing: LYC, HRB,ZWZ,NSK

Packaging Information: Wooden boxes , Cantons packed in 1 pallet

TRC collection helical gearbox speed reducer electric motor helical gearbox reduction gear motor transmisson equipment box

Technological features:The extremely modular is a style functions of SRC helical gearboxes variety. It can be related respectively with motors such as normal motor,brake motor,explosion-evidence motor,frequency conversion motor,servo motor,IEC motor and so on. This variety of solution is extensively utilized in push fields these kinds of as textile, BN excavator hydraulic gear motor shaft coupling foodstuff,ceramics packing,logistics,plastics and so on. It is feasible to set up the version essential utilizing flanges or feet

Solution attributes:SLRC collection helical gear units has more than 4 varieties,power .12kw-4kw,ratio3.66-54max torque120-500NM,It can be related(foot or flange)discretionary and use multi-mounting positions in accordance customers’ requirements1 Floor-hardened helical gears2. Modularity,can be mixed in many forms3. Aluminum casing,light weight4. Gears in carbonize tough,durable5. Universal mouting6. Refined style, compact in structure and lower sound

| Certification | ISO9001-2008 |

| Bearing | C&U |

| Coloration | Blue/black |

| Ratio | three.seventy seven~fifty.4 |

| Mount Placement | Foot Mounted |

| Bearing | LYC, SF08 Aluminum Push Coating Adapter Steering Axle Coupling Ball Spline Shaft HRB,ZWZ,SKF,NSK |

Business Info

Certifications

Our Services

Packaging & Shipping and delivery

Expo& Consumers

Related Products

FAQ: Are you trading firm or manufacturer ?A: We are factory.

Q: How prolonged is your supply time?A: Usually it is 5-10 days if the merchandise are in stock. or it is 15-20 days if the products are not in stock, it is according to amount.

Q: Do you offer samples ? is it cost-free or extra ?A: Sure, we could supply the sample for free of charge cost but do not pay the expense of freight.

Q: What is your terms of payment ?A: Payment=1000USD, 30% T/T in progress ,stability prior to shippment.If you have an additional issue, pls come to feel free to get in touch with us as under:

Types of Vehicle Gearboxes

In a vehicle, there are many types of gearboxes available. There are planetary gearboxes, Coaxial helical gearboxes, and skew bevel helical gearboxes, among others. In this article, we’ll cover all of them and help you determine which type of gearbox would be right for your vehicle. Also, we’ll discuss how each differs from the others.

planetary gearbox

A planetary gearbox is composed of three main components: a sun gear, an input bevel gear, and an output shaft. A planetary gearbox can have different output torques and ratios. The basic model of a planetary gearbox is highly efficient and transmits 97% of the power input. There are several kinds of planetary gearboxes, depending on the type of operation. In general, there are three types: the simple, the intermediate, and the complex.

The price of a planetary gearbox can vary a lot, and it’s important to know what you’ll need. Different manufacturers produce different planetary gearboxes, so check with a manufacturer to see what they have available. Make sure to check the quality of the planetary gearbox before making a final purchase. In addition, be sure to compare the prices and the availability of a particular product. A quality planetary gearbox will provide years of trouble-free operation and will not break your bank.

Planetary gears feature an integer number of teeth. Each planet has teeth that must mesh with its ring or sun. The number of planets, ring, and tooth count of each gear determine whether the teeth mesh. Some planets have fewer teeth than others, so they mesh better than others. However, compound planets can be more flexible and achieve higher reduction ratios. If you’re looking for a planetary gearbox for your next project, consider getting in touch with a manufacturer who specializes in this technology.

When it comes to construction, a planetary gearbox is no exception. It’s extremely important to choose the right planetary gear for your application, because an imbalance in the planet gear can cause increased wear and failure. Moreover, the compact size of a planetary gear ensures maximum heat dissipation. However, a planetary gear box may require cooling in some applications. A planetary gearbox will make your life easier, and it will give you years of trouble-free operation.

Straight bevel helical gearbox

The Straight bevel helical gearbox has a number of advantages, but it has a relatively short manufacturing process. Its most popular application is in the automotive industry, where it is used in many types of vehicles. Other applications include heavy and light equipment and the aviation and marine industries. Below is a brief introduction to this gearbox type. Read on to learn about its benefits. This type of gearbox is one of the easiest to manufacture.

The spiral bevel gear has larger teeth than straight bevel gears, resulting in a smoother, quieter rotation. It can handle high-speed heavy loads with less vibration. Spiral bevel gears are classified by their tooth form and cutting method. Straight bevel gears are easier to design and manufacture, but spiral bevel gears are more expensive. Both designs are suitable for high-speed, heavy-load operations, and general manufacturing applications.

In addition to being easy to install, the modular bevel gears have many advantages. They have an exceptionally high degree of interchangeability and feature the highest standards of component integrity. They can also be tailored to meet your specific requirements. The advantages of this gearbox type include high precision, optimum performance, and low noise. And because they are modular, they can be produced in a variety of finishes. These include stainless steel, titanium, and bronze.

Straight bevel helical gearbox manufacturers are committed to a high degree of precision in their designs. The radii, torques, and tooth profiles of straight bevel gears are more precisely measured than those of cylindrical bevel gears. The same calculations are used for all traditional bevel gear generators. This ensures that your 5-axis milled bevel gear sets have the same calculations and layout.

Coaxial helical gearbox

The Coaxial helical gearbox is a highly efficient transmission system that is well suited for light-duty applications. Compared to spur-type gearboxes, the real pitch of a Coaxial helical gearbox is low at all helix angles. This is because the coaxial type has the same number of teeth and center gap as the spur gearbox. Coaxial helical gearboxes also have a smaller footprint and are compact.

Several nations have implemented lockdown regulations for Industrial Gearbox trade, threatening the global economy. Several factors have been implicated in COVID-19, including supply chain, market, and financial markets. Experts are monitoring the situation globally and project remunerative prospects for gearbox manufacturers after the crisis. This report depicts the latest scenario and offers a comprehensive analysis of COVID-19’s impact on the entire industry.

This Coaxial helical gearbox features a compact structure and high precision gear. Its three-stage design combines two-stage gears with a single-stage gear, forging high-quality alloy steel for high precision and durability. The gears are serially-designed for easy interchangeability. They are also available in high-frequency heat-treated steel. A Coaxial helical gearbox is the perfect solution for many applications.

Coaxial helical gearboxes have the added benefit of using cylindrical gears instead of shafts. They operate quietly, and have more surface area to interact with. Their fixed angles make them suitable for heavy-duty applications, like in conveyors, coolers, and grinders. Compared to other gearbox types, Helical gearboxes have higher power-carrying capacity. Listed below are the benefits of a Coaxial Helical Gearbox

Skew bevel helical gearbox

A Skew bevel helical gear box is a common type of industrial gearbox. These gearboxes are rigid and compact and can be used in a variety of applications. They are commonly used in heavy-duty applications such as grinding mills, conveyors, and coolers. They are used in many applications to provide rotary motions between non-parallel shafts. They also have the added benefit of high-efficiency in a variety of industries.

Skew bevel helical gear boxes are suitable for heavy loads and are monolithic in construction. This type of gearbox combines the benefits of bevel and helical gears for right-angle torque, which makes it a popular choice for heavy-duty applications. In addition to being a robust and reliable gearbox, these gearboxes are highly customizable and can meet almost any industrial need.

To maximize the efficiency of bevel gears, FE-based tooth contact analysis is used to develop a sophisticated geometry optimization algorithm. The software also allows users to define optimal flank topography by introducing application-specific weightings for specific load levels. With this data, a manufacturing simulation is conducted to determine the best variant. A robust variant combines the benefits of efficiency, load-carrying capacity, and low excitation behavior.

The helical gear can be angled at 90 degrees. This is similar to a spur gear but produces less noise. It can achieve a nine-to-one speed reduction with one stage. However, a helical gear requires a larger driver gear for higher reductions. This gearbox is suitable for speeds from 1:1 to three times. They are often used in the manufacture of motors and generators.

Extruder helical gearbox

An extruder helical gearbox is one of the most common industrial gears. It is compact in size and low-power consuming, making it ideal for heavy-duty applications. Extruder helical gearboxes are suitable for a variety of industrial applications, including cement, plastics, rubber, conveyors, and coolers. In addition to its use in plastics and rubber manufacturing, this gearbox is also useful in other low-power applications such as crushers, coolers, and conveyors.

CZPT SG series Extruder Helical Gearboxes are available in Single Screw and Twin Screw Variations. These gears feature a compact design, high power density, and long service life. Axial bearing housing and thrust bearings are mounted on the input shafts. Extruder helical gearboxes can be installed in various positions, including horizontal, vertical, and inclined.

Helicoidal gears are often produced in a modular manner. This design provides multiple benefits, including engineering and performance advantages, modular production, and the highest level of component integrity. A single helical gearbox can be assembled into a larger gearbox if needed, but modular production ensures consistent performance and economy. This modular design is also cost-effective. It is a versatile and reliable solution for a wide range of applications.

In addition to its efficiencies, Extruder helical gearboxes also have a low noise profile. They have no squeal sounds, and they are silent when running. They can transfer more power than conventional gearboxes. This type of gear has been used in the manufacturing of high-quality plastic products for years. They are often used for applications in automotive transmissions. Aside from being quiet, helical gears have higher contact levels and lower vibration.

editor by czh2023-03-17

China Jiangyin Gearbox Coaxial Gear Reduction Boxes with Electric Motor components of gearbox

Product Quantity: Coaxial Gearbox

Gearing Arrangement: Helical

Output Torque: 375~8800000Nm

Rated Electricity: .18~160KW

Input Speed: 750~1500Rpm

Output Speed: 8 – 500Rpm

Color: OEM

Provider: OEM ODM Custom made Services

Packaging Specifics: Pallet/Export normal wooden scenario AS YOU Request

Port: ZheJiang

HangZhou Gearbox Coaxial Equipment Reduction Boxes with Electric Motor

Specifications1. Light-weight weight 2. Reduced noice

three. High precision 4. Big capability

5. Large performance 6. Higher reliability

seven. Extended services existence 8. Easy operation

9. Competitive cost 10. Strict QC

one. Gears are produced of high-grade alloy steel after carburizing, quenching, and ending processes.

2. The middle length and other significant each by optimizing design and style, the principal elements and components have excellent compatibility.

3. The rewards, gentle excess weight, For Polaris Slingshot components motorcycle ATVUTV add-ons Central Handle Equipment Change Panel trim higher precision, big potential, high effectiveness, substantial dependability, prolonged services lifestyle, Hot sale unique gearbox double H valve F99660 smooth operation and low noise.

4. Normally the equipment velocity reducers are lubricated by the oil sump and cooled by natural means.

This sequence pace reducer can be extensive utilized for mining equipment, metallurgical market, transportation, cement industry, developing sector, S45C ODM Personalized Pinions Straight Gears Manufacturing facility Manufacture in China chemical market, textile sector, mild market and energy sector, and so on.

Make contact with Us

Packaging & Transport

Products

Patent Certification

Cooperation Partener

Choosing a Gearbox For Your Application

The gearbox is an essential part of bicycles. It is used for several purposes, including speed and force. A gearbox is used to achieve one or both of these goals, but there is always a trade-off. Increasing speed increases wheel speed and forces on the wheels. Similarly, increasing pedal force increases the force on the wheels. This makes it easier for cyclists to accelerate their bicycles. However, this compromise makes the gearbox less efficient than an ideal one.

Dimensions

Gearboxes come in different sizes, so the size of your unit depends on the number of stages. Using a chart to determine how many stages are required will help you determine the dimensions of your unit. The ratios of individual stages are normally greater at the top and get smaller as you get closer to the last reduction. This information is important when choosing the right gearbox for your application. However, the dimensions of your gearbox do not have to be exact. Some manufacturers have guides that outline the required dimensions.

The service factor of a gearbox is a combination of the required reliability, the actual service condition, and the load that the gearbox will endure. It can range from 1.0 to 1.4. If the service factor of a gearbox is 1.0, it means that the unit has just enough capacity to meet your needs, but any extra requirements could cause the unit to fail or overheat. However, service factors of 1.4 are generally sufficient for most industrial applications, since they indicate that a gearbox can withstand 1.4 times its application requirement.

Different sizes also have different shapes. Some types are concentric, while others are parallel or at a right angle. The fourth type of gearbox is called shaft mount and is used when mounting the gearbox by foot is impossible. We will discuss the different mounting positions later. In the meantime, keep these dimensions in mind when choosing a gearbox for your application. If you have space constraints, a concentric gearbox is usually your best option.

Construction

The design and construction of a gearbox entails the integration of various components into a single structure. The components of a gearbox must have sufficient rigidity and adequate vibration damping properties. The design guidelines note the approximate values for the components and recommend the production method. Empirical formulas were used to determine the dimensions of the various components. It was found that these methods can simplify the design process. These methods are also used to calculate the angular and axial displacements of the components of the gearbox.

In this project, we used a 3D modeling software called SOLIDWORKS to create a 3-D model of a gear reducer. We used this software to simulate the structure of the gearbox, and it has powerful design automation tools. Although the gear reducer and housing are separate parts, we model them as a single body. To save time, we also removed the auxiliary elements, such as oil inlets and oil level indicators, from the 3D model.

Our method is based on parameter-optimized deep neural networks (DBNs). This model has both supervised and unsupervised learning capabilities, allowing it to be self-adaptive. This method is superior to traditional methods, which have poor self-adaptive feature extraction and shallow network generalization. Our algorithm is able to recognize faults in different states of the gearbox using its vibration signal. We have tested our model on two gearboxes.

With the help of advanced material science technologies, we can now manufacture the housing for the gearbox using high-quality steel and aluminium alloys. In addition, advanced telematics systems have increased the response time of manufacturers. These technologies are expected to create tremendous opportunities in the coming years and fuel the growth of the gearbox housing market. There are many different ways to construct a gearbox, and these techniques are highly customizable. In this study, we will consider the design and construction of various gearbox types, as well as their components.

Working

A gearbox is a mechanical device that transmits power from one gear to another. The different types of gears are called planetary gears and are used in a variety of applications. Depending on the type of gearbox, it may be concentric, parallel, or at a right angle. The fourth type of gearbox is a shaft mount. The shaft mount type is used in applications that cannot be mounted by foot. The various mounting positions will be discussed later.

Many design guidelines recommend a service factor of 1.0, which needs to be adjusted based on actual service conditions. This factor is the combined measure of external load, required reliability, and overall gearbox life. In general, published service factors are the minimum requirements for a particular application, but a higher value is necessary for severe loading. This calculation is also recommended for high-speed gearboxes. However, the service factor should not be a sole determining factor in the selection process.

The second gear of a pair of gears has more teeth than the first gear. It also turns slower, but with greater torque. The second gear always turns in the opposite direction. The animation demonstrates this change in direction. A gearbox can also have more than one pair of gears, and a first gear may be used for the reverse. When a gear is shifted from one position to another, the second gear is engaged and the first gear is engaged again.

Another term used to describe a gearbox is “gear box.” This term is an interchangeable term for different mechanical units containing gears. Gearboxes are commonly used to alter speed and torque in various applications. Hence, understanding the gearbox and its parts is essential to maintaining your car’s performance. If you want to extend the life of your vehicle, be sure to check the gearbox’s efficiency. The better its functioning, the less likely it is to fail.

Advantages

Automatic transmission boxes are almost identical to mechanical transmission boxes, but they also have an electronic component that determines the comfort of the driver. Automatic transmission boxes use special blocks to manage shifts effectively and take into account information from other systems, as well as the driver’s input. This ensures accuracy and positioning. The following are a few gearbox advantages:

A gearbox creates a small amount of drag when pedaling, but this drag is offset by the increased effort to climb. The external derailleur system is more efficient when adjusted for friction, but it does not create as little drag in dry conditions. The internal gearbox allows engineers to tune the shifting system to minimize braking issues, pedal kickback, and chain growth. As a result, an internal gearbox is a great choice for bikes with high-performance components.

Helical gearboxes offer some advantages, including a low noise level and lower vibration. They are also highly durable and reliable. They can be extended in modular fashion, which makes them more expensive. Gearboxes are best for applications involving heavy loads. Alternatively, you can opt for a gearbox with multiple teeth. A helical gearbox is more durable and robust, but it is also more expensive. However, the benefits far outweigh the disadvantages.

A gearbox with a manual transmission is often more energy-efficient than one with an automatic transmission. Moreover, these cars typically have lower fuel consumption and higher emissions than their automatic counterparts. In addition, the driver does not have to worry about the brakes wearing out quickly. Another advantage of a manual transmission is its affordability. A manual transmission is often available at a lower cost than its automatic counterpart, and repairs and interventions are easier and less costly. And if you have a mechanical problem with the gearbox, you can control the fuel consumption of your vehicle with appropriate driving habits.

Application

While choosing a gearbox for a specific application, the customer should consider the load on the output shaft. High impact loads will wear out gear teeth and shaft bearings, requiring higher service factors. Other factors to consider are the size and style of the output shaft and the environment. Detailed information on these factors will help the customer choose the best gearbox. Several sizing programs are available to determine the most appropriate gearbox for a specific application.

The sizing of a gearbox depends on its input speed, torque, and the motor shaft diameter. The input speed must not exceed the required gearbox’s rating, as high speeds can cause premature seal wear. A low-backlash gearbox may be sufficient for a particular application. Using an output mechanism of the correct size may help increase the input speed. However, this is not recommended for all applications. To choose the right gearbox, check the manufacturer’s warranty and contact customer service representatives.

Different gearboxes have different strengths and weaknesses. A standard gearbox should be durable and flexible, but it must also be able to transfer torque efficiently. There are various types of gears, including open gearing, helical gears, and spur gears. Some of the types of gears can be used to power large industrial machines. For example, the most popular type of gearbox is the planetary drive gearbox. These are used in material handling equipment, conveyor systems, power plants, plastics, and mining. Gearboxes can be used for high-speed applications, such as conveyors, crushers, and moving monorail systems.

Service factors determine the life of a gearbox. Often, manufacturers recommend a service factor of 1.0. However, the actual value may be higher or lower than that. It is often useful to consider the service factor when choosing a gearbox for a particular application. A service factor of 1.4 means that the gearbox can handle 1.4 times the load required. For example, a 1,000-inch-pound gearbox would need a 1,400-inch-pound gearbox. Service factors can be adjusted to suit different applications and conditions.

editor by czh2023-02-21

China ABA China Supply Ratio 10:1 Gear Box Motor Speed Reducer Precision Planetary Gearbox For New Energy Equipment components of gearbox

Warranty: 1 year

Applicable Industries: Printing Shops, Energy & Mining

Weight (KG): 39 KG

Customized support: OEM, ODM, OBM

Gearing Arrangement: Planetary

Output Torque: 14N.m-2000N.m

Input Speed: 720-2800rpm

Output Speed: 0.1-400rpm

Product nam: Planetary reducer

Operating temperature: -10℃~+90℃

Humidity: no more than 85%

Color: Customized

Working life: 30000h

Work efficiency: 97%

Certification: CCC CE

Packaging Details: standard export packing

Port: HangZhou

Products Description

| Stage | Ratio | Unit | PGC42 | PGC60 | PGC90 | PGC120 | PGC160 | |||||||

| 1 | 3 | kg/cm² | 0.03 | 0.20 | 0.81 | 2.20 | 7.89 | |||||||

| Usage | 4 | 0.03 | 0.16 | 0.65 | 1.80 | 5.83 | ||||||||

| Motor insulation grade | 5 | 0.03 | 0.15 | 0.62 | 1.61 | 5.38 | ||||||||

| Motor protection class | 7 | 0.03 | 0.14 | 0.60 | 1.55 | 5.22 | ||||||||

| Use environment | 10 | 0.03 | 0.14 | 0.60 | 1.53 | 5.20 | ||||||||

| Stage | Ratio | PGC42(T) | PGC60(T) | PGC90(T) | PGC120(T) | PGC160(T) | ||||||||

| 2 | 15/20/25 | 0.02 | 0.15(0.02) | 0.62(O.15) | 1.61(0.62) | 5.38(1.61) | ||||||||

| 30/35040 | 0.02 | 0.14(0.02) | 0.60(O.14) | 1.55(0.60) | 5.22(1.55) | |||||||||

| 50/70/100 | 0.02 | 0.15(0.02) | 0.60(O.14) | 1.53(0.60) | 5.20(1.53) | |||||||||

| *1.Applied to the output shaft center@100rpm.*2.Measured at 3000rpm with no load The above figures/specification are subject to change without prior notice | ||||||||||||||

Types of Vehicle Gearboxes

In a vehicle, there are many types of gearboxes available. There are planetary gearboxes, Coaxial helical gearboxes, and skew bevel helical gearboxes, among others. In this article, we’ll cover all of them and help you determine which type of gearbox would be right for your vehicle. Also, we’ll discuss how each differs from the others.

planetary gearbox

A planetary gearbox is composed of three main components: a sun gear, an input bevel gear, and an output shaft. A planetary gearbox can have different output torques and ratios. The basic model of a planetary gearbox is highly efficient and transmits 97% of the power input. There are several kinds of planetary gearboxes, depending on the type of operation. In general, there are three types: the simple, the intermediate, and the complex.

The price of a planetary gearbox can vary a lot, and it’s important to know what you’ll need. Different manufacturers produce different planetary gearboxes, so check with a manufacturer to see what they have available. Make sure to check the quality of the planetary gearbox before making a final purchase. In addition, be sure to compare the prices and the availability of a particular product. A quality planetary gearbox will provide years of trouble-free operation and will not break your bank.

Planetary gears feature an integer number of teeth. Each planet has teeth that must mesh with its ring or sun. The number of planets, ring, and tooth count of each gear determine whether the teeth mesh. Some planets have fewer teeth than others, so they mesh better than others. However, compound planets can be more flexible and achieve higher reduction ratios. If you’re looking for a planetary gearbox for your next project, consider getting in touch with a manufacturer who specializes in this technology.

When it comes to construction, a planetary gearbox is no exception. It’s extremely important to choose the right planetary gear for your application, because an imbalance in the planet gear can cause increased wear and failure. Moreover, the compact size of a planetary gear ensures maximum heat dissipation. However, a planetary gear box may require cooling in some applications. A planetary gearbox will make your life easier, and it will give you years of trouble-free operation.

Straight bevel helical gearbox

The Straight bevel helical gearbox has a number of advantages, but it has a relatively short manufacturing process. Its most popular application is in the automotive industry, where it is used in many types of vehicles. Other applications include heavy and light equipment and the aviation and marine industries. Below is a brief introduction to this gearbox type. Read on to learn about its benefits. This type of gearbox is one of the easiest to manufacture.

The spiral bevel gear has larger teeth than straight bevel gears, resulting in a smoother, quieter rotation. It can handle high-speed heavy loads with less vibration. Spiral bevel gears are classified by their tooth form and cutting method. Straight bevel gears are easier to design and manufacture, but spiral bevel gears are more expensive. Both designs are suitable for high-speed, heavy-load operations, and general manufacturing applications.

In addition to being easy to install, the modular bevel gears have many advantages. They have an exceptionally high degree of interchangeability and feature the highest standards of component integrity. They can also be tailored to meet your specific requirements. The advantages of this gearbox type include high precision, optimum performance, and low noise. And because they are modular, they can be produced in a variety of finishes. These include stainless steel, titanium, and bronze.

Straight bevel helical gearbox manufacturers are committed to a high degree of precision in their designs. The radii, torques, and tooth profiles of straight bevel gears are more precisely measured than those of cylindrical bevel gears. The same calculations are used for all traditional bevel gear generators. This ensures that your 5-axis milled bevel gear sets have the same calculations and layout.

Coaxial helical gearbox

The Coaxial helical gearbox is a highly efficient transmission system that is well suited for light-duty applications. Compared to spur-type gearboxes, the real pitch of a Coaxial helical gearbox is low at all helix angles. This is because the coaxial type has the same number of teeth and center gap as the spur gearbox. Coaxial helical gearboxes also have a smaller footprint and are compact.

Several nations have implemented lockdown regulations for Industrial Gearbox trade, threatening the global economy. Several factors have been implicated in COVID-19, including supply chain, market, and financial markets. Experts are monitoring the situation globally and project remunerative prospects for gearbox manufacturers after the crisis. This report depicts the latest scenario and offers a comprehensive analysis of COVID-19’s impact on the entire industry.

This Coaxial helical gearbox features a compact structure and high precision gear. Its three-stage design combines two-stage gears with a single-stage gear, forging high-quality alloy steel for high precision and durability. The gears are serially-designed for easy interchangeability. They are also available in high-frequency heat-treated steel. A Coaxial helical gearbox is the perfect solution for many applications.

Coaxial helical gearboxes have the added benefit of using cylindrical gears instead of shafts. They operate quietly, and have more surface area to interact with. Their fixed angles make them suitable for heavy-duty applications, like in conveyors, coolers, and grinders. Compared to other gearbox types, Helical gearboxes have higher power-carrying capacity. Listed below are the benefits of a Coaxial Helical Gearbox

Skew bevel helical gearbox

A Skew bevel helical gear box is a common type of industrial gearbox. These gearboxes are rigid and compact and can be used in a variety of applications. They are commonly used in heavy-duty applications such as grinding mills, conveyors, and coolers. They are used in many applications to provide rotary motions between non-parallel shafts. They also have the added benefit of high-efficiency in a variety of industries.

Skew bevel helical gear boxes are suitable for heavy loads and are monolithic in construction. This type of gearbox combines the benefits of bevel and helical gears for right-angle torque, which makes it a popular choice for heavy-duty applications. In addition to being a robust and reliable gearbox, these gearboxes are highly customizable and can meet almost any industrial need.

To maximize the efficiency of bevel gears, FE-based tooth contact analysis is used to develop a sophisticated geometry optimization algorithm. The software also allows users to define optimal flank topography by introducing application-specific weightings for specific load levels. With this data, a manufacturing simulation is conducted to determine the best variant. A robust variant combines the benefits of efficiency, load-carrying capacity, and low excitation behavior.

The helical gear can be angled at 90 degrees. This is similar to a spur gear but produces less noise. It can achieve a nine-to-one speed reduction with one stage. However, a helical gear requires a larger driver gear for higher reductions. This gearbox is suitable for speeds from 1:1 to three times. They are often used in the manufacture of motors and generators.

Extruder helical gearbox

An extruder helical gearbox is one of the most common industrial gears. It is compact in size and low-power consuming, making it ideal for heavy-duty applications. Extruder helical gearboxes are suitable for a variety of industrial applications, including cement, plastics, rubber, conveyors, and coolers. In addition to its use in plastics and rubber manufacturing, this gearbox is also useful in other low-power applications such as crushers, coolers, and conveyors.

CZPT SG series Extruder Helical Gearboxes are available in Single Screw and Twin Screw Variations. These gears feature a compact design, high power density, and long service life. Axial bearing housing and thrust bearings are mounted on the input shafts. Extruder helical gearboxes can be installed in various positions, including horizontal, vertical, and inclined.

Helicoidal gears are often produced in a modular manner. This design provides multiple benefits, including engineering and performance advantages, modular production, and the highest level of component integrity. A single helical gearbox can be assembled into a larger gearbox if needed, but modular production ensures consistent performance and economy. This modular design is also cost-effective. It is a versatile and reliable solution for a wide range of applications.

In addition to its efficiencies, Extruder helical gearboxes also have a low noise profile. They have no squeal sounds, and they are silent when running. They can transfer more power than conventional gearboxes. This type of gear has been used in the manufacturing of high-quality plastic products for years. They are often used for applications in automotive transmissions. Aside from being quiet, helical gears have higher contact levels and lower vibration.

editor by czh

in Chongjin Dem. People’s Republic of Korea sales price shop near me near me shop factory supplier 1.5V 3.4V 3.7V 10mm Flat Coin DC Gear Vibration Motor for Massager Beauty Instrument Intelligent Watch Wearing manufacturer best Cost Custom Cheap wholesaler

High quality and credit history are the bases that make a corporation alive. a specialized provider of a complete selection of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers. The high specific CNC tools, such as Sluggish-feeding wire-minimize equipment, jig grinding device and electrical discharge equipment, makes certain the prime top quality precision of mould processing, with the substantial effective and environmental safety acid rolling line currently being the greatest raw content changing equipment in the discipline in china The wildly use of computerized milling equipment, large-pace automatic feeding punch, higher speed automated rolling and assembling machine assures the higher quality and performance of components and chain creating.

one.5V 3.4v 3.7v 10MM flat coin DC EPT vibration motor for Massager Beauty instrument Intelligent View sporting .

Merchandise Description:

| Reduction ratio | 4 | 10 | 21 | 34 | forty seven | seventy eight | 103 | one hundred thirty | 227 | |

| 12V | no load rpm | 1500 | 29 | eighteen | 12 | 10 | 8 | 6 | five | 4 |

| rated pace | 1200 | 24 | fifteen | 10 | 9 | seven | 5 | 4 | 4 | |

| rated torque | .06 | .fourteen | .three | .four | .six | .9 | 1.1 | 1.4 | two.five | |

FAQ

Q: Are you buying and selling business or company ?

A: We are the EPT EPTTized in types of micro motors for virtually ten a long time presently, in ZheJiang Province, EPTT.

Q: How to purchase?

A: send us inquiry #8594 EPT our quotation #8594 negotiate particulars #8594 affirm the sample #8594 signal agreement/deposit #8594 mass creation #8594

cargo ready #8594 harmony/supply #8594 even more cooperation

Q: How about Sample order?

A: Sample is available for you. please make contact with us for specifics. Once we charge you sample charge, please really feel effortless, it would be refund

when you location formal get.

Q: How EPTT is the supply[Generating] and delivery?

A: Supply time relies upon on the quantity you get. normally it requires 15-25 doing work days.

Q: My deal has lacking goods. What can I do?

A: Make sure you contact our support staff and we will verify your orEPTTwith the deal contents. We apologize for any inconveniences.

Q: How to verify the payment?

A: We settle for payment by T/T, PayPal, the other payment waEPTTalso could be acknowledged, Please speak to us ahead of you spend by the other

payment approaches. Also thirty-fifty% deposit is accessible, the stability money must be paid out ahead of transport.

China manufacturer & factory supplier for High in Pyongyang Dem. People’s Republic of Korea Driving Efficiency Helical Worm Gear Motor With high quality best price & service

As a consequence, we have become a comprehensive maker in the motion and control field supplying an in depth lineup of products with excellent longevity, setting-friendliness, and top quality.EPG has been successfully qualified by ISO9002 Good quality Management System, ISO9001 Quality Management System, API certification, ISO/TS16949:2002 and ISO10012 measurement administration technique.

Overview

Rapid Details

- Relevant Industries:

-

Developing Material Retailers, Production Plant, Equipment Restore Stores, Farms, Design works , Meals & Beverage Outlets

- Merchandise title:

-

Worm Gear Reducer

A power take-off or power takeoff (PTO) is any of several techniques for taking power from a electricity source, these kinds of as a operating engine, and transmitting it to an application such as an hooked up employ or individual device.

- Coloration:

-

Blue,Grey,Or Personalized

- Warranty:

-

1 Yr

- Application:

-

Meals ,Plastic, Convery, Equipment, Feed, Mining and so on

- Certification:

-

ISO9001 , CE

- Mounting Situation:

-

Horizontal (Foot Mounted, Shaft Mounted)

- Packing:

-

Wood Box

- Ratio:

-

nine.96-244.74

- Bearing:

-

C&U, NAK, NSK,SKF

- OEM service:

-

Accessible

Provide Capability

- Source Capability:

- 1000 Piece/Pieces per Thirty day period

Packaging & Delivery

- Packaging Specifics

- Plywood scenario

- Port

- Ningbo,Shanghai

-

Guide Time

: -

Amount(Containers) one – ten >10 the wants and specifications of our consumers – from normal options to client-particular patterns. Est. Time(days) It is our aim to offer a extensive range of high quality merchandise at affordable charges, give the very best service for clients happy and contribute to our ongoing enhancement.

15 To be negotiated

On the web Customization

Characteristics

High modular style, biomimetic area with owned mental residence proper.

Undertake German worm hob to process the worm wheel.

With the unique gear geometry, it receives higher torque, effectiveness and prolonged daily life circle.

It can achieve the direct mix for two sets of gearbox.

Mounting mode: foot mounted, flange mounted, torque arm mounted.

Output shaft: strong shaft, hollow shaft.

Major applied for

Chemical market and environmental security

Metallic processing

Developing and development

Agriculture and foods

Textile and leather

Forest and paper

Auto washing equipment

|

Housing content |

Cast iron/Ductile iron |

|

Housing hardness |

HBS190-240 |

|

Gear substance |

20CrMnTi alloy steel |

|

Surface area hardness of gears |

HRC58°~62 ° |

|

Gear core hardness |

HRC33~forty |

|

Input / Output shaft materials |

42CrMo alloy steel |

|

Enter / Output shaft hardness |

HRC25~30 |

|

Machining precision of gears |

exact grinding, 6~5 Quality |

|

Lubricating oil |

GB L-CKC220-460, Shell Omala220-460 |

|

Heat remedy |

tempering, cementiting, quenching, and so forth. |

|

Efficiency |

94%~96% (is dependent on the transmission phase) |

|

Noise (MAX) |

60~68dB |

|

Temp. rise (MAX) |

40°C |

|

Temp. rise (Oil)(MAX) |

50°C |

|

Vibration |

≤20µm |

|

Backlash |

≤20Arcmin |

|

Model of bearings |

China best brand bearing, HRB/LYC/ZWZ/C&U. Or other makes requested, SKF, FAG, INA, NSK. |

|

Brand of oil seal |

NAK — Taiwan or other manufacturers asked for |

Q: Are you trading organization or maker ?

Q: Are you trading organization or maker ?

A: We Ever-Power Team 1 of the biggest transmission suppliers in the planet are manufacturing unit.

Q: How lengthy is your delivery time?

A: Usually it is 5-10 days if the products are in stock. or it is 15-twenty days if the items are not in inventory.

Q: Can we purchase 1 pc of every single item for high quality tests?

A: Sure, we are happy to settle for trial buy for high quality tests.

Q: What is your conditions of payment ?

A: Payment=1000USD, thirty% T/T in progress, stability prior to shippment.

If you have other query, freely to contact us,you should.