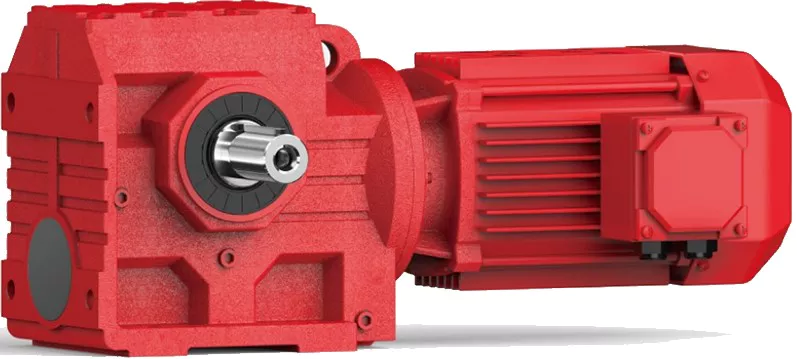

Product Description

Two Stage Helical Gearbox Motor Parallel Shaft Bevel Reducer Speed Spiral 90 Degree Right Angle Straight Supplier Competitive Price Stainless Steel Gearbox

Application of Helical Gearbox

Helical gearboxes are used in a wide variety of applications, including:

- Automotive: Helical gearboxes are used in a variety of automotive applications, including transmissions, differentials, and steering systems. They help to transmit power smoothly and efficiently, which improves the overall performance of the vehicle.

- Machinery: Helical gearboxes are used in a variety of machinery applications, including conveyor belts, elevators, and cranes. They help to transmit power smoothly and efficiently, which improves the overall performance of the equipment.

- Aerospace: Helical gearboxes are used in a variety of aerospace applications, including aircraft engines, landing gear, and control surfaces. They help to transmit power smoothly and efficiently, which improves the overall performance of the aircraft.

- Construction: Helical gearboxes are used in a variety of construction applications, including excavators, bulldozers, and cranes. They help to transmit power smoothly and efficiently, which improves the overall performance of the equipment.

- Other: Helical gearboxes are also used in a variety of other applications, such as wind turbines, robotics, and medical devices. They help to transmit power smoothly and efficiently, which improves the overall performance of the system.

Helical gears are a type of gear that has teeth that are cut at an angle. This angle allows the teeth to engage each other gradually and smoothly, which reduces noise and vibration. Helical gears are often used in high-speed applications, such as in automotive differentials.

Helical gears are made of a variety of materials, including steel, cast iron, and aluminum. The material of the gear will depend on the specific application and the environment in which it will be used.

Helical gears are available in a variety of sizes and styles to accommodate a wide range of applications. They are also available in a variety of ratios, which allows them to be used in a variety of applications.

Here are some of the advantages of using helical gears:

- Reduced noise and vibration: Helical gears help to reduce noise and vibration, which can improve the overall working environment.

- Increased efficiency: Helical gears are more efficient than straight gears, which can help to improve the overall performance of a system.

- Increased durability: Helical gears are made of durable materials that can withstand a lot of wear and tear.

- Cost-effectiveness: Helical gears are a cost-effective way to improve the performance and durability of a system.

Overall, helical gears are a versatile and reliable component that can be used in a wide variety of applications. They offer a number of advantages, including reduced noise and vibration, increased efficiency, increased durability, and cost-effectiveness.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Three-Ring |

| Hardness: | Hardened Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Stepless |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Key Factors for Selecting a Helical Gearbox

Choosing the right helical gearbox for an application involves considering several key factors:

- Load and Torque: Evaluate the maximum load and torque requirements to ensure the gearbox can handle the application’s demands.

- Speed Range: Determine the required speed range and ensure the gearbox’s gear ratios can accommodate it.

- Efficiency: Helical gearboxes are known for their high efficiency. Select a gearbox with efficiency ratings that meet your application’s needs.

- Space Constraints: Consider the available installation space and choose a compact gearbox that fits within the available dimensions.

- Mounting Position: The mounting position affects lubrication, cooling, and overall performance. Ensure the gearbox is suitable for the desired mounting orientation.

- Service Life: Choose a gearbox with a service life that matches your application’s expected lifespan.

- Backlash: Evaluate the allowable backlash, which affects precision and positioning accuracy.

- Noise and Vibration: Assess the acceptable noise and vibration levels and choose a gearbox with suitable characteristics.

- Environmental Conditions: Consider factors like temperature, humidity, and dust levels to ensure the gearbox can operate reliably in the application environment.

- Maintenance: Factor in maintenance requirements and choose a gearbox with manageable maintenance needs.

- Cost: Balance performance with budget constraints to find a gearbox that offers the best value for your application.

By carefully evaluating these factors, you can select a helical gearbox that optimally meets your application’s requirements and ensures efficient and reliable operation.

Relationship Between Helix Angle and Load Capacity in Helical Gears

The helix angle of helical gears plays a significant role in determining their load-carrying capacity and overall performance. Here’s the relationship between the helix angle and load capacity:

1. Load Distribution: The helix angle affects how the load is distributed along the gear teeth. A larger helix angle results in a more gradual tooth engagement, allowing for smoother load sharing across multiple teeth. This improves the gear’s ability to handle higher loads.

2. Contact Ratio: The contact ratio, which indicates the number of teeth in contact at any given time, increases with a larger helix angle. A higher contact ratio helps distribute the load over a larger area of the gear teeth, enhancing load-carrying capacity.

3. Tooth Meshing: The helix angle affects how the teeth mesh with each other. A higher helix angle promotes gradual and smoother meshing, reducing the concentration of stress on individual teeth. This results in improved resistance to wear and fatigue.

4. Axial Thrust: Helical gears produce axial thrust due to their helical nature. This thrust can affect the gear’s ability to handle radial loads. Proper consideration of the helix angle can help manage axial thrust and prevent overloading.

5. Lubrication: The helix angle affects the lubrication conditions between gear teeth. A larger helix angle may allow better oil flow and lubrication, reducing friction and wear, thereby enhancing load capacity.

6. Noise and Vibration: The helix angle also influences noise and vibration levels in helical gears. Optimal helix angle selection can minimize noise and vibration, contributing to smoother operation and prolonged gear life.

Optimal Helix Angle Selection: While a larger helix angle generally increases load capacity, it’s important to strike a balance. Extremely large helix angles can lead to reduced tooth strength and efficiency. Engineers consider factors like application requirements, tooth strength, and noise considerations when selecting the optimal helix angle for a specific gear design.

The relationship between the helix angle and load capacity underscores the importance of proper gear design to ensure optimal performance, durability, and reliability in various applications.

Limitations and Disadvantages of Helical Gear Systems

While helical gear systems offer numerous advantages, they also come with certain limitations and disadvantages:

- Axial Thrust: Helical gears generate axial thrust due to the helix angle of the teeth. This thrust can cause additional load on bearings and may require additional measures to counteract.

- Complex Manufacturing: The manufacturing process for helical gears is more complex than that of straight-toothed gears, which can lead to higher production costs.

- Axial Length: Helical gears require more axial space compared to spur gears with the same gear ratio. This can be a limitation in applications with space constraints.

- Sliding Contact: Helical gears have sliding contact between their teeth, which can result in higher friction and more heat generation compared to rolling contact gears.

- Efficiency: Although helical gears are generally efficient, their efficiency can be slightly lower than that of some other gear types, especially at high speeds.

- Complexity in Gearbox Design: The inclination of helical gear teeth introduces additional complexity in gearbox design and alignment.

- Reverse Thrust: In some cases, reverse thrust can occur when helical gears are subjected to high axial loads, leading to undesirable effects.

It’s important to consider these limitations and disadvantages when selecting gear systems for specific applications. Despite these challenges, helical gears remain a popular choice in various industries due to their benefits and overall performance characteristics.

editor by CX 2023-09-04

in Bangkok Thailand sales price shop near me near me shop factory supplier OEM CNC Machining Hardened Steel Driving Toothed Shaft Intermediate Gear for Reduction Gear Box manufacturer best Cost Custom Cheap wholesaler

We examine each piece of bearing by ourselves ahead of shipping and delivery. If you need any info or samples, make sure you make contact with us and you will have our shortly reply. Our goods are made by present day computerized machinery and tools. OEM CNC Machining Hardened Metal Driving Toothed Shaft Intermediate EPT for Reduction EPT Box

EPT method :lathe machining solid hobbing

Testing tools:projector

We are willing to provide you with sample for testing, we have 16-yr producing and answers experiences.

We are ISO 9001: 2008 accredited company.

Our Solutions

| Business EPT | EPTT/ EPTT/ EPTT EPTs/ EPTT/ Maritime EPT/ EPTs/ EPTs Oil and Gas/ EPT/ EPTT |

| Intended Application | Shafts EPT Parts EPTT Doorway Factors EPTT/ EPT EPTor Fireplace Suppression System Parts Fittings/ Fasteners EPTs/ EPT Roller EPTTs |

| EPT Instances Accessible | Max: 2 Weeks (On Preliminary Get) Hurry Solutions Offered |

| Industry StXiHu (West EPT) Dis.Hu (West EPT) Dis.rds | ISO 9001:2008 PPAP RoHS Compliant |

| Added Capabilities | CAD Design Services CAM Programming Companies Coordinate Measuring EPTTs (CMM) Reverse EPT |

| EPT Record | From basic two-aXiHu (West EPT) Dis.s turning to seven-aXiHu (West EPT) Dis.s, switch-mill-drill CNC Swiss-sort EPTTs, molding EPTTs/ stamping EPTTs automated lathe EPTTs/ EPT EPTTs. |

| EPT (EPTs or plastic) |

Alloy Steels/ EPTT/ Brass/ Bronze Alloys EPTT Steel/ Copper/ Stainless Metal/ Tool Steel Cold Rolled Steel/ EPTT Metal Abdominal muscles/ Delrin/ Nylon/ PVC |

| Tests equipment | Projector. Calliper, micrometer, plug gauge, ring gauge, thread gauge |

| Processes (EPT Capabilities) |

Broaching/ Hobbing/ Slotting/tapping |

| Tolerance | plusmn0.0002 in plusmn0.0051 mm |

| EPTT | For ligEPTT objects: bubble pack individually to avoid from detrimental and scratches in transporting, then in carton for hefty objects: wrapped in PE baggage and then in wood boxes |

Other GEARS for your seem,

EPTT Details

EPT EPTT Co,. Minimal, is located in NO 4 EPTT, EPTTEPTT EPTT Zone EPTTEPTTng Road, XiHu (West EPT) Dis.ekeng, EPTTngXiHu (West EPT) Dis., HangEPT, ZheJiang province, EPTT. EPT was started in 1998, masking an area of 11,000 square meters and two hundred employees . 90% of our products are marketed to overEPTT market this sort of as United states, Canada, Germany, Uk, EPTT, Australia, Japan, South Korea and many others. We are ISO 9001:2008, ISO13485 (medical)and TS16949(automotive) certified organization. We will have AS9100 certification(aerospace) In 2018.

EPT

one. We are willing to provide with sample for top quality and operate tests.

2. Shipping time:inside 20 working daEPTT.

FAQ

Q1:How to guarantee the EPTT of EPTT Elements?

A1:we are ISO 9001-2008 qualified firm. we have the integrated technique for EPTT areas quality manage. We have IQC (incoming top quality manage), IPQCS (in approach quality control EPT), FQC (last top quality handle) and OQC (out-going high quality handle) to manage each process of EPTT components prodution.

Q2:What is the Gain of Your Components for Business EPT?

A2:Our edge is the competitive charges, quick delivery and high high quality. Our personnel are responsible-oriEPTTd, pleasant-oriEPTTd,and dilient-oriEPTTd. our EPTT elements merchandise are featured by strict tolerance, smooth complete and EPTT-existence efficiency.

Q3:what are our machining equipmengts?

A3:Our machining equipments incEPTT CNC milling EPTTs, CNC turning EPTTs, stamping

EPTTs,hobbing EPTTs, computerized lathe EPTTs, tapping EPTTs, grinding EPTTs,

screw EPTTs, chopping EPTTs and so on.

This autumn: What delivery waEPTTour use?

A4:EPTTly sEPTing, we will use UPS or DHL to ship the merchandise. Our clients can attain the

products inside of 3 days.

If our customers do not need to have them urgently, we will also use Fedex and TNT.

If the goods are of weighty weigEPTT and huge volumn, we will ship them by sea. This way can save

our buyers a great deal of cash.

Q5:Who are our main clients?

A5:HP, Samsung, Jabil Team,Lexmark,Flextronic Group.

Q6:What resources can you manage?

A6:Brass,bronze,copper,stainless metal, metal,EPT,EPTTium And plastic.

Q7:How EPTT is the Supply for Your EPTT Portion?

A7:EPTTly sEPTing, it will get us 15 functioning daEPTTfor machining components and 25 working daEPTTfor

the for stamping areas products. But we will shorten our guide time according to customers’ needs if we are capable to.