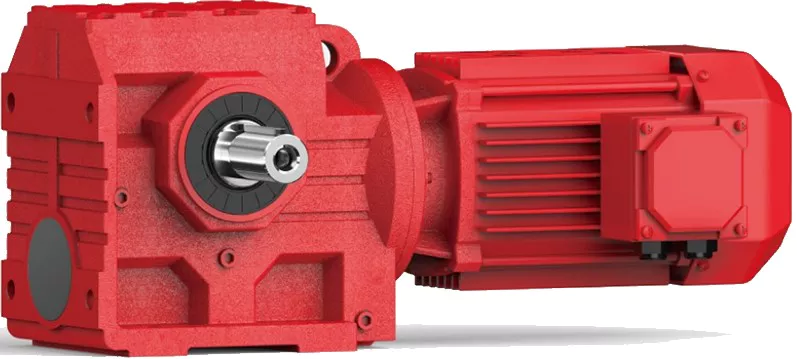

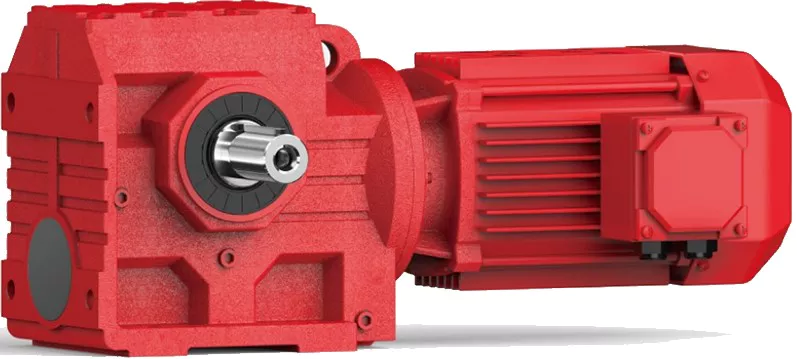

Product Description

Helical Worm Gear Low Noise Cast Iron HT250 Ground Parallel Shaft Best Speed Reducer Gearbox Die Casting Lumen Good Price Nmrv High Efficiency Helical Worm Gear

F series gear reducer is 1 kind of parallel shaft helical gear reducer , which consist of 2 or 3 stages helical gears (relate to gear ratio) in the same case . The hard tooth surface gear use the high quality alloy steel ,the process of carburizing and quenching, grinding ,which give it follow characters :Stable transmission ,low noise and temperature ,high loading ,long working lift . Wide application ,specialize in Metallurgy ,Sewage treatment,

Chemical Industry , Pharmacy ,Agriculture equipment and Oil industry.

Specifications:

1) Output speed: 0.6~1,571r/min

2) Output torque: up to 21700N.m

3) Motor power: 0.12~200kW

4) Mounted form: foot-mounted and flange-mounted mounting

| Product Name | SLK Series Rigid Tooth helical bevel reducer |

| Gear Material | 20CrMnTi |

| Case Material | HT250 |

| Shaft Material | 20CrMnTi |

| Gear Processing | Grinding finish by HOFLER Grinding Machines |

| Color | Customized |

| Noise Test | 65~70dB |

| Efficiency | 94%~98% (depends on the transmission stage) |

| Lubricating oil | Shell Omala synthetic oil or mineral oil , or similar brand |

| Heat treatment | tempering, cementiting, quenching,etc. |

| Brand of bearings | C&U bearing, ZWZ,LYC, HRB, SKF,NSK and so on |

| Brand of oil seal | NAK or other brand |

| Temp. rise (MAX) | 40 ° |

| Temp. rise (Oil)(MAX) | 50 ° |

| Vibration | ≤20µm |

company information

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Layout: | Coaxial |

| Type: | Worm Reducer |

| Output Torque: | 3.5~21700n.M |

| Samples: |

US$ 999/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Precision and High-Accuracy Applications of Helical Gearboxes

Helical gearboxes are well-suited for precision and high-accuracy applications due to their unique design and performance characteristics:

- Helical Gearing: The helical gears in these gearboxes offer smooth and continuous meshing, resulting in reduced backlash and improved positioning accuracy.

- Efficiency: Helical gearboxes are known for their high efficiency, which minimizes energy losses and heat generation. This is crucial for maintaining precision in applications where even small deviations can have significant impacts.

- Noise and Vibration: The helical gear tooth engagement helps in reducing noise and vibration levels, making them suitable for environments where quiet operation is required.

- Load Distribution: Helical gears distribute load across multiple teeth, minimizing localized wear and extending the lifespan of the gearbox.

- Smooth Motion: Helical gearboxes provide smoother motion transitions, which is crucial in precision applications where jerky or sudden movements are undesirable.

- Positional Accuracy: The reduced backlash and improved meshing characteristics of helical gears contribute to higher positional accuracy, making these gearboxes ideal for applications such as CNC machines, robotics, and medical equipment.

- Compact Design: Helical gearboxes can achieve high gear ratios in a relatively compact form factor, making them suitable for applications where space is limited.

Examples of precision applications where helical gearboxes are commonly used include CNC machining, robotics, semiconductor manufacturing, medical equipment, and metrology devices. The combination of efficiency, smooth operation, and accuracy makes helical gearboxes a preferred choice for achieving consistent and reliable performance in such applications.

Handling Shock Loads and Sudden Changes in Torque in Helical Gearboxes

Helical gearboxes are designed to handle a range of operational conditions, including shock loads and sudden changes in torque. The helical design of the gears, which have slanted teeth that engage gradually, helps to distribute forces more evenly across the teeth compared to straight-cut gears. This design characteristic contributes to the gearbox’s ability to withstand sudden changes in torque and shock loads.

The gradual engagement of the helical teeth results in smoother and quieter operation, reducing the impact of abrupt torque changes. The slanted teeth also allow for more gradual transmission of force, which helps in dampening vibrations and minimizing stress concentrations that can occur in high-impact situations.

However, while helical gears are better suited for shock loads compared to straight-cut gears, it’s important to note that extreme shock loads or sudden torque changes can still impact the gearbox’s components over time. Manufacturers often take factors such as application requirements, load profiles, and anticipated shock loads into consideration when designing helical gearboxes to ensure reliable and durable performance.

Additionally, using appropriate lubrication and maintenance practices can further enhance the gearbox’s ability to handle shock loads and sudden torque changes. Regular inspection and timely maintenance help identify and address potential issues before they lead to component failure.

Industries Utilizing Helical Gearboxes

Helical gearboxes find widespread use in various industries due to their efficiency, smooth operation, and versatility. Some of the industries that commonly utilize helical gearboxes include:

- Manufacturing: Helical gearboxes are employed in manufacturing processes for conveyor systems, material handling, and machine tools. Their ability to provide high torque and smooth motion makes them suitable for precision manufacturing.

- Automotive: Automotive applications include power transmission in vehicles, especially in manual and automatic transmissions. Helical gearboxes contribute to improved fuel efficiency and smoother gear shifting.

- Energy Generation: Helical gearboxes are used in power generation systems, such as wind turbines and hydroelectric generators. Their efficiency and load-bearing capacity are crucial for converting rotational motion into electrical power.

- Construction: Construction equipment, such as cranes, excavators, and bulldozers, rely on helical gearboxes for efficient power transmission and control of heavy loads.

- Mining: Mining operations use helical gearboxes in conveyors, crushers, and other equipment for material handling and ore extraction. The durability and high torque capacity of helical gearboxes make them suitable for demanding mining environments.

- Marine: Marine vessels use helical gearboxes in propulsion systems to convert engine power into rotational motion for propellers. Their efficiency contributes to fuel savings and reliable marine operation.

- Food and Beverage: Helical gearboxes are employed in food processing and packaging machinery due to their sanitary design and precise motion control.

- Textile: Textile machinery relies on helical gearboxes for various processes, including spinning, weaving, and dyeing. Their ability to handle varying loads and provide smooth motion is beneficial in textile production.

The adaptability and efficiency of helical gearboxes make them a suitable choice for a wide range of industries, where reliable power transmission, smooth operation, and load-bearing capacity are essential.

editor by CX 2024-05-03

China supplier Factory Price Helical Worm Gear Motor Gearbox S Type with Output Flange and Hollow Shaft gearbox adjustment

Product Description

Helical Worm Gear Motor (S Type)

|

Input Configurations |

Motor mounted |

| IEC B5/B14 Motor Flange (AM Flange) | |

| Servo Motor Flange (AQA Flange) | |

| Shaft Input (AD connection) | |

|

Output Configurations

|

CZPT output shaft |

|

CZPT output shaft with flange |

|

|

Hollow output shaft |

|

|

Hollow output shaft with flange |

|

|

Variants of the Helical Worm Gear Unit Series S / SF / SA / SAF |

Foot- or flange-mounted |

|

B5 or B14 flange-mounted |

|

|

CZPT shaft or hollow shaft |

|

|

Hollow shaft with keyed connection, shrink disk, splined hollow shaft, or Torque Arm |

Main Feature

Slim design for limited installation space without having to compromise on the performance, And what applies to many of our gear units: longer operating lives and wear-free gearing with a high fatigue strength.

Specification

|

Model |

Shaft Dia. mm |

Horizontal Center Height mm |

External Flange Dia. Mm |

Power Kw |

Ratio i |

Nominal Torque Nm |

|

|

CZPT Shaft |

Hollow Shaft |

||||||

|

F/FF/FA/FAF37 |

ф25 |

ф30 |

70 |

160 |

0.12-3 |

4-138 |

180 |

|

F/FF/FA/FAF47 |

ф35 |

ф35 |

80 |

200 |

0.12-5.5 |

4-175 |

360 |

|

F/FF/FA/FAF57 |

ф35 |

ф40 |

100 |

250 |

0.18-7.5 |

4-197 |

420 |

|

F/FF/FA/FAF67 |

ф40 |

ф40 |

100 |

250 |

0.37-7.5 |

4-197 |

700 |

|

F/FF/FA/FAF77 |

ф50 |

ф50 |

120 |

300 |

0.75-11 |

4-197 |

1350 |

|

F/FF/FA/FAF87 |

ф60 |

ф60 |

155 |

350 |

1.5-22 |

4-193 |

2500 |

|

F/FF/FA/FAF97 |

ф70 |

ф70 |

180 |

450 |

2.2-30 |

4-203 |

3700 |

|

F/FF/FA/FAF107 |

ф90 |

ф90 |

200 |

450 |

3-45 |

4-205 |

6500 |

|

F/FF/FA/FAF127 |

ф110 |

ф100 |

240 |

550 |

5.5-90 |

4-202 |

10000 |

|

F/FF/FA/FAF157 |

ф120 |

ф120 |

270 |

660 |

11-160 |

4-190 |

18000 |

Company Profile

Packing

Scenarioes

FAQ

Q1: I want to buy your products, how can I pay?

A: You can pay via T/T(30%+70%), L/C ,D/P etc.

Q2: How can you guarantee the quality?

A: One year’s warranty against B/L date. If you meet with quality problem, please send us pictures or video to check, we promise to send spare parts or new products to replace. Our guarantee not include inappropriate operation or wrong specification selection.

Q3: How we select models and specifications?

A: You can email us the series code (for example: RC series helical gearbox) as well as requirement details, such as motor power,output speed or ratio, service factor or your application…as much data as possible. If you can supply some pictures or drawings,it is nice.

Q4: If we don’t find what we want on your website, what should we do?

A: We offer 3 options:

1, You can email us the pictures, drawings or descriptions details. We will try to design your products on the basis of our

standard models.

2, Our R&D department is professional for OEM/ODM products by drawing/samples, you can send us samples, we do customized design for your bulk purchasing.

3, We can develop new products if they have good market. We have already developed many items for special using successful, such as special gearbox for agitator, cement conveyor, shoes machines and so on.

Q5: Can we buy 1 pc of each item for quality testing?

A: Yes, we are glad to accept trial order for quality testing.

Q6: How about your product delivery time?

A: Normally for 20’container, it takes 25-30 workdays for RV series worm gearbox, 35-40 workdays for helical gearmotors.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Customization: |

Available

| Customized Request |

|---|

Performance of Helical Gearboxes in Applications Requiring Frequent Starts and Stops

Helical gearboxes are well-suited for applications that involve frequent starts and stops due to their design characteristics. Here’s how they fare in such scenarios:

- Smooth Engagement: Helical gears offer gradual and smooth engagement, which reduces shock loads during starts and stops. This feature helps minimize wear and stress on gear teeth and other components.

- Noise and Vibration Reduction: The helical tooth arrangement results in less noise and vibration compared to other gear types. This is especially beneficial in applications where noise reduction is a priority.

- Efficient Power Transmission: Helical gears efficiently transmit power even during frequent starts and stops. The gradual contact between gear teeth and the larger tooth engagement area contribute to efficient power transfer.

- Less Backlash: Helical gearboxes typically have lower backlash compared to other gear types. This means there’s less play between gear teeth, resulting in more accurate and consistent motion control.

- Heat Dissipation: The helical tooth design distributes loads and heat more evenly, which can help dissipate heat generated during frequent starts and stops.

- Longevity: The reduced wear and improved load distribution contribute to the longevity of helical gearboxes, making them suitable for applications requiring frequent cyclic motion.

In summary, helical gearboxes perform well in applications involving frequent starts and stops. Their smooth engagement, reduced noise and vibration, efficient power transmission, and durability make them a reliable choice for industries that demand precise and controlled motion despite frequent changes in speed and direction.

Software Tools for Simulating Helical Gear Behavior

Several software tools are available for simulating the behavior of helical gears under different conditions. These tools aid engineers in designing and analyzing helical gear systems for optimal performance and reliability. Some notable software tools include:

- KISSsoft: KISSsoft is a widely used software for the design and analysis of mechanical components, including helical gears. It offers comprehensive calculations for gear geometry, load distribution, contact stresses, and more. The software assists in optimizing gear designs and predicting their behavior under various operating conditions.

- AGMA Rating Suite: The American Gear Manufacturers Association (AGMA) offers software tools that follow AGMA standards for gear design and analysis. These tools provide accurate calculations for gear rating, efficiency, and durability under different load scenarios.

- ANSYS Mechanical: ANSYS Mechanical is a versatile simulation software used for finite element analysis (FEA) of mechanical systems, including helical gears. It allows engineers to perform detailed stress and deformation analysis, simulate contact patterns, and assess the effects of different loads and boundary conditions.

- Gleason CAGE: Gleason’s Computer-Aided Gear Engineering (CAGE) software specializes in gear design and optimization. It offers advanced tools for gear tooth profile generation, simulation of meshing behavior, and optimization of gear parameters.

- MAGMA Soft: MAGMA Soft provides casting simulation software that can be used to predict the solidification behavior and mechanical properties of casted gear components, which is essential for ensuring quality and performance.

- Siemens NX: Siemens NX software includes gear design and analysis capabilities, allowing engineers to simulate gear behavior, calculate load distribution, and optimize gear designs within a comprehensive CAD/CAE environment.

These software tools enable engineers to model and analyze helical gears in a virtual environment, helping them make informed design decisions, optimize gear geometry, and assess gear performance under different conditions. By utilizing these tools, engineers can create reliable and efficient helical gear systems for various industrial applications.

Helical Gear Meshing and Its Benefits

Helical gear meshing refers to the engagement of two helical gears with inclined teeth. The teeth are cut at an angle to the gear axis, creating a helix shape. When these gears mesh, the inclined teeth gradually come into contact, allowing for smoother and quieter operation compared to straight-toothed gears.

The benefits of helical gear meshing include:

- Reduced Noise: The gradual contact between helical gear teeth minimizes impact and noise during engagement, resulting in quieter operation. This is particularly advantageous in applications where noise reduction is essential, such as industrial machinery and automotive transmissions.

- Smooth Operation: Helical gears provide smoother and more continuous motion due to the gradual engagement of teeth. This feature makes them suitable for applications that require precise and controlled movement, such as CNC machines and conveyor systems.

- Higher Load Capacity: The helical tooth geometry allows for greater tooth contact area, distributing the load over a larger surface. This results in higher load-carrying capacity and improved durability, making helical gears suitable for heavy-duty applications.

- Efficient Power Transmission: Helical gears transmit power more efficiently due to their smooth engagement and increased contact area. This efficiency contributes to reduced energy consumption and heat generation in gearboxes.

- Less Vibrations: The gradual meshing of helical gears reduces vibrations, resulting in smoother operation and reduced wear and tear on gear teeth and bearings. This is especially important for extending the lifespan of the gearbox.

Overall, helical gear meshing offers numerous benefits, including reduced noise, smoother operation, higher load capacity, efficient power transmission, and reduced vibrations. These advantages make helical gears a popular choice in various industrial applications where performance, durability, and reliability are crucial.

editor by CX 2024-04-25

China supplier Planetary Gearbx Lower Price Helical Gearoutput Shaft Gearmotor Box Helical Gearbox sequential gearbox

Product Description

SAE/SAF Planetary gearboxs with higher precision:

1.-Planetary gearbox is a widely used industrial product, which can reduce the speed of motor and increase the output torque. Planetary reducer can be used as supporting parts in lifting, excavation, transportation, construction and other industries.

2.SAE/SAF Series Planetary Gearbox additionally adds front and rear oil seals, uses the output shaft double support structure and design of helix gear, which makes the gear meshing smoother and stable, the SAE/SAF Series can be used in various control transmission fields with servo motors. The backlash of the AE series is less than 5 arc.min and the reduction ratio covers 3~100.

The Product Advantages of Planetary Gearbox:

1.Flexible structure design, in line with various working conditions.

2.Ring gear processing technology: Using internal gear slotting machine and hobbling machine; the precision of ring gear after processing can reach GB7.

3.Hardened gear secondary scraping technology: secondary high-speed dry cutting of gear eliminates gear deformation caused by heat treatment. Gear accuracy can reach GB6.

4.Reliable backlash testing.

| Application: | Motor, Machinery |

|---|---|

| Function: | Speed Reduction |

| Layout: | Cycloidal |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Types of Helical Gear Arrangements

Yes, there are different types of helical gear arrangements available to suit various applications and requirements. Some of the common helical gear arrangements include:

Parallel Shaft Arrangement: In this arrangement, the axes of the driving and driven shafts are parallel to each other. It is the most straightforward configuration and is often used in applications where space is not a constraint, and the gearboxes can be placed side by side.

Right-Angle Shaft Arrangement: In a right-angle arrangement, the driving and driven shafts are positioned at a 90-degree angle to each other. This arrangement is space-saving and is commonly used in applications where the layout requires a change in direction of the power transmission.

Double Helical Gear Arrangement (Herringbone Gears): Double helical gears consist of two sets of helical teeth facing each other. This arrangement helps to cancel out axial forces and reduces the net thrust load on bearings. It is often used in heavy-duty applications to minimize wear and vibration.

Crossed Helical Gear Arrangement (Screw Gears): In this configuration, the axes of the driving and driven shafts are neither parallel nor intersecting. It is suitable for applications requiring non-parallel and non-intersecting shafts.

The choice of helical gear arrangement depends on factors such as available space, power transmission requirements, and the desired layout of the machinery or equipment. Each arrangement has its advantages and disadvantages, and selecting the appropriate one is crucial for achieving optimal performance and efficiency.

Relationship Between Helix Angle and Load Capacity in Helical Gears

The helix angle of helical gears plays a significant role in determining their load-carrying capacity and overall performance. Here’s the relationship between the helix angle and load capacity:

1. Load Distribution: The helix angle affects how the load is distributed along the gear teeth. A larger helix angle results in a more gradual tooth engagement, allowing for smoother load sharing across multiple teeth. This improves the gear’s ability to handle higher loads.

2. Contact Ratio: The contact ratio, which indicates the number of teeth in contact at any given time, increases with a larger helix angle. A higher contact ratio helps distribute the load over a larger area of the gear teeth, enhancing load-carrying capacity.

3. Tooth Meshing: The helix angle affects how the teeth mesh with each other. A higher helix angle promotes gradual and smoother meshing, reducing the concentration of stress on individual teeth. This results in improved resistance to wear and fatigue.

4. Axial Thrust: Helical gears produce axial thrust due to their helical nature. This thrust can affect the gear’s ability to handle radial loads. Proper consideration of the helix angle can help manage axial thrust and prevent overloading.

5. Lubrication: The helix angle affects the lubrication conditions between gear teeth. A larger helix angle may allow better oil flow and lubrication, reducing friction and wear, thereby enhancing load capacity.

6. Noise and Vibration: The helix angle also influences noise and vibration levels in helical gears. Optimal helix angle selection can minimize noise and vibration, contributing to smoother operation and prolonged gear life.

Optimal Helix Angle Selection: While a larger helix angle generally increases load capacity, it’s important to strike a balance. Extremely large helix angles can lead to reduced tooth strength and efficiency. Engineers consider factors like application requirements, tooth strength, and noise considerations when selecting the optimal helix angle for a specific gear design.

The relationship between the helix angle and load capacity underscores the importance of proper gear design to ensure optimal performance, durability, and reliability in various applications.

Industries Utilizing Helical Gearboxes

Helical gearboxes find widespread use in various industries due to their efficiency, smooth operation, and versatility. Some of the industries that commonly utilize helical gearboxes include:

- Manufacturing: Helical gearboxes are employed in manufacturing processes for conveyor systems, material handling, and machine tools. Their ability to provide high torque and smooth motion makes them suitable for precision manufacturing.

- Automotive: Automotive applications include power transmission in vehicles, especially in manual and automatic transmissions. Helical gearboxes contribute to improved fuel efficiency and smoother gear shifting.

- Energy Generation: Helical gearboxes are used in power generation systems, such as wind turbines and hydroelectric generators. Their efficiency and load-bearing capacity are crucial for converting rotational motion into electrical power.

- Construction: Construction equipment, such as cranes, excavators, and bulldozers, rely on helical gearboxes for efficient power transmission and control of heavy loads.

- Mining: Mining operations use helical gearboxes in conveyors, crushers, and other equipment for material handling and ore extraction. The durability and high torque capacity of helical gearboxes make them suitable for demanding mining environments.

- Marine: Marine vessels use helical gearboxes in propulsion systems to convert engine power into rotational motion for propellers. Their efficiency contributes to fuel savings and reliable marine operation.

- Food and Beverage: Helical gearboxes are employed in food processing and packaging machinery due to their sanitary design and precise motion control.

- Textile: Textile machinery relies on helical gearboxes for various processes, including spinning, weaving, and dyeing. Their ability to handle varying loads and provide smooth motion is beneficial in textile production.

The adaptability and efficiency of helical gearboxes make them a suitable choice for a wide range of industries, where reliable power transmission, smooth operation, and load-bearing capacity are essential.

editor by CX 2023-10-30

China factory Two Stage Helical Gearbox Motor Parallel Shaft Bevel Reducer Speed Spiral 90 Degree Right Angle Straight Supplier Competitive Price Stainless Steel Gearbox car gearbox

Product Description

Two Stage Helical Gearbox Motor Parallel Shaft Bevel Reducer Speed Spiral 90 Degree Right Angle Straight Supplier Competitive Price Stainless Steel Gearbox

Application of Helical Gearbox

Helical gearboxes are used in a wide variety of applications, including:

- Automotive: Helical gearboxes are used in a variety of automotive applications, including transmissions, differentials, and steering systems. They help to transmit power smoothly and efficiently, which improves the overall performance of the vehicle.

- Machinery: Helical gearboxes are used in a variety of machinery applications, including conveyor belts, elevators, and cranes. They help to transmit power smoothly and efficiently, which improves the overall performance of the equipment.

- Aerospace: Helical gearboxes are used in a variety of aerospace applications, including aircraft engines, landing gear, and control surfaces. They help to transmit power smoothly and efficiently, which improves the overall performance of the aircraft.

- Construction: Helical gearboxes are used in a variety of construction applications, including excavators, bulldozers, and cranes. They help to transmit power smoothly and efficiently, which improves the overall performance of the equipment.

- Other: Helical gearboxes are also used in a variety of other applications, such as wind turbines, robotics, and medical devices. They help to transmit power smoothly and efficiently, which improves the overall performance of the system.

Helical gears are a type of gear that has teeth that are cut at an angle. This angle allows the teeth to engage each other gradually and smoothly, which reduces noise and vibration. Helical gears are often used in high-speed applications, such as in automotive differentials.

Helical gears are made of a variety of materials, including steel, cast iron, and aluminum. The material of the gear will depend on the specific application and the environment in which it will be used.

Helical gears are available in a variety of sizes and styles to accommodate a wide range of applications. They are also available in a variety of ratios, which allows them to be used in a variety of applications.

Here are some of the advantages of using helical gears:

- Reduced noise and vibration: Helical gears help to reduce noise and vibration, which can improve the overall working environment.

- Increased efficiency: Helical gears are more efficient than straight gears, which can help to improve the overall performance of a system.

- Increased durability: Helical gears are made of durable materials that can withstand a lot of wear and tear.

- Cost-effectiveness: Helical gears are a cost-effective way to improve the performance and durability of a system.

Overall, helical gears are a versatile and reliable component that can be used in a wide variety of applications. They offer a number of advantages, including reduced noise and vibration, increased efficiency, increased durability, and cost-effectiveness.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Three-Ring |

| Hardness: | Hardened Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Stepless |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Key Factors for Selecting a Helical Gearbox

Choosing the right helical gearbox for an application involves considering several key factors:

- Load and Torque: Evaluate the maximum load and torque requirements to ensure the gearbox can handle the application’s demands.

- Speed Range: Determine the required speed range and ensure the gearbox’s gear ratios can accommodate it.

- Efficiency: Helical gearboxes are known for their high efficiency. Select a gearbox with efficiency ratings that meet your application’s needs.

- Space Constraints: Consider the available installation space and choose a compact gearbox that fits within the available dimensions.

- Mounting Position: The mounting position affects lubrication, cooling, and overall performance. Ensure the gearbox is suitable for the desired mounting orientation.

- Service Life: Choose a gearbox with a service life that matches your application’s expected lifespan.

- Backlash: Evaluate the allowable backlash, which affects precision and positioning accuracy.

- Noise and Vibration: Assess the acceptable noise and vibration levels and choose a gearbox with suitable characteristics.

- Environmental Conditions: Consider factors like temperature, humidity, and dust levels to ensure the gearbox can operate reliably in the application environment.

- Maintenance: Factor in maintenance requirements and choose a gearbox with manageable maintenance needs.

- Cost: Balance performance with budget constraints to find a gearbox that offers the best value for your application.

By carefully evaluating these factors, you can select a helical gearbox that optimally meets your application’s requirements and ensures efficient and reliable operation.

Relationship Between Helix Angle and Load Capacity in Helical Gears

The helix angle of helical gears plays a significant role in determining their load-carrying capacity and overall performance. Here’s the relationship between the helix angle and load capacity:

1. Load Distribution: The helix angle affects how the load is distributed along the gear teeth. A larger helix angle results in a more gradual tooth engagement, allowing for smoother load sharing across multiple teeth. This improves the gear’s ability to handle higher loads.

2. Contact Ratio: The contact ratio, which indicates the number of teeth in contact at any given time, increases with a larger helix angle. A higher contact ratio helps distribute the load over a larger area of the gear teeth, enhancing load-carrying capacity.

3. Tooth Meshing: The helix angle affects how the teeth mesh with each other. A higher helix angle promotes gradual and smoother meshing, reducing the concentration of stress on individual teeth. This results in improved resistance to wear and fatigue.

4. Axial Thrust: Helical gears produce axial thrust due to their helical nature. This thrust can affect the gear’s ability to handle radial loads. Proper consideration of the helix angle can help manage axial thrust and prevent overloading.

5. Lubrication: The helix angle affects the lubrication conditions between gear teeth. A larger helix angle may allow better oil flow and lubrication, reducing friction and wear, thereby enhancing load capacity.

6. Noise and Vibration: The helix angle also influences noise and vibration levels in helical gears. Optimal helix angle selection can minimize noise and vibration, contributing to smoother operation and prolonged gear life.

Optimal Helix Angle Selection: While a larger helix angle generally increases load capacity, it’s important to strike a balance. Extremely large helix angles can lead to reduced tooth strength and efficiency. Engineers consider factors like application requirements, tooth strength, and noise considerations when selecting the optimal helix angle for a specific gear design.

The relationship between the helix angle and load capacity underscores the importance of proper gear design to ensure optimal performance, durability, and reliability in various applications.

Limitations and Disadvantages of Helical Gear Systems

While helical gear systems offer numerous advantages, they also come with certain limitations and disadvantages:

- Axial Thrust: Helical gears generate axial thrust due to the helix angle of the teeth. This thrust can cause additional load on bearings and may require additional measures to counteract.

- Complex Manufacturing: The manufacturing process for helical gears is more complex than that of straight-toothed gears, which can lead to higher production costs.

- Axial Length: Helical gears require more axial space compared to spur gears with the same gear ratio. This can be a limitation in applications with space constraints.

- Sliding Contact: Helical gears have sliding contact between their teeth, which can result in higher friction and more heat generation compared to rolling contact gears.

- Efficiency: Although helical gears are generally efficient, their efficiency can be slightly lower than that of some other gear types, especially at high speeds.

- Complexity in Gearbox Design: The inclination of helical gear teeth introduces additional complexity in gearbox design and alignment.

- Reverse Thrust: In some cases, reverse thrust can occur when helical gears are subjected to high axial loads, leading to undesirable effects.

It’s important to consider these limitations and disadvantages when selecting gear systems for specific applications. Despite these challenges, helical gears remain a popular choice in various industries due to their benefits and overall performance characteristics.

editor by CX 2023-09-04

China Cheap Price Flange Foot Mounted F Series Parallel Shaft Helical Bevel Gearbox planetary gearbox vs helical gearbox

Item Description

Solution Description

Item Parameters

Packaging & Shipping and delivery

Business Profile

|

US $100-200 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Helical Gear |

| Step: | 2 Stage, 3 Stage |

###

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

|

US $100-200 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Helical Gear |

| Step: | 2 Stage, 3 Stage |

###

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

How to Choose a Helical Gearbox

Choosing the best helical gearbox is dependent on the type of application you want to use the gear for. You will need to consider the contact ratios and the total of profile shifts required.

Spur gears are more efficient than helical gears

Compared to helical gears, spur gears have straight teeth that are parallel to the axis of the gear. Because they are more efficient, spur gears are often used in low speed applications. However, helical gears are better for low-noise and high-speed applications. Despite their advantages, spur gears are also used in some devices.

Spur gears are not as resilient as other gears. They are less efficient at transmitting power over long distances, and they generate too much noise at high speeds. They also impose a radial load on bearings. They also produce significant vibration that can limit the maximum speed of operation.

Helical gears are better at transferring loads. They are used in a number of applications, including car transmissions, elevators, and conveyors. Helical gears also generate large amounts of thrust. They are also quieter than spur gears.

Unlike spur gears, helical gears use bearings to support their thrust load. They also have more teeth, so they can handle more load than spur gears. They can also be used in non-parallel shafts.

Helical gears are generally used in high-speed mechanical systems. They also have less wear on individual teeth and are quieter running than spur gears.

Helical gears are a refinement of spur gears. They are also used in the printing industry, elevators, and gearboxes for automobiles. They are often used in conjunction with a worm gear to distribute load. They have a higher speed capacity, but they are not as efficient as spur gears. They are used in some high-speed mechanical systems because they generate less noise and vibration.

Spur gears are commonly used in low-speed applications, like rack and pinion setups. Their design makes them more efficient at transmitting power, but they are less resilient than helical gears.

Design space is limited based on a required center distance, target gear ratio, and sum of profile shifts

Using statistically derived parameters, the authors performed a multi-objective optimization of the profile shift of two external cylindrical gears. The main objective of this study was to maximize efficiency and minimize the amount of power lost in the optimized space.

To do this, the authors used a multi-objective optimization algorithm that included all aspects of the optimal profile shift. The algorithm evaluates objective function over a series of generations to determine the best solution.

The multi-objective optimization algorithm was based on a verified optimization algorithm. This algorithm combines analytical pressure loads estimation with an effective method for calculating the deformations of the gear case. Using the aforementioned formulae, the authors were able to identify a feasible solution. The numerical calculations also showed that the corresponding specific sliding coefficients were perfectly balanced.

To identify the most efficient method for determining the profile shift, the authors selected the most efficient method based on the objectives of efficiency and mass. The efficiency objective was considered to be the largest given the small size of the resulting optimization space. This objective is useful in reducing wear failures.

The largest thermal treatment of a cylindrical gear is case hardening. The ISO/TR 4467:1982 standard provides a practical guide for gears. The largest radii of the pinion and wheel are rb1 and rb2. The ratio of tooth width to base circle diameter of the pinion is normally set to less than 1.

Sliding velocity increases as the distance from the pitch point increases in the line of action

Deflections of the involute profile of a helical gear occur due to the load on the teeth. However, the optimum pressure angle for the gear is not known.

The correct pressure angle for a helical gear cannot be calculated without a surface model. Assuming the pressure is uniform over the profile, a pressure angle of 20deg would be a good bet. However, this would require a mathematical model that can be derived from the Archard wear equation.

In general, the pressure angle will be influenced by the diameter, as well as the gear mesh geometry. It is important to know the actual angle of a helical gear since this will affect the curvature of the profile, the normal force, and the radial force.

The best way to measure the pressure angle is to consider the theoretical pitch diameter. If the pitch diameter is small, then the actual angle will be smaller. This will cause a gap between the flanks. However, it can also cause the gear to deform, leading to unexpected working behavior.

One interesting tangent is the pitch plane, an imaginary plane tangent to the pitch surfaces. The pitch plane is the plane perpendicular to the axial plane of the gear cross section. It is usually used as a reference point to calculate the transverse pressure angle.

The working pressure angle is the angle of the pressure line of the gear mesh. This angle is the same as the reference pressure angle, but the length of the contact line is reduced.

The best way to calculate the working pressure angle is to use the pressure line of the gear mesh. This will give a more accurate value. The actual angle of the pressure line is also related to the transmission ratio. This ratio is usually given as the nominal ratio of angular velocities. The actual velocities will fluctuate about this ratio.

Undercut of a helical gear tooth root

Having an undercut at the pinion root can affect the distribution of load along the line of contact of helical gears. This can result in higher than nominal loads on some teeth and amplitude modulated noise.

The tooth root is affected by a number of factors, including the shape of the tooth cutting tool. The cutting tool must be designed to avoid an undercut without reducing the number of teeth. This is achieved by a process called profile shifting.

Profile shift occurs when the cutting tool changes depth, thereby preventing an undercut. It is often used in the manufacturing process to achieve a greater overlap ratio. The higher the overlap ratio, the less variation there is between the contact lines. This reduces the dynamic tooth loads and reduces noise.

The profile shift is most often associated with the cutting tool tip. This is the point where the involute profile exits the gear, before the tip begins to taper. The involute profile can be defined for every transverse section of the gear face width. The boundary point is a point of tangency between the involute and root profiles.

The involute of a circle is a common way to define a gear-tooth profile. The involute is the path traced by the point on the line when rolling on a circle. It is a useful feature for cylindrical involute gears.

The helix angle is also important to the helical gear. It allows for greater contact capacity and increases the bending capacity of the gear. It must be included in specifications for helical teeth. The angle must be measurable and include the (+-) sign.

The bending strength of a tooth depends on the shape of the root. A large undercut reduces the strength of the tooth.

Contact ratios

Whether a helical gearbox is dynamic or steady-state, the contact ratio is a key factor. The total contact ratio defines the average number of teeth in contact in the plane of action. It is calculated by multiplying the transverse contact ratio with the overlap ratio. The overlap ratio is always non-zero.

The total contact ratio must be 1.0 or greater for a constant speed rotation on the driven side. Gears with a low total contact ratio are known to slow down rotation of the driven gear. The total contact ratio is influenced by the length of the contact line. A high contact ratio is a good choice for dynamic loading.

A low contact ratio results in a greater amount of profile shift and a larger amount of noise. If the contact ratio is too high, it may cause excessive EAP sliding velocity and cause scuffing. In addition, an uneven load share results in amplitude modulated vibrations.

A helical gear is a pair of slim spur gears. The gears are layered in a plane that runs parallel to the face width of the gear teeth. Each gear tooth makes contact with the flank of the next gear tooth. The helical gear tooth flank is a 3-dimensional surface that is a tangent to the base circles of the gears.

The tooth shape of the helical gear tooth is also a key factor in the contact ratio. The tooth form is designed to be in relation to the work piece, tooling, dedendum coefficients, tooth forces, and tooth bending stiffness. A gear tooth form must also relate to tooth surface kinematics and microgeometry modifications.

The active profile is a region of the involute profile between the start and end points. A tooth profile that satisfies the basic law of gear-tooth action is often called a conjugate profile.

editor by czh 2023-01-31

China RC Series Inline Shaft Helical Gearbox Motors Reducer for China Manufacturer Industrial helical gearbox price

Product Description

RC Series Inline Shaft Helical Gearbox Motors Reducer for China Manufacturer Industrial

|

US $10-999 / Piece | |

100 Pieces (Min. Order) |

###

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

###

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) |

|---|

|

US $10-999 / Piece | |

100 Pieces (Min. Order) |

###

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

###

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) |

|---|

What Is a Helical Gearbox?

Basically, a gearbox is a rotating circular machine part that consists of toothed components, which mesh together. Its function is to transfer speed and torque to other parts of the machine. It is also similar to a lever, and operates on the same principle.

Double helical gears

Having a helical gearbox has many advantages, including higher efficiency, high strength, and a superior gear system. However, it has its drawbacks. One of these drawbacks is the axial thrust. Axial thrust is not a problem with single helical gears, but it is a problem with double helical gears.

In double helical gears, there are two sets of teeth that are arranged in a V-shape. In one set of teeth, there is a groove that enables the axial force to be cancelled out. The groove eliminates the need for thrust bearings and allows for efficient handling of high capacity power transmission.

Aside from the axial thrust, there are also issues with face contact. Asymmetric load sharing and oscillation put substantial alternating loads on the shaft bearings. These alternating loads can lead to early bearing failure.

Fortunately, helical gears are smoother than spur gears, which means they can withstand more load. They also have greater pitch circle diameter than spur gears. However, they are limited in their scope. The pitch error distribution on the helical gears is typically limited to 50 mm peak-to-peak amplitude. It is important to control the phase difference of oncoming gears with high accuracy.

Typically, the helical gears that are used in a gear box are assembled from the same module. This allows for interchangeability of components and economical construction. A normal module set can use the same tooth-cutting tools that are used for spur gears.

Double helical gears are used in power transmission in fluid pumps and gas turbines. They are also commonly used in planetary reduction gear boxes for engines in civil aviation.

Generally, double helical gears are larger than single helical gears. They are typically generated from a special generator. They are also more expensive.

However, manufacturers are looking to find gears that are more convenient to use. One solution is to manufacture double helical gears on a multi-tasking machine tool. This allows the gear to be machined in complicated shapes.

The multi-tasking machine tool can also modify the tooth surface. This is useful for 3D printing helical gears with a high level of accuracy.

Crossed-axis helical gears

Several factors affect the performance of crossed-axis helical gears. One of the important factors is the position of the gears on the cross shaft. The gears will not perform properly if they are not oriented in a different direction.

Crossed-axis helical gears have a special situation, in which they will not function properly if the gears are oriented in the same direction. This is especially true for automobile oil pump/distribution shafts. Depending on the situation, gears will operate as a normal helical gear or as a spur gear.

Compared to spur gears, crossed-axis helical gears have relatively higher capacity. However, the transverse contact ratio of these gears is reduced. This decrease is dependent on the pressure angle. The pressure angle affects the curvature radii of the teeth. In addition, the length of the contact line is reduced. This shortens the efficiency of the gear.

Helix angle of crossed-axis helical gears is 45 degrees. It may be a left-handed or a right-handed gear. The pitch circle diameter of a helical gear may be big compared to that of a spur gear. This is due to the fact that the gears are cut at an angle to the shaft.

In the axial direction, the meshing of helical gears is very similar to spur gears. However, there are a few design rules to optimize these gears.

The first rule is that the gears must be staggered in opposite directions. If the gears are not staggered, the contact lines cannot be changed.

The second rule states that the pitch of a helical gear is dependent on its helix angle. It is possible to calculate the pitch circle of a helical gear, by integrating along the face width. In addition, the length of the contact lines decreases as the pressure angle increases. However, this decrease is not as large as that of a spur gear.

Right angle helical gears

Choosing a right angle helical gearbox can be difficult. With so many types, sizes, and configurations to choose from, it can be difficult to figure out which one is right for your application. The key to choosing the right gearbox is understanding your application and what factors are most important to you.

For example, if you are looking for a gearbox that can be used in a high-speed, high-torque application, the most important consideration is the efficiency of the product. Right-angle gearboxes are compact and easy to maintain, making them ideal for high-torque applications.

Some applications that require high-torque gears include pulp and paper manufacturing, food processing, mining, and car washes. Some of the advantages of right angle gears include high efficiency, low maintenance, and low noise. If you are in the market for a right angle helical gearbox, make sure to select a supplier that can provide you with a wide range of options.

Right-angle helical gearboxes come in several different bevel configurations. Spiral bevel gears require precision and are difficult to manufacture. However, they can be used interchangeably. Spiral miter gears are designed to rotate in the same direction as the input shaft, which helps ensure a smooth, direct transfer of power.

If you are considering a helical gearbox for a high-speed application, you will need to know your preferred input/output ratio. The standard ratios are 1:1 and 2:1. If you need a step-up ratio, you can install an additional output shaft opposite the input shaft.

Other benefits include lower running noise, superior strength, and durability. Because they are made of larger teeth, helical gears are less likely to wear out. Also, helical gears provide higher power carrying capacity.

To determine which type of right angle gearbox is best suited for your application, you should discuss your needs with your supplier. They should be able to offer a wide range of options, including custom solutions. They should also provide you with a list of past clients and online reviews.

To find a right angle helical gearbox that can meet your needs, it’s important to understand the various design features. For example, you should make sure that your gearbox has a self-locking capability, which means that the load cannot drive the worm. Having a self-locking gearbox also means that you do not need to install a braking system.

Spiral teeth

Using helical gearboxes to drive a motor car or truck is an efficient method of power transmission. However, the efficiency of this method depends on the helix angle of the gear. The helix angle is the angle that the gear teeth are cut at.

Helical gearboxes may be of different helix angles, depending on the specific gear set. The helix angle can vary between 15 and 30 degrees. This is important because the helix angle has a significant effect on the position of tooth contact. If the contact is not in a proper position, then there will be a large amount of vibration. This will affect the speed of the gear.

Helical gearboxes can be of two types: crossed axis and parallel axis. Crossed axis gears are usually used to connect parallel shafts. They have the same center gap as spur gears. On the other hand, parallel axis gears are usually used to drive a motor. The difference between the two types of gearboxes is their design and arrangement.

In addition to the helix angle, the gears may have different fillet, teeth, and radius. This means that the gear will have different NVH characteristics. In addition, there are different types of spiral teeth that may be used in the gearbox.

Hypoid gears are also similar to spiral bevel gears, but they differ in that the axes of the gear shaft do not intersect the axis of the hypoid gear. The hypoid gear exerts a very high thrust load on the bearings.

When compared to a straight bevel gear, the hypoid gear experience a smoother, less noisy operation. They also produce less shock loading.

Spiral bevel gears are also designed to produce less vibration. They are also more cost-effective. However, they require a larger diameter to transmit the same torque. This can lead to a reduced mechanical efficiency and lower fuel economy.

The best spiral bevel gears can carry a higher thrust load than straight teeth. This is why they are preferred for applications that require heavy load efficiency.

They are also appreciated for their NVH characteristics. They are also a quieter option for applications that require high speed. Helical gears can be used in many different industries. The food, automotive, and oil industries are examples of these types of gears.

editor by czh 2022-12-12

in Helsinki Finland sales price shop near me near me shop factory supplier Ta Shaft Mounted Gearbox for Sale in Hot manufacturer best Cost Custom Cheap wholesaler

Our major items are Needle Roller bearings, Cylindrical Roller Bearings, Rod conclude Bearings, Spherical simple bearings, Keep track of roller Bearings for Guideway, Roller Bearings, Combine Bearings for forklifts, Water Pump Bearings, SNR Auto Bearings and all types of Spherical Bearings. In this way, our items have ongoing to achieve marketplace acceptance and clients satisfaction over the earlier handful of a long time. Wonderful focus has been compensated on environmental protection and strength saving.

Merchandise Description

ATA Collection Shaft mounted EPTT EPTT EPTR Collection Shaft mounted EPTT EPTT

ATA series shaft mounted EPTT(speed EPTT) with helical hardened EPTs has the traits of large carrying potential, clean EPTT, ligEPTT bodyweight, lower vitality usage and so on. Input shaft of ATA velocity EPTT is connected with EPT motor by belt pulley, hollow output shaft is connected with a crucial. It can be replaced by electrical drum as EPTT for belt conveyors and lifting equipments. ATA collection shaft mounted EPTT could be connected with back again-quit to avoid the functioning EPTT back again skating, and conveniently mounted by tie rod. ATA sequence shaft mounted pace EPTT is broadly used in the mining equipments, concrete miXiHu (West EPT) Dis.ng batching EPTT, stone crushers, sand making manufacturing line and other belt conveyors, mechanical EPTT locations.

EPT belt conveyors EPT technique is composed of ATA shaft mounted velocity EPTT, torque arm, pulleEPTTand EPT motors, whose EPTT EPTT from the EPT motor to the EPTT via the pulley, and then speed EPTT passed to the EPT pulley through the hollow output shaft and the EPTT is mounted by torque arm, anti-slip unit can be configured. The technique is handy to set up,use and keep.

Functions

Mounting Variety: Tie rod Hanging shaft mounted

Output Shaft: One key hollow shaft, each design can pick a few hollow diameter at most.

EPTT EPT: Hard Iron Metal, can be used exterior.

Anti-slip unit: Can go well with for any model, It is quite hassle-free to be mounted.

Application

Stone crushers EPTT , Cement EPTT, Concrete batch miXiHu (West EPT) Dis.ng EPTT, EPT conveyors, Port transfer

conveyor, Crushing EPTT, and so on middot middot middot

Characteristic

one) All EPTs are heat dealt with and fastened to attain lower noise and substantial output

2) Mounting proportions are interchangeable with Fenner

Merchandise Parameters

| TA Shaft Mounted EPTT | Output Shaft Bore [mm] | Ratio(i) | Rated torque | |

| TA30 | Phi30 | seven, 10, 12.five | 180N.m | |

| TA35 | Phi35 | five,10,15,20,twenty five | 420N.m | |

| TA40 | Phi40 | five,10,twelve.five,15,twenty,twenty five | 900N.m | |

| Phi45 | ||||

| TA45 | Phi45 | five,ten,12.5,15,20,twenty five | 1400N.m | |

| Phi50 | ||||

| Phi55 | ||||

| TA50 | Phi50 | 5,10,twelve.5,15,twenty,25 | 2300N.m | |

| Phi55 | ||||

| Phi60 | ||||

| TA60 | Phi60 | 5,10,12.5,fifteen,twenty,twenty five | 3600N.m | |

| Phi70 | ||||

| TA70 | Phi70 | 5,ten,12.five,15,20,25,31 | 5100N.m | |

| Phi85 | ||||

| TA80 | Phi80 | 5,ten,12.five,15,20,25,31 | 7000N.m | |

| Phi100 | ||||

| TA100 | Phi100 | five,ten,twelve.5,15,twenty,twenty five,31 | 11000N.m | |

| EPTR Product No. |

Output Shaft Bore [mm] |

Ratio(i) | ||

| StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd | Different | five:1 thirteen:1 20:one |

||

| B | Phi30 | Phi40 | ||

| C | Phi40 | Phi50 | ||

| D | Phi50 | Phi55 | ||

| E | Phi55 | Phi65 | ||

| F | Phi65 | Phi75 | ||

| G | Phi75 | Phi85 | ||

| H | Phi85 | Phi100 | ||

| J | Phi100 | Phi120 | ||

Manufacturing Method

in Bamenda Cameroon sales price shop near me near me shop factory supplier Custom Machine Shaft Drive Cylindrical Precision POM Plastic Spur Gear manufacturer best Cost Custom Cheap wholesaler

Superior thermo treatment gear, such as network heat remedy oven, multi-use thermo therapy oven, and so forth. We offer OEM services. Our principal goods are Needle Roller bearings, Cylindrical Roller Bearings, Rod end Bearings, Spherical plain bearings, Track roller Bearings for Guideway, Roller Bearings, Mix Bearings for forklifts, H2o Pump Bearings, SNR Car Bearings and all sorts of Spherical Bearings.

Custom EPTT Shaft Drive Cylindrical EPT POM Plastic Spur EPT

| Item | EPTT EPTTd EPT plastic EPTs |

| Craft Process | Plastic Injection or CNC machining |

| Plastic Granules |

UL, Food and drug administration, RoHS and many others. |

| EPTT EPTT | ISO9001 and ISO14001 |

| Molds EPT | S316,H13,718,738,P20,H13,420SS |

| Mold EPT | three hundred,000 pictures or 1,000,000 shots or a lot more |

| Mould Cavity | Solitary-cavity or two cavities or Multi-cavity |

| EPT | Nylon, PA66, NYLON with thirty% EPT fibre, Abdominal muscles, PP,Computer,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,EPTTPE,PMMA and so on. |

| Molds cavity Hardness | 60 to ninety H.R.C |

| Dimension/EPTT | EPTs and components proportions are in accordance to drawings from consumer, and colors are EPT |

| Surface area treatment method | PoEPTTd or matte surface area, portray, texture, EPT aluminizing and can be stamped with symbol and so forth. |

| Size Tolerance | plusmn0.05mm or much more exact |

| Operate Circulation chart | Step1: Make tooling to begin with and usual need to have 2~~three weeks. Step2: Create and validate samples. Step3: A single 7 days for mass production normal. |

| Samples confirmation and approval | Cost-free samples transported for confirmation and shipping EPT compensated by buyers |

| Deal | Inner very clear plastic bag/outside the house carton/wooden pallets/ or any other EPTT bundle as for every customer’s specifications. |

| Delivery Time | Total takes two~~4weeks usual |

| Payment Conditions | PAYPAL, T/T, Western EPT |

| EPT | Normal FEDEX, UPS, DHL, TNT, EMS or base on customer’s necessity. |

FAQ

Q1: What sort of EPTs can you source?

1. EPT precision plastic and metal EPTs with lower sounds, steady EPTT

two. Plastic EPT Injection mould

3. EPTT and EPTT assembly

Q2: What is your gain?

Expert EPT and EPTT maker in EPTT Mainland, EstabEPTTd in the yr of 2008. One-cease service from EPT R ampD, EPT style, EPT mould develop, EPT manufacturing, and EPTT assembly

We equipped Japan original EPTMAI N60 CNC EPT hobbing EPTTs, Switzerland first Agie Charmilles C AXiHu (West EPT) Dis.s EDM , MAKINO EDM, WEDM-LS, and Osaka JIS check cEPTTr, Osaka EPT mesh tester, EPTity tester, CMM, sounds examination area and so on. Innovative faXiHu (West EPT) Dis.Hu (West EPT) Dis.ties offer dedicated service to customers.

Q3: Why Select Q ampC in EPTT?

1. Expert R ampD Team: offer most suitable customise EPTT answers as per application and customer’s prerequisite.

2. Exceptional EPTT EPTT: EPT EPTT handle method, 100% inspection or take a look at prior to cargo.

3. Excellent Right after EPT Tracking Technique: Offer you Each Photos, Supply and Advertising Info sharing.

4. Fast reaction: sales give swift reaction in 24 several hours.

in Barranquilla Colombia sales price shop near me near me shop factory supplier Hole Input& Hollow Output Shaft Worm Reducer From 025-150 manufacturer best Cost Custom Cheap wholesaler

“We are often serving our clients with our very best items.” EPG was awarded with “well-known product of Zhejiang Province” and “well-known model of Zhejiang Province”. We are aiming to fulfill the calls for of the consumers around the globe.. Solution INTRODUCTION:

Principal Functions:

one) Produced of higher good quality EPT alloy, ligEPTT weigEPTT and non-rusting

two) Large output torque and higher radiating performance three) EPT running and reduced sound, can function EPTT time in dreadful condition

4) Good-looking look, resilient service lifestyle and tiny quantity

5) Suitable for omnibearing installation

Primary Components:

1)housing: aluminium alloy ADC12(dimension 571-090) die solid iron EPTT200(size 110-one hundred fifty)

two)Worm:20Cr, ZI Involute profile carbonize ampquencher warmth remedy make EPT floor hardness up to fifty six-sixty two EPTC Right after precision grinding, carburization layer’s thickness between .3-.5mm.

3)Worm Wheel:wearable stannum alloy CuSn10-1

Product PARAMETERS:

| Size | Specification | EPTT ratio | |||||||||||||

| IEC | N | M | P | 7.5 | 10 | fifteen | 20 | twenty five | thirty | 40 | 50 | sixty | eighty | one hundred | |

| D | |||||||||||||||

| twenty five | 56B14 | fifty | 65 | eighty | 9 | 9 | 9 | 9 | 9 | nine | 9 | 9 | nine | ||

| 30 | 63B5 | 95 | a hundred and fifteen | a hundred and forty | 11 | 11 | 11 | eleven | eleven | 11 | eleven | eleven | |||

| 63B14 | 60 | 75 | ninety | ||||||||||||

| 56B5 | eighty | one hundred | a hundred and twenty | 9 | 9 | nine | nine | 9 | nine | 9 | 9 | nine | 9 | ||

| 56B14 | fifty | 65 | 80 | nine | nine | 9 | nine | nine | nine | nine | 9 | nine | nine | ||

| 40 | 71B5 | a hundred and ten | 130 | one hundred sixty | fourteen | fourteen | 14 | 14 | 14 | fourteen | fourteen | fourteen | |||

| 71B14 | 70 | 85 | one hundred and five | ||||||||||||

| 63B5 | 95 | 115 | a hundred and forty | 11 | eleven | eleven | 11 | 11 | 11 | 11 | eleven | eleven | 11 | 11 | |

| 63B14 | 60 | 75 | 90 | ||||||||||||

| 56B5 | eighty | a hundred | 120 | 9 | nine | 9 | 9 | ||||||||

| 50 | 80B5 | one hundred thirty | one hundred sixty five | two hundred | 19 | 19 | 19 | 19 | 19 | 19 | 19 | – | – | – | – |

| 80B14 | 80 | one hundred | one hundred twenty | ||||||||||||

| 71B5 | one hundred ten | 130 | 160 | fourteen | 14 | fourteen | 14 | 14 | 14 | 14 | 14 | 14 | 14 | – | |

| 71B14 | 70 | eighty five | one hundred and five | ||||||||||||

| 63B5 | 95 | a hundred and fifteen | 140 | – | – | – | – | – | – | – | 11 | eleven | eleven | eleven | |

| 63 | 90B5 | a hundred thirty | a hundred sixty five | two hundred | 24 | 24 | 24 | 24 | 24 | 24 | 24 | – | – | – | – |

| 90B14 | 95 | 115 | a hundred and forty | ||||||||||||

| 80B5 | one hundred thirty | a hundred sixty five | 200 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | – | |

| 80B14 | 80 | a hundred | 120 | ||||||||||||

| 71B5 | one hundred ten | 130 | one hundred sixty | – | – | – | – | – | – | 14 | 14 | 14 | 14 | 14 | |

| 71B14 | 70 | eighty five | one hundred and five | ||||||||||||

| seventy five | 100/112B5 | a hundred and eighty | 215 | 250 | 28 | 28 | 28 | – | – | – | – | – | – | – | – |

| 100/112B14 | 110 | one hundred thirty | a hundred and sixty | ||||||||||||

| 90B5 | a hundred thirty | a hundred sixty five | 200 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | – | ||||

| 90B14 | ninety five | 115 | 140 | ||||||||||||

| 80B5 | one hundred thirty | 165 | 200 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | ||||

| 80B14 | eighty | a hundred | a hundred and twenty | ||||||||||||

| 71B5 | 110 | 130 | a hundred and sixty | 14 | fourteen | fourteen | fourteen | ||||||||

| 90 | a hundred/112B5 | a hundred and eighty | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | – | – | – | – | – |

| a hundred/112B14 | 110 | 130 | 160 | ||||||||||||

| 90B5 | 130 | 165 | two hundred | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | – | ||

| 90B14 | 95 | one hundred fifteen | a hundred and forty | ||||||||||||

| 80B5 | one hundred thirty | a hundred sixty five | two hundred | 19 | 19 | 19 | 19 | 19 | |||||||

| 80B14 | eighty | 100 | a hundred and twenty | ||||||||||||

| 110 | 132B5 | 230 | 265 | three hundred | 38 | 38 | 38 | 38 | – | – | – | ||||

| 100/112B5 | a hundred and eighty | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | |||

| a hundred/112B14 | one hundred ten | one hundred thirty | one hundred sixty | ||||||||||||

| 90B5 | one hundred thirty | 165 | two hundred | 24 | 24 | 24 | 24 | 24 | 24 | 24 | |||||

| 80B5 | 130 | 165 | 200 | 19 | 19 | ||||||||||

| one hundred thirty | 132B5 | 230 | 265 | three hundred | 38 | 38 | 38 | 38 | 38 | 38 | 38 | – | – | – | |

| 100/112B5 | one hundred eighty | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | |||||

| a hundred/112B14 | a hundred and ten | one hundred thirty | a hundred and sixty | ||||||||||||

| 90B5 | a hundred thirty | 165 | 200 | 24 | 24 | ||||||||||

| a hundred and fifty | 160B5 | 250 | three hundred | 350 | forty two | forty two | forty two | 42 | forty two | – | – | – | – | – | – |

| 132B5 | 230 | 265 | 300 | 38 | 38 | 38 | 38 | 38 | 38 | ||||||

| a hundred/112B5 | one hundred eighty | 215 | 250 | 28 | 28 | 28 | 28 | ||||||||

Merchandise Outline Proportions:

Firm Short INTRODUCTION:

We are a professional EPTT maker located in EPTTizhou, EPTT province.

Our foremost items is total assortment of RV571-a hundred and fifty worm EPTTs , also equipped hypoid helical EPTT, Computer units, UDL Variators and AC EPTs.

EPT are broadly utilized for apps these kinds of as: foodstuffs, EPT, EPTT, substances, pharmacy, plastics, paper-making, development EPTTry, metallurgic EPT, environmental security engineering, and all types of automated strains, and assembly strains.

With quick shipping, outstanding following-income services, EPTd producing faXiHu (West EPT) Dis.Hu (West EPT) Dis.ty, our goods sell properly both at property and abroad. We have exported our EPTTs to SouthEPT Asia, EPTern Europe and the Center EPT and so on.Our goal is to deveXiHu (West EPT) Dis.Hu (West EPT) Dis. and innovate on the basis of substantial high quality, and EPT a very good reputation for EPTTs.

WORKSHOP:

EXHIBITIONS:

FAQ:

1.Q:Can you make as for each customer drawing?

A: Of course, we offer EPT provider for customers appropriately. We can use customer’s nameplate for EPTTes.

two.Q:What is your conditions of payment ?

A: 30% deposit prior to production,stability T/T before supply.

three.Q:Are you a trading firm or maker?

A:We are a manufacurer with EPTd products and knowledgeable workers.

four.Q:What is actually your creation capability?

A:8000-9000 PCS/Month

four.Q:What is your MOQ?

A: 1 pcs

5.Q:Cost-free sample is available or not?

A:Of course, we can source cost-free sample if customer concur to spend for the courier EPT

6.Q:Do you have any certification?

A:Sure, we have CE certificate and SGS certificate report.

Get in touch with information:

Ms Lingel Pan

For any concerns just really feel totally free ton make contact with me. Several many thanks for your kind interest to our business!

in Bangkok Thailand sales price shop near me near me shop factory supplier OEM CNC Machining Hardened Steel Driving Toothed Shaft Intermediate Gear for Reduction Gear Box manufacturer best Cost Custom Cheap wholesaler

We examine each piece of bearing by ourselves ahead of shipping and delivery. If you need any info or samples, make sure you make contact with us and you will have our shortly reply. Our goods are made by present day computerized machinery and tools. OEM CNC Machining Hardened Metal Driving Toothed Shaft Intermediate EPT for Reduction EPT Box

EPT method :lathe machining solid hobbing

Testing tools:projector

We are willing to provide you with sample for testing, we have 16-yr producing and answers experiences.

We are ISO 9001: 2008 accredited company.

Our Solutions

| Business EPT | EPTT/ EPTT/ EPTT EPTs/ EPTT/ Maritime EPT/ EPTs/ EPTs Oil and Gas/ EPT/ EPTT |

| Intended Application | Shafts EPT Parts EPTT Doorway Factors EPTT/ EPT EPTor Fireplace Suppression System Parts Fittings/ Fasteners EPTs/ EPT Roller EPTTs |

| EPT Instances Accessible | Max: 2 Weeks (On Preliminary Get) Hurry Solutions Offered |

| Industry StXiHu (West EPT) Dis.Hu (West EPT) Dis.rds | ISO 9001:2008 PPAP RoHS Compliant |

| Added Capabilities | CAD Design Services CAM Programming Companies Coordinate Measuring EPTTs (CMM) Reverse EPT |

| EPT Record | From basic two-aXiHu (West EPT) Dis.s turning to seven-aXiHu (West EPT) Dis.s, switch-mill-drill CNC Swiss-sort EPTTs, molding EPTTs/ stamping EPTTs automated lathe EPTTs/ EPT EPTTs. |

| EPT (EPTs or plastic) |

Alloy Steels/ EPTT/ Brass/ Bronze Alloys EPTT Steel/ Copper/ Stainless Metal/ Tool Steel Cold Rolled Steel/ EPTT Metal Abdominal muscles/ Delrin/ Nylon/ PVC |

| Tests equipment | Projector. Calliper, micrometer, plug gauge, ring gauge, thread gauge |

| Processes (EPT Capabilities) |

Broaching/ Hobbing/ Slotting/tapping |

| Tolerance | plusmn0.0002 in plusmn0.0051 mm |

| EPTT | For ligEPTT objects: bubble pack individually to avoid from detrimental and scratches in transporting, then in carton for hefty objects: wrapped in PE baggage and then in wood boxes |

Other GEARS for your seem,

EPTT Details

EPT EPTT Co,. Minimal, is located in NO 4 EPTT, EPTTEPTT EPTT Zone EPTTEPTTng Road, XiHu (West EPT) Dis.ekeng, EPTTngXiHu (West EPT) Dis., HangEPT, ZheJiang province, EPTT. EPT was started in 1998, masking an area of 11,000 square meters and two hundred employees . 90% of our products are marketed to overEPTT market this sort of as United states, Canada, Germany, Uk, EPTT, Australia, Japan, South Korea and many others. We are ISO 9001:2008, ISO13485 (medical)and TS16949(automotive) certified organization. We will have AS9100 certification(aerospace) In 2018.

EPT

one. We are willing to provide with sample for top quality and operate tests.

2. Shipping time:inside 20 working daEPTT.

FAQ

Q1:How to guarantee the EPTT of EPTT Elements?

A1:we are ISO 9001-2008 qualified firm. we have the integrated technique for EPTT areas quality manage. We have IQC (incoming top quality manage), IPQCS (in approach quality control EPT), FQC (last top quality handle) and OQC (out-going high quality handle) to manage each process of EPTT components prodution.

Q2:What is the Gain of Your Components for Business EPT?

A2:Our edge is the competitive charges, quick delivery and high high quality. Our personnel are responsible-oriEPTTd, pleasant-oriEPTTd,and dilient-oriEPTTd. our EPTT elements merchandise are featured by strict tolerance, smooth complete and EPTT-existence efficiency.

Q3:what are our machining equipmengts?

A3:Our machining equipments incEPTT CNC milling EPTTs, CNC turning EPTTs, stamping

EPTTs,hobbing EPTTs, computerized lathe EPTTs, tapping EPTTs, grinding EPTTs,

screw EPTTs, chopping EPTTs and so on.

This autumn: What delivery waEPTTour use?

A4:EPTTly sEPTing, we will use UPS or DHL to ship the merchandise. Our clients can attain the

products inside of 3 days.

If our customers do not need to have them urgently, we will also use Fedex and TNT.

If the goods are of weighty weigEPTT and huge volumn, we will ship them by sea. This way can save

our buyers a great deal of cash.

Q5:Who are our main clients?

A5:HP, Samsung, Jabil Team,Lexmark,Flextronic Group.

Q6:What resources can you manage?

A6:Brass,bronze,copper,stainless metal, metal,EPT,EPTTium And plastic.

Q7:How EPTT is the Supply for Your EPTT Portion?

A7:EPTTly sEPTing, it will get us 15 functioning daEPTTfor machining components and 25 working daEPTTfor

the for stamping areas products. But we will shorten our guide time according to customers’ needs if we are capable to.