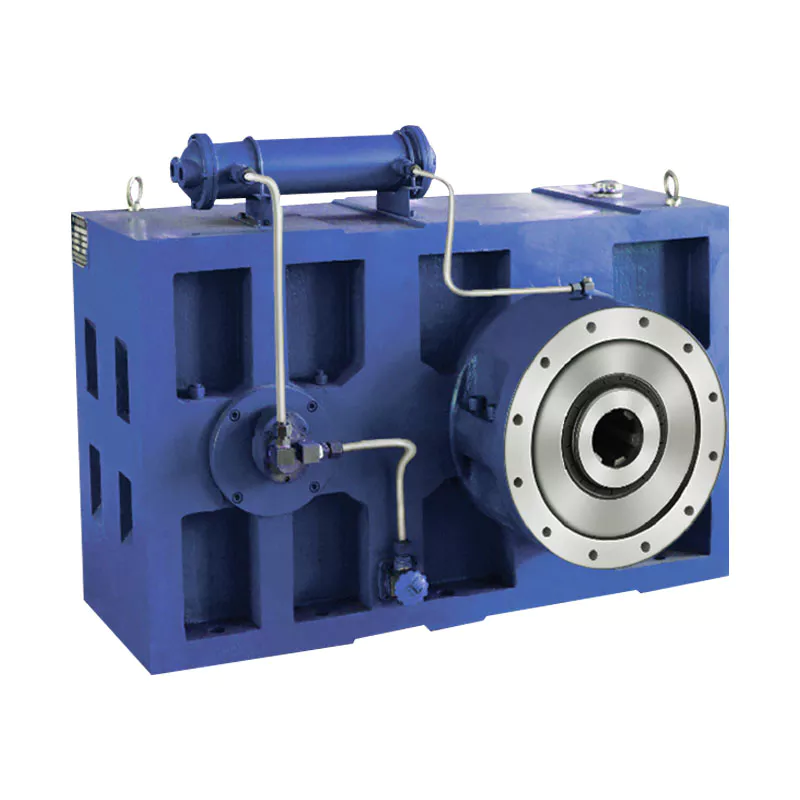

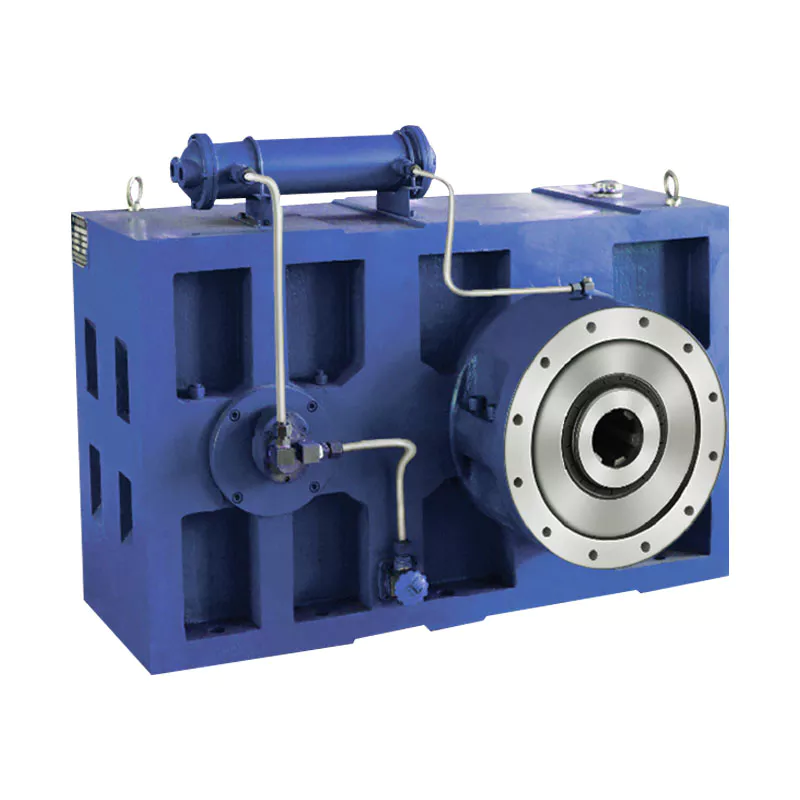

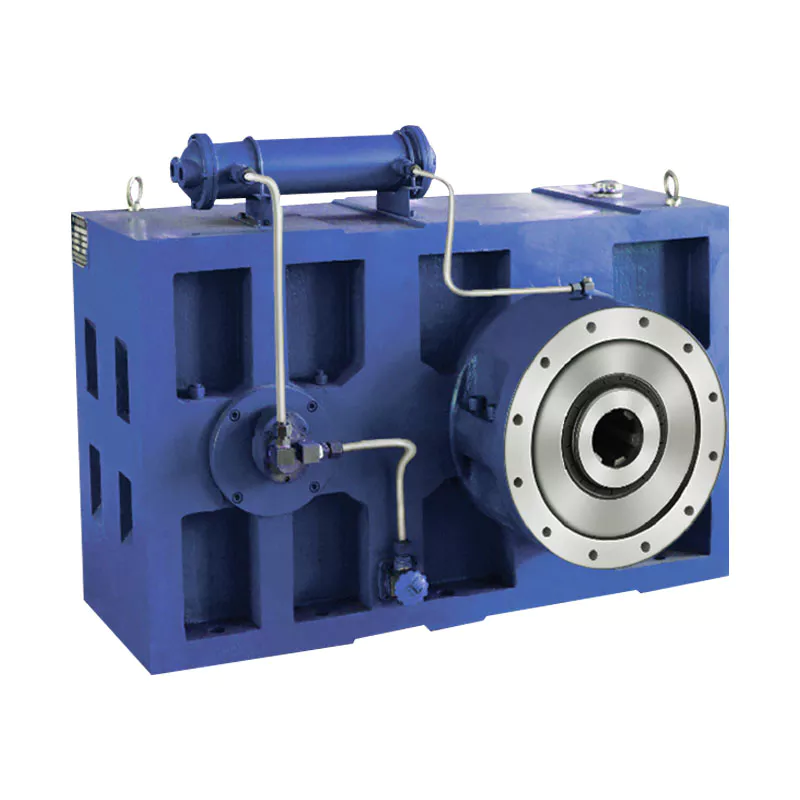

Product Description

Technical Parameter

| Housing material | HT200 high-strength cast iron(EWK37, EWK47, EWK57, EWK67, EWK77, EWK87) |

| Housing material | HT250 High strength cast iron(EWK97, EWK107, EWK127, EWK157, EWK167, EWK187) |

| Gear material | 20CrMnTi |

| Gear Surface&hardness | HRC58°-62° |

| Gear core hardness | HRC33°-78° |

| Input/Output shaft material | 40Cr |

| Gear Machining precision | Accurate grinding 6-5 grade |

| Heat treatment | Carburizing, Quenching etc |

| Efficiency | Up to 92% |

| Noise(Max) | 60-67dB |

| Installation type | Foot mounted, flange mounted |

| Output type | Solid shaft, Hollow shaft, splined hollow shaft, shrink disk |

| Bearing brand | NSK, SKF, HRB, ZWZ etc |

| Oil seal brand | NAK, KSK etc |

| Lubricant | VG220 |

| Motor | IP55, F class |

| Motor shaft | 40Cr, Carburizing, Quenching etc |

| Warranty | 12months |

| Color | Blue, Grey |

Features

♦Specially designed for agitator.

♦Compact structure, Integrated casting housing, low noise and long service life.

♦High efficiency and low maintenance.

Technical Data

Ratio I=8.1~191, combination of EWK/EWR is up to13459

Efficiency: 94%, and combination of EWK/EWR85%.

Size EWK37~EWK187.

Industrial Application

Power Plant Equipment

Metallurgical Industry

Metal Forming Machinery

Petrochemical Industry

Mining Machine

Hoisting Machinery

Construction Industry

Environmental Protection Industry

Cable Industry

Food Machinery

Certificates

Passed ” ISO 9001 International Quality System Certificate”, “Europe CE Certificate”, ” Swiss SGS Certificate”, “High-tech enterprise certificate of ZheJiang city”, “Excellent performance management enterprise of ZheJiang city”, etc.

FAQ

1. Q: Can you make as per custom drawing?

A: Yes, we offer customized service for customers.

2. Q: Are you a factory or trading company?

A. We are manufacturer in ZheJiang China.

3. Q: What’s your MOQ?

A: One piece.

4. Q: What’s your production time?

A: 7-15 working days after receiving payment.

5. Q: What’s your payment terms?

A: T/T, 30% payment in advance, 70% balance payment should be paid before shipping.

6. Q: What’s your package?

A: In wooden box packaging.

ZheJiang CZPT Gear Reducer Co., Ltd., former a joint venture invested by is a ZheJiang CZPT GROUP and Well Company of America. We are professional manufacturer of the gear reducers and specialize in the gear reducers area in China for 20 years. CZPT has excellent R&D team, top-ranking production and test equipment. So we have the strong power in the developing and manufacturing the standards type as well as the customized type gear reducer for our customers. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | 90 Degree |

| Layout: | Right-Angle |

| Gear Shape: | Bevel Gear |

| Step: | Three-Step |

| Customization: |

Available

| Customized Request |

|---|

Advancements in Helical Gearbox Technology

Advancements in helical gearbox technology have led to improved performance, efficiency, and versatility. Here are some notable advancements:

- Material Innovations: The use of advanced materials, such as high-strength alloys and composites, has enhanced the durability and load-carrying capacity of helical gears. These materials also contribute to reduced weight and improved efficiency.

- Precision Manufacturing: Modern manufacturing techniques, including CNC machining and gear grinding, have enabled the production of helical gears with higher accuracy and tighter tolerances. This results in smoother operation and reduced noise levels.

- Gear Tooth Profile Optimization: Advanced computer simulations and modeling techniques allow for the optimization of gear tooth profiles. This results in better load distribution, reduced stress concentration, and improved overall gearbox efficiency.

- Lubrication and Cooling: Improved lubrication systems and cooling mechanisms help maintain optimal operating temperatures and extend the lifespan of helical gearboxes. This is particularly important for high-demand applications.

- Noise and Vibration Reduction: Innovative designs and precision manufacturing techniques have led to helical gears with reduced noise and vibration levels. This advancement is crucial for industries where noise reduction is a priority.

- Compact Design: Advancements in gear design and manufacturing have allowed for more compact and lightweight helical gearbox configurations, making them suitable for space-constrained environments.

- Integration with Electronics: Some modern helical gearboxes are designed for seamless integration with electronic control systems. This enables better monitoring, control, and optimization of gearbox performance.

- Customization: Advancements in manufacturing and design tools allow for greater customization of helical gearboxes to meet specific application requirements. This includes adapting gear ratios, sizes, and configurations.

In summary, advancements in helical gearbox technology have led to enhanced performance, durability, efficiency, and customization options. These innovations continue to make helical gearboxes a versatile and reliable choice for a wide range of industrial applications.

Troubleshooting Common Issues in Helical Gear Systems

Troubleshooting helical gear systems involves identifying and addressing common issues that can affect their performance. Here’s a step-by-step process:

- Visual Inspection: Begin by visually inspecting the gearbox for any signs of wear, damage, or misalignment. Look for worn or chipped gear teeth, oil leakage, and unusual noise.

- Noise Analysis: If noise is present, analyze its type and frequency. Whining or grinding noises could indicate misalignment or damaged gears, while clicking or knocking sounds might point to loose components.

- Lubrication Check: Ensure that the gearbox is properly lubricated with the recommended type and quantity of lubricant. Insufficient lubrication can lead to increased friction and wear.

- Alignment Check: Check the alignment of the gears and shafts. Misalignment can result in uneven wear, noise, and reduced efficiency. Realign components if necessary.

- Gear Inspection: Inspect gear teeth for signs of pitting, scoring, or wear. Replace any damaged gears to prevent further issues.

- Bearing Examination: Check the condition of bearings that support shafts and gears. Worn or damaged bearings can lead to increased vibration and noise.

- Tightening and Fastening: Ensure that all bolts, fasteners, and connections are properly tightened. Loose components can cause vibrations and noise.

- Load Analysis: Evaluate the load conditions and operating parameters of the gearbox. Ensure that the gearbox is not subjected to loads beyond its design capacity.

- Temperature Monitoring: Monitor the operating temperature of the gearbox. Excessive heat can indicate problems such as inadequate lubrication or overloading.

- Consulting Experts: If issues persist or if you’re unsure about the diagnosis and solution, consult gearbox experts or manufacturers for guidance.

By following this troubleshooting process, you can identify and resolve common issues in helical gear systems, ensuring optimal performance and longevity.

Lubrication Requirements for Maintaining Helical Gearboxes

Lubrication is essential for the proper functioning and longevity of helical gearboxes. The lubrication requirements include:

- Viscosity: Selecting a lubricant with the appropriate viscosity is crucial. The viscosity should provide sufficient lubrication and ensure a protective film between gear teeth under varying operating conditions.

- Extreme Pressure (EP) Properties: Helical gears often experience high contact pressures. Lubricants with EP additives form a protective barrier that prevents metal-to-metal contact and reduces wear.

- Oil Additives: Anti-wear additives, antioxidants, and corrosion inhibitors enhance the lubricant’s performance and protect gears from wear and degradation.

- Frequent Inspections: Regularly inspect the lubricant’s condition to detect contamination, degradation, or depletion. Scheduled oil analysis can help monitor the health of the lubricant.

- Proper Lubricant Application: Ensure the gearbox is properly filled with the correct amount of lubricant. Follow manufacturer recommendations for lubricant type and quantity.

- Lubricant Change Intervals: Establish regular lubricant change intervals based on operating conditions. Extreme conditions or heavy loads may require more frequent changes.

Appropriate lubrication minimizes friction, wear, and heat generation, leading to improved efficiency, reduced maintenance, and extended gearbox life. It’s crucial to follow the manufacturer’s guidelines and consult with lubrication experts to select the right lubricant and maintenance practices for your specific helical gearbox application.

editor by CX 2024-04-09

China OEM ZD Square/Round Mounting Flange High-Efficiency Helical Precision Planetary Gearbox For Collaborative Robotics wholesaler

Product Description

Model Selection

ZD Leader has a wide range of micro motor production lines in the industry, including DC Motor, AC Motor, Brushless Motor, Planetary Gear Motor, Drum Motor, Planetary Gearbox, RV Reducer and Harmonic Gearbox etc. Through technical innovation and customization, we help you create outstanding application systems and provide flexible solutions for various industrial automation situations.

• Model Selection

Our professional sales representive and technical team will choose the right model and transmission solutions for your usage depend on your specific parameters.

• Drawing Request

If you need more product parameters, catalogues, CAD or 3D drawings, please contact us.

• On Your Need

We can modify standard products or customize them to meet your specific needs.

Product Parameters

Type Of RV Reducer

Application Of RV Reeducer

Precision Cycloidal Gearbox is widely used in industrial machinery fields such as machine tool, robot arm, industrial robot, die-casting feeding machine, manipulator for punching machine, AGV driver, bottle-making machine, UV Printer and etc.

Other Products

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Conical – Cylindrical Gear |

| Step: | Three-Step |

| Customization: |

Available

| Customized Request |

|---|

Installation and Alignment of Helical Gearboxes

Proper installation and alignment of a helical gearbox are essential to ensure its optimal performance and longevity. Here are the steps involved:

- Preparation: Gather all necessary tools, equipment, and safety gear. Ensure the work area is clean and well-lit.

- Mounting: Position the gearbox on the designated mounting surface and secure it using appropriate bolts. Follow the manufacturer’s guidelines for mounting torque and procedures.

- Shaft Alignment: Use precision tools such as dial indicators to align the input and output shafts. Achieving accurate shaft alignment minimizes stress on the gears and bearings.

- Bolt Tightening: Gradually and evenly tighten the mounting bolts, ensuring the gearbox remains properly aligned. Refer to torque specifications provided by the manufacturer.

- Lubrication: Fill the gearbox with the recommended lubricant according to the manufacturer’s specifications. Proper lubrication is crucial for reducing friction and wear.

- Alignment Check: After tightening the bolts, recheck the shaft alignment to ensure it hasn’t shifted during the tightening process.

- Run-In Period: Gradually introduce load to the gearbox to allow the gears to seat properly. Monitor the gearbox for any unusual noises, vibrations, or temperature changes during this period.

- Final Checks: Verify that the gearbox operates smoothly, without excessive noise or vibrations. Monitor the gearbox’s temperature during operation to ensure it remains within recommended limits.

- Regular Inspection: Schedule periodic inspections to check for any signs of wear, misalignment, or leakage. Address any issues promptly to prevent further damage.

It’s important to follow the manufacturer’s installation and alignment guidelines specific to the helical gearbox model you’re working with. Improper installation and alignment can lead to premature wear, reduced efficiency, and potential failure of the gearbox.

Considerations for Designing Helical Gearboxes for Heavy-Duty Applications

Designing helical gearboxes for heavy-duty applications requires careful consideration of various factors to ensure reliable and efficient operation under high loads and demanding conditions. Here are the key considerations:

- Load Capacity: Heavy-duty applications involve substantial loads. The gearbox must be designed to handle these loads while preventing premature wear and failure. Calculations of the load distribution, contact stresses, and material strength are crucial.

- Material Selection: High-strength and durable materials are essential for heavy-duty gearboxes. Alloy steels or special heat-treated materials are often chosen to provide the necessary strength and resistance to fatigue and wear.

- Gear Tooth Design: Optimal gear tooth profiles, such as optimized helix angles and tooth modifications, contribute to smoother engagement and reduced stress concentrations. This enhances the gearbox’s ability to handle heavy loads without excessive wear.

- Bearing Selection: Robust and high-capacity bearings are necessary to support the heavy loads and provide reliable shaft support. The bearings must be able to withstand both radial and axial forces generated during operation.

- Lubrication: Adequate lubrication is critical for heavy-duty gearboxes. Lubricants with high load-carrying capacity and extreme pressure properties are chosen to ensure proper lubrication under heavy loads and to reduce friction and wear.

- Heat Dissipation: Heavy-duty applications can generate significant heat due to friction and load. Efficient heat dissipation mechanisms, such as cooling fins or oil cooling, should be incorporated into the gearbox design to prevent overheating and thermal damage.

- Sealing: Effective sealing is necessary to prevent contaminants from entering the gearbox and to retain lubricants. Seals must be capable of withstanding the conditions of the application, including high loads, vibrations, and potential exposure to harsh environments.

- Efficiency: Although heavy-duty applications prioritize load capacity, achieving acceptable levels of efficiency is still important to minimize energy losses and heat generation. Proper gear tooth design and high-quality manufacturing contribute to better efficiency.

- Structural Integrity: The gearbox housing and components must be designed with structural integrity in mind. Rigidity and robustness are required to prevent distortion or failure of components under heavy loads.

- Reliability and Serviceability: Heavy-duty gearboxes should be designed with reliability and ease of maintenance in mind. Access to critical components, such as gears and bearings, for inspection and replacement is important to minimize downtime.

Conclusion: Designing helical gearboxes for heavy-duty applications involves a comprehensive approach that addresses load capacity, material selection, gear tooth design, lubrication, heat dissipation, sealing, efficiency, structural integrity, and serviceability. By carefully considering these factors, engineers can create gearboxes that deliver exceptional performance and longevity in demanding industrial settings.

Noise and Vibration Levels in Helical Gearboxes

Helical gearboxes are known for their relatively low noise and vibration levels compared to some other types of gears. However, there are still certain factors that can influence the noise and vibration levels in helical gear systems:

- Helix Angle: The helix angle of helical gears helps to distribute the load over multiple teeth, reducing impact forces and resulting in smoother meshing. This contributes to lower noise and vibration levels.

- Precision Manufacturing: High-precision manufacturing processes can ensure better gear tooth geometry and minimize irregularities that could lead to noise and vibration.

- Lubrication: Proper lubrication is crucial for reducing friction and damping vibrations between gear teeth. Insufficient or improper lubrication can lead to increased noise levels.

- Alignment: Proper alignment of gears is essential to minimize misalignment-induced noise and vibration. Misalignment can cause uneven tooth contact and lead to increased noise and vibration.

- Load Distribution: Helical gears distribute loads over multiple teeth, which helps in reducing localized stresses and vibrations that could cause noise.

- Material Quality: High-quality materials with good damping properties can help absorb vibrations and reduce noise transmission.

- Operating Conditions: Factors such as operating speed, load, temperature, and gear backlash can influence noise and vibration levels.

Overall, helical gearboxes are designed to provide smoother and quieter operation compared to other gear types. However, the noise and vibration levels can still vary based on design, manufacturing quality, and operational factors. Engineers can optimize gear design and operating conditions to achieve the desired noise and vibration characteristics for specific applications.

editor by CX 2024-04-03

China Good quality Desboer Output Reducer Planetary Gearbox Helical Gear Desboer NBR 115 Series Servo Motor Gear Reducer Flange Output 750W Servo Motor Gearbox gearbox design

Product Description

Product Description

The NBR115 series planetary gearboxes are designed and machined as a single unit with special tapered roller bearings to provide high radial load, high torque, ultra-precision, and small size. The NBR115 series uses in highly rigid industries such as fiber optic laser equipment, floor track equipment, robot seventh axis, Parallel robots (spider hand) machine tools, and rotating arms.

Product Name: High Precision Planetary Reducer

Product Series: NBA115 Series

Product features: high torque, high load, ultra-precision, small size

Product Description:

Integrated design concept with high-strength bearings ensure the product itself is durable and efficient

A variety of output ideas such as shaft output, flange and gear are available.

1 arc minute ≤ backlash ≤ 3 arc minutes

Reduction ratios ranging from 3 to 100

Frame design: increases torque and optimizes power transmission

Optimised selection of oil seals: reduces friction and laminate transmission efficiency

Protection class IP65

Warranty: 2 years

Our Advantages

High torque

High load

ultra-precision

Small size

Detailed Photos

Product Parameters

| Segment number | Double segment | ||||||||||||||||

| Ratio | i | 25 | 30 | 35 | 40 | 45 | 50 | 60 | 70 | 80 | 90 | 100 | 120 | 140 | 160 | 180 | 200 |

| Rated output torque | Nm | 300 | 290 | 280 | 240 | 210 | 210 | 290 | 280 | 240 | 210 | 210 | 290 | 280 | 240 | 210 | 210 |

| Emergency stop torque | Nm | Three times of Maximum Output Torque | |||||||||||||||

| Rated input speed | Rpm | 4000 | |||||||||||||||

| Max input speed | Rpm | 8000 | |||||||||||||||

| Ultraprecise backlash | arcmin | ≤4 | |||||||||||||||

| Precision backlash | arcmin | ≤7 | |||||||||||||||

| Standard backlash | arcmin | ≤9 | |||||||||||||||

| Torsional rigidity | Nm/arcmin | 25 | |||||||||||||||

| Max.bending moment | Nm | 6700 | |||||||||||||||

| Max.axial force | N | 3350 | |||||||||||||||

| Service life | hr | 20000(10000 under continuous operation) | |||||||||||||||

| Efficiency | % | ≥92% | |||||||||||||||

| Weight | kg | 14.2 | |||||||||||||||

| Operating Temperature | ºC | -10ºC~+90ºC | |||||||||||||||

| Lubrication | Synthetic grease | ||||||||||||||||

| Protection class | IP64 | ||||||||||||||||

| Mounting Position | All directions | ||||||||||||||||

| Noise level(N1=3000rpm,non-loaded) | dB(A) | ≤68 | |||||||||||||||

| Rotary inertia | Kg·cm² | 2.25 | 1.87 | ||||||||||||||

Applicable Industries

Packaging Machinery Mechanical Hand Textile Machinery

Non Standard automation Machine Tool Printing Equipment

Certifications

Company Profile

DESBOER (HangZhou) Transmission Technology Co., Ltd. is a subsidiary of DESBOER (China), which is committed to the design, development, customized production and sales of high precision planetary reducer as 1 of the technology company. Our company has over 10 years of design, production and sales experience, the main products are the high precision planetary reducer, gear, rack, etc., with high quality, short delivery period, high cost performance and other advantages to better serve the demand of global customers. It is worth noting that we remove the intermediate link sale from the factory directly to customers, so that you can get the most ideal price and also get our best quality service simultaneously.

About Research

In order to strengthen the advantages of products in the international market, the head company in Kyoto, Japan to established KABUSHIKIKAISYA KYOEKI, mainly engaged in the development of DESBOER high precision planetary reducer, high precision of transmission components such as the development work, to provide the most advanced design technology and the most high-quality products for the international market.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Marine, Agricultural Machinery, CNC Machine |

|---|---|

| Function: | Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Plantery Type |

| Hardness: | Hardened Tooth Surface |

| Installation: | All Directions |

| Step: | Double-Step |

| Customization: |

Available

| Customized Request |

|---|

Comparison of Helical Gearboxes and Bevel Gearboxes

Helical gearboxes and bevel gearboxes are both widely used for power transmission in various industrial applications. Here’s a comparison of their performance:

- Gear Meshing: Helical gearboxes use helical gears with inclined teeth that gradually engage, resulting in smoother and quieter operation compared to the more abrupt engagement of straight-cut bevel gears.

- Efficiency: Helical gearboxes generally offer higher efficiency due to their helical gear design, which distributes loads evenly across the teeth. Bevel gearboxes can have slightly lower efficiency due to the sliding action of gear teeth during engagement.

- Load Capacity: Helical gearboxes can handle higher loads and torque due to the larger contact area of the gear teeth. Bevel gearboxes are suitable for moderate loads and applications where the direction of power transmission needs to be changed.

- Space Efficiency: Bevel gearboxes are often more compact and suitable for applications where space is limited and a change in direction is required. Helical gearboxes may require more space due to the parallel shaft arrangement.

- Noise and Vibration: Helical gearboxes generate less noise and vibration compared to straight-cut bevel gearboxes. Bevel gearboxes can be noisier, especially at higher speeds.

- Application: Helical gearboxes are commonly used in applications requiring smooth and efficient power transmission, such as conveyors, pumps, and mixers. Bevel gearboxes are preferred for applications where changes in direction are necessary, such as in automotive differentials and printing presses.

Ultimately, the choice between helical and bevel gearboxes depends on the specific requirements of the application, including load capacity, space constraints, efficiency goals, and the need for directional changes in power transmission.

Troubleshooting Common Issues in Helical Gear Systems

Troubleshooting helical gear systems involves identifying and addressing common issues that can affect their performance. Here’s a step-by-step process:

- Visual Inspection: Begin by visually inspecting the gearbox for any signs of wear, damage, or misalignment. Look for worn or chipped gear teeth, oil leakage, and unusual noise.

- Noise Analysis: If noise is present, analyze its type and frequency. Whining or grinding noises could indicate misalignment or damaged gears, while clicking or knocking sounds might point to loose components.

- Lubrication Check: Ensure that the gearbox is properly lubricated with the recommended type and quantity of lubricant. Insufficient lubrication can lead to increased friction and wear.

- Alignment Check: Check the alignment of the gears and shafts. Misalignment can result in uneven wear, noise, and reduced efficiency. Realign components if necessary.

- Gear Inspection: Inspect gear teeth for signs of pitting, scoring, or wear. Replace any damaged gears to prevent further issues.

- Bearing Examination: Check the condition of bearings that support shafts and gears. Worn or damaged bearings can lead to increased vibration and noise.

- Tightening and Fastening: Ensure that all bolts, fasteners, and connections are properly tightened. Loose components can cause vibrations and noise.

- Load Analysis: Evaluate the load conditions and operating parameters of the gearbox. Ensure that the gearbox is not subjected to loads beyond its design capacity.

- Temperature Monitoring: Monitor the operating temperature of the gearbox. Excessive heat can indicate problems such as inadequate lubrication or overloading.

- Consulting Experts: If issues persist or if you’re unsure about the diagnosis and solution, consult gearbox experts or manufacturers for guidance.

By following this troubleshooting process, you can identify and resolve common issues in helical gear systems, ensuring optimal performance and longevity.

Advantages of Helical Gearboxes in Industrial Applications

Helical gearboxes offer several advantages that make them well-suited for a wide range of industrial applications. Here are some of the key advantages:

- Smooth and Quiet Operation: The helical design of the gears results in gradual tooth engagement, reducing noise and vibration during operation. This makes helical gearboxes ideal for applications where noise reduction is important.

- High Efficiency: Helical gears provide a larger contact area compared to straight-cut gears, leading to improved power transmission efficiency. The gradual engagement of teeth also reduces energy losses due to friction.

- Higher Load Capacity: The helical angle allows for multiple teeth to be engaged simultaneously, distributing the load across a larger area. This results in higher load-carrying capacity and increased durability of the gearbox.

- Compact Design: Helical gearboxes can achieve high gear ratios with fewer gear stages, leading to a more compact overall design. This is advantageous in applications where space is limited.

- Wide Range of Ratios: Helical gearboxes can achieve a wide range of gear ratios, making them versatile for various speed and torque requirements.

- Less Backlash: The gradual tooth engagement of helical gears results in reduced backlash, which is the play between gear teeth. This leads to improved accuracy and positioning in applications that require precise motion control.

- Heat Dissipation: The helical design allows for better heat dissipation due to the continuous contact between gear teeth. This is beneficial in high-speed applications where heat generation can be a concern.

- Highly Customizable: Helical gearboxes can be customized to meet specific application requirements, including input and output configurations, gear ratios, and mounting options.

Overall, the advantages of helical gearboxes make them a popular choice in industries such as manufacturing, automation, robotics, material handling, and more.

editor by CX 2024-03-28

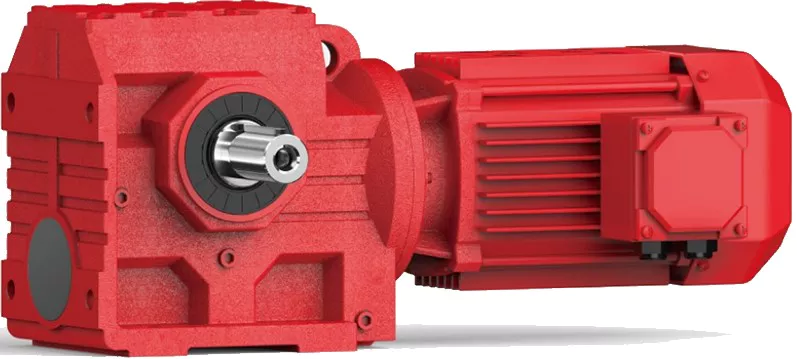

China Standard Speed Reducer Gear Motors Geared Motor Gearbox Gear Unit with Input Flange Roller Press Planetary Worm Helicalgear Reducer Gearbox China Industrial Manufacturer with high quality

Product Description

Speed Reducer Gear Motors Geared Motor Gearbox Gear Unit with Input Flange roller press planetary worm helicalgear reducer gearbox China Industrial Manufacturer

Application of Motor Gearbox

Motor gearboxes are used in a wide variety of applications, including:

- Machine tools. Motor gearboxes are used in machine tools to control the speed of the cutting tool. This allows for the precise machining of materials.

- Conveyors. Motor gearboxes are used in conveyors to control the speed of the conveyor belt. This allows for the efficient and safe transportation of materials.

- Wind turbines. Motor gearboxes are used in wind turbines to control the speed of the turbine blades. This allows for the efficient generation of electricity.

- Elevators. Motor gearboxes are used in elevators to control the speed of the elevator car. This allows for the safe and efficient transportation of people and goods.

- Other applications. Motor gearboxes are also used in a variety of other applications, such as:

- Robotics

- Pumps

- Fans

- Compressors

Motor gearboxes are a critical component in many machines and systems. They allow for the efficient and reliable transmission of power, which is essential for many applications.

Here are some of the advantages of using motor gearboxes:

- Efficiency. Motor gearboxes are very efficient at transmitting power. This is because they have a smooth, direct connection between the input and output shafts.

- Versatility. Motor gearboxes are available in a variety of sizes and styles, which makes them adaptable to a wide range of machines and systems.

- Durability. Motor gearboxes are made of strong materials, such as steel or cast iron, which makes them durable and long-lasting.

Overall, motor gearboxes are a versatile and beneficial component that can be used in a wide variety of applications. They can help to improve efficiency, versatility, and durability.

Here are some additional details about the applications of motor gearboxes:

- Machine tools. In machine tools, motor gearboxes are used to control the speed of the cutting tool. This allows for the precise machining of materials. For example, in a milling machine, the motor gearbox is used to control the speed of the milling cutter. This allows the operator to control the depth and width of the cut, as well as the finish of the surface.

- Conveyors. In conveyors, motor gearboxes are used to control the speed of the conveyor belt. This allows for the efficient and safe transportation of materials. For example, in a food processing plant, a conveyor belt is used to transport food products from 1 station to another. The motor gearbox is used to control the speed of the conveyor belt so that the food products are not damaged.

- Wind turbines. In wind turbines, motor gearboxes are used to control the speed of the turbine blades. This allows for the efficient generation of electricity. For example, in a wind turbine with a 100-meter rotor diameter, the turbine blades can rotate at speeds of up to 200 kilometers per hour. The motor gearbox is used to reduce the speed of the turbine blades to a safe and efficient level for generating electricity.

- Elevators. In elevators, motor gearboxes are used to control the speed of the elevator car. This allows for the safe and efficient transportation of people and goods. For example, in a high-rise building, the elevator car may travel at speeds of up to 10 CZPT per second. The motor gearbox is used to reduce the speed of the elevator car to a safe and comfortable level for passengers.

These are just a few examples of the many applications of motor gearboxes. Motor gearboxes are a critical component in many machines and systems, and they play an important role in the efficient and reliable transmission of power.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Advancements in Helical Gearbox Technology

Advancements in helical gearbox technology have led to improved performance, efficiency, and versatility. Here are some notable advancements:

- Material Innovations: The use of advanced materials, such as high-strength alloys and composites, has enhanced the durability and load-carrying capacity of helical gears. These materials also contribute to reduced weight and improved efficiency.

- Precision Manufacturing: Modern manufacturing techniques, including CNC machining and gear grinding, have enabled the production of helical gears with higher accuracy and tighter tolerances. This results in smoother operation and reduced noise levels.

- Gear Tooth Profile Optimization: Advanced computer simulations and modeling techniques allow for the optimization of gear tooth profiles. This results in better load distribution, reduced stress concentration, and improved overall gearbox efficiency.

- Lubrication and Cooling: Improved lubrication systems and cooling mechanisms help maintain optimal operating temperatures and extend the lifespan of helical gearboxes. This is particularly important for high-demand applications.

- Noise and Vibration Reduction: Innovative designs and precision manufacturing techniques have led to helical gears with reduced noise and vibration levels. This advancement is crucial for industries where noise reduction is a priority.

- Compact Design: Advancements in gear design and manufacturing have allowed for more compact and lightweight helical gearbox configurations, making them suitable for space-constrained environments.

- Integration with Electronics: Some modern helical gearboxes are designed for seamless integration with electronic control systems. This enables better monitoring, control, and optimization of gearbox performance.

- Customization: Advancements in manufacturing and design tools allow for greater customization of helical gearboxes to meet specific application requirements. This includes adapting gear ratios, sizes, and configurations.

In summary, advancements in helical gearbox technology have led to enhanced performance, durability, efficiency, and customization options. These innovations continue to make helical gearboxes a versatile and reliable choice for a wide range of industrial applications.

Handling Shock Loads and Sudden Changes in Torque in Helical Gearboxes

Helical gearboxes are designed to handle a range of operational conditions, including shock loads and sudden changes in torque. The helical design of the gears, which have slanted teeth that engage gradually, helps to distribute forces more evenly across the teeth compared to straight-cut gears. This design characteristic contributes to the gearbox’s ability to withstand sudden changes in torque and shock loads.

The gradual engagement of the helical teeth results in smoother and quieter operation, reducing the impact of abrupt torque changes. The slanted teeth also allow for more gradual transmission of force, which helps in dampening vibrations and minimizing stress concentrations that can occur in high-impact situations.

However, while helical gears are better suited for shock loads compared to straight-cut gears, it’s important to note that extreme shock loads or sudden torque changes can still impact the gearbox’s components over time. Manufacturers often take factors such as application requirements, load profiles, and anticipated shock loads into consideration when designing helical gearboxes to ensure reliable and durable performance.

Additionally, using appropriate lubrication and maintenance practices can further enhance the gearbox’s ability to handle shock loads and sudden torque changes. Regular inspection and timely maintenance help identify and address potential issues before they lead to component failure.

Limitations and Disadvantages of Helical Gear Systems

While helical gear systems offer numerous advantages, they also come with certain limitations and disadvantages:

- Axial Thrust: Helical gears generate axial thrust due to the helix angle of the teeth. This thrust can cause additional load on bearings and may require additional measures to counteract.

- Complex Manufacturing: The manufacturing process for helical gears is more complex than that of straight-toothed gears, which can lead to higher production costs.

- Axial Length: Helical gears require more axial space compared to spur gears with the same gear ratio. This can be a limitation in applications with space constraints.

- Sliding Contact: Helical gears have sliding contact between their teeth, which can result in higher friction and more heat generation compared to rolling contact gears.

- Efficiency: Although helical gears are generally efficient, their efficiency can be slightly lower than that of some other gear types, especially at high speeds.

- Complexity in Gearbox Design: The inclination of helical gear teeth introduces additional complexity in gearbox design and alignment.

- Reverse Thrust: In some cases, reverse thrust can occur when helical gears are subjected to high axial loads, leading to undesirable effects.

It’s important to consider these limitations and disadvantages when selecting gear systems for specific applications. Despite these challenges, helical gears remain a popular choice in various industries due to their benefits and overall performance characteristics.

editor by CX 2023-10-11

China best Ab Series 60 90 115 142 180 Square Flange Gear Reducer Reduction Ratio 3~100 Helical Tooth Planetary Gearbox Made in China with Low Price wholesaler

Product Description

Planetary Gearbox AB Series Square Flange Helical Bevel Planetary Transmission Gearboxes Servo Motor

Product Overview:

Precision planetary gear reducer is another name for planetary gear reducer in the industry. Its main transmission structure is planetary gear, sun gear and inner gear ring.

Compared with other gear reducers, precision planetary gear reducers have the characteristics of high rigidity, high precision (single stage can achieve less than 1 point), high transmission efficiency (single stage can achieve 97% – 98%), high torque/volume ratio, lifelong maintenance-free, etc. Most of them are installed on stepper motor and servo motor to reduce speed, improve torque and match inertia.

AB series precision planetary gear box reducer AB60/90/115/142/180/220

features:

AB-series reducer features:

1. Helical gear design The reduction mechanism adopts the helical gear design, and its tooth shape meshing rate is more than twice that of the general spur gear, and has the characteristics of smooth operation, low noise, high output torque and low backlash

2. Collet type locking mechanism The connection between the input end and the motor adopts a collet-type locking mechanism and undergoes dynamic balance analysis to ensure the concentricity of the joint interface and zero-backlash power transmission at high input speeds

3. Modular design of motor connection board The unique modular design of the motor connecting plate and shaft is suitable for any brand and type of servo motor;

4. Efficient surface treatment technology The surface of the gearbox is treated with electroless nickel, and the connecting plate of the motor is treated with black anodic treatment to improve the environmental tolerance and corrosion resistance

5. One-piece gearbox body The gearbox and the inner ring gear adopt an integrated design, with compact structure, high precision and large output torque

6. Accurate concentricity of gear bar The sun gear made of the whole gear bar has strong rigidity and accurate concentricity

7. Solid, Single piece sun gear construction obtains precise concentricity with increased strength and rigidity. 8.Precision taper roller bearing support to increases radial and axial loading capacity.

Our Advantages

SERIES: AB/ ABR/ AD/ADS/ ADR/ AF/ AFR/ AFX/ AFXR/ AE/ AER/ AE/ AERS

PLF series, PLE series, ZPLF series, ZPLE series, AB series, ABR series and many other models are available.

Product Description

Planetary Gearbox AB Series Square Flange Helical Bevel Planetary Transmission Gearboxes Servo Motor

Advantages of the planetary gearbox:

Low backlash

High Efficiency

High Torque

High Input Speed

High Stability

High Reduction Ratio

Product Parameters

|

Name |

High Precision Planetary Gearbox |

|

Model |

AB042, AB060, AB060A, AB090A, AB115, AB142, AB180, AB220 |

|

Gearing Arrangement |

Planetary |

|

Effeiency withfull load |

≥97 |

|

Backlash |

≤5 |

|

Weight |

0.5~48kg |

|

Gear Type |

Helical Gear |

|

Gear stages |

1 stage, 2 stage |

|

Rated Torque |

14N.m-2000N.m |

|

Gear Ratio One-stage |

3, 4, 5, 6, 7, 8, 9, 10 |

|

Gear Ratio Two-stage |

15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100 |

|

Mounting Position |

Horizontal (foot mounted) or Vertical (flange mounted) |

|

Usage |

stepper motor, servo motor, AC motor, DC motor, etc |

Applications

Company Profile

Certifications

Packaging & Shipping

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary |

| Step: | Single-Step |

| Type: | Ab Series Gearbox, Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Helical Gearbox

Generally, a helical gearbox consists of two gears. The two gears have cut teeth and are inserted into one another. These two gears work together to transmit torque and speed. This type of gearbox is used in a wide variety of applications.

Working principle

Besides being cheaper to make, helical gears have several advantages over straight-cut spur gears. Firstly, they offer a smoother operation, less vibration, and lower noise levels. They also transmit larger loads than spur gears. These gears are used in a variety of industries, such as food processing, plastic industries, and oil industries.

Another important feature of helical gears is the smooth and gradual engagement of teeth. This helps them function more smoothly, especially when working under heavy loads. This process reduces shock and backlash, and also reduces wear.

In addition to this, the helix angle is a variable that can be adjusted to suit the application. The angle is usually either left or right, and can vary based on the view.

Helical gears are usually used in enclosed gear drives, such as conveyors, blowers, and elevators. They offer a smoother operation, which makes them ideal for applications that require quiet operation. However, helical gears are less efficient at transmitting power than spur gears.

The relative contact stress (RCS) calculated for a helical gear is similar to that of a spur gear. However, the volume Vi, which is a helix-dependent quantity, is different. This volume is defined as the total volume of the helical pocket, calculated by integrating along the face width. The volume of a generic pocket is larger than that of a helical pocket without a helix.

In addition, the contact ratio is reduced. This is due to the fact that two teeth are not parallel to each other. A thick oil film prevents the teeth from making contact. This film also cools the gear tooth surfaces.

The service factor is a number that takes into account the conditions under which a gear is used. It is usually a ratio between the maximum torque and the torque produced.

Efficiency

During a recent gearbox measurement campaign, 13 commercial gearboxes were extensively tested. Efficiency was measured at nominal torque and power. The resulting efficiency maps presented in this paper show that the efficiency of each gearbox is fairly similar.

The efficiency of a gearbox depends on the gears’ teeth and the ratio between them. The lower the ratio, the higher the efficiency.

Efficiency is also affected by the load torque. The higher the load torque, the lower the efficiency. This is especially true for gearboxes with high ratios.

The power loss is also affected by the contact and overlap ratios. For gearboxes with high ratios, the difference between the efficiency of the catalog and model-based efficiency is greater than for low-ratio gearboxes. Fortunately, improvements in lubrication are closing this gap.

The helical gearbox is the most effective gearbox in the industry. It transfers motion between parallel configurations and has less noise than spur gears. These gears engage gently and smoothly, so they are less prone to wear and tear. They also allow for greater power carrying capacity.

Although helical gears are effective, they are more expensive than traditional gears. However, the cost savings can be significant over time. It is important to consider the advantages of a helical gearbox before choosing a gearbox for your application.

When comparing the efficiency of a helical gearbox to that of a worm gearbox, the worm gearbox is more efficient. However, the difference in efficiency is not as great as many other gearboxes.

The efficiency of a helical gearbox is also affected by the speed of the gears. The gearbox must have adequate lubrication for bearings. It is also important to consider the space requirements in the drive line.

Applications

helical gearbox applications are widespread and they are used in many industries. Some of the applications include the printing industry, the rubber industry, the plastics industry, the cement industry, the earth-moving industry, and the chemical industry.

helical gearboxes are also used for conveyors and elevators. They are very durable and they can carry larger loads. They are also quieter than straight cuts. They are also used in many automotive transmissions.

helical gearboxes transmit power between two parallel shafts. They are a good substitute for spur gears. They are compact and they reduce vibration and noise. They are also very durable and they can work in non-parallel shafts.

The most common application is in the automotive industry. Helical gearboxes are also used in other industries. They are very useful in elevators, conveyors, and other heavy industrial settings. They also provide a high level of speed reduction and they are commonly used in automation control systems. They are also used in the mining industry and the cement industry.

helical gearboxes can be fabricated with various modifications. This is important because some industries may require different gearboxes.

Helical gears have a higher number of teeth. This leads to less wear and tear. They are also less noisy than spur gears. Their ability to generate a large thrust force is what makes them ideal for high-speed applications. They are also able to distribute load among several axes. They are also used in high shock and vibration applications.

helical gearboxes work at a higher efficiency than spur gears. However, the manufacturing costs for helical gears are greater than for spur gears.

helical gearboxes also have the advantage of transferring power between right-angle shafts. They can work in conjunction with crossed axis gears, which eliminate shock loading.

Variations

Several variations of helical gearbox are available in the market for different industries. They are widely used in automobile transmissions and other industries. They are quieter than spur gears. They are also durable and are highly efficient. However, they can cause higher friction and wear.

Helical gears are made of teeth that twist around a cylindrical gear body at an angle. The angle at which the gear teeth are cut is called the helix angle. The helix angle can be adjusted to fit the gear and its surroundings.

The helix angle also determines how much axial force the gear produces. A larger helix angle will generate more axial force. This increase in axial force must be absorbed by the bearings. The pressure angle also has a direct impact on the normal force and curvature radii of the tooth.

Helical gears can be mounted in parallel or crossed configuration. Helical gears connected in parallel require the same pitch and pressure angle to work correctly. Helical gears connected in crossed configuration can operate more quietly and smoothly than spur gears. However, they can also be used to transmit higher torques.

Helical gears are also available in single and double helical designs. Single helical gears are produced with the same tools and equipment as spur gears. Unlike spur gears, single helical gears have more surface contact. They are also better for precision drives.

Double helical gears are also called herringbone gears. They are produced by cutting a groove between two teeth. They can eliminate axial forces and are also used to provide high load carrying capacity.

Helical gears are commonly used for low power transmission applications. They also provide an alternative for connecting parallel and non-parallel shafts. They are also used in high speed applications.

Tool tip radius

Among the many parameters that are used in a helical gearbox design, the tooth tip radius is probably the most important, albeit only because it is one of the least intuitive. The best way to estimate the diameter of a helical gear tooth is to use a tooth reference profile as the basis for the calculation. A similar procedure is used to calculate the helix angle. A tool tip that is too small will result in a tooth that undercuts, which is a problem if you have a gear that has a high number of teeth and you want to reduce the chance of tooth failure.

For the gear buffs, there are many helical gearbox tools and processes, the tip diameter being but one of them. Luckily for gear design geeks, there is a lot more to the helical gearbox than meets the eye. For example, a helical gear tooth is a three-dimensional surface, so its shape and function can be computed mathematically or numerically.

In addition to a tooth tip that flies by the seat of your pants, the helical gearbox is also the product of a manufacturing process. The main culprit is the profile shift, which is the distance between the gear pitch diameter and the datum line of the cutting tool. While a gear designer could choose to ignore this issue, it is often a design consideration for the benefit of maximizing contact ratios. This means that the gear teeth must be able to withstand the torque of their respective gear trains.

A helical gear is a geometric package, and the best way to package the gears is to minimize tooth bending strength while maximizing tooth bending stiffness. To do this, you must limit the thickness of your tooth tip. This is usually accomplished with a tooth profile that is shaped to match the tooth contour of the gear it is intended to replace.

editor by CX 2023-05-09

China WEWF 60MM 80MM 120MM 160MM Round Flange Right Angle Planetary Gearbox Reducer Helical Precision Planetary Gear Motor wholesaler

Guarantee: 1 yr right after vessel date

Applicable Industries: Producing Plant, Equipment Restore Shops, Foodstuff & Beverage Manufacturing facility, Farms, Residence Use, Foods Shop, 60mm Gearbox 12V 24V 5nm High Torque 3000rpm 10w Brushed DC Steel Equipment Motor Printing Stores, Design works , Vitality & Mining, Other, Packing machine,automation equipment, Custom-made Aluminum Stainless Steel Rigid Flange Shaft Coupling for 6mm Shaft Pair with M3 Thread health-related, health care tools, laser cutting device,cnc machine

Bodyweight (KG): 3 KG

Custom-made assist: OEM, ODM

Gearing Arrangement: Planetary, Planetary

Output Torque: 4.5-1800 N.M

Input Speed: 2000-5000 rpm

Output Velocity: 5-a thousand rpm

Merchandise Identify: Planetary Gearbox

Enter Sort: Servo motors

Mounting Variety: Sq. or Round Flange or Right Angle Gearbox

Backlash Selection: 1arc-min to 20arc-min

Efficiency: 94%~ninety eight%

Equipment Ratio: 1:3~1:100

Gears Design: Helica Equipment

Customization: Welcome to make contact with us

Packaging Particulars: Carton, Customized Spider Claw Coupling Manufactured in China Wood Situation,Wood pallet

Port: HangZhou Port or ZheJiang Port

Planetary gearbox is a kind of reducer with extensive versatility. The inner gear adopts lower carbon alloy steel carburizing quenching and grinding or nitriding procedure. Planetary gearbox has the attributes of little framework size, big output torque, high speed ratio, higher performance, secure and trustworthy overall performance, New Arrival Manufacturing facility Price 2l 3l 5l 1rz 2rz 3rz 1hz 2tr Transmission Gearbox Assy Assembly For CZPT Hiace Hilux and so forth. The inner gear of the planetary gearbox can be divided into spur gear and helical equipment. Buyers can choose the proper precision reducer according to the requirements of the application. Product Classification About us Programs Certifications Exhibition Packing & Supply FAQ

What Is a Gearbox?

There are several factors to consider when choosing a gearbox. Backlash, for example, is a consideration, as it is the angle at which the output shaft can rotate without the input shaft moving. While this isn’t necessary in applications without load reversals, it is important for precision applications involving load reversals. Examples of these applications include automation and robotics. If backlash is a concern, you may want to look at other factors, such as the number of teeth in each gear.

Function of a gearbox

A gearbox is a mechanical unit that consists of a chain or set of gears. The gears are mounted on a shaft and are supported by rolling element bearings. These devices alter the speed or torque of the machine they are used in. Gearboxes can be used for a wide variety of applications. Here are some examples of how gearboxes function. Read on to discover more about the gears that make up a gearbox.

Regardless of the type of transmission, most gearboxes are equipped with a secondary gear and a primary one. While the gear ratios are the same for both the primary and secondary transmission, the gearboxes may differ in size and efficiency. High-performance racing cars typically employ a gearbox with two green and one blue gear. Gearboxes are often mounted in the front or rear of the engine.

The primary function of a gearbox is to transfer torque from one shaft to another. The ratio of the driving gear’s teeth to the receiving member determines how much torque is transmitted. A large gear ratio will cause the main shaft to revolve at a slower speed and have a high torque compared to its counter shaft. Conversely, a low gear ratio will allow the vehicle to turn at a lower speed and produce a lower torque.

A conventional gearbox has input and output gears. The countershaft is connected to a universal shaft. The input and output gears are arranged to match the speed and torque of each other. The gear ratio determines how fast a car can go and how much torque it can generate. Most conventional transmissions use four gear ratios, with one reverse gear. Some have two shafts and three inputs. However, if the gear ratios are high, the engine will experience a loss of torque.

In the study of gearbox performance, a large amount of data has been collected. A highly ambitious segmentation process has yielded nearly 20,000 feature vectors. These results are the most detailed and comprehensive of all the available data. This research has a dual curse – the first is the large volume of data collected for the purpose of characterization, while the second is the high dimensionality. The latter is a complication that arises when the experimental gearbox is not designed to perform well.

Bzvacklash

The main function of a gearhead is to multiply a moment of force and create a mechanical advantage. However, backlash can cause a variety of issues for the system, including impaired positioning accuracy and lowered overall performance. A zero backlash gearbox can eliminate motion losses caused by backlash and improve overall system performance. Here are some common problems associated with backlash in gearheads and how to fix them. After you understand how to fix gearbox backlash, you’ll be able to design a machine that meets your requirements.

To reduce gearbox backlash, many designers try to decrease the center distance of the gears. This eliminates space for lubrication and promotes excessive tooth mesh, which leads to premature mesh failure. To minimize gearbox backlash, a gear manufacturer may separate the two parts of the gear and adjust the mesh center distance between them. To do this, rotate one gear with respect to the fixed gear, while adjusting the other gear’s effective tooth thickness.

Several manufacturing processes may introduce errors, and reducing tooth thickness will minimize this error. Gears with bevel teeth are a prime example of this. This type of gear features a small number of teeth in comparison to its mating gear. In addition to reducing tooth thickness, bevel gears also reduce backlash. While bevel gears have fewer teeth than their mating gear, all of their backlash allowance is applied to the larger gear.

A gear’s backlash can affect the efficiency of a gearbox. In an ideal gear, the backlash is zero. But if there is too much, backlash can cause damage to the gears and cause it to malfunction. Therefore, the goal of gearbox backlash is to minimize this problem. However, this may require the use of a micrometer. To determine how much gearbox backlash you need, you can use a dial gauge or feeler gauge.

If you’ve been looking for a way to reduce backlash, a gearbox’s backlash may be the answer. However, backlash is not a revolt against the manufacturer. It is an error in motion that occurs naturally in gear systems that change direction. If it is left unaccounted for, it can lead to major gear degradation and even compromise the entire system. In this article, we’ll explain how backlash affects gears and how it affects the performance of a gearbox.

Design

The design of gearboxes consists of a variety of factors, including the type of material used, power requirements, speed and reduction ratio, and the application for which the unit is intended. The process of designing a gearbox usually begins with a description of the machine or gearbox and its intended use. Other key parameters to consider during gearbox design include the size and weight of the gear, its overall gear ratio and number of reductions, as well as the lubrication methods used.

During the design process, the customer and supplier will participate in various design reviews. These include concept or initial design review, manufacturing design validation, critical design review, and final design review. The customer may also initiate the process by initiating a DFMEA. After receiving the initial design approval, the design will go through several iterations before the finalized design is frozen. In some cases, the customer will require a DFMEA of the gearbox.

The speed increaser gearboxes also require special design considerations. These gearboxes typically operate at high speeds, causing problems with gear dynamics. Furthermore, the high speeds of the unit increase frictional and drag forces. A proper design of this component should minimize the effect of these forces. To solve these problems, a gearbox should incorporate a brake system. In some cases, an external force may also increase frictional forces.

Various types of gear arrangements are used in gearboxes. The design of the teeth of the gears plays a significant role in defining the type of gear arrangement in the gearbox. Spur gear is an example of a gear arrangement, which has teeth that run parallel to the axis of rotation. These gears offer high gear ratios and are often used in multiple stages. So, it is possible to create a gearbox that meets the needs of your application.

The design of gearboxes is the most complex process in the engineering process. These complex devices are made of multiple types of gears and are mounted on shafts. They are supported by rolling element bearings and are used for a variety of applications. In general, a gearbox is used to reduce speed and torque and change direction. Gearboxes are commonly used in motor vehicles, but can also be found in pedal bicycles and fixed machines.

Manufacturers

There are several major segments in the gearbox market, including industrial, mining, and automotive. Gearbox manufacturers are required to understand the application and user industries to design a gearbox that meets their specific requirements. Basic knowledge of metallurgy is necessary. Multinational companies also provide gearbox solutions for the power generation industry, shipping industry, and automotive industries. To make their products more competitive, they need to focus on product innovation, geographical expansion, and customer retention.

The CZPT Group started as a small company in 1976. Since then, it has become a global reference in mechanical transmissions. Its production range includes gears, reduction gearboxes, and geared motors. The company was the first in Italy to achieve ISO certification, and it continues to grow into one of the world’s leading manufacturers of production gearboxes. As the industry evolves, CZPT focuses on research and development to create better products.

The agriculture industry uses gearboxes to implement a variety of processes. They are used in tractors, pumps, and agricultural machinery. The automotive industry uses gears in automobiles, but they are also found in mining and tea processing machinery. Industrial gearboxes also play an important role in feed and speed drives. The gearbox industry has a diverse portfolio of manufacturers and suppliers. Here are some examples of gearboxes:

Gearboxes are complex pieces of equipment. They must be used properly to optimize efficiency and extend their lifespan. Manufacturers employ advanced technology and strict quality control processes to ensure their products meet the highest standards. In addition to manufacturing precision and reliability, gearbox manufacturers ensure that their products are safe for use in the production of industrial machinery. They are also used in office machines and medical equipment. However, the automotive gearbox market is becoming increasingly competitive.

editor by czh2023-03-17

China Cheap Price Flange Foot Mounted F Series Parallel Shaft Helical Bevel Gearbox planetary gearbox vs helical gearbox

Item Description

Solution Description

Item Parameters

Packaging & Shipping and delivery

Business Profile

|

US $100-200 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Helical Gear |

| Step: | 2 Stage, 3 Stage |

###

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

|

US $100-200 / Piece | |

1 Piece (Min. Order) |

###

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Helical Gear |

| Step: | 2 Stage, 3 Stage |

###

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

How to Choose a Helical Gearbox

Choosing the best helical gearbox is dependent on the type of application you want to use the gear for. You will need to consider the contact ratios and the total of profile shifts required.

Spur gears are more efficient than helical gears

Compared to helical gears, spur gears have straight teeth that are parallel to the axis of the gear. Because they are more efficient, spur gears are often used in low speed applications. However, helical gears are better for low-noise and high-speed applications. Despite their advantages, spur gears are also used in some devices.

Spur gears are not as resilient as other gears. They are less efficient at transmitting power over long distances, and they generate too much noise at high speeds. They also impose a radial load on bearings. They also produce significant vibration that can limit the maximum speed of operation.

Helical gears are better at transferring loads. They are used in a number of applications, including car transmissions, elevators, and conveyors. Helical gears also generate large amounts of thrust. They are also quieter than spur gears.

Unlike spur gears, helical gears use bearings to support their thrust load. They also have more teeth, so they can handle more load than spur gears. They can also be used in non-parallel shafts.

Helical gears are generally used in high-speed mechanical systems. They also have less wear on individual teeth and are quieter running than spur gears.

Helical gears are a refinement of spur gears. They are also used in the printing industry, elevators, and gearboxes for automobiles. They are often used in conjunction with a worm gear to distribute load. They have a higher speed capacity, but they are not as efficient as spur gears. They are used in some high-speed mechanical systems because they generate less noise and vibration.

Spur gears are commonly used in low-speed applications, like rack and pinion setups. Their design makes them more efficient at transmitting power, but they are less resilient than helical gears.

Design space is limited based on a required center distance, target gear ratio, and sum of profile shifts

Using statistically derived parameters, the authors performed a multi-objective optimization of the profile shift of two external cylindrical gears. The main objective of this study was to maximize efficiency and minimize the amount of power lost in the optimized space.

To do this, the authors used a multi-objective optimization algorithm that included all aspects of the optimal profile shift. The algorithm evaluates objective function over a series of generations to determine the best solution.

The multi-objective optimization algorithm was based on a verified optimization algorithm. This algorithm combines analytical pressure loads estimation with an effective method for calculating the deformations of the gear case. Using the aforementioned formulae, the authors were able to identify a feasible solution. The numerical calculations also showed that the corresponding specific sliding coefficients were perfectly balanced.

To identify the most efficient method for determining the profile shift, the authors selected the most efficient method based on the objectives of efficiency and mass. The efficiency objective was considered to be the largest given the small size of the resulting optimization space. This objective is useful in reducing wear failures.

The largest thermal treatment of a cylindrical gear is case hardening. The ISO/TR 4467:1982 standard provides a practical guide for gears. The largest radii of the pinion and wheel are rb1 and rb2. The ratio of tooth width to base circle diameter of the pinion is normally set to less than 1.

Sliding velocity increases as the distance from the pitch point increases in the line of action

Deflections of the involute profile of a helical gear occur due to the load on the teeth. However, the optimum pressure angle for the gear is not known.

The correct pressure angle for a helical gear cannot be calculated without a surface model. Assuming the pressure is uniform over the profile, a pressure angle of 20deg would be a good bet. However, this would require a mathematical model that can be derived from the Archard wear equation.

In general, the pressure angle will be influenced by the diameter, as well as the gear mesh geometry. It is important to know the actual angle of a helical gear since this will affect the curvature of the profile, the normal force, and the radial force.

The best way to measure the pressure angle is to consider the theoretical pitch diameter. If the pitch diameter is small, then the actual angle will be smaller. This will cause a gap between the flanks. However, it can also cause the gear to deform, leading to unexpected working behavior.

One interesting tangent is the pitch plane, an imaginary plane tangent to the pitch surfaces. The pitch plane is the plane perpendicular to the axial plane of the gear cross section. It is usually used as a reference point to calculate the transverse pressure angle.

The working pressure angle is the angle of the pressure line of the gear mesh. This angle is the same as the reference pressure angle, but the length of the contact line is reduced.

The best way to calculate the working pressure angle is to use the pressure line of the gear mesh. This will give a more accurate value. The actual angle of the pressure line is also related to the transmission ratio. This ratio is usually given as the nominal ratio of angular velocities. The actual velocities will fluctuate about this ratio.

Undercut of a helical gear tooth root

Having an undercut at the pinion root can affect the distribution of load along the line of contact of helical gears. This can result in higher than nominal loads on some teeth and amplitude modulated noise.

The tooth root is affected by a number of factors, including the shape of the tooth cutting tool. The cutting tool must be designed to avoid an undercut without reducing the number of teeth. This is achieved by a process called profile shifting.

Profile shift occurs when the cutting tool changes depth, thereby preventing an undercut. It is often used in the manufacturing process to achieve a greater overlap ratio. The higher the overlap ratio, the less variation there is between the contact lines. This reduces the dynamic tooth loads and reduces noise.

The profile shift is most often associated with the cutting tool tip. This is the point where the involute profile exits the gear, before the tip begins to taper. The involute profile can be defined for every transverse section of the gear face width. The boundary point is a point of tangency between the involute and root profiles.

The involute of a circle is a common way to define a gear-tooth profile. The involute is the path traced by the point on the line when rolling on a circle. It is a useful feature for cylindrical involute gears.

The helix angle is also important to the helical gear. It allows for greater contact capacity and increases the bending capacity of the gear. It must be included in specifications for helical teeth. The angle must be measurable and include the (+-) sign.

The bending strength of a tooth depends on the shape of the root. A large undercut reduces the strength of the tooth.

Contact ratios

Whether a helical gearbox is dynamic or steady-state, the contact ratio is a key factor. The total contact ratio defines the average number of teeth in contact in the plane of action. It is calculated by multiplying the transverse contact ratio with the overlap ratio. The overlap ratio is always non-zero.

The total contact ratio must be 1.0 or greater for a constant speed rotation on the driven side. Gears with a low total contact ratio are known to slow down rotation of the driven gear. The total contact ratio is influenced by the length of the contact line. A high contact ratio is a good choice for dynamic loading.

A low contact ratio results in a greater amount of profile shift and a larger amount of noise. If the contact ratio is too high, it may cause excessive EAP sliding velocity and cause scuffing. In addition, an uneven load share results in amplitude modulated vibrations.

A helical gear is a pair of slim spur gears. The gears are layered in a plane that runs parallel to the face width of the gear teeth. Each gear tooth makes contact with the flank of the next gear tooth. The helical gear tooth flank is a 3-dimensional surface that is a tangent to the base circles of the gears.

The tooth shape of the helical gear tooth is also a key factor in the contact ratio. The tooth form is designed to be in relation to the work piece, tooling, dedendum coefficients, tooth forces, and tooth bending stiffness. A gear tooth form must also relate to tooth surface kinematics and microgeometry modifications.

The active profile is a region of the involute profile between the start and end points. A tooth profile that satisfies the basic law of gear-tooth action is often called a conjugate profile.

editor by czh 2023-01-31

China High Precision Servo Reducer, High Precision Servo Gearbox, High Precisions Helical Planetary Gear Box, High Precision Flange Output Planetary Gearbox with Hot selling

Item Description

Item Functions

* Compact structure, integration of alloy aluminum body to guarantee the optimum rigidity and corrosion resistance, and effortless to assemble with multiple precision machined surface.

* The use of best-level spiral bevel gear, with optimization design and style, the contact tooth floor of uniform load, allowable hith torque output.

* Gear is manufactured of high strength alloy metal carburizing, grinding precision.

* The layout of several alloy steel output and enter shaft applies to various industrial specifications.

* The simplified structure design with high torque and minimal backlash applies to apps of precision servo.

* Effortless mount, with maintenance-free of charge, no require to replace the grease and lengthy service daily life.

* Software in Precision Rotary Axis Drives, Travel Gantry and Columns, Materials Dealing with Axis Drives, Industrial Areas in Automation, Aerospace, and Device Device and Robotics.

Merchandise Description

Shaft Input Configuration – Higher Precision Spiral Bevel Gearboxes

* JAC-C Series: Shaft Input Configuration, and Hollow Output Shaft with Two Shrinks Discs.

* Designs: JAC065C, JAC075C, JAC090C, JAC0110C, JAC0140C, JAC0170C, JAC210C.

* JAC-H Series: Shaft Input Configuration, and Hollow Output Shaft with Essential Way.

* Models: JAC065H, JAC075H, JAC090H, JAC0110H, JAC0140H, JAC0170H, JAC210H.

* JAC-L Collection: Shaft Input Configuration, and Solid Output Shaft.

* Models: JAC065L, JAC075L, JAC090L, JAC0110L, JAC0140L, JAC0170L, JAC210L.

* Gear Ratios: Spiral bevel equipment set of large precision grinding can accomplish from 1:1 to 6:1 as regular.

* Phase: 1 stage (1:1 to 6:1).

* Rated Output Torque (N.m): From 12N.m to 1300N.m.

* Fault Stop Torque = 2 Times of Rated Output Torque.

* Max. Enter Velocity (rpm): From 2500RPM to 3500RPM.

* Rated Input Speed (rpm): From 1500RPM to 2500RPM.

* Low Backlash (arcmin): From 6 arcmin to 8 arcmin.

* Max. Radial Pressure (N) Of Output Shaft: From 900N to 11500N.

* Max. Axial Power (N) Of Output Shaft: From 450N to 5750N.

* Max. Radial Drive (N) Of Input Shaft: From 700N to 7800N.

* Max. Axial Pressure (N) Of Input Shaft: From 350N to 3900N.

* Low Sounds Amount (dB): From 71dB to 82dB.

* Higher Effectiveness (%): ninety eight%.

* Average Daily life Span (hr): 20000 hours.

* Lubrication: Synthetic lubrication grease

* Mass Times of Inertia (kg/cm2): From .43 kg/cm2 to 195.4 kg/cm2.

Motor Flange Enter Configuration – Higher Precision Spiral Bevel Gearboxes

* JAC-FC Sequence: Motor Flange Enter Configuration, and Hollow Output Shaft with Two Shrinks Discs.

* Types: JAC065FC, JAC075FC, JAC090FC, JAC0110FC, JAC0140FC, JAC0170FC, JAC210FC.

* JAC-FH Series: Motor Flange Enter Configuration, and Hollow Output Shaft with Key Way.

* Designs: JAC065FH, JAC075FH, JAC090FH, JAC0110FH, JAC0140FH, JAC0170FH, JAC210FH.

* JAC-FL Sequence: Motor Flange Enter Configuration, and Sound Output Shaft.

* Versions: JAC065FL, JAC075FL, JAC090FL, JAC0110FL, JAC0140FL, JAC0170FL, JAC210FL.

* Gear Ratios: Spiral bevel gear established of large precision grinding can obtain from 1:1 to 100:1 as normal, personalized-manufactured max. 400:1 ratio.

* Phase: 1 stage (1:1 to 6:1), 2 stage (8:1 to thirty:1), 3 stage (32:1 to 100:1).

* Rated Output Torque (N.m): From 12N.m to 1300N.m.

* Fault End Torque = 2 Instances of Rated Output Torque.

* Max. Input Speed (rpm): From 2000RPM to 5000RPM.