Product Description

Model Selection

ZD Leader has a wide range of micro motor production lines in the industry, including DC Motor, AC Motor, Brushless Motor, Planetary Gear Motor, Drum Motor, Planetary Gearbox, RV Reducer and Harmonic Gearbox etc. Through technical innovation and customization, we help you create outstanding application systems and provide flexible solutions for various industrial automation situations.

• Model Selection

Our professional sales representive and technical team will choose the right model and transmission solutions for your usage depend on your specific parameters.

• Drawing Request

If you need more product parameters, catalogues, CAD or 3D drawings, please contact us.

• On Your Need

We can modify standard products or customize them to meet your specific needs.

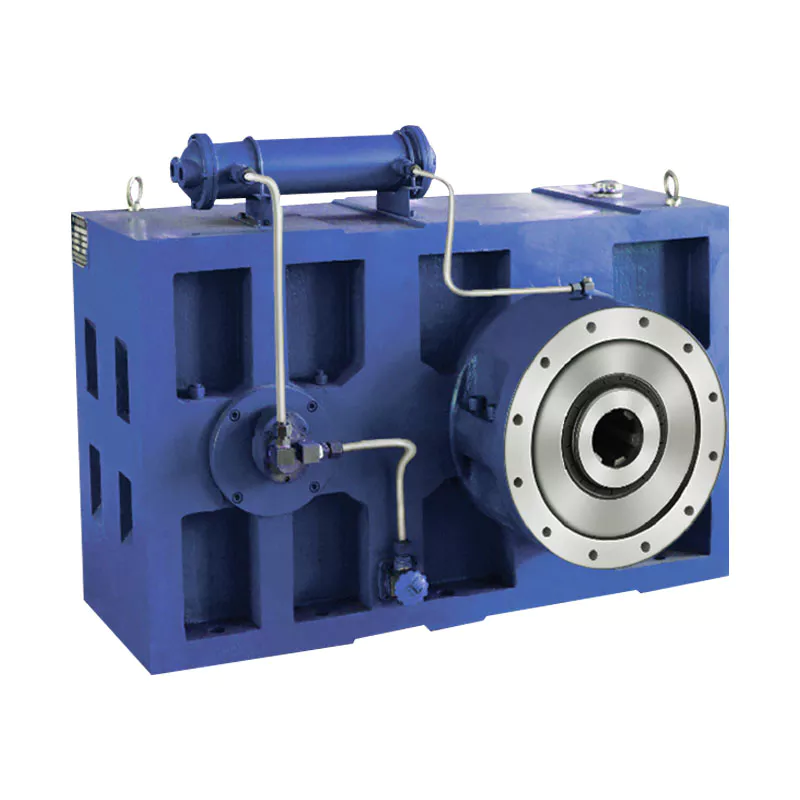

Product Parameters

Type Of RV Reducer

Application Of RV Reeducer

Precision Cycloidal Gearbox is widely used in industrial machinery fields such as machine tool, robot arm, industrial robot, die-casting feeding machine, manipulator for punching machine, AGV driver, bottle-making machine, UV Printer and etc.

Other Products

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Conical – Cylindrical Gear |

| Step: | Three-Step |

| Customization: |

Available

| Customized Request |

|---|

Installation and Alignment of Helical Gearboxes

Proper installation and alignment of a helical gearbox are essential to ensure its optimal performance and longevity. Here are the steps involved:

- Preparation: Gather all necessary tools, equipment, and safety gear. Ensure the work area is clean and well-lit.

- Mounting: Position the gearbox on the designated mounting surface and secure it using appropriate bolts. Follow the manufacturer’s guidelines for mounting torque and procedures.

- Shaft Alignment: Use precision tools such as dial indicators to align the input and output shafts. Achieving accurate shaft alignment minimizes stress on the gears and bearings.

- Bolt Tightening: Gradually and evenly tighten the mounting bolts, ensuring the gearbox remains properly aligned. Refer to torque specifications provided by the manufacturer.

- Lubrication: Fill the gearbox with the recommended lubricant according to the manufacturer’s specifications. Proper lubrication is crucial for reducing friction and wear.

- Alignment Check: After tightening the bolts, recheck the shaft alignment to ensure it hasn’t shifted during the tightening process.

- Run-In Period: Gradually introduce load to the gearbox to allow the gears to seat properly. Monitor the gearbox for any unusual noises, vibrations, or temperature changes during this period.

- Final Checks: Verify that the gearbox operates smoothly, without excessive noise or vibrations. Monitor the gearbox’s temperature during operation to ensure it remains within recommended limits.

- Regular Inspection: Schedule periodic inspections to check for any signs of wear, misalignment, or leakage. Address any issues promptly to prevent further damage.

It’s important to follow the manufacturer’s installation and alignment guidelines specific to the helical gearbox model you’re working with. Improper installation and alignment can lead to premature wear, reduced efficiency, and potential failure of the gearbox.

Considerations for Designing Helical Gearboxes for Heavy-Duty Applications

Designing helical gearboxes for heavy-duty applications requires careful consideration of various factors to ensure reliable and efficient operation under high loads and demanding conditions. Here are the key considerations:

- Load Capacity: Heavy-duty applications involve substantial loads. The gearbox must be designed to handle these loads while preventing premature wear and failure. Calculations of the load distribution, contact stresses, and material strength are crucial.

- Material Selection: High-strength and durable materials are essential for heavy-duty gearboxes. Alloy steels or special heat-treated materials are often chosen to provide the necessary strength and resistance to fatigue and wear.

- Gear Tooth Design: Optimal gear tooth profiles, such as optimized helix angles and tooth modifications, contribute to smoother engagement and reduced stress concentrations. This enhances the gearbox’s ability to handle heavy loads without excessive wear.

- Bearing Selection: Robust and high-capacity bearings are necessary to support the heavy loads and provide reliable shaft support. The bearings must be able to withstand both radial and axial forces generated during operation.

- Lubrication: Adequate lubrication is critical for heavy-duty gearboxes. Lubricants with high load-carrying capacity and extreme pressure properties are chosen to ensure proper lubrication under heavy loads and to reduce friction and wear.

- Heat Dissipation: Heavy-duty applications can generate significant heat due to friction and load. Efficient heat dissipation mechanisms, such as cooling fins or oil cooling, should be incorporated into the gearbox design to prevent overheating and thermal damage.

- Sealing: Effective sealing is necessary to prevent contaminants from entering the gearbox and to retain lubricants. Seals must be capable of withstanding the conditions of the application, including high loads, vibrations, and potential exposure to harsh environments.

- Efficiency: Although heavy-duty applications prioritize load capacity, achieving acceptable levels of efficiency is still important to minimize energy losses and heat generation. Proper gear tooth design and high-quality manufacturing contribute to better efficiency.

- Structural Integrity: The gearbox housing and components must be designed with structural integrity in mind. Rigidity and robustness are required to prevent distortion or failure of components under heavy loads.

- Reliability and Serviceability: Heavy-duty gearboxes should be designed with reliability and ease of maintenance in mind. Access to critical components, such as gears and bearings, for inspection and replacement is important to minimize downtime.

Conclusion: Designing helical gearboxes for heavy-duty applications involves a comprehensive approach that addresses load capacity, material selection, gear tooth design, lubrication, heat dissipation, sealing, efficiency, structural integrity, and serviceability. By carefully considering these factors, engineers can create gearboxes that deliver exceptional performance and longevity in demanding industrial settings.

Noise and Vibration Levels in Helical Gearboxes

Helical gearboxes are known for their relatively low noise and vibration levels compared to some other types of gears. However, there are still certain factors that can influence the noise and vibration levels in helical gear systems:

- Helix Angle: The helix angle of helical gears helps to distribute the load over multiple teeth, reducing impact forces and resulting in smoother meshing. This contributes to lower noise and vibration levels.

- Precision Manufacturing: High-precision manufacturing processes can ensure better gear tooth geometry and minimize irregularities that could lead to noise and vibration.

- Lubrication: Proper lubrication is crucial for reducing friction and damping vibrations between gear teeth. Insufficient or improper lubrication can lead to increased noise levels.

- Alignment: Proper alignment of gears is essential to minimize misalignment-induced noise and vibration. Misalignment can cause uneven tooth contact and lead to increased noise and vibration.

- Load Distribution: Helical gears distribute loads over multiple teeth, which helps in reducing localized stresses and vibrations that could cause noise.

- Material Quality: High-quality materials with good damping properties can help absorb vibrations and reduce noise transmission.

- Operating Conditions: Factors such as operating speed, load, temperature, and gear backlash can influence noise and vibration levels.

Overall, helical gearboxes are designed to provide smoother and quieter operation compared to other gear types. However, the noise and vibration levels can still vary based on design, manufacturing quality, and operational factors. Engineers can optimize gear design and operating conditions to achieve the desired noise and vibration characteristics for specific applications.

editor by CX 2024-04-03

in Pontianak Indonesia sales price shop near me near me shop factory supplier One Year Quality Assuarance RV Universal Mounting Worm Gearbox manufacturer best Cost Custom Cheap wholesaler

Our item assortment also handles locking assemblies (clamping factors/locking unit), taper bushes, QD bushes, bolt-on hubs, torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, common joint, rod finishes and yokes. We can provide a full-assortment of energy transmission goods like chains, sprockets and plate wheels, pulleys, gearboxes, motors, couplings, gears and racks. Complete use has been made of all types of sophisticated strategies and engineering to achieve excelsior manufacturing. Item INTRODUCTION:

Primary Features:

one) Produced of large top quality EPTT alloy, ligEPTT weigEPTT and non-rusting

two) Huge output torque and substantial radiating effectiveness three) Easy operating and low sound, can function EPTT time in dreadful issue

four) Great-looking visual appeal, resilient support lifestyle and little quantity

5) Ideal for omnibearing installation

Primary Resources:

1)housing: aluminium alloy ADC12(dimension 571-090) die solid iron EPTT200(dimensions one hundred ten-a hundred and fifty)

2)Worm:20Cr, ZI Involute profile carbonize ampquencher heat remedy make EPTT area hardness up to fifty six-62 EPTC After precision grinding, carburization layer’s thickness among .3-.5mm.

3)Worm Wheel:wearable stannum alloy CuSn10-1

Product PARAMETERS:

| Measurement | Specification | EPTT ratio | |||||||||||||

| IEC | N | M | P | seven.5 | 10 | 15 | twenty | 25 | 30 | forty | fifty | 60 | 80 | 100 | |

| D | |||||||||||||||

| 25 | 56B14 | 50 | sixty five | 80 | 9 | nine | 9 | 9 | nine | 9 | nine | nine | nine | ||

| 30 | 63B5 | 95 | one hundred fifteen | 140 | eleven | eleven | eleven | 11 | 11 | 11 | 11 | 11 | |||

| 63B14 | 60 | seventy five | 90 | ||||||||||||

| 56B5 | 80 | 100 | 120 | 9 | nine | nine | 9 | 9 | 9 | nine | nine | nine | nine | ||

| 56B14 | fifty | 65 | eighty | 9 | nine | nine | nine | nine | 9 | nine | 9 | 9 | nine | ||

| 40 | 71B5 | a hundred and ten | a hundred thirty | 160 | 14 | 14 | fourteen | fourteen | fourteen | 14 | 14 | 14 | |||

| 71B14 | 70 | 85 | 105 | ||||||||||||

| 63B5 | 95 | one hundred fifteen | a hundred and forty | eleven | 11 | 11 | eleven | eleven | eleven | eleven | 11 | 11 | 11 | eleven | |

| 63B14 | sixty | 75 | ninety | ||||||||||||

| 56B5 | eighty | 100 | 120 | 9 | 9 | 9 | nine | ||||||||

| fifty | 80B5 | 130 | a hundred sixty five | 200 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | – | – | – | – |

| 80B14 | 80 | 100 | 120 | ||||||||||||

| 71B5 | 110 | 130 | a hundred and sixty | 14 | fourteen | 14 | fourteen | 14 | fourteen | fourteen | 14 | fourteen | 14 | – | |

| 71B14 | 70 | eighty five | one zero five | ||||||||||||

| 63B5 | ninety five | one hundred fifteen | a hundred and forty | – | – | – | – | – | – | – | 11 | 11 | eleven | eleven | |

| sixty three | 90B5 | one hundred thirty | 165 | two hundred | 24 | 24 | 24 | 24 | 24 | 24 | 24 | – | – | – | – |

| 90B14 | ninety five | 115 | a hundred and forty | ||||||||||||

| 80B5 | a hundred thirty | one hundred sixty five | 200 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | – | |

| 80B14 | 80 | one hundred | a hundred and twenty | ||||||||||||

| 71B5 | one hundred ten | 130 | a hundred and sixty | – | – | – | – | – | – | fourteen | 14 | fourteen | 14 | fourteen | |

| 71B14 | 70 | 85 | a hundred and five | ||||||||||||

| seventy five | 100/112B5 | one hundred eighty | 215 | 250 | 28 | 28 | 28 | – | – | – | – | – | – | – | – |

| a hundred/112B14 | one hundred ten | a hundred thirty | one hundred sixty | ||||||||||||

| 90B5 | 130 | one hundred sixty five | 200 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | – | ||||

| 90B14 | 95 | 115 | 140 | ||||||||||||

| 80B5 | a hundred thirty | a hundred sixty five | 200 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | ||||

| 80B14 | 80 | a hundred | 120 | ||||||||||||

| 71B5 | 110 | 130 | one hundred sixty | 14 | fourteen | fourteen | fourteen | ||||||||

| 90 | one hundred/112B5 | one hundred eighty | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | – | – | – | – | – |

| one hundred/112B14 | 110 | one hundred thirty | 160 | ||||||||||||

| 90B5 | a hundred thirty | one hundred sixty five | 200 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | – | ||

| 90B14 | ninety five | 115 | a hundred and forty | ||||||||||||

| 80B5 | a hundred thirty | 165 | two hundred | 19 | 19 | 19 | 19 | 19 | |||||||

| 80B14 | 80 | 100 | 120 | ||||||||||||

| a hundred and ten | 132B5 | 230 | 265 | three hundred | 38 | 38 | 38 | 38 | – | – | – | ||||

| 100/112B5 | 180 | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | |||

| 100/112B14 | a hundred and ten | 130 | one hundred sixty | ||||||||||||

| 90B5 | a hundred thirty | a hundred sixty five | two hundred | 24 | 24 | 24 | 24 | 24 | 24 | 24 | |||||

| 80B5 | a hundred thirty | 165 | two hundred | 19 | 19 | ||||||||||

| a hundred thirty | 132B5 | 230 | 265 | three hundred | 38 | 38 | 38 | 38 | 38 | 38 | 38 | – | – | – | |

| one hundred/112B5 | a hundred and eighty | 215 | 250 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | |||||

| one hundred/112B14 | one hundred ten | a hundred thirty | a hundred and sixty | ||||||||||||

| 90B5 | 130 | one hundred sixty five | two hundred | 24 | 24 | ||||||||||

| one hundred fifty | 160B5 | 250 | three hundred | 350 | forty two | forty two | 42 | forty two | forty two | – | – | – | – | – | – |

| 132B5 | 230 | 265 | three hundred | 38 | 38 | 38 | 38 | 38 | 38 | ||||||

| a hundred/112B5 | one hundred eighty | 215 | 250 | 28 | 28 | 28 | 28 | ||||||||

Product Define Dimensions:

Organization Brief INTRODUCTION:

We are a professional EPTT maker situated in EPTTizhou, EPTT province.

Our foremost items is complete assortment of RV571-one hundred fifty worm EPTTs , also provided hypoid helical EPTT, Laptop units, UDL Variators and AC EPTTs.

EPTT are broadly employed for programs this sort of as: foodstuffs, EPTT, EPTT, chemical substances, pharmacy, plastics, paper-generating, building EPTTry, metallurgic EPTT, environmental security engineering, and all varieties of automatic traces, and assembly lines.

With rapidly shipping and delivery, superior soon after-sales services, EPTT creating faXiHu (West Lake) Dis.Hu (West Lake) Dis.ty, our items market properly each at home and abroad. We have exported our EPTTs to SouthEPTT Asia, EPTTern Europe and the Center EPTT and so on.Our goal is to deveXiHu (West Lake) Dis.Hu (West Lake) Dis. and innovate on the basis of higher high quality, and EPTT a great status for EPTTs.

WORKSHOP:

EXHIBITIONS:

FAQ:

one.Q:Can you make as for every customer drawing?

A: Yes, we supply EPT service for customers accordingly. We can use customer’s nameplate for EPTTes.

two.Q:What is your phrases of payment ?

A: 30% deposit prior to generation,harmony T/T before supply.

three.Q:Are you a investing business or manufacturer?

A:We are a manufacurer with EPTT products and seasoned staff.

4.Q:What is your generation potential?

A:8000-9000 PCS/Month

4.Q:What is your MOQ?

A: one pcs

5.Q:Free of charge sample is accessible or not?

A:Yes, we can source free sample if consumer concur to spend for the courier EPTT

six.Q:Do you have any certificate?

A:Indeed, we have CE certification and SGS certificate report.

Contact data:

Ms Lingel Pan

For any questions just really feel totally free ton make contact with me. Numerous many thanks for your type interest to our firm!