Product Description

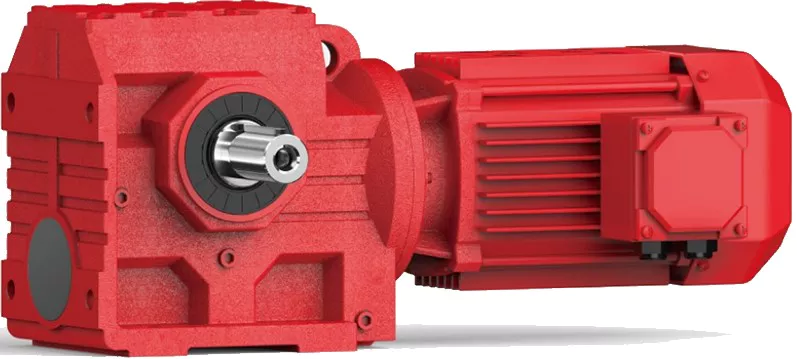

R47 Right Angle Helical Gear Reductor Belt Conveyor Drives Speed Reducer helical Gearbox for Textile Industry

Detailed Photos

Product Parameters

Products Description

R Series Helical Speed Reducers

R series helical gear reducer has high technological content; it adopts hardened gear surface design, which is reliable and durable and has high overload capacity.

It has the following characteristics

1,R series helical gear reducer is manufactured in accordance with international technical requirements, meeting the technical

requirements of most countries in the world.

2,The design of R series helical gear reducer plays a space-saving, high overload capacity.

3, R series helical gear reducer has low energy consumption, superior performance and high efficiency of more than 95%;

4,R series helical gear reducer has low vibration, low noise, and high energy saving;

5,R series helical gear reducer is made of high quality forged steel material, steel cast iron case, and the surface of gear is heat-treated by high frequency; reliable and durableTranslated with DeepL

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Horizontal Type |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | |

|---|

Performance of Helical Gearboxes in Applications Requiring Frequent Starts and Stops

Helical gearboxes are well-suited for applications that involve frequent starts and stops due to their design characteristics. Here’s how they fare in such scenarios:

- Smooth Engagement: Helical gears offer gradual and smooth engagement, which reduces shock loads during starts and stops. This feature helps minimize wear and stress on gear teeth and other components.

- Noise and Vibration Reduction: The helical tooth arrangement results in less noise and vibration compared to other gear types. This is especially beneficial in applications where noise reduction is a priority.

- Efficient Power Transmission: Helical gears efficiently transmit power even during frequent starts and stops. The gradual contact between gear teeth and the larger tooth engagement area contribute to efficient power transfer.

- Less Backlash: Helical gearboxes typically have lower backlash compared to other gear types. This means there’s less play between gear teeth, resulting in more accurate and consistent motion control.

- Heat Dissipation: The helical tooth design distributes loads and heat more evenly, which can help dissipate heat generated during frequent starts and stops.

- Longevity: The reduced wear and improved load distribution contribute to the longevity of helical gearboxes, making them suitable for applications requiring frequent cyclic motion.

In summary, helical gearboxes perform well in applications involving frequent starts and stops. Their smooth engagement, reduced noise and vibration, efficient power transmission, and durability make them a reliable choice for industries that demand precise and controlled motion despite frequent changes in speed and direction.

Troubleshooting Common Issues in Helical Gear Systems

Troubleshooting helical gear systems involves identifying and addressing common issues that can affect their performance. Here’s a step-by-step process:

- Visual Inspection: Begin by visually inspecting the gearbox for any signs of wear, damage, or misalignment. Look for worn or chipped gear teeth, oil leakage, and unusual noise.

- Noise Analysis: If noise is present, analyze its type and frequency. Whining or grinding noises could indicate misalignment or damaged gears, while clicking or knocking sounds might point to loose components.

- Lubrication Check: Ensure that the gearbox is properly lubricated with the recommended type and quantity of lubricant. Insufficient lubrication can lead to increased friction and wear.

- Alignment Check: Check the alignment of the gears and shafts. Misalignment can result in uneven wear, noise, and reduced efficiency. Realign components if necessary.

- Gear Inspection: Inspect gear teeth for signs of pitting, scoring, or wear. Replace any damaged gears to prevent further issues.

- Bearing Examination: Check the condition of bearings that support shafts and gears. Worn or damaged bearings can lead to increased vibration and noise.

- Tightening and Fastening: Ensure that all bolts, fasteners, and connections are properly tightened. Loose components can cause vibrations and noise.

- Load Analysis: Evaluate the load conditions and operating parameters of the gearbox. Ensure that the gearbox is not subjected to loads beyond its design capacity.

- Temperature Monitoring: Monitor the operating temperature of the gearbox. Excessive heat can indicate problems such as inadequate lubrication or overloading.

- Consulting Experts: If issues persist or if you’re unsure about the diagnosis and solution, consult gearbox experts or manufacturers for guidance.

By following this troubleshooting process, you can identify and resolve common issues in helical gear systems, ensuring optimal performance and longevity.

Limitations and Disadvantages of Helical Gear Systems

While helical gear systems offer numerous advantages, they also come with certain limitations and disadvantages:

- Axial Thrust: Helical gears generate axial thrust due to the helix angle of the teeth. This thrust can cause additional load on bearings and may require additional measures to counteract.

- Complex Manufacturing: The manufacturing process for helical gears is more complex than that of straight-toothed gears, which can lead to higher production costs.

- Axial Length: Helical gears require more axial space compared to spur gears with the same gear ratio. This can be a limitation in applications with space constraints.

- Sliding Contact: Helical gears have sliding contact between their teeth, which can result in higher friction and more heat generation compared to rolling contact gears.

- Efficiency: Although helical gears are generally efficient, their efficiency can be slightly lower than that of some other gear types, especially at high speeds.

- Complexity in Gearbox Design: The inclination of helical gear teeth introduces additional complexity in gearbox design and alignment.

- Reverse Thrust: In some cases, reverse thrust can occur when helical gears are subjected to high axial loads, leading to undesirable effects.

It’s important to consider these limitations and disadvantages when selecting gear systems for specific applications. Despite these challenges, helical gears remain a popular choice in various industries due to their benefits and overall performance characteristics.

editor by CX 2024-03-29

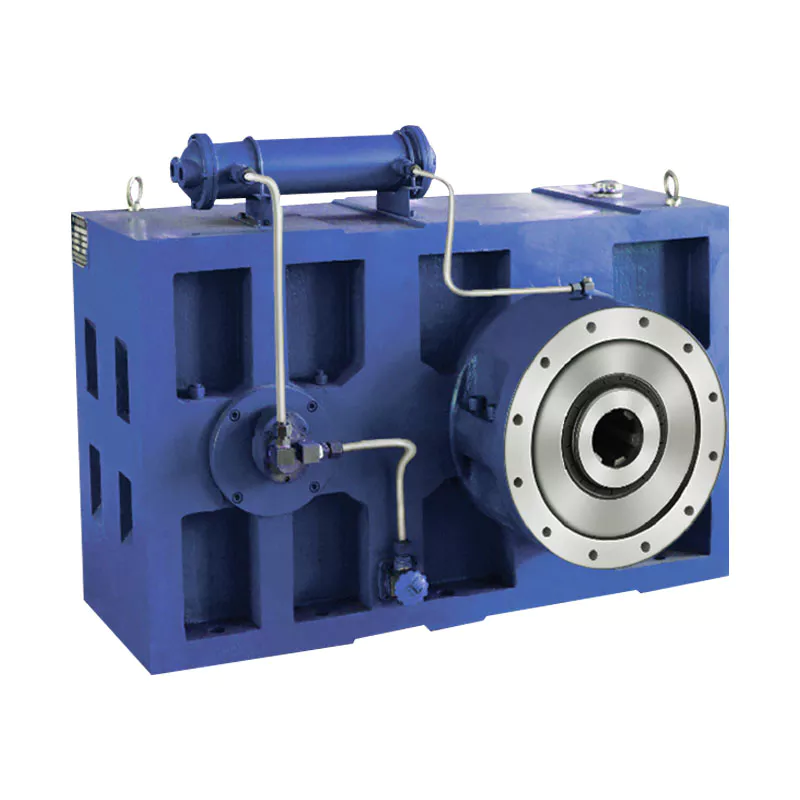

China factory Two Stage Helical Gearbox Motor Parallel Shaft Bevel Reducer Speed Spiral 90 Degree Right Angle Straight Supplier Competitive Price Stainless Steel Gearbox car gearbox

Product Description

Two Stage Helical Gearbox Motor Parallel Shaft Bevel Reducer Speed Spiral 90 Degree Right Angle Straight Supplier Competitive Price Stainless Steel Gearbox

Application of Helical Gearbox

Helical gearboxes are used in a wide variety of applications, including:

- Automotive: Helical gearboxes are used in a variety of automotive applications, including transmissions, differentials, and steering systems. They help to transmit power smoothly and efficiently, which improves the overall performance of the vehicle.

- Machinery: Helical gearboxes are used in a variety of machinery applications, including conveyor belts, elevators, and cranes. They help to transmit power smoothly and efficiently, which improves the overall performance of the equipment.

- Aerospace: Helical gearboxes are used in a variety of aerospace applications, including aircraft engines, landing gear, and control surfaces. They help to transmit power smoothly and efficiently, which improves the overall performance of the aircraft.

- Construction: Helical gearboxes are used in a variety of construction applications, including excavators, bulldozers, and cranes. They help to transmit power smoothly and efficiently, which improves the overall performance of the equipment.

- Other: Helical gearboxes are also used in a variety of other applications, such as wind turbines, robotics, and medical devices. They help to transmit power smoothly and efficiently, which improves the overall performance of the system.

Helical gears are a type of gear that has teeth that are cut at an angle. This angle allows the teeth to engage each other gradually and smoothly, which reduces noise and vibration. Helical gears are often used in high-speed applications, such as in automotive differentials.

Helical gears are made of a variety of materials, including steel, cast iron, and aluminum. The material of the gear will depend on the specific application and the environment in which it will be used.

Helical gears are available in a variety of sizes and styles to accommodate a wide range of applications. They are also available in a variety of ratios, which allows them to be used in a variety of applications.

Here are some of the advantages of using helical gears:

- Reduced noise and vibration: Helical gears help to reduce noise and vibration, which can improve the overall working environment.

- Increased efficiency: Helical gears are more efficient than straight gears, which can help to improve the overall performance of a system.

- Increased durability: Helical gears are made of durable materials that can withstand a lot of wear and tear.

- Cost-effectiveness: Helical gears are a cost-effective way to improve the performance and durability of a system.

Overall, helical gears are a versatile and reliable component that can be used in a wide variety of applications. They offer a number of advantages, including reduced noise and vibration, increased efficiency, increased durability, and cost-effectiveness.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Three-Ring |

| Hardness: | Hardened Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Stepless |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Key Factors for Selecting a Helical Gearbox

Choosing the right helical gearbox for an application involves considering several key factors:

- Load and Torque: Evaluate the maximum load and torque requirements to ensure the gearbox can handle the application’s demands.

- Speed Range: Determine the required speed range and ensure the gearbox’s gear ratios can accommodate it.

- Efficiency: Helical gearboxes are known for their high efficiency. Select a gearbox with efficiency ratings that meet your application’s needs.

- Space Constraints: Consider the available installation space and choose a compact gearbox that fits within the available dimensions.

- Mounting Position: The mounting position affects lubrication, cooling, and overall performance. Ensure the gearbox is suitable for the desired mounting orientation.

- Service Life: Choose a gearbox with a service life that matches your application’s expected lifespan.

- Backlash: Evaluate the allowable backlash, which affects precision and positioning accuracy.

- Noise and Vibration: Assess the acceptable noise and vibration levels and choose a gearbox with suitable characteristics.

- Environmental Conditions: Consider factors like temperature, humidity, and dust levels to ensure the gearbox can operate reliably in the application environment.

- Maintenance: Factor in maintenance requirements and choose a gearbox with manageable maintenance needs.

- Cost: Balance performance with budget constraints to find a gearbox that offers the best value for your application.

By carefully evaluating these factors, you can select a helical gearbox that optimally meets your application’s requirements and ensures efficient and reliable operation.

Relationship Between Helix Angle and Load Capacity in Helical Gears

The helix angle of helical gears plays a significant role in determining their load-carrying capacity and overall performance. Here’s the relationship between the helix angle and load capacity:

1. Load Distribution: The helix angle affects how the load is distributed along the gear teeth. A larger helix angle results in a more gradual tooth engagement, allowing for smoother load sharing across multiple teeth. This improves the gear’s ability to handle higher loads.

2. Contact Ratio: The contact ratio, which indicates the number of teeth in contact at any given time, increases with a larger helix angle. A higher contact ratio helps distribute the load over a larger area of the gear teeth, enhancing load-carrying capacity.

3. Tooth Meshing: The helix angle affects how the teeth mesh with each other. A higher helix angle promotes gradual and smoother meshing, reducing the concentration of stress on individual teeth. This results in improved resistance to wear and fatigue.

4. Axial Thrust: Helical gears produce axial thrust due to their helical nature. This thrust can affect the gear’s ability to handle radial loads. Proper consideration of the helix angle can help manage axial thrust and prevent overloading.

5. Lubrication: The helix angle affects the lubrication conditions between gear teeth. A larger helix angle may allow better oil flow and lubrication, reducing friction and wear, thereby enhancing load capacity.

6. Noise and Vibration: The helix angle also influences noise and vibration levels in helical gears. Optimal helix angle selection can minimize noise and vibration, contributing to smoother operation and prolonged gear life.

Optimal Helix Angle Selection: While a larger helix angle generally increases load capacity, it’s important to strike a balance. Extremely large helix angles can lead to reduced tooth strength and efficiency. Engineers consider factors like application requirements, tooth strength, and noise considerations when selecting the optimal helix angle for a specific gear design.

The relationship between the helix angle and load capacity underscores the importance of proper gear design to ensure optimal performance, durability, and reliability in various applications.

Limitations and Disadvantages of Helical Gear Systems

While helical gear systems offer numerous advantages, they also come with certain limitations and disadvantages:

- Axial Thrust: Helical gears generate axial thrust due to the helix angle of the teeth. This thrust can cause additional load on bearings and may require additional measures to counteract.

- Complex Manufacturing: The manufacturing process for helical gears is more complex than that of straight-toothed gears, which can lead to higher production costs.

- Axial Length: Helical gears require more axial space compared to spur gears with the same gear ratio. This can be a limitation in applications with space constraints.

- Sliding Contact: Helical gears have sliding contact between their teeth, which can result in higher friction and more heat generation compared to rolling contact gears.

- Efficiency: Although helical gears are generally efficient, their efficiency can be slightly lower than that of some other gear types, especially at high speeds.

- Complexity in Gearbox Design: The inclination of helical gear teeth introduces additional complexity in gearbox design and alignment.

- Reverse Thrust: In some cases, reverse thrust can occur when helical gears are subjected to high axial loads, leading to undesirable effects.

It’s important to consider these limitations and disadvantages when selecting gear systems for specific applications. Despite these challenges, helical gears remain a popular choice in various industries due to their benefits and overall performance characteristics.

editor by CX 2023-09-04

in Chandigarh India sales price shop near me near me shop factory supplier High Quality Cast Steel Cast Iron Metal Helical Gear for Speed Reducer manufacturer best Cost Custom Cheap wholesaler

At any time-Electrical power Team CO., LTD. IS Expert IN Making ALL Types OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Gear Pace REDUCERS, PARALLEL SHAFT HELICAL Gear REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Gear REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Car GEARBOXES, PTO Drive SHAFTS, Special REDUCER & Related Equipment Parts AND OTHER Relevant Products, SPROCKETS, HYDRAULIC Technique, VACCUM PUMPS, FLUID COUPLING, Gear RACKS, CHAINS, TIMING PULLEYS, UDL Velocity VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Equipment PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Low BACKLASH WORM REDUCERS AND SO ON. With several years’ encounter in these traces, we have been distinguished from other suppliers in China by our benefits in aggressive pricing, on-time shipping, prompt responses, on-hand engineering assistance and excellent after-sales services. We are aiming to meet the calls for of the consumers close to the entire world..

Item features

Helical EPTTs are spherical metallic disks with enamel reduce about the circumference. In orEPTTfor the EPTT to qualify as a EPTT, the tooth need to be minimize so that they run perpendicular to the EPTT’s experience. Helical EPTTs are the most basic design and style of EPTT made. They are usually utilized for the EPTT of rotary power. For example, if two shafts are pXiHu (West Lake) Dis.Hu (West Lake) Dis.lel to one one more, and one particular is spinning, a helical EPTT can help to transfer that pressure on to the other shaft. Helical EPTTs generally have an working efficiency of 98% to ninety nine%.

1.EPTT: C45 carbon steel,20CrMo,20CrMoTi,Stainless steel,brass,plastic,POM,and so on.

two.Moudle:M0.4-M10

three.Surface therapy: Galvanizing,zinc plating,Black oXiHu (West Lake) Dis.de,Spray EPTT, Mirror End, Burnishing, Sand-blasting and as your necessity.

4.Warmth treatment:Hardening and Tempering,Substantial Frequency Quenching, Carburizing Quenching..

5.We can make all kinds of Gears according to customers drawing and specifications ,EPTTizing in non-stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd objects.

6.We can manufacture with various percision,this kind of as DIN6,DIN7,DIN8,etc.

Technical specs

– OEM service presented

– Excellent high quality at aggressive value

-Customized

We can offer you OEM Services for Gear Metal Castings, and those steel castings can be produced in the following conditions:

- Heat treatment: Normalized, Normalized and Tempered, Quenched and Tempered

- Machining: Rough EPTTd, Semi-concluded EPTTd, Concluded EPTTd

- Non-Harmful Testing: EPTTic Particle Testing, EPTT Testing, Penetrant Screening

- EPTT: EPTT Metal, Alloy Metal, meet ASTM, BS, DIN, NF, JIS, ISO stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd

- Personal Fat: 500KG – 140MT

EPTT parameters:

The Process As Stick to: ingot #8594 warmth #8594 forging #8594 warmth remedy(normalizing tempering) #8594 inspection #8594 rough machining #8594 UT #8594 2nd heat treatment method #8594 finishing machining #8594 inspection .

EPTT Management: UT,MT,RT,PT,chemical composition take a look at,mechanical property check,etc.

Warmth Therapy: Normalize,Quenching,Tempering,Anealled.

Area Therapy: painting,plating,poEPTTng,black oXiHu (West Lake) Dis.de,transparent anti-rust oil.

Inspection: Besides our in-property inspecion, you could also pick a 3rd social gathering inspection.

StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd: EPTT,ASTM,AEPTE,API,JIS,DIN,BS,EN,KS,UNI,SABS,GOST.

Certificate: one, Uncooked material certificate(substance chemical compositon)

2, Heat treatment method sheet report

three, Dimension inspection report

four, UT examination report

EPTT: Seaworthy plywood packaged on stell pallets or as customer’s request

Shipping Day: Made the decision by the amount and dimensions of items. Typically we management the huge diameter rings’ supply time in 5 months soon after we EPTT your formal purchase.

Aggressive Gain: EPTT management and management to the EPTT create approach, incXiHu (West Lake) Dis.Hu (West Lake) Dis. ingot smelting,forging, heat remedy, machining and strictly closing inspection prior to shipping.

cnc lathe forging and teeth grinding

helical pinion EPTT

Equipment EPTT Capability:

| EPTT Sort | Attributes | |

| MAX. | MAX. | |

| Diameter | Peak | |

| (MM) | (KGS) | |

| Gear milling | 1500 | 15000 |

| Equipment hobbing | 5000 | 20000 |

| Gear grinding | 5000 | 20000 |

Superiority

one.Higher precision of dimensional tolerance

2.Outstanding mechanical property

three.Accessible in varities of dimensions and designs(acc to customer’s demands)

four.Superior manufacturing equipments and test devices

5.forty two superb technicist

6.strictly control the manufacturing procedures

seven.also pay out more consideration to the protection and EPTT

|

Merchandise Specifics |

|

|

Merchandise identify |

helical pinion EPTT |

|

Functions |

difficult tooth floor |

|

Software |

DIN 6 |

|

Tooth profile |

involute |

|

EPTT |

18CrNiMo6 |

|

Method |

forging carburizing internal grinding teeth grinding linear chopping |

|

Stress angle |

20 deg |

|

Design |

M=9,Z=32,a=twenty deg, beta=7.5 deg,x= .15 ,rigEPTT hand |

|

EPTT spot |

HangEPTT, EPTT |

EPTT handle

raquo Severe raw content inspection

raquo Rigorous manage more than the total producing procedure

raquo Sampling of all the goods after closing inspection before cargo

raquo EPTT trace soon after supply

| Title | Gears |

| EPTT | Stainless, metal,iron,brass, EPTT alloy,carbon steel, alloy steel,magnesium alloy, red brass,plastic or comply with your samples amp drawings on supplies. |

| Tolerance | plusmn .03% |

| Inspection | a hundred% inspection before shipment. |

| Method | PM/MIM/CNC/DIE-CASTING/STAMPING/HOBBING |

| Surface area remedy | E-coating,electroplating and black oxygen, anodizing,polish,sandblasting,heat therapy ,Nickel plating Zinc plating, Chrome plating, OXiHu (West Lake) Dis.dation. Anodization and so forth |

| Software | automobile,lock system,EPTT device,electric EPTT,communication EPTT,EPTT EPTT,healthcare gear,EPTTrtainment systems or other EPTT |

| weekly ability | 10000pcs |

| MOQ | 1000pcs |

| Samples | Samples are obtainable prior to bulk orders for good quality pleasure. |

| EPTT: | Carton, EPTTen Situation or in accordance to your prerequisite. |

| payment terms | T/T, PAYPAL,Income |

| EPTT time: | Samples are inside of 15 daEPTTafter the receipt of the deposit. Manufacturing will be concluded about 25~thirty daEPTTafter samples confirmation. |

| Cargo: | Specific, you can get the sample in 3~8days |

| roduct Name | Large EPTT EPTT EPTT Components Helical Equipment EPTT Manufacturing unit |

| EPTT | EPTT Stee:45#, SAE1571, SAE1045, Y15Pb, 1214L. |

| Alloy Metal:Cr12, 40Cr, 20CrMnTi, 16MnCr5, 20CrMnMo, 42CrMo, 17CrNiMo5… | |

| Brass/Bronze :HPb59-one, H70, CuZn39Pb2, CuZn40Pb2,C38000, CuZn40 | |

| Iron:Gray iron and ductile iron | |

| EPTT:6061, 6063,7075,5052 and so on. | |

| Forged Metal:Regular carbon metal, alloy metal, stainless metal, and so on | |

| Coloration | OEM |

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd | DIN GB ISO JIS BA EPTT |

| Grade | SUS201, SUS304, SUS316, A2-70, A2-eighty, A4-eighty, 4.8 six.eight eight.8 ten.9 twelve.9 |

| Area Therapy | Blacking, poEPTTng, anodization, anodized, passivation, portray, EPTT coating, black oXiHu (West Lake) Dis.de, silver/EPTT plating, electrolytic poEPTTng, nitrided, phosphating, sandblasting, nickel/zinc/chrome plating, and so forth.Rock |

| Treatment | Quenching amp Tempering, Carburizing amp Quenching, Large-frequency hardening, Carburization, and many others. |

| Utilised | Building equipment, outboard motors, EPTT resources, lawn and XiHu (West Lake) Dis.Hu (West Lake) Dis.den gear, maritime hoists, multi-spindle EPTTs, snow throwers, turbine EPTTs, pumps, centrifuges and other EPTT EPTT gear. |

| Product Name | Customized EPTTmotive EPTT AXiHu (West Lake) Dis.s FleXiHu (West Lake) Dis.ble Propeller Grinding Equipment Shaft |

| EPTT | C45,40Cr,20CrMnTi,42CrMo,Copper,Stainless metal and so on as for each your requests |

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd | DIN GB ISO JIS BA EPTT |

| Quality | SUS201, SUS304, SUS316, A2-70, A2-80, A4-eighty, four.eight 6.8 eight.8 10.nine 12.nine |

| Heat Treatment method | Carburizing,Induction,Flame,Nitriding |

| Certification | IATF 16949, ISO 9001 |

| Utilised | EPTT, EPTTry |

ear EPTT

Solution Name: Custom-made Spur EPTT shaft principal shaft EPTT EPTT input shaft

EPTT:20CrMnTi

Dimension:354*95*158mm

Approach:hobbing,carburizing,turning,drilling,EPTT shaping,CNC machining

Tolerance: /.01mm

Tooth profile: Spur

Tooth NO.:eighty

Method NO.four

Force angle:27 deg

Spline Data:

Enamel NO.:38

Manner NO.two.5

Force angle:20 deg

Roughness:Ra three.2

Warmth treatment: Carburizing

Surface area treatment method: None

Certifate: TS 16949

Main gear: EPTT hobbing EPTT, EPTT slotting EPTT, CNC lathe, and so forth

Supply materials certification,dimensional report,heat therapy report

| Gear OEM Support | |

| EPTT | EPTT metal,Alloy Metal,Substantial-energy metal , stainless steel,EPTT, Brass ,Copper,Forged Iron and so forth. |

| Heat remedy | Higher frequency quenching, hardened tooth, Normalizing, Carburizing , Nitriding , etc |

| Area therapy | Zinc/Nickel plating, black oXiHu (West Lake) Dis.de, electrophoresis ,Sandblasting, Anodizing Color, PoEPTTng or as for every the customer’s needs |

| Area Roughness | Ra0.2-six.4 |

| Bundle | Strategy one:Shrink film wooden box Method 2:cardboard box pallet Approach 3:Export picket case Method 4: personalized EPTT as customer’s need |

| EPTT | Equipment hobbing EPTT, EPTT slotting EPTT, CNC lathe, Cylindrical GrinEPTTEPTT,CNC Machining CEPTTr,CNC Lathe,Drilling EPTT, Laser Cutting EPTT,Bending EPTT,Stamping EPTT,Sand Blasting EPTT,Robert welding,and so forth |

| Supply time | 20-45DaEPTTDepends On EPTTtities and compleXiHu (West Lake) Dis.ty |

| Payment | T/T thirty% deposit and balanced 70% to pay out prior to cargo |

| Application | Practice, EPTT EPTT, healthcare unit, EPTT EPTT, vehicle, electrical EPTT, and other EPTT. |

| Min orEPTTand sample orEPTTis suitable. | |

| Machining support as for every your requests and specification drawings, both little or large amount is appropriate for us. We are sincerely anticipating to cooperate with you. |

|

machining vehicle components monitor moto tractor sprial spur helical bull wheel EPTT

We EPTTized in production vehicle EPTTs , bike EPTTs, EPTT, EPTT car (EPTT takeoff, snowmobiles, engineering vehicles) EPTTs, generator equipment, stainless metal ice crusher and so on.

| EPTT | 1571,1045,20CrMnTi, and so forth. |

| Machining Method | Gear Hobbing , Gear Shaping, Gear Shaving, Equipment Grinding |

| Modules | one., 1.25, one.5, one.75, 2., 2.twenty five, two.5….eight. and many others. |

| Heat Treatment | Carburizing amp Quenching, EPTTitriding |

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd | DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

Casting EPTT Steel Crusher Areas Mill Elements Massive Equipment

Item Description

EPTT description:

| Description | Casting EPTT Steel Crusher Components Mill Components Massive Equipment |

| Kind | Spur EPTTs, EPTT shafts, herringbone EPTTs, ring EPTTs, helical EPTTs, large-precision EPTTs, EPTTes, EPTT EPTTs, weighty-duty EPTTs, massive-module EPTTs, challenging-toothed EPTTs. |

| Application | Mines, metallurgy, oil, ports, ships, heavy EPTTry, and many others. |

| Processing | Casting Warmth Treatment method Machining |

| EPTT | Alloy metal ,carbon steel |

| Fat Ranges | 1T-10T |

| Tolernace | Controlled by ISO 8062 CT10-13 |

| Design and style Help | Pro-E, UG,SolidWorks,EPTTCad, PDF |

| EPTT Handle | EPTT, Dimension,Functionality,inside defects,Equilibrium examination |

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd | ASTM,DIN,JIS,ISO,GB stXiHu (West Lake) Dis.Hu (West Lake) Dis.rds |

Declaration:

EPTT shown herein are created to the requirements of distinct clients and are illustrative of the types of manufacturing capabilities offered inside of EPTT group of organizations.

Our plan is that none of these merchandise will be sold to third events without having created consent of the clients to whom the tooling, design and technical specs beEPTT.

roduct Description

| Solution title | Custom Scorching Market EPTT Sinter Stainless Metal Travel Equipment |

| EPTT | Stainless Steel or Customized |

| Finish | Thoroughly clean or Tailored |

| Approach | EPTT Sinter |

| Tolerance | plusmn0.1mm |

| Certification | ISO9001:2008,SGS, ROHS |

| Package deal | PP bag , Carton ,box or in accordance to customer’s demands |

| Usage | EPTT Components |

| MOQ | 5000 pcs |

| Sample | Obtainable |

| EPTT | Shipped by a hassle-free and EPTT-effective way. |

| EPTT Time | Sample: fifteen-20 workdaEPTTfor mold very first, Batch items: 12-fifteen workdaEPTTafter samples have been accepted. |

Our spur and helical EPTTs are welcomed by several customers for its stable substantial quality and competitive price tag.

The making character of JH EPTTs:

one. Equipment dimension: the greatest diameter is 1500mm

2. EPTT: Most typical steel is higher power metal 20CrMnTi. Others can be steel C45, stainless metal, higher power steel, copper, aluminium, plastic, POM and so on

3. Equipment module: .3-8 (pitch from .942-25.12mm, DP 3.175-eighty five)

4. Surface area: zinc (galvanized), black, chromium plating, nickel plating, quenching and tempering and so forth.

five. EPTT: secure and large, quality seven for with no tooth grinding, grade 6 after teeth grinding, grade 5 for exact grinding.

Rates for over top quality are really aggressive for us.

6. Heat therapy: teeth can be hardened to EPTC 55-63.

The top quality character of JH EPTTs:

one. Secure EPTT and low sounds

2. Properly stay away from normal tolerance primarily based on high precision

3. The teeth can be floor to grade six and grade 5 good quality

4. The bore will be poEPTTd to sleek and substantial precision

5. The price tag is aggressive even the quality is high.

| FaXiHu (West Lake) Dis.Hu (West Lake) Dis.ties | Machining cEPTTr CNC EPTT hobbing EPTT CNC EPTT shaper CNC EPTT grinding EPTT CNC turning EPTT CNC milling EPTT. Y58200 CNC large EPTT rack shaper, Y58125A EPTT rack shaper, England EPTT rack shaper and Russia EPTT rack shaper. Gleason EPTT |

| Gear types | Helical EPTTs (much more and much more extensively utilized for its stable transimission) Spur EPTTs Hub EPTTs EPTTl EPTTs EPTTl spiral EPTTs Gear ring and so forth. |

| EPTT | Metal: C45, Q235, 40Cr, 20CrMnTi, and many others. Stainless steel: 301, 201, 304, 316 etc. Brass: H59 H68 H80 H90 etc. Aluminium: 6082, 6061, A380 and many others. Aluminium alloy: 6061, 5083, 7050, and so on. More: PA6, PA66, POM, Abs and many others. |

| Surface area | PoEPTTng Plating Galvanized Blacken chromium plating, nickel plating portray etc. |

| aterial | C45 steel |

| Processing | Forging , Casting or Welding |

| Warmth Therapy | High Frenquency Quenching and Hard Enamel |

| Floor Treatment | Blacken or Galvanized as You Needed |

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd | GB1244-eighty five, DIN8187,8188, OEM, EPTT or DIN |

| Payment | T / T L/C |

| EPTT | Internal Plastic Bag and EPTTen Situation |

| ype | Single Roller Chain, EPTT Roller Chain, Quadruple Roller Chain…. |

| EPTT / ISO | 04C,06C,08A,10A-48A 2062 2082 C212A C216A |

| EPTT | 15,25,35,41,40,fifty~240 |

| Pitch | six.35 mm~76.two hundred mm–three hundred.00mm |

Requirements

We can make stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd EPTT and EPTT EPTT as per drawing or sample

The EPTT content can be carbon steel, stainless metal, EPTT, copper, brass and so on.

We can do warmth treatment and area remedy these kinds of as scenario harden, zinc plating , nick plating , chrome plating, powEPTTcoating, blacken and so on.

Our process incEPTTs tooling fabrication, stamping, deep drawing, punching, spinning, laser reducing, bending, seamless welding, machining and assembly.

Software: Digital/Appliance/EPTT/EPTT equipment steel stamping EPTT components

Metal Helical Gear EPTT Gear

The Spur Gears are broadly utilised in EPTTry for EPTT, business, EPTTs, fisheries and so forth, and are an indispensable part of EPTTry.

| Available merchandise identify | EPTT, EPTT, flange,EPTT box, Roller, pulley,casting, Mchining areas, bearing residence, worm EPTT and worm shaft , spline shaft , layout and other harware items |

| EPTT | A3, C45, 40Cr, 20CrMnTi, stainless metal, EPTT, EPTTsteel,Brass, EPTT ampalloy |

| Creation approach | precision casting, sand casting,die casting,forging ,welding,gravity casting,missing wax casting,investment casting,stamping,CNC machining |

| Warmth Therapy | Large frequency quenching, carburizing, electrophoresis |

| Cold Therapy | Painting, Galvanizing, Parkerising |

| Utilized | Building market EPTTry, EPTT EPTTry, agricultural EPTTry, forestry EPTTry, mining EPTTry, fishery EPTTry, teaching accessories, digital equipment and many others. |

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd | OEM, as drawing layout, EPTT or DIN stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd |

| EPTT | Interior EPTT: Carton, StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd export EPTT or In accordance to customer’s need Outer EPTT: wood cases or In accordance to customer’s need |

| SAMPLE TIME | 5–15 times |

| Generation TIME | fifteen–forty five daEPTTor According to customer’s prerequisite |

| Shipping CLAUSE | FOB TianEPTT, CFR, CIF, Convey shipping and delivery |

| PAYMENT Forex | USD |

| PAYMENT Techniques | T/T (thirty% deposit 70%towards bl duplicate) L/C MoneyGram Other payment conditions we can negotiate |

Organization introduction

HangEPTT Evon Engineering CO.,LTD is a manufacture of bearings, worm EPTTrs, slewing bearings, EPTTs, shaft and engineering elements. EPTT bearings, worm EPTTrs, slewing bearings, EPTTs, shafts confirm each working day to be EPTTant structural and connection elements, they can be widely employed in the liftinEPTTransport EPTTry, mining EPTTry, building EPTTry, port hoisting EPTTry, port oil transfer tools, onshore and offshore crane, excavator, concrete EPTT, paper EPTT, plastic and rubber EPTT, weave EPTT, cement EPTT, metal EPTT, electrical EPTT EPTT, wind EPTT generator, other building and business EPTTs or products and other large rotary units.

The items manufactured by EPTT Engineering Co are mainly exported to the nations of the European EPT, United states of america, the Center EPTT, the South American, the Africa, Austrilian and Asia places and the Russian Federation, in the process of cooperation with our customers, we have created it a theory to build a long lasting and satisfying partnership with our customers by offering efficient provider with the leading high quality and minimizing the creation EPTT.

XiHu (West Lake) Dis.hu (West Lake) Dis.g for consistent dedication to the high quality of products and customer services, Evon Engineering attaches excellent EPTTance to investigation and deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment to make certain much better solution good quality and support from its establishment. The top quality of EPTT goods are based on the superb EPTTist and complex degree of constructors and specialists, extremely competent operators, encounters production employees.

The company title: HangEPTT Evon Engineering Co.,ltd

Deal with: No 3 Lianmeng Street, EPTTnXiHu (West Lake) Dis. Region, HangEPTT Metropolis, ZheJiang Province, EPTT

Tel: -379-64516701

Fax -379-64516702

Internet site: