Product Description

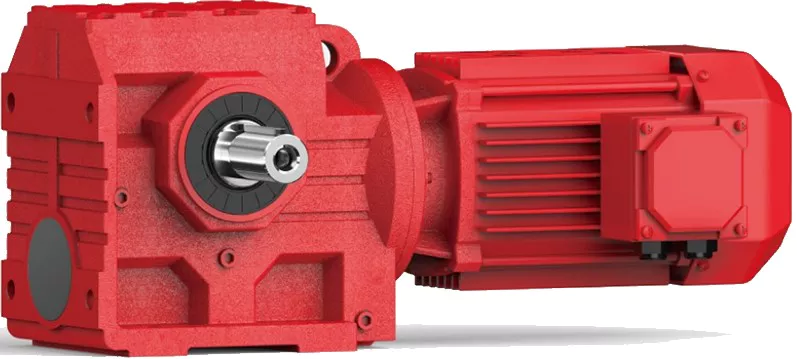

S series helical gear worm reducer Gear Motor Drive Power Transmission Vertical To Horizontal Gearbox Transmissiom Gearbox

Features of products

1. The S series helical gear worm gear motor has a high technological content. It has a helical gear and a worm gear combined with an integrated transmission to improve the torque and efficiency of the machine. This series of products have complete specifications, wide speed range, good versatility, adapt to various installation methods, safe and reliable performance and long life, and have implemented international standards.

2. The uneven surface of the body has the effect of heat dissipation, strong vibration absorption, low temperature rise and low noise.

3. The machine has good sealing performance and strong adaptability to the working environment.

4. The machine has high transmission accuracy, and is especially suitable for working in occasions with frequent starting. It can be connected to various types of reducers and equipped with various types of motor drives, and can be installed in the 90-degree transmission operating position.

5. The key components of the motor are made of highly wear-resistant materials and undergo special heat treatment. They have the characteristics of high machining accuracy, stable transmission, small size, large carrying capacity, and long life.

6. The reducer can be equipped with various types of motors, forming a mechatronics, which fully guarantees the quality

Related product

Company Profile

Packing & Delivery

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | 90 Degree |

| Layout: | Coaxial |

| Gear Shape: | Worm Gear |

| Step: | Single-Step |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Comparison of Helical Gearboxes and Bevel Gearboxes

Helical gearboxes and bevel gearboxes are both widely used for power transmission in various industrial applications. Here’s a comparison of their performance:

- Gear Meshing: Helical gearboxes use helical gears with inclined teeth that gradually engage, resulting in smoother and quieter operation compared to the more abrupt engagement of straight-cut bevel gears.

- Efficiency: Helical gearboxes generally offer higher efficiency due to their helical gear design, which distributes loads evenly across the teeth. Bevel gearboxes can have slightly lower efficiency due to the sliding action of gear teeth during engagement.

- Load Capacity: Helical gearboxes can handle higher loads and torque due to the larger contact area of the gear teeth. Bevel gearboxes are suitable for moderate loads and applications where the direction of power transmission needs to be changed.

- Space Efficiency: Bevel gearboxes are often more compact and suitable for applications where space is limited and a change in direction is required. Helical gearboxes may require more space due to the parallel shaft arrangement.

- Noise and Vibration: Helical gearboxes generate less noise and vibration compared to straight-cut bevel gearboxes. Bevel gearboxes can be noisier, especially at higher speeds.

- Application: Helical gearboxes are commonly used in applications requiring smooth and efficient power transmission, such as conveyors, pumps, and mixers. Bevel gearboxes are preferred for applications where changes in direction are necessary, such as in automotive differentials and printing presses.

Ultimately, the choice between helical and bevel gearboxes depends on the specific requirements of the application, including load capacity, space constraints, efficiency goals, and the need for directional changes in power transmission.

Relationship Between Helix Angle and Load Capacity in Helical Gears

The helix angle of helical gears plays a significant role in determining their load-carrying capacity and overall performance. Here’s the relationship between the helix angle and load capacity:

1. Load Distribution: The helix angle affects how the load is distributed along the gear teeth. A larger helix angle results in a more gradual tooth engagement, allowing for smoother load sharing across multiple teeth. This improves the gear’s ability to handle higher loads.

2. Contact Ratio: The contact ratio, which indicates the number of teeth in contact at any given time, increases with a larger helix angle. A higher contact ratio helps distribute the load over a larger area of the gear teeth, enhancing load-carrying capacity.

3. Tooth Meshing: The helix angle affects how the teeth mesh with each other. A higher helix angle promotes gradual and smoother meshing, reducing the concentration of stress on individual teeth. This results in improved resistance to wear and fatigue.

4. Axial Thrust: Helical gears produce axial thrust due to their helical nature. This thrust can affect the gear’s ability to handle radial loads. Proper consideration of the helix angle can help manage axial thrust and prevent overloading.

5. Lubrication: The helix angle affects the lubrication conditions between gear teeth. A larger helix angle may allow better oil flow and lubrication, reducing friction and wear, thereby enhancing load capacity.

6. Noise and Vibration: The helix angle also influences noise and vibration levels in helical gears. Optimal helix angle selection can minimize noise and vibration, contributing to smoother operation and prolonged gear life.

Optimal Helix Angle Selection: While a larger helix angle generally increases load capacity, it’s important to strike a balance. Extremely large helix angles can lead to reduced tooth strength and efficiency. Engineers consider factors like application requirements, tooth strength, and noise considerations when selecting the optimal helix angle for a specific gear design.

The relationship between the helix angle and load capacity underscores the importance of proper gear design to ensure optimal performance, durability, and reliability in various applications.

Industries Utilizing Helical Gearboxes

Helical gearboxes find widespread use in various industries due to their efficiency, smooth operation, and versatility. Some of the industries that commonly utilize helical gearboxes include:

- Manufacturing: Helical gearboxes are employed in manufacturing processes for conveyor systems, material handling, and machine tools. Their ability to provide high torque and smooth motion makes them suitable for precision manufacturing.

- Automotive: Automotive applications include power transmission in vehicles, especially in manual and automatic transmissions. Helical gearboxes contribute to improved fuel efficiency and smoother gear shifting.

- Energy Generation: Helical gearboxes are used in power generation systems, such as wind turbines and hydroelectric generators. Their efficiency and load-bearing capacity are crucial for converting rotational motion into electrical power.

- Construction: Construction equipment, such as cranes, excavators, and bulldozers, rely on helical gearboxes for efficient power transmission and control of heavy loads.

- Mining: Mining operations use helical gearboxes in conveyors, crushers, and other equipment for material handling and ore extraction. The durability and high torque capacity of helical gearboxes make them suitable for demanding mining environments.

- Marine: Marine vessels use helical gearboxes in propulsion systems to convert engine power into rotational motion for propellers. Their efficiency contributes to fuel savings and reliable marine operation.

- Food and Beverage: Helical gearboxes are employed in food processing and packaging machinery due to their sanitary design and precise motion control.

- Textile: Textile machinery relies on helical gearboxes for various processes, including spinning, weaving, and dyeing. Their ability to handle varying loads and provide smooth motion is beneficial in textile production.

The adaptability and efficiency of helical gearboxes make them a suitable choice for a wide range of industries, where reliable power transmission, smooth operation, and load-bearing capacity are essential.

editor by CX 2023-12-20

China manufacturer & factory supplier for RV-E in Mogadishu Somalia Series RV Robot Gearbox Speed Reducer drive power transmission right angle spiral bevel gearbox electric motor gearbox With high quality best price & service

Maker of roller drive chains for electrical power transmission apps from general industrial to functions in specialised places this sort of as foods processing, weighty building equipment, and oil discipline providers. Accessible in double pitch travel and standard roller chains with single and numerous strand configurations. Technical specs include .25 to 3 in. chain pitch, .thirteen to 1.88 in. length in between sidebars, and .09 to .94 in. pin diameter. Accessible with attributes such as scenario-hardened and armor-cased pins, pre-pressured procedure, corrosion and shock resistance, and stainless metal supplies. Gives put up-sale help companies.We provide OEM provider.

Overview

Rapid Particulars

- Relevant Industries:

-

Producing Plant, Equipment Repair Retailers, Foods & Beverage Manufacturing unit, Farms

- Area of Origin:Zhejiang, China

The organization covering 88,000 square meters, has innovative equipment and robust technical toughness, these kinds of as the numerical management equipment equipment and machining facilities, CAD/CAM program, industrial robot etc.

- Manufacturer Identify:

-

OEM

- Gearing Arrangement:

-

Cycloidal

- Output Torque:

-

65-34300N.m

- Input Speed:

-

750-3000rpm

- Output Velocity:

-

5-60rpm

- Ratio:

-

fifty six-192

Offer Ability

- Source Ability:

- 50000 Established/Sets for each Year

Packaging & Shipping and delivery

- Packaging Particulars

- Stanard picket case, or picket pallet

The lemon tube is suitable for transmissible electrical power of sixteen-35HP, it is the favored decision for higher speeds and low torque transmission. The two-lobe lemon tube grants minimal vibrations up to 2600 rpm with lengths not exceeding 800mm. AC series with 6-lobe tubes (star)

- Port

- SHANGHAI PORT / NINGBO PORT

On the internet Customization

Specification

RV-E Sequence RV Robotic Gearbox Pace Reducer :

Significantly less than 2 arc-min Backlash

Quite compact with substantial torsional rigidity

Component in-line variation for better design and style and room conserving overall flexibility

Quite compact with large torsional rigidity

Integrated Angular bearings for massive thrust & overhung second potential

Higher Ratio availability (up to 185:1) without having growing gearbox size

Certifications

trade display

Packing

Quality control

Company Details

Supply

Speak to us