Product Description

|

item |

value |

|

Warranty |

1 year |

|

Applicable Industries |

Manufacturing Plant, Construction works , Energy & Mining, Other |

|

Customized support |

OEM |

|

Place of Origin |

ZheJiang , China |

|

Input speed |

750-1500rpm |

|

Ratio |

7.5 10 12.5 |

|

Material |

Aluminum |

|

Product name |

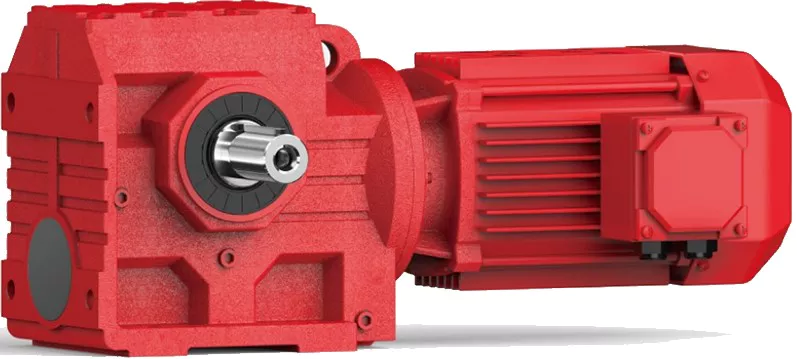

KM Series Hypoid Gear Reducer |

|

MOQ |

10pcs |

|

Color |

Customization |

PRODUCTS CHARACTERISTICS

1. Mad of high-quality aluminum alloy,light weight and non-rusting

2. Large output torque

3. Smooth in running and low in noise,can work long time in dreadful conditions.

4. High in radiating efficiency.

5. Good-looking in appearance,durable in service life and small in volume.

6. Suitable for omnibearing installation.

FAQ

Q1:Are you a manufacturer or trading company?

Yes, We are a leading manufacturer specialized in production of various kinds of small and medium-sized

motor.

Q2:How to choose a gearbox which meets our requirement?

You can refer to our catalogue to choose the gearbox or we can help to choose when you provide

the technical information of required output torque, output speed and motor parameter etc.

Q3:What information shall we give before placing a purchase order?

a) Type of the gearbox, ratio, input and output type, input flange, mounting position, and motor information etc.

b) Housing color.

c) Purchase quantity.

d) Other special requirements.

Q4:What industries are your gearboxes being used?

Our gearboxes are widely used in the areas of textile, food processing, beverage, chemical industry, escalator,automatic storage equipment, metallurgy, tabacco, environmental protection, logistics and etc.

Q5:How about your delivery time?

For micro brush dc gear motor, the sample delivery time is 2-5 days, bulk delivery time is about 15-20 days, depends on the order qty. For brushless dc motor, the sample deliver time is about 10-15 days; bulk time is 15-20 days.Please take the sales confirmation for final reference.

Q6:What’s your warranty terms?

One year

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | as for Request |

| Hardness: | Hardened Tooth Surface |

| Installation: | as for Request |

| Step: | as for Request |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Lubrication Requirements for Maintaining Helical Gearboxes

Lubrication is essential for the proper functioning and longevity of helical gearboxes. The lubrication requirements include:

- Viscosity: Selecting a lubricant with the appropriate viscosity is crucial. The viscosity should provide sufficient lubrication and ensure a protective film between gear teeth under varying operating conditions.

- Extreme Pressure (EP) Properties: Helical gears often experience high contact pressures. Lubricants with EP additives form a protective barrier that prevents metal-to-metal contact and reduces wear.

- Oil Additives: Anti-wear additives, antioxidants, and corrosion inhibitors enhance the lubricant’s performance and protect gears from wear and degradation.

- Frequent Inspections: Regularly inspect the lubri

Can Helical Gearboxes Be Retrofitted into Existing Machinery Designs?

Yes, helical gearboxes can often be retrofitted into existing machinery designs, providing an opportunity to upgrade the performance, efficiency, and reliability of older equipment. Here are the key points to consider when retrofitting helical gearboxes:

1. Compatibility: Before proceeding with a retrofit, it’s essential to ensure that the new helical gearbox is compatible with the existing machinery in terms of size, mounting, and shaft connections. Proper measurements and analysis are necessary to avoid any misalignment or fitment issues.

2. Space Considerations: Helical gearboxes may have a different physical profile compared to the original gearboxes. Engineers need to assess the available space in the machinery and confirm that the new gearbox will fit without major modifications.

3. Shaft Alignment: Proper shaft alignment is crucial to ensure smooth and efficient operation. During the retrofit, it’s important to align the new helical gearbox with other components in the system to prevent premature wear, noise, and vibration.

4. Power and Torque Ratings: The power and torque ratings of the helical gearbox should match or exceed the requirements of the machinery. This ensures that the new gearbox can handle the loads and stresses that the machinery may encounter.

5. Performance Improvements: Retrofitting with helical gearboxes can lead to improved efficiency, reduced noise, and smoother operation. These benefits can positively impact the overall performance and lifespan of the machinery.

6. Engineering Expertise: Retrofitting involves careful planning, engineering analysis, and implementation. Working with experienced engineers or gearbox specialists is advisable to ensure a succ

Role of Helical Gearboxes in Automotive Transmissions

Helical gearboxes play a crucial role in automotive transmissions, contributing to the efficient power transfer and smooth operation of vehicles:

- Power Transmission: Helical gearboxes are used to transmit power from the engine to the wheels through different gear ratios. They help in converting the high-speed, low-torque output of the engine into the appropriate speed and torque for the wheels.

- Smooth Shifting: In manual and automatic transmissions, helical gears are often used to provide smooth and quiet gear shifts. The gradual engagement of helical gear teeth helps in reducing the shock and noise associated with gear changes.

- Noise Reduction: Helical gears are known for their quieter operation compared to other gear types. This is especially important in automotive applications where minimizing noise and vibration is desired for a comfortable driving experience.

- Efficiency: The efficiency of helical gearboxes helps in optimizing fuel efficiency and reducing energy losses. This is crucial for improving the overall performance and economy of vehicles.

- Load Distribution: Helical gears distribute the load over multiple teeth, reducing wear and ensuring the gearbox’s longevity. This is important in vehicles that experience varying loads and driving conditions.

- Torque Handling: Helical gears can handle higher torque loads compared to some other gear types. This is essential for vehicles, especially those with powerful engines, towing capabilities, or off-road use.

In modern automotive transmissions, helical gearboxes can be found in various components, including the main transmission, differential, and gearbox synchronizers. They contribute to the smooth operation, improved fuel efficiency, and overall performance of vehicles. The design and arrangement of helical gears can be tailored to meet the specific requirements of different vehicle types, making them a versatile choice for automotive applications.

essful retrofit without compromising the integrity of the machinery.

7. Cost-Benefit Analysis: Assessing the costs of the retrofit, including the cost of the new gearbox, installation, downtime, and potential modifications, is essential. Comparing these costs to the anticipated benefits of improved performance and efficiency will help make an informed decision.

8. Maintenance Considerations: Retrofitting may also impact maintenance practices. It’s important to understand any changes in lubrication requirements, inspection intervals, and servicing needs that come with the new gearbox.

Conclusion: Retrofitting helical gearboxes into existing machinery designs can be a cost-effective way to enhance the performance and extend the lifespan of equipment. However, careful planning, engineering analysis, and professional expertise are crucial to ensure a successful retrofit that delivers the desired improvements without causing unforeseen issues.

cant’s condition to detect contamination, degradation, or depletion. Scheduled oil analysis can help monitor the health of the lubricant.

- Proper Lubricant Application: Ensure the gearbox is properly filled with the correct amount of lubricant. Follow manufacturer recommendations for lubricant type and quantity.

- Lubricant Change Intervals: Establish regular lubricant change intervals based on operating conditions. Extreme conditions or heavy loads may require more frequent changes.

Appropriate lubrication minimizes friction, wear, and heat generation, leading to improved efficiency, reduced maintenance, and extended gearbox life. It’s crucial to follow the manufacturer’s guidelines and consult with lubrication experts to select the right lubricant and maintenance practices for your specific helical gearbox application.

editor by CX 2023-08-14